Method for solving boiler tail flue abrasion based on gas-solid two-phase flow numerical research

A tail flue and phase flow technology, applied in the field of resources and environment, can solve the problems of predicting wear parts and wear amount, and not forming the anti-wear thinking of boiler tail flue, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with the embodiments.

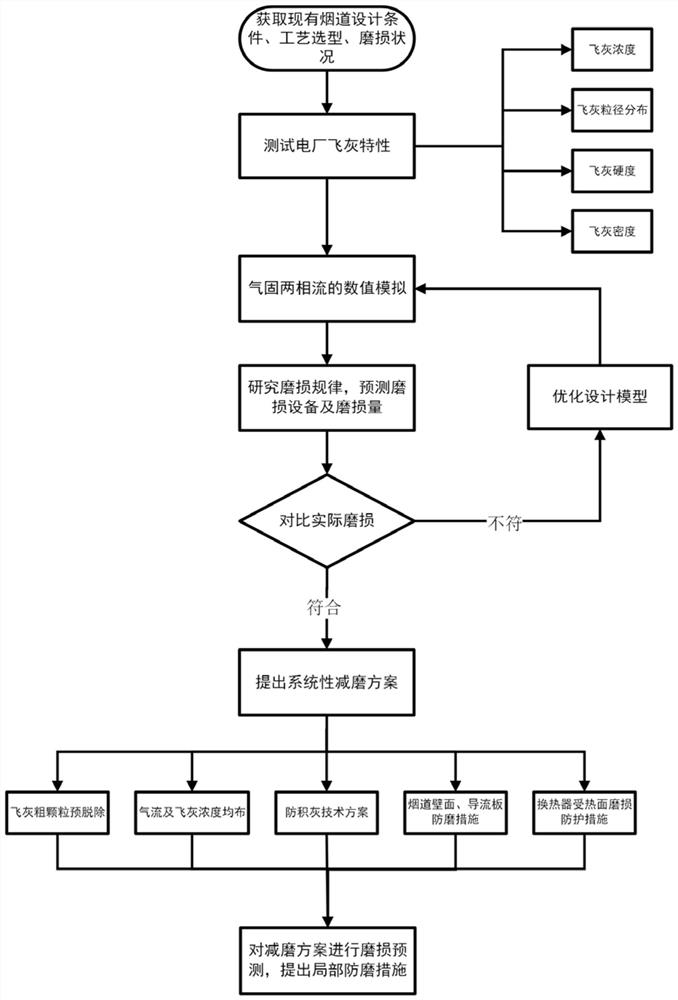

[0034] This embodiment is based on the gas-solid two-phase flow numerical research to solve the method of boiler tail flue wear, including the following steps:

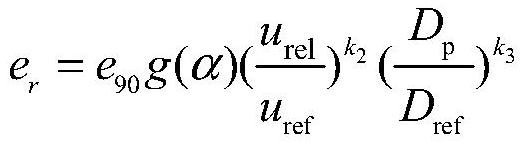

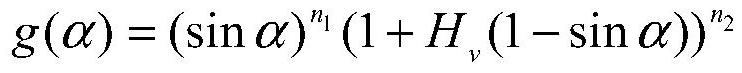

[0035] 1. Based on the numerical simulation research of gas-solid two-phase flow and the test data of fly ash characteristics, a wear model suitable for the tail flue of the boiler in a coal-fired power plant is established.

[0036] 2. Based on the wear model applicable to the tail flue of coal-fired power plant boilers, reveal the wear rules of flue internals and equipment, predict the wear parts and wear amount, and judge the service life of materials and equipment.

[0037]3. According to the wear pattern of the internal parts and equipment in the tail flue of each coal-fired power plant, a systematic anti-friction and anti-ashing scheme is proposed: pre-removal of coarse fly ash particles, multi-stage airflow and u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com