Servo double-surface heating vacuum packaging machine

A double-sided heating and packaging machine technology, applied in the direction of sustainable manufacturing/processing, electrical components, climate sustainability, etc., can solve the problems of limited production efficiency, low battery packaging yield, explosion, etc., and achieve high packaging accuracy, The effect of compact structure and precise positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below in conjunction with specific embodiment, the present invention will be further described:

[0017] refer to figure 1 , Servo double-sided heating vacuum packaging machine, including feeding device, packaging mechanism and electrical control system.

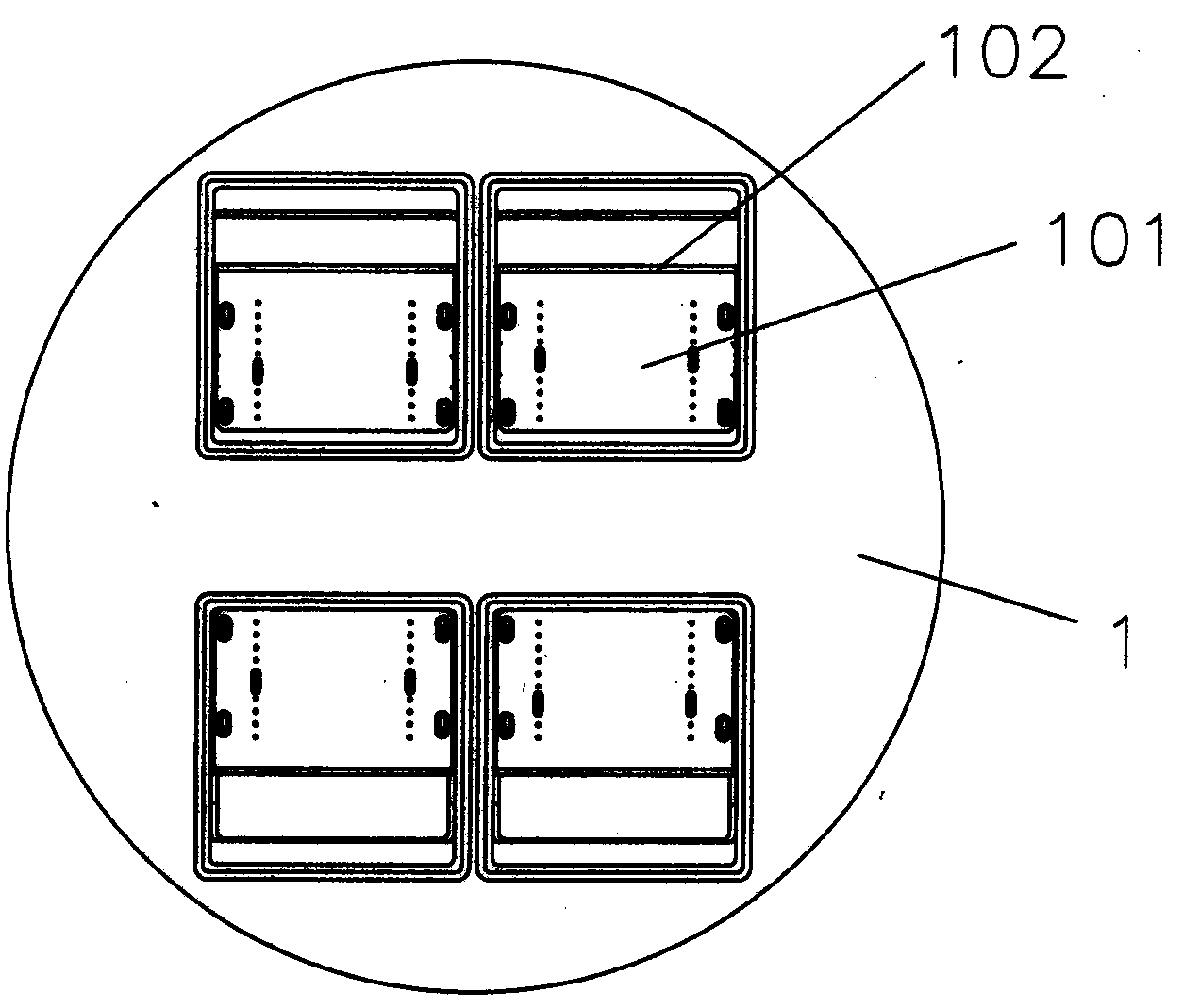

[0018] The feeding device is a double-station turntable feeding method, including a double-station cam divider and a turntable 1 driven by it to rotate. The turntable 1 is provided with two groups of symmetrical grooves that are suitable for the packaging processing position. The groove, the cell support plate 101 and the side rail 102 arranged in the groove form a cell positioning structure for positioning the cell to be packaged, and the cell is placed on the support plate 101 and the side rail of the positioning structure 102 (reference figure 2 ).

