Fixed abrasive polishing cloth adopting nanometer aggregation structure adhesive

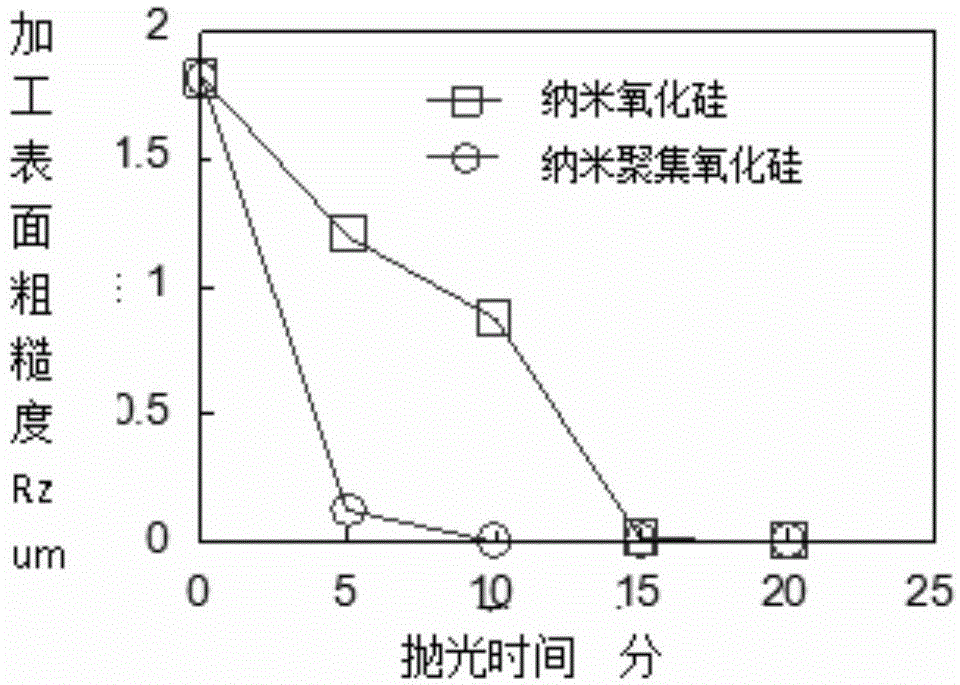

A polishing cloth and nanomaterial technology, applied in abrasives, metal processing equipment, manufacturing tools, etc., can solve the problems of difficult pH control, easy to scratch the processed surface, affecting the surface processing quality, etc., to achieve low mechanical removal effect, improve Chemical removal effect, effect of reducing environmental burden

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below through the specific examples, the following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention with this.

