Method for detecting shrinkage porosity hole of root of motor barrel of rocker arm of cutting unit of coal mining machine

A technology for cutting part of a shearer and a detection method, which is applied in directions such as detecting the appearance of fluid at the leak point and using liquid/vacuum degree for liquid tightness measurement, etc. , oil leakage and other problems, to ensure the quality, low detection cost, simple operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

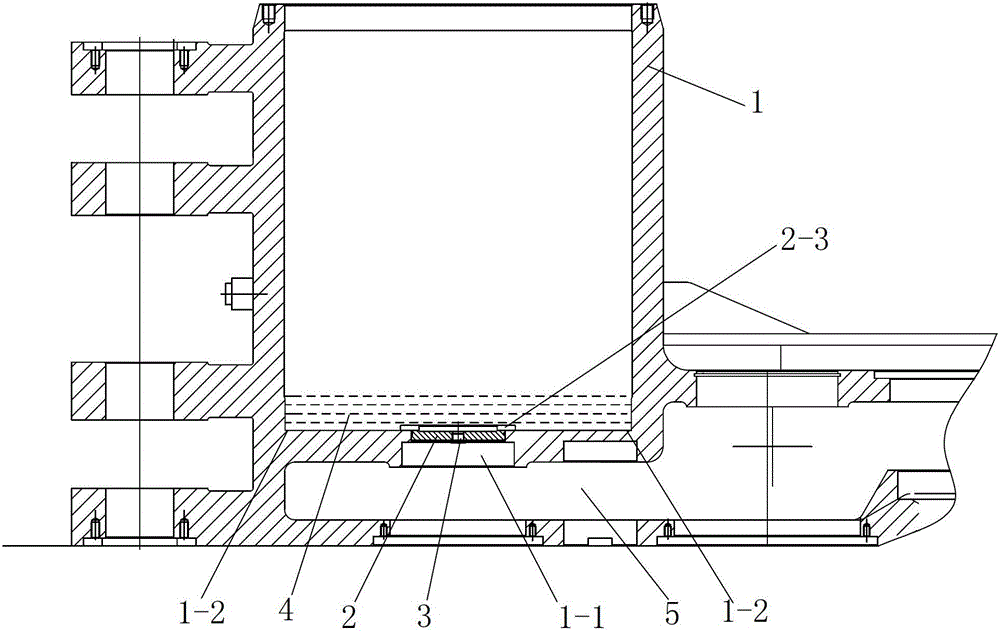

[0029] Such as figure 1 , figure 2 and image 3 Shown is a detection method for shrinkage holes at the root of the rocker arm motor cylinder of the shearer cutting section, the motor cylinder 1 is located above the gear chamber 5 of the rocker arm, the upper part of the motor cylinder 1 is open and the bottom is opened There is a motor hole 1-1, and the detection method includes the following steps:

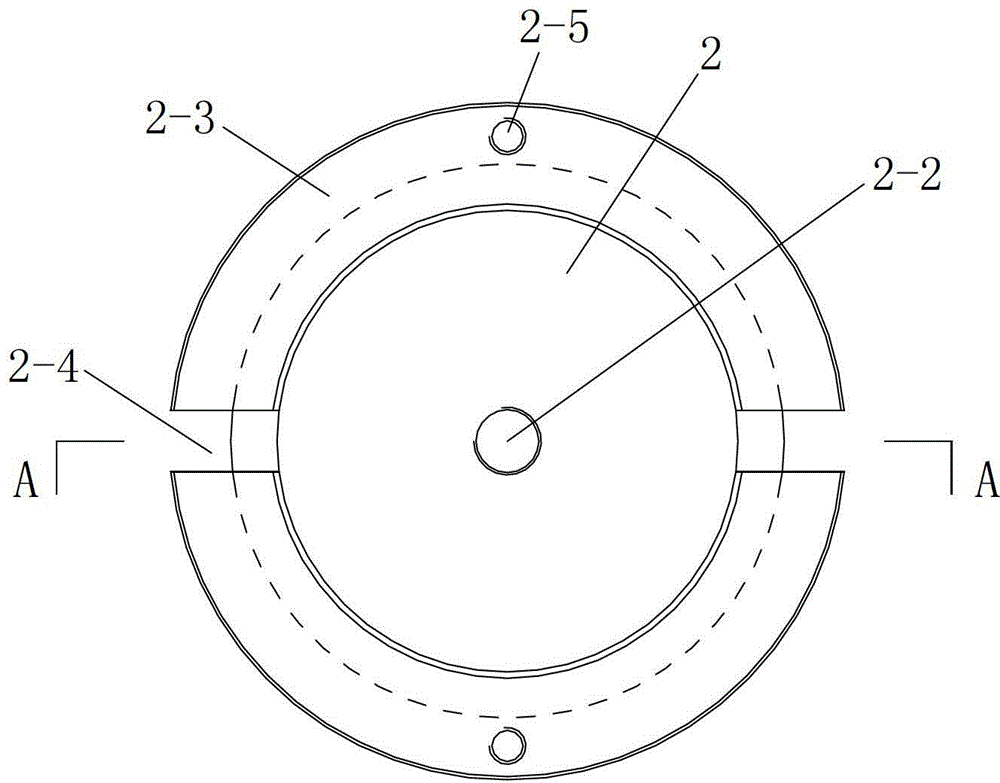

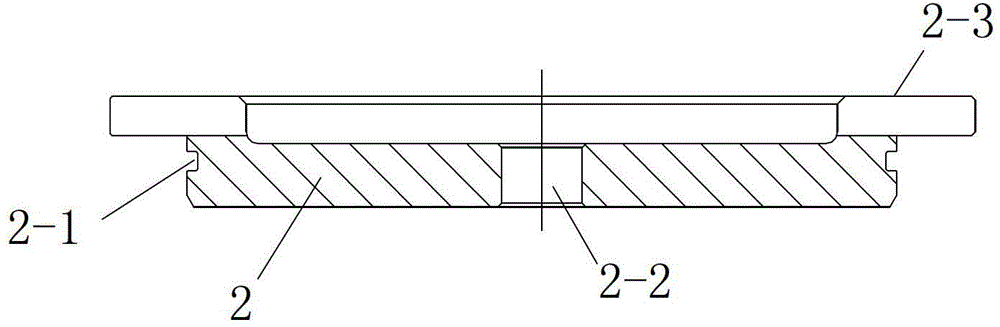

[0030] Step 1. Installation of the blocking device: the blocking device includes a plug 2 for plugging the motor hole 1-1 and a ring 2-3 fixedly installed on the upper surface of the plug 2. Preferably, the The ring 2-3 is integrally formed on the plug 2, and the plug 2 is provided with a threaded through hole 2-2 for communicating with the inside of the motor cylinder 1 and the gear chamber 5, and the outer portion of the ring 2-3 The diameter is larger than that of the motor hole 1-1, and the sealing plug 2 is put into the motor hole 1-1 from the top of the motor hole 1-1, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com