Patents

Literature

31 results about "Coal permeability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

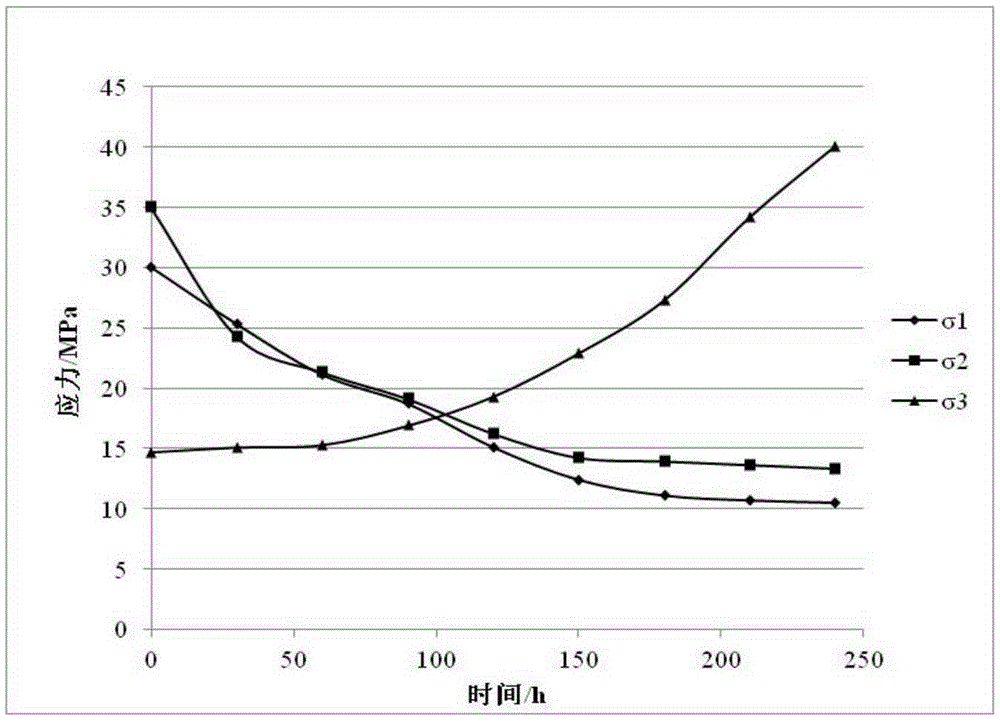

Coal permeability is an important parameter in mine methane control and CBM exploitation because it determines the practicability of methane extraction. The permeability determined in the laboratory is not the real value of coal seam tested in the field.

Device for Simultaneous Measurement of Gas Injection Coal Expansion and Permeability under Triaxial Stress Conditions

InactiveCN102288529ASolve the amount of deformationSolve permeabilityPermeability/surface area analysisUsing fluid meansPressure systemStress conditions

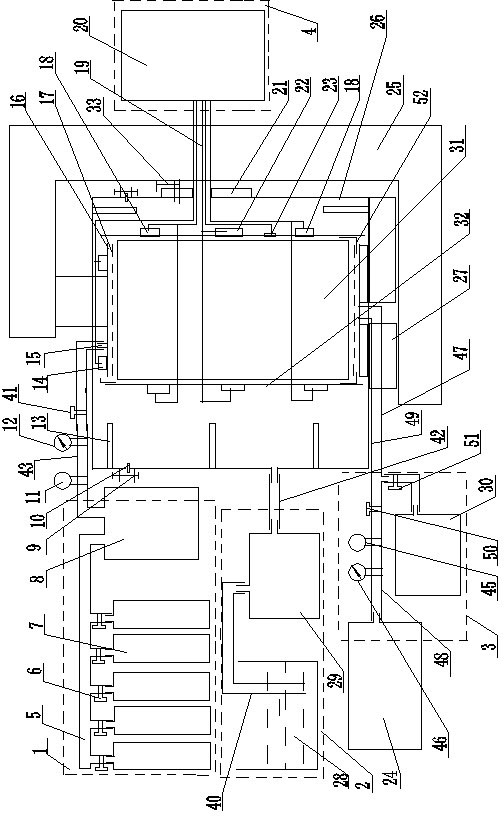

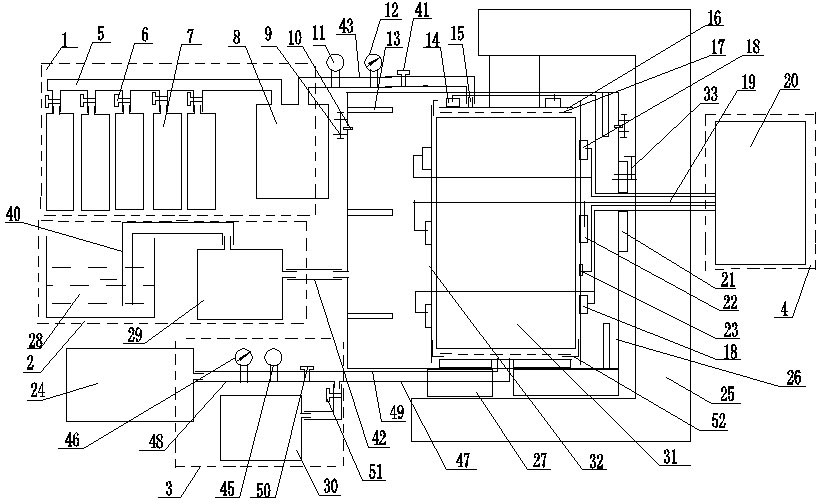

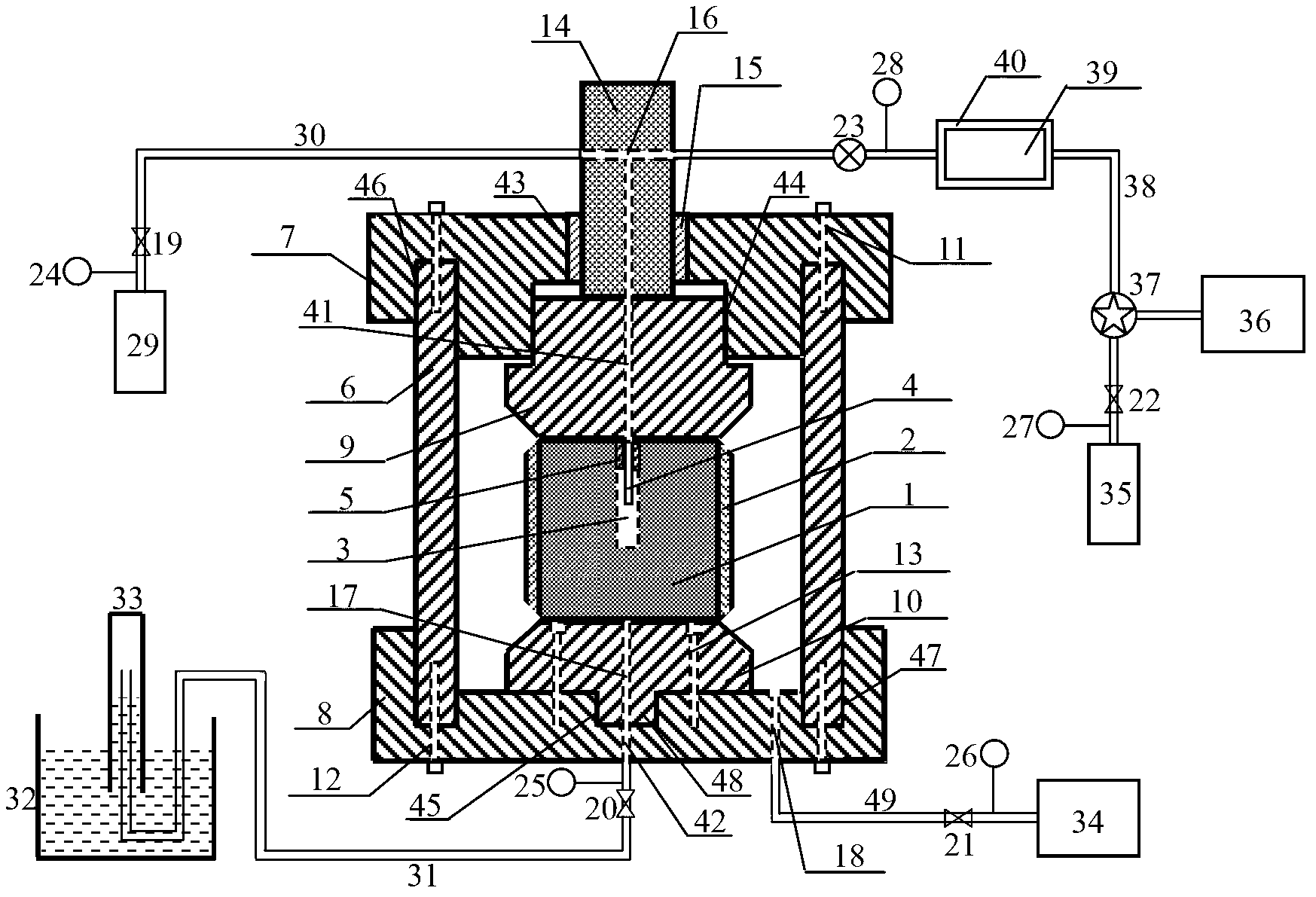

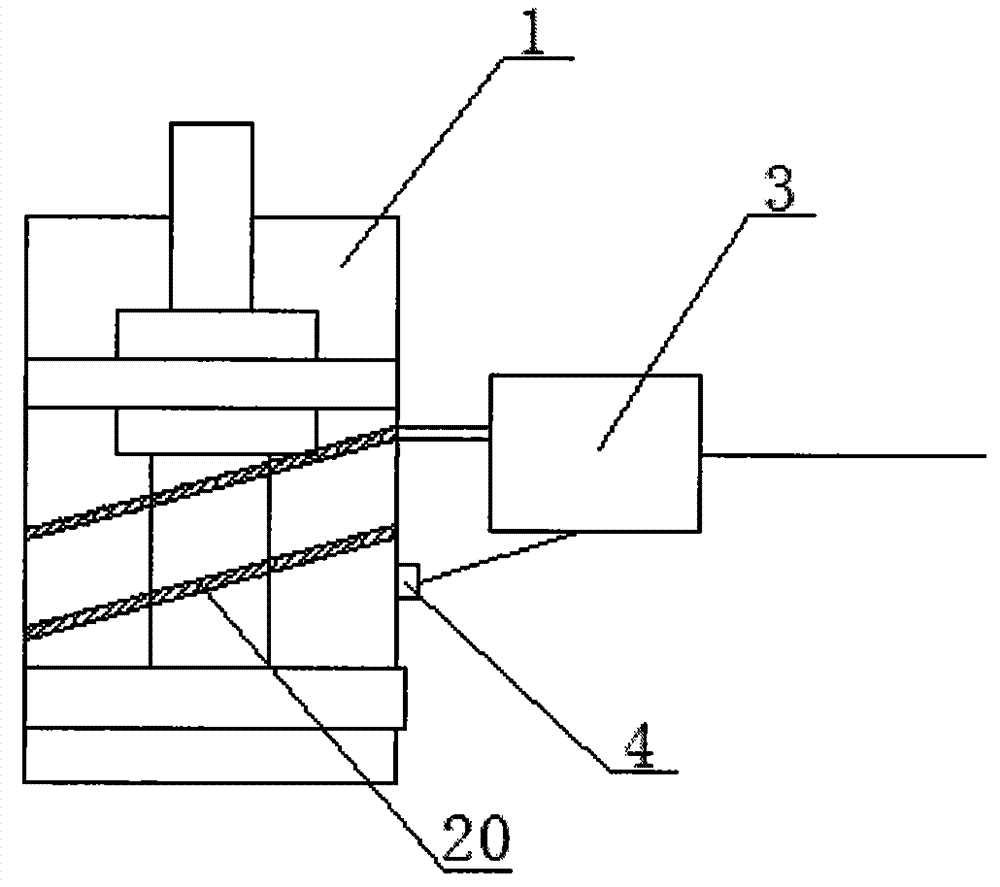

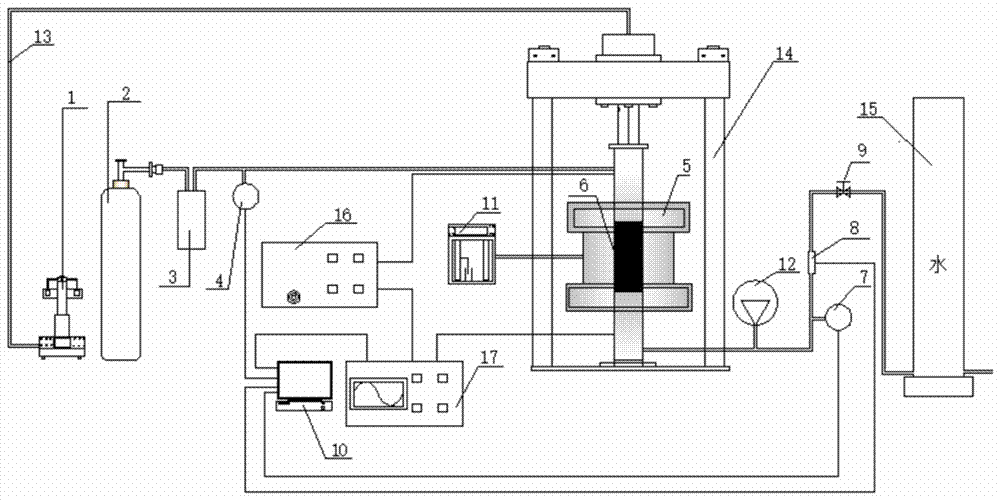

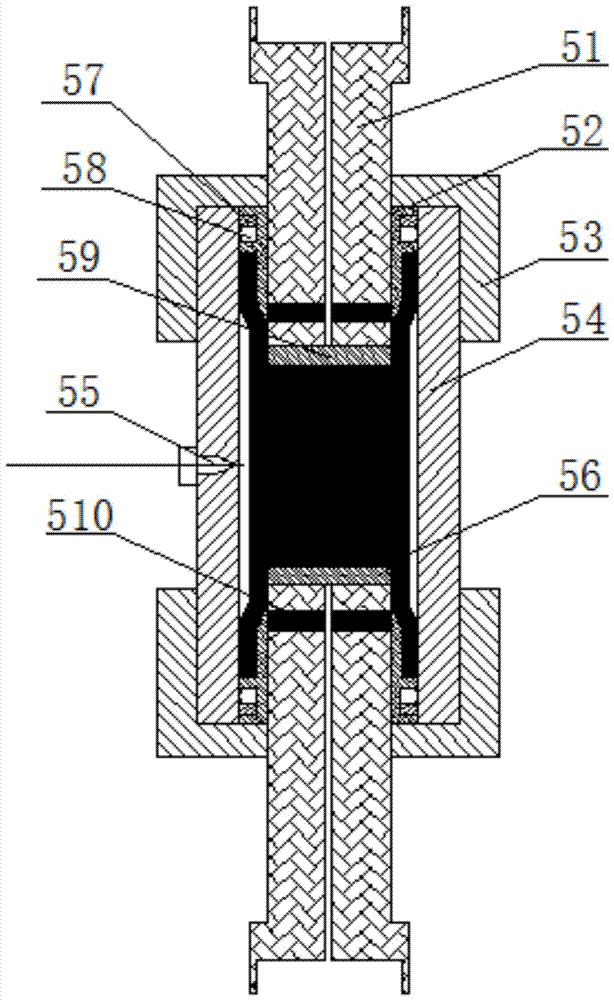

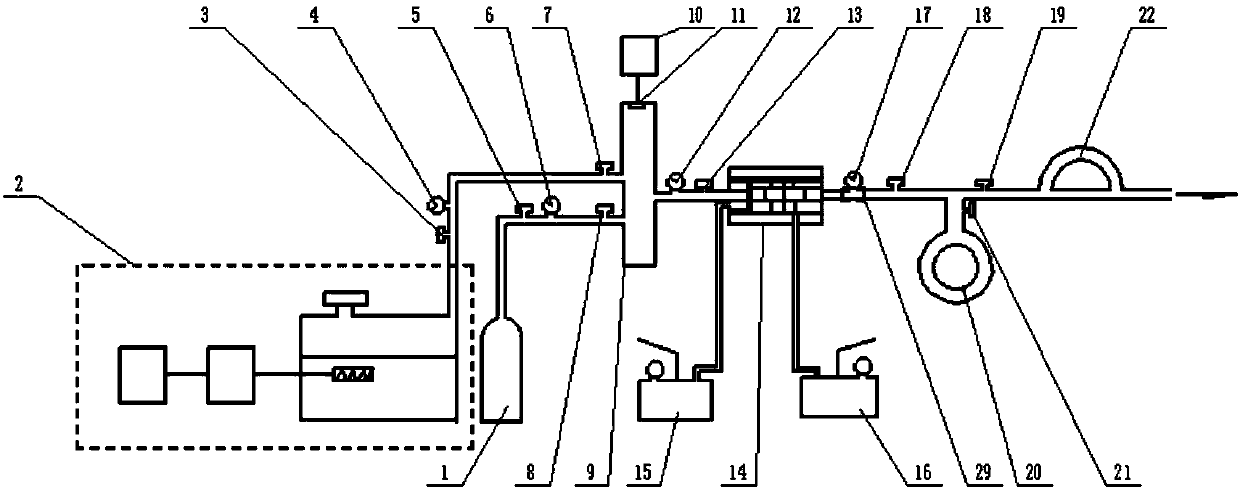

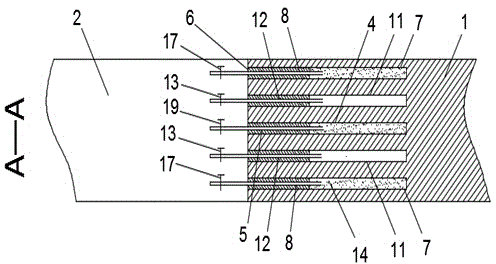

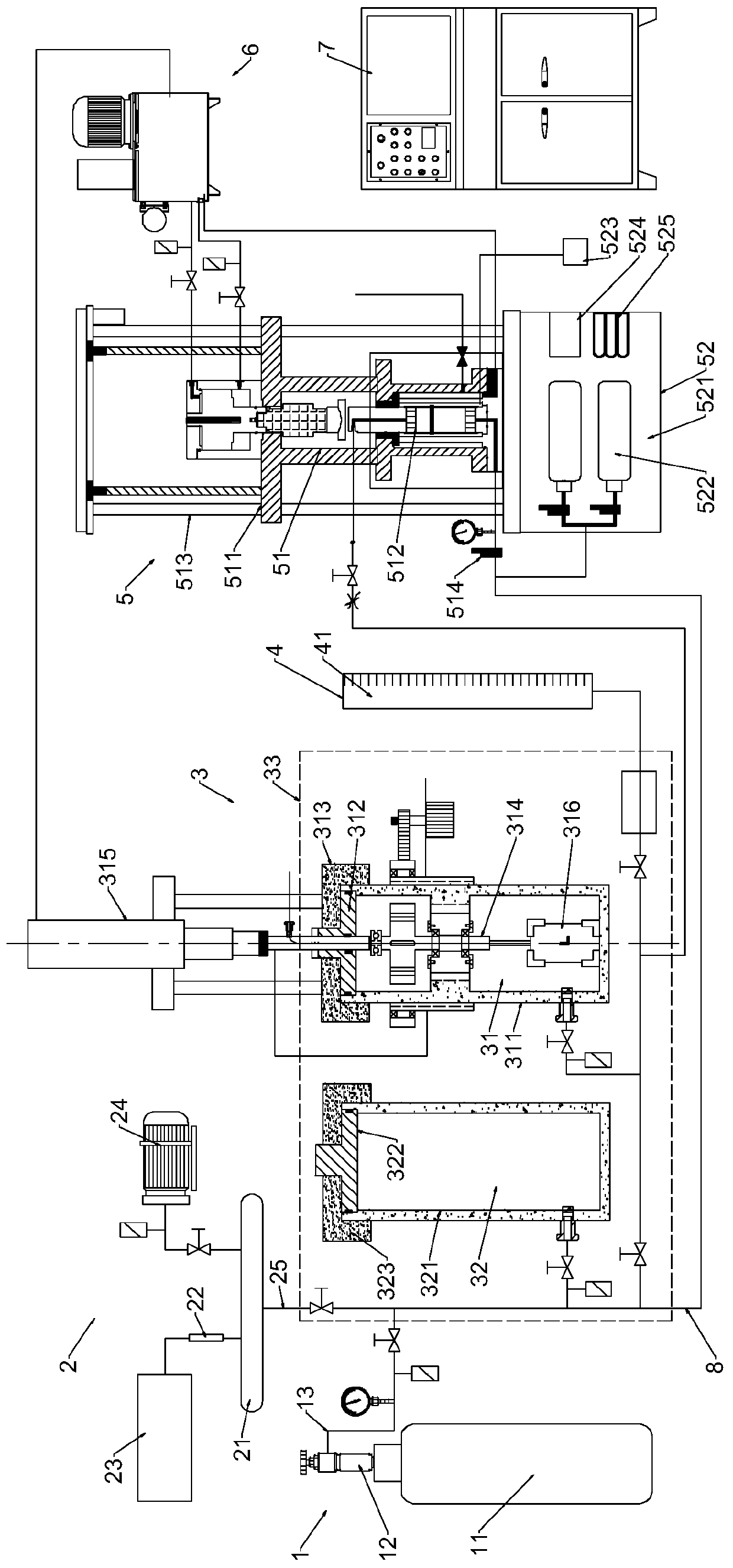

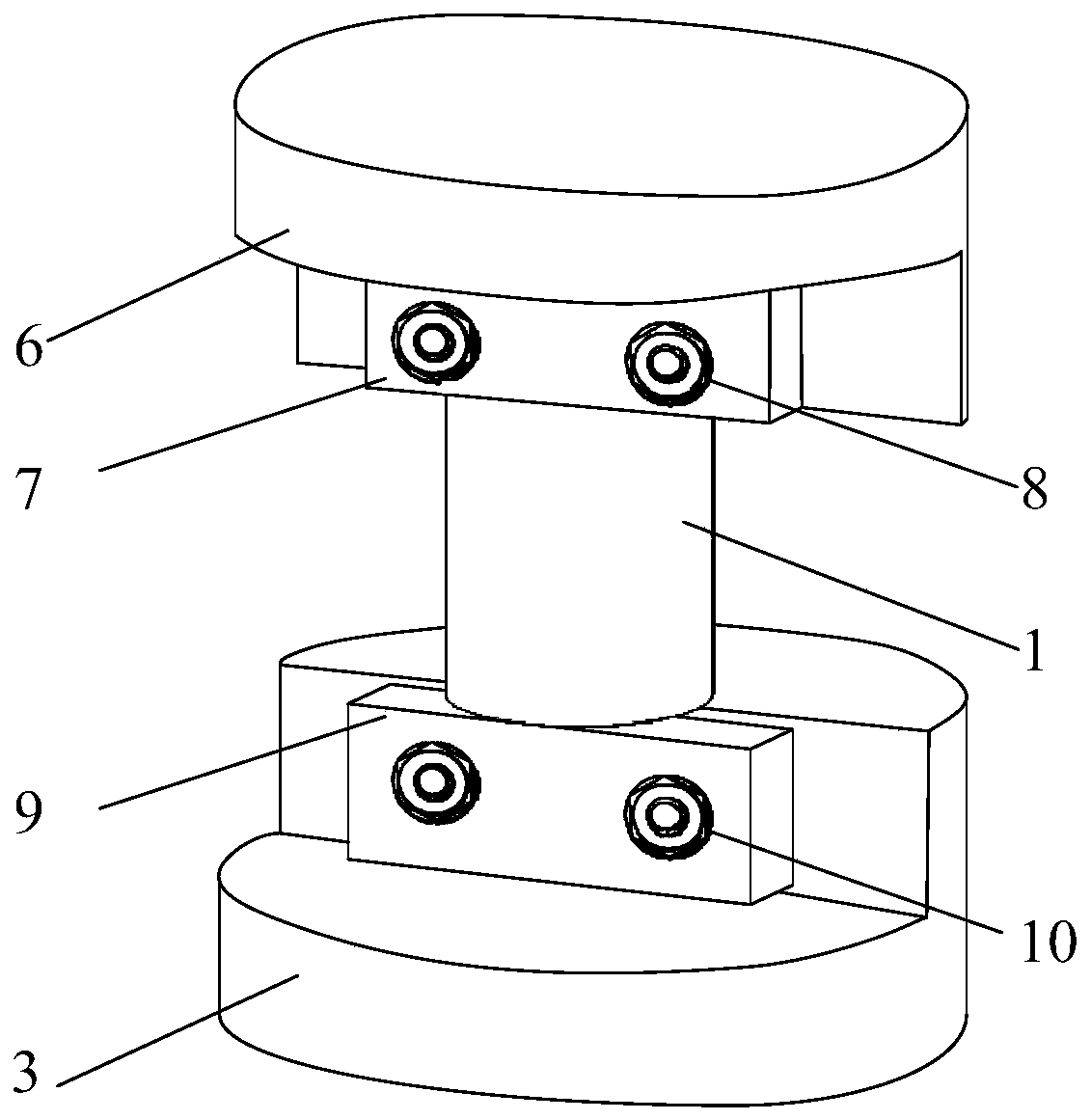

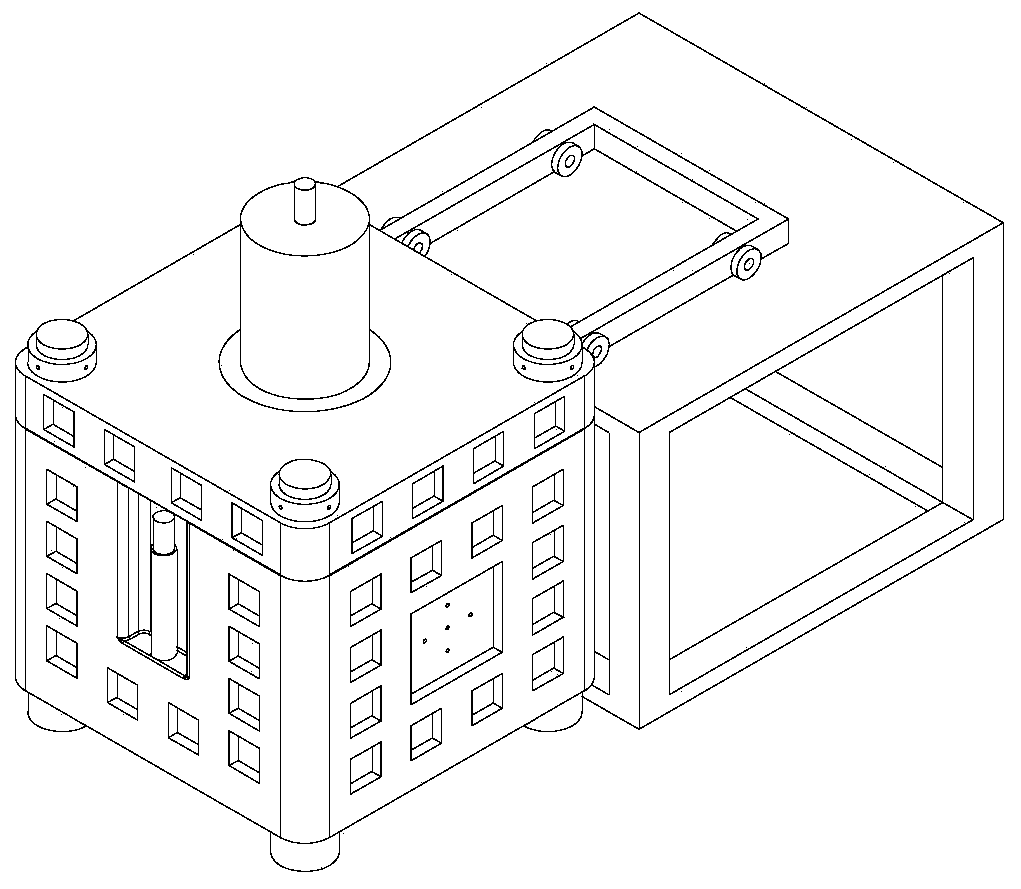

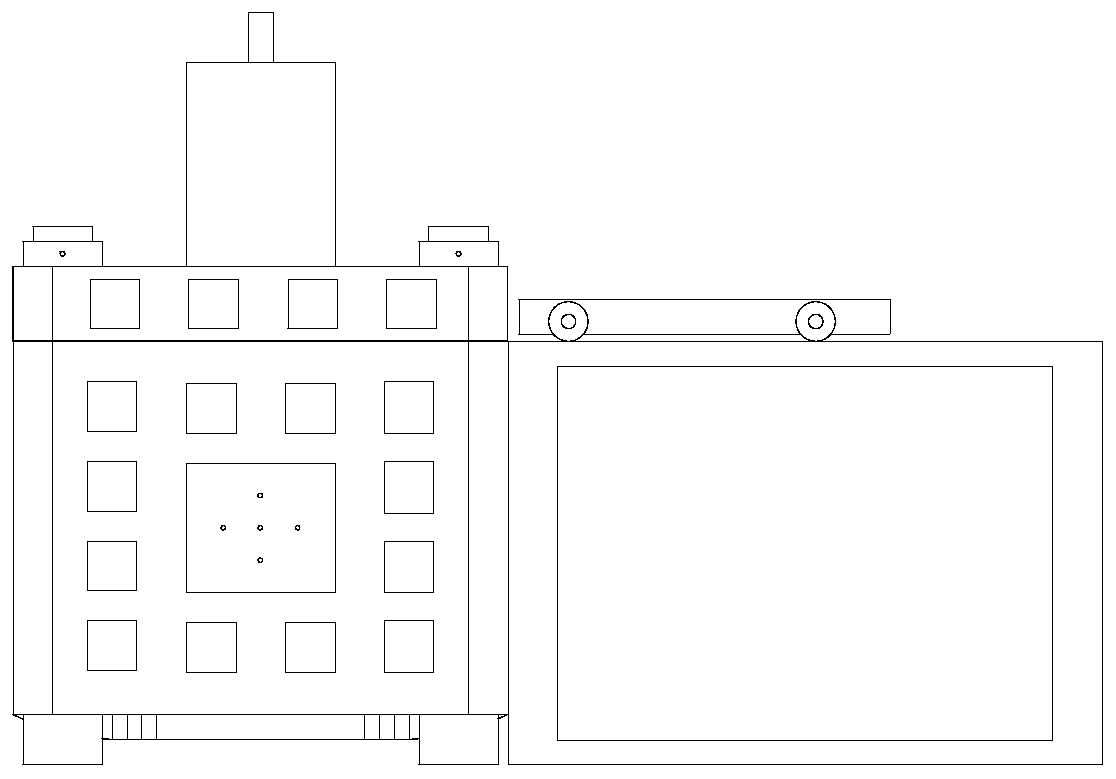

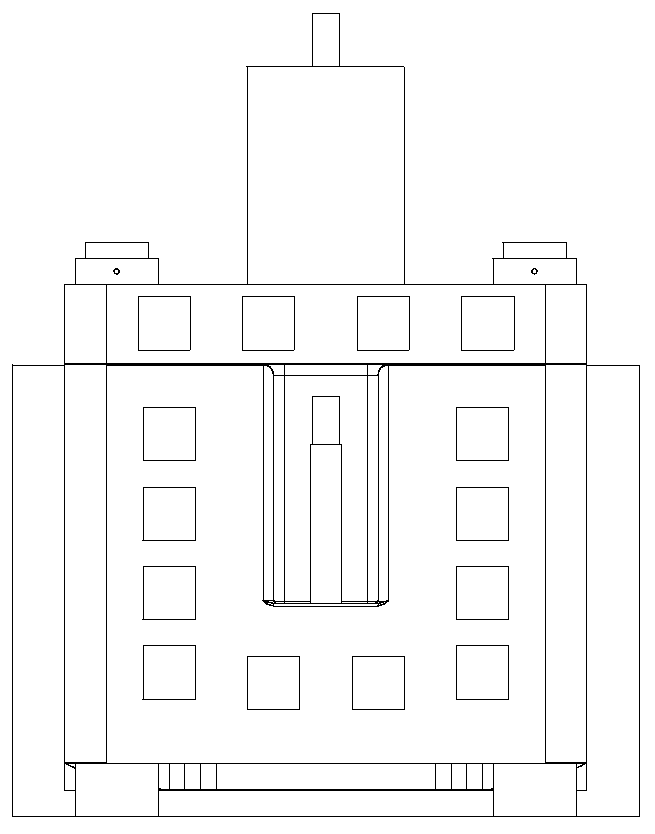

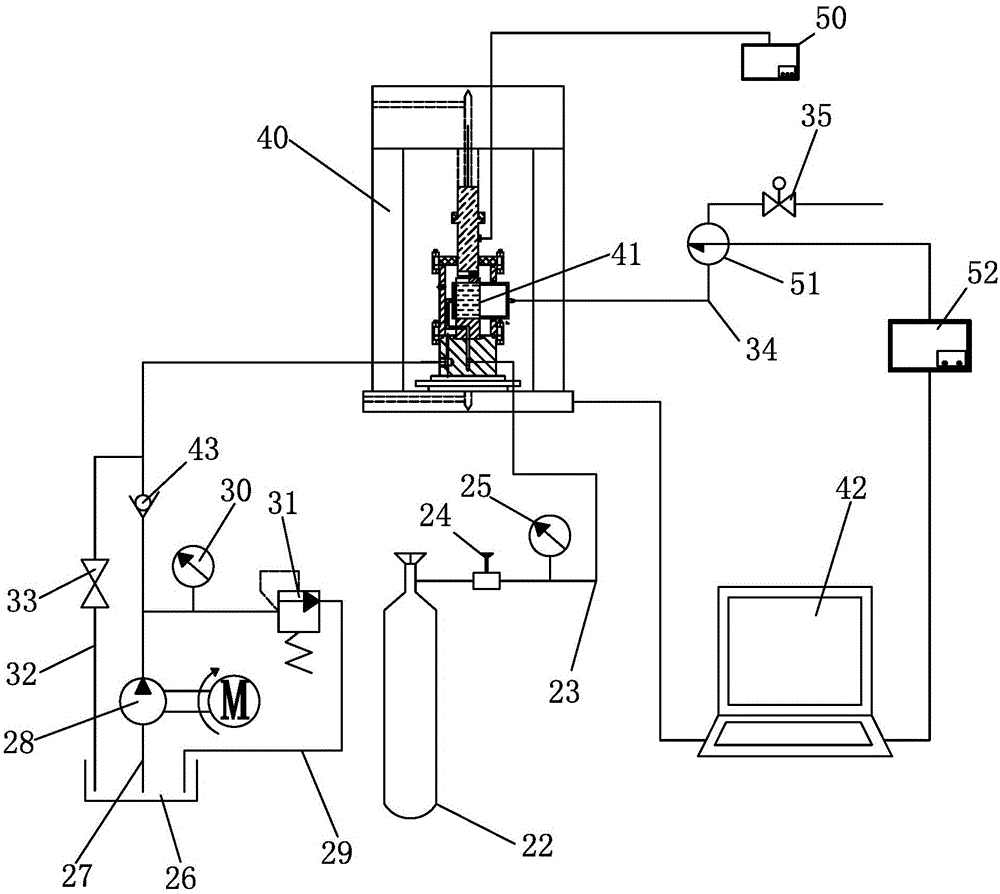

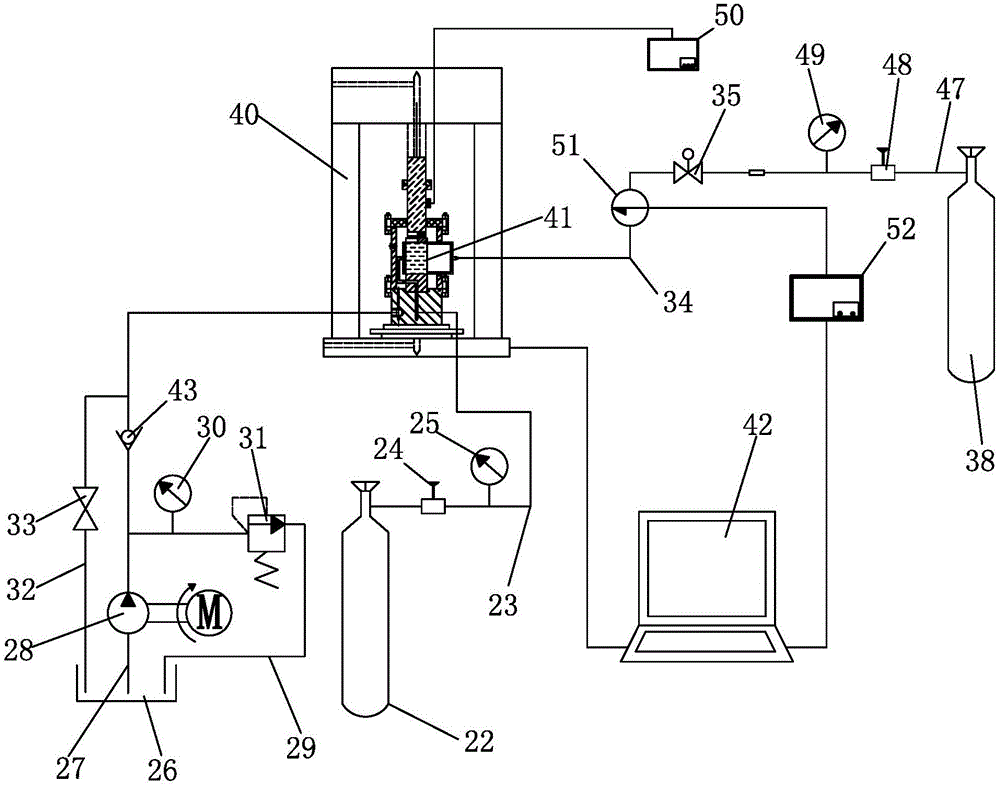

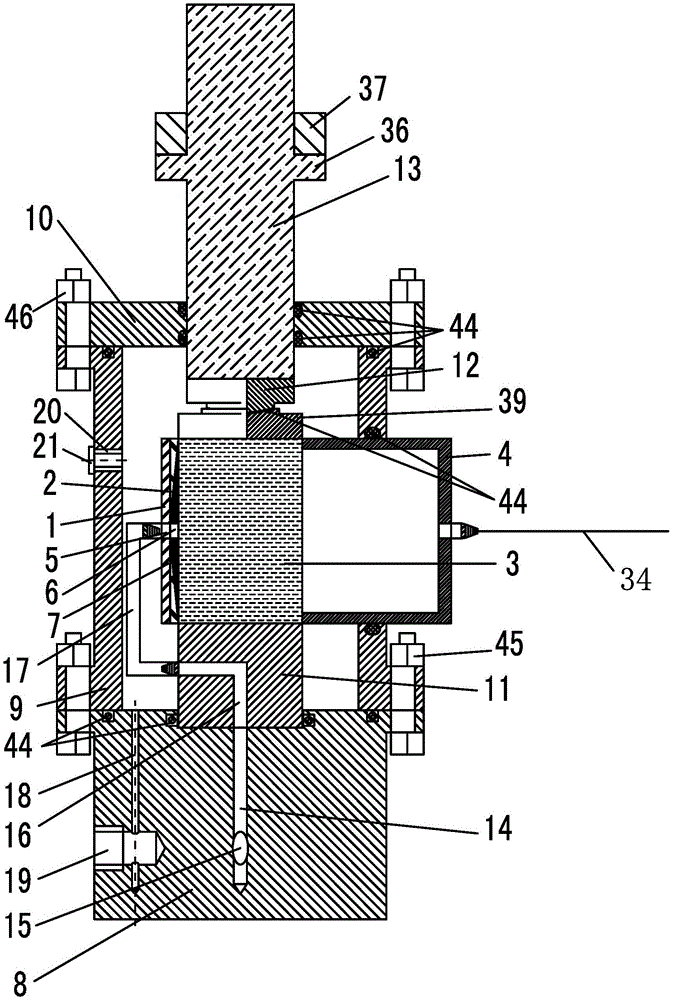

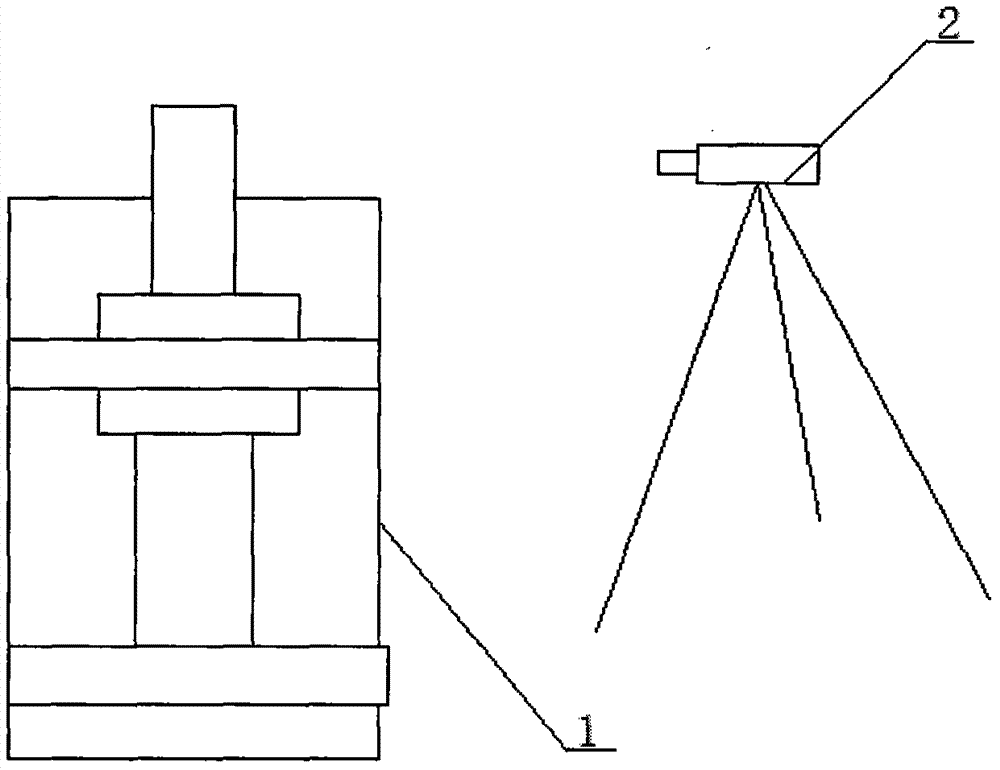

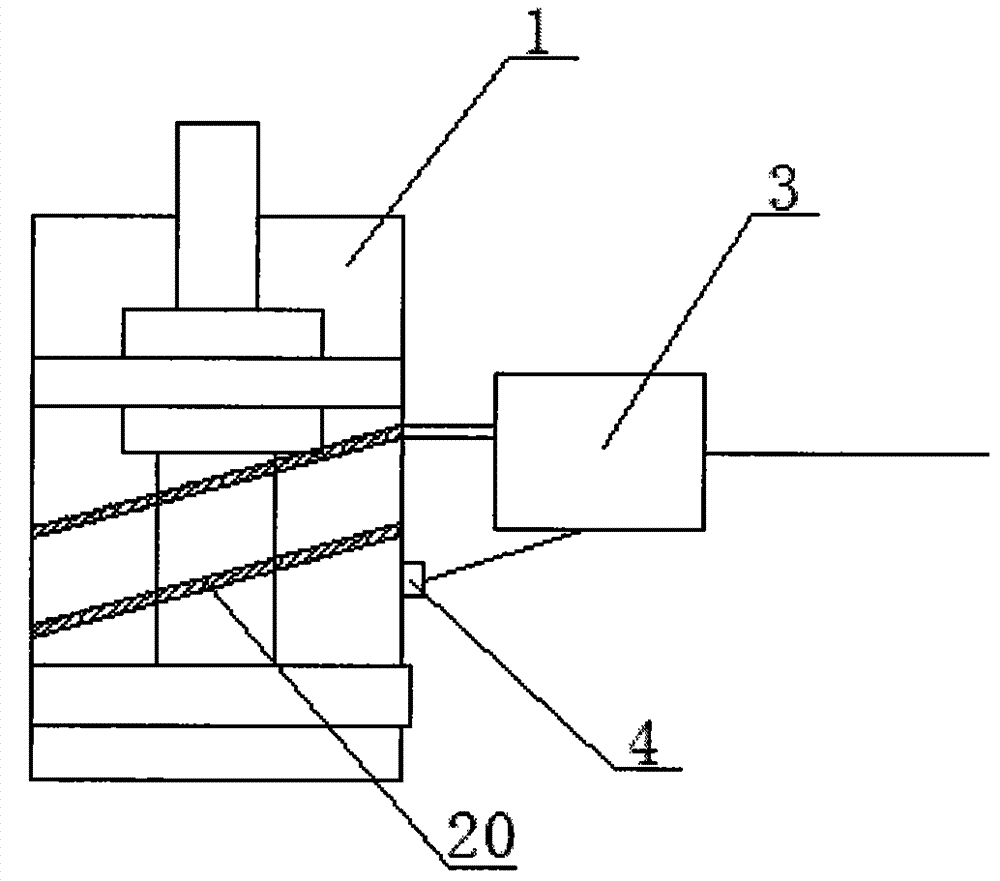

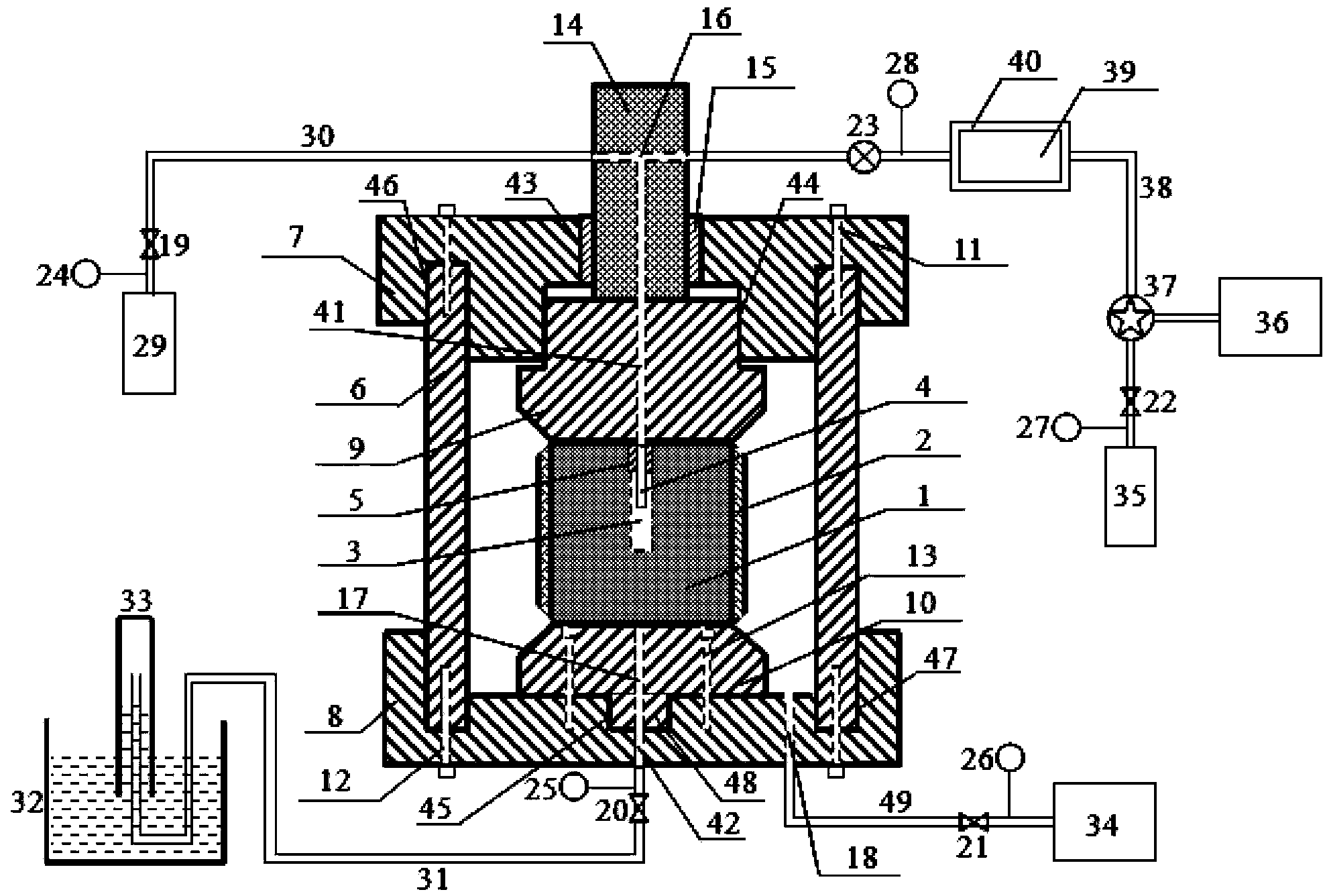

The invention discloses a device for simultaneously measuring expansion and permeability rate of gas injected into a coal rock under a tri-axial stress condition. The device comprises a gas injection system (1), a confining pressure system (2), an axial pressure loading machine (25), a permeability measuring system (3) and a data acquisition system (4), wherein the gas outlet port of the gas injection system (1) is connected with the gas inlet port of the confining pressure system (2) through a high pressure gas inlet pipe (43); the axial pressure loading machine (25) is arranged at the external part of the confining pressure system (2); the permeability measuring system (3) is connected with the gas outlet port of the confining pressure system (2) through a high pressure gas pipe; and the data acquisition system (4) is connected with the confining pressure system (2) through a data line with a sensor. According to the device provided by the invention, the problem of measuring coal-body deformations and permeability variations of different adsorption gases at different temperatures and different pressures is effectively solved; in addition, the permeability and coal-body change laws caused by a gas injection displacement in the process of developing coal bed gases are effectively simulated so that the production practice is beneficial to be further guided.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

Low-permeability coal high-pressure gas cycle pulse fracturing anti-reflection experimental method

InactiveCN103234891AMonitor disseminationMonitor the laws of disseminationPermeability/surface area analysisCoal briquetteExperimental methods

Owner:LIAONING TECHNICAL UNIVERSITY

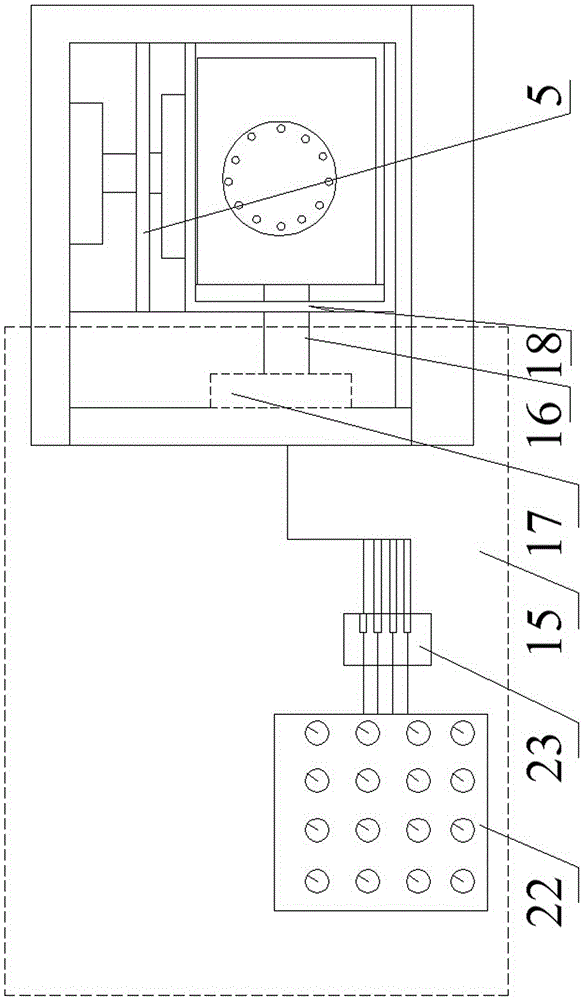

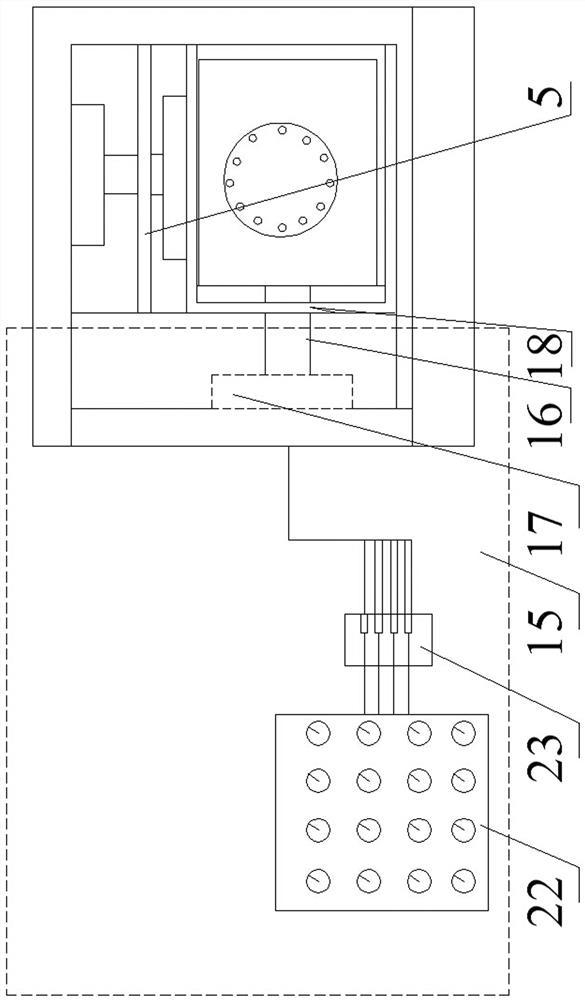

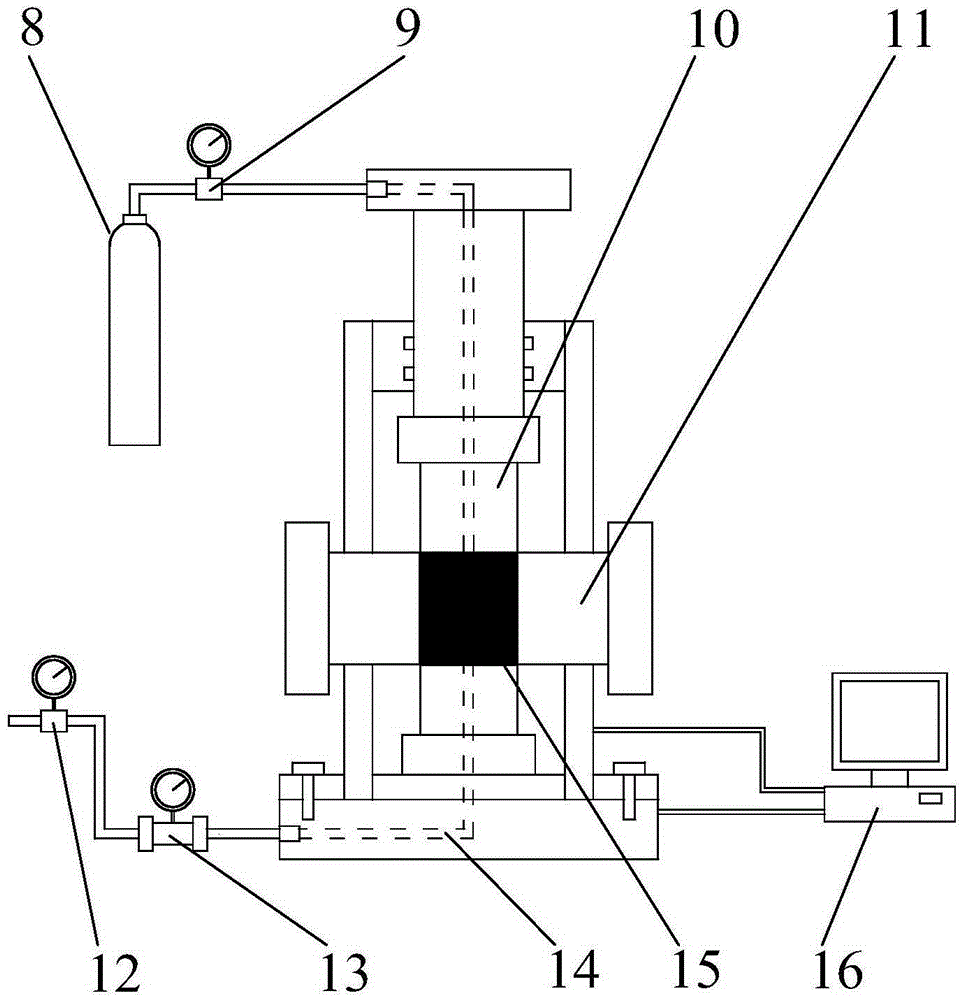

Triaxial seepage stress temperature creep coupling experimental device based on digital image

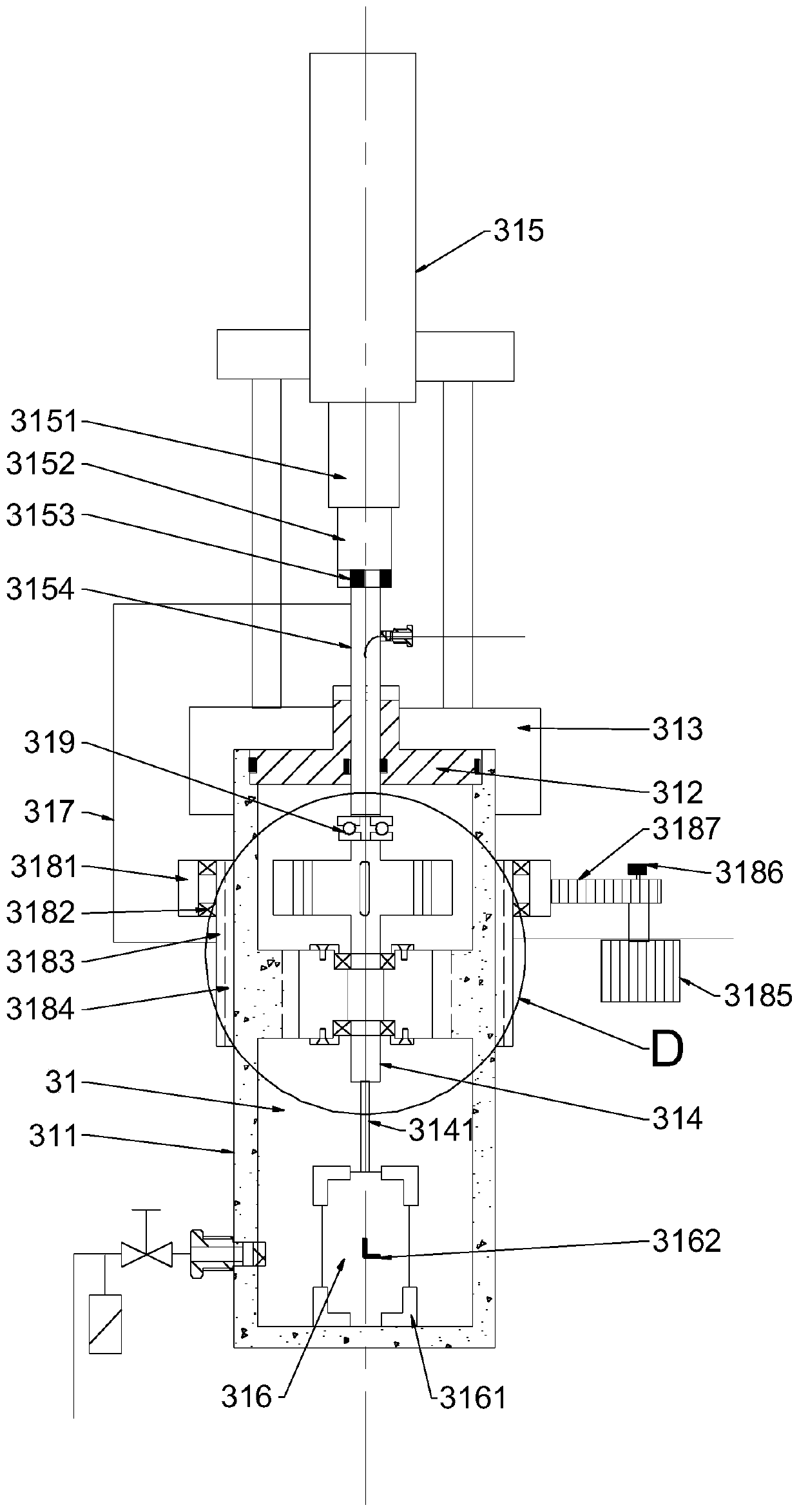

InactiveCN104849194APrecise creep deformationReduce manpower consumptionPermeability/surface area analysisAxial compressorAxial pressure

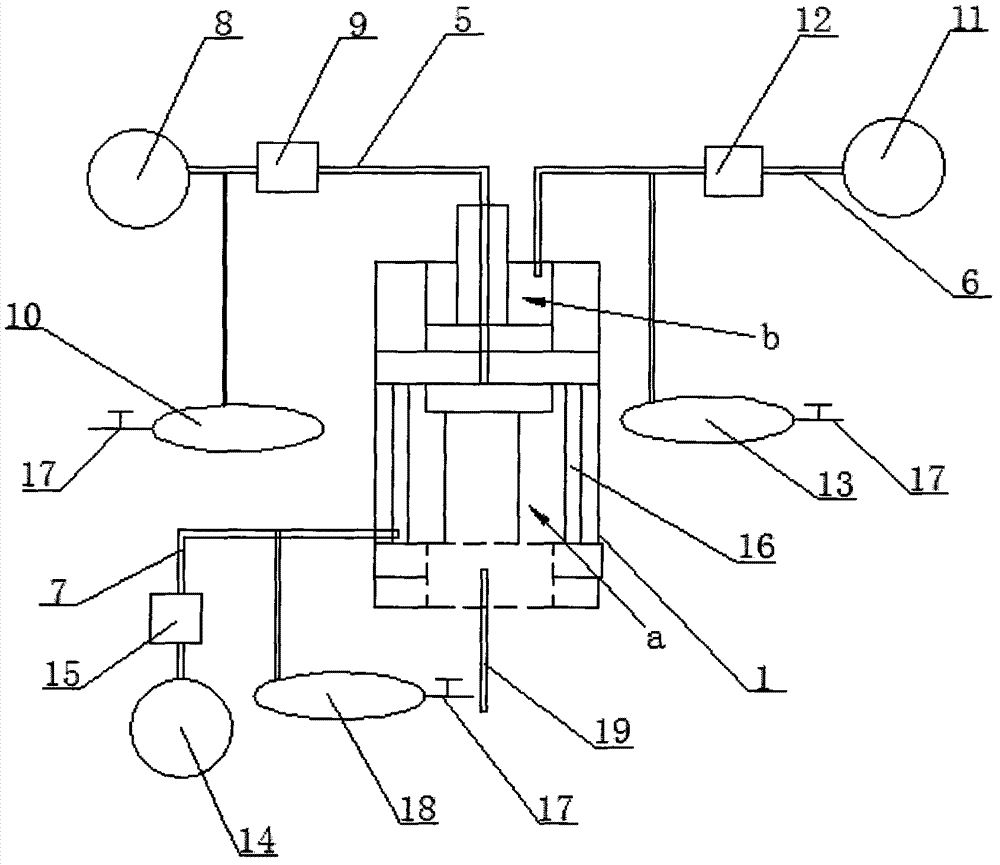