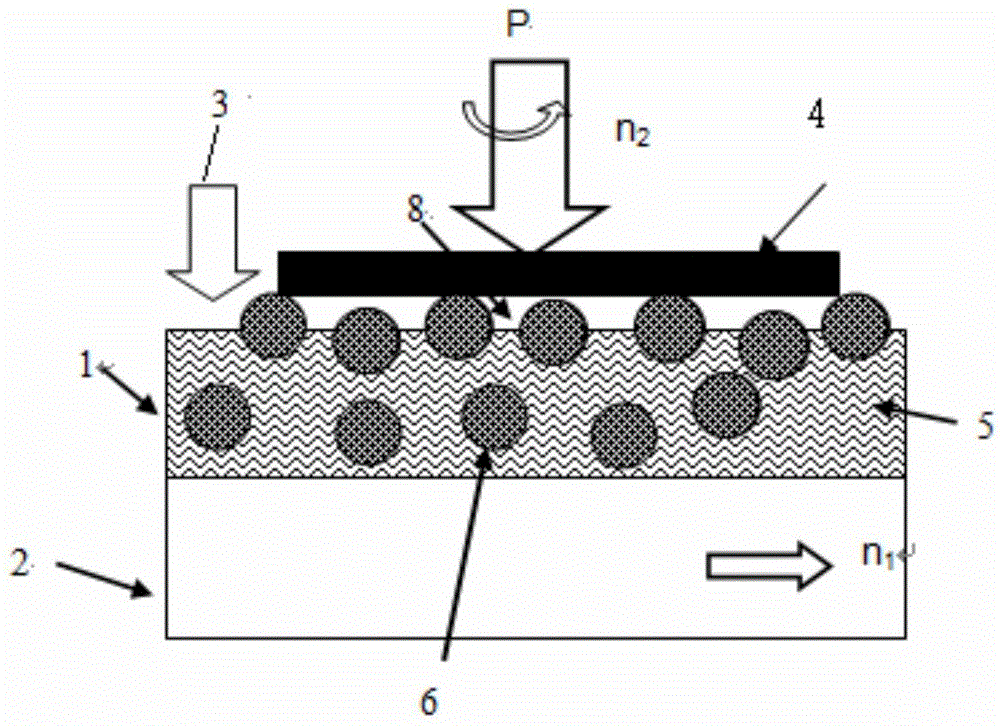

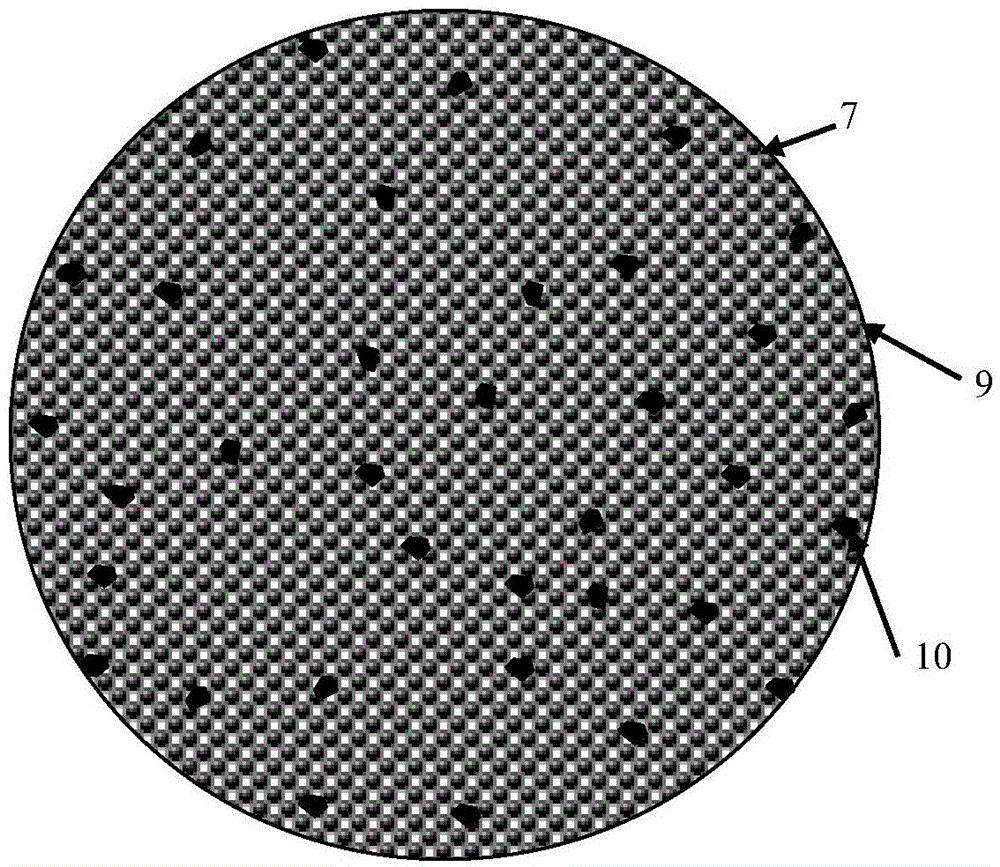

[0025] A fixed abrasive polishing cloth adopting a nano aggregate structure abrasive, which is composed of a polishing cloth base material 5 and a fixed abrasive uniformly added to the polishing cloth base material, the fixed abrasive is a nano aggregate structure abrasive 6, and the nano aggregate structure abrasive is Micron-sized spherical abrasive aggregated by nano-particles 7.

[0026] The base material of the polishing cloth is a viscoelastic material such as polyurethane. The addition rate of the nano-aggregated abrasive to the polishing cloth base material is 6 vol%-50 vol%, and the porosity is 10 vol%-50 vol%. Nanoparticles have a particle size of 1-80nm, with a pore volume of 0.1cm 3 / g-5cm 3 The aggregation density of / g aggre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com