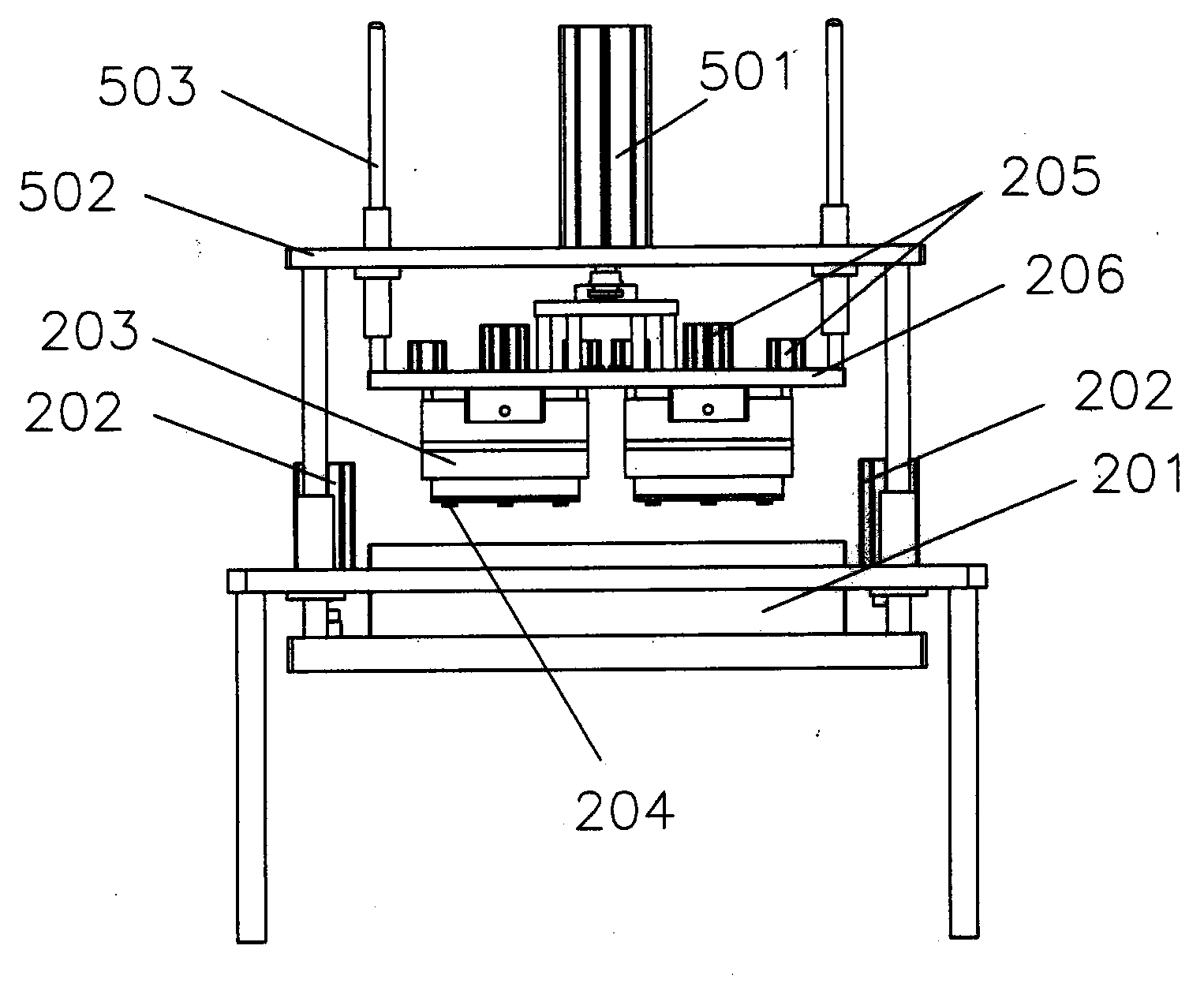

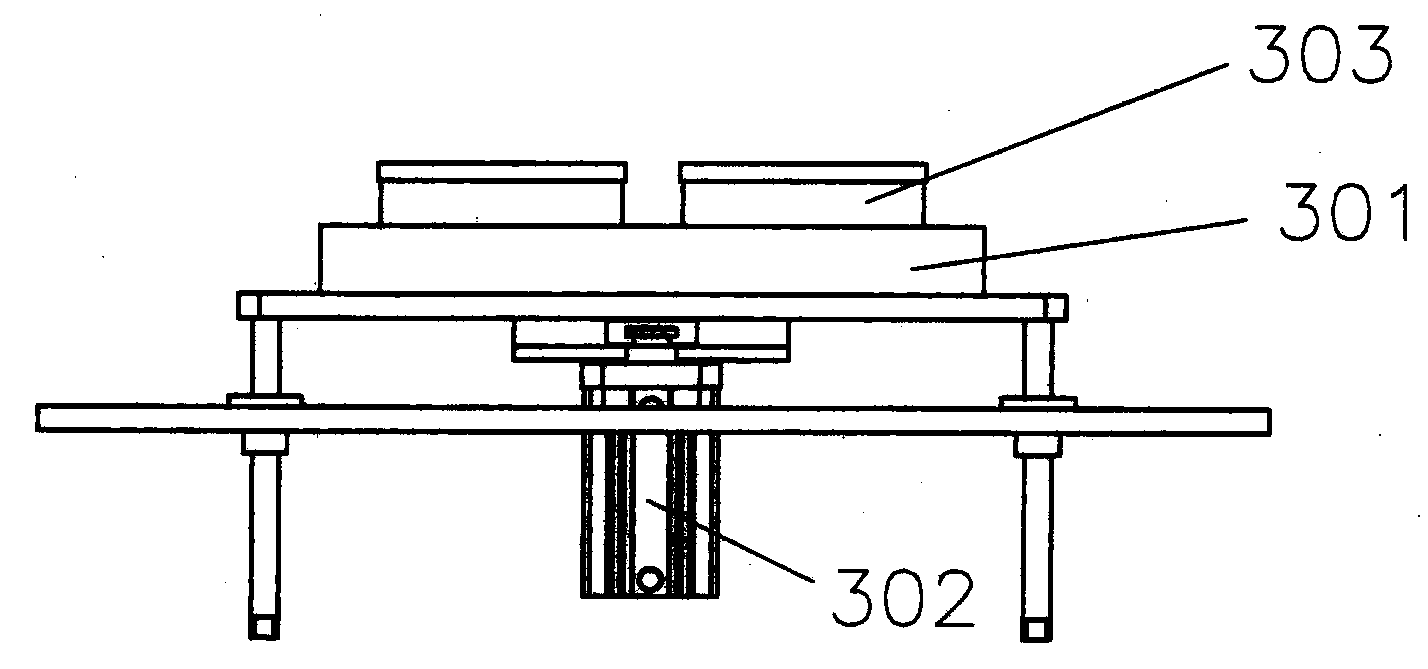

[0019] refer to image 3 and Figure 4 The packaging mechanism includes an upper packaging device and a lower packaging device, which are located on the upper an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com