SiC/epoxy resin composite material and method for manufacturing pump components with it

A technology of epoxy resin and composite material, which is applied to parts, pump elements, pumps, etc. of pumping devices for elastic fluids, and achieves the effects of low raw material cost, shortened curing time, and good erosion and wear resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

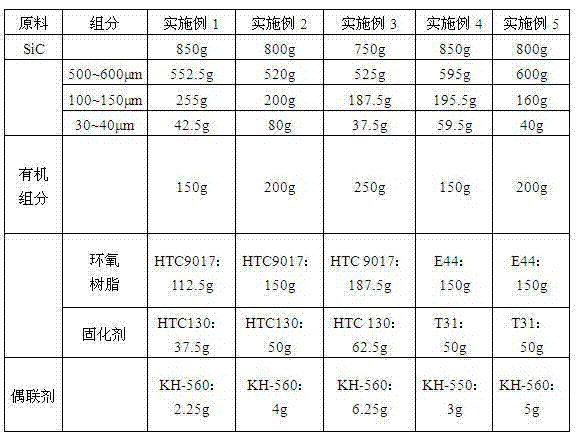

Embodiment 1

[0027] Treat the SiC particles at 350°C for 1 hour, ultrasonically clean them in acetone for 30 minutes, wash them with water, and dry them for later use.

[0028] Mix epoxy resin, curing agent and coupling agent, evacuate and stir in a closed container at 40°C for 40 minutes, add SiC and continue stirring under vacuum for 40 minutes to obtain a mixed slurry, and the relative vacuum in the closed container is less than -0.07MPa.

[0029] The mixed slurry is injected into the pump impeller mold through a pipeline with a height difference of 1 meter from the mold, and the pump impeller mold is placed in a closed container at 60°C, and vibrated for 1 hour while vacuuming, and the relative vacuum degree in the closed container is less than –0.05 MPa.

[0030] Dry the green body after vacuum vibration molding at 80°C for 4 hours and demould it. After demoulding, put it into an electric furnace to heat and solidify. The heating temperature is 80°C and the time is 2 hours. The SiC / ep...

Embodiment 2

[0033] Treat the SiC particles at 350°C for 1 hour, ultrasonically clean them in acetone for 30 minutes, wash them with water, and dry them for later use.

[0034] Mix epoxy resin, curing agent and coupling agent, vacuumize and stir in a closed container at 50°C for 30 minutes, add SiC and continue stirring under vacuum for 30 minutes to obtain a mixed slurry, and the relative vacuum in the closed container is less than -0.07MPa.

[0035] The mixed slurry is injected into the pump impeller mold through a pipeline with a height difference of 1 meter from the mold, and the pump impeller mold is placed in a closed container at 55 °C, and vibrates for 1.5 h while vacuuming, and the relative vacuum degree in the closed container is less than –0.05 MPa.

[0036] Dry the green body after vacuum vibration molding at 70°C for 5 hours and demould it. After demoulding, put it into an electric furnace to heat and solidify. The heating temperature is 120°C and the time is 4 hours. The SiC / ...

Embodiment 3

[0039] Treat the SiC particles at 350°C for 1 hour, ultrasonically clean them in acetone for 30 minutes, wash them with water, and dry them for later use.

[0040] Mix epoxy resin, curing agent and coupling agent, evacuate and stir in a closed container at 60°C for 25 minutes, add SiC and continue stirring under vacuum for 25 minutes to obtain a mixed slurry, and the relative vacuum in the closed container is less than -0.07MPa.

[0041] Press the mixed slurry into the pump body mold through compressed air, put the pump body mold into a closed container at 50°C, and vibrate for 2 hours while vacuuming, and the relative vacuum degree in the closed container is less than –0.05Mpa.

[0042]Dry the green body after vacuum vibration molding at 90°C for 3 hours and demould it. After demoulding, put it into a gas heating oven for heating and curing. The heating temperature is 160°C and the time is 4 hours, and the SiC / epoxy resin can be obtained Composite pump body.

[0043] The typ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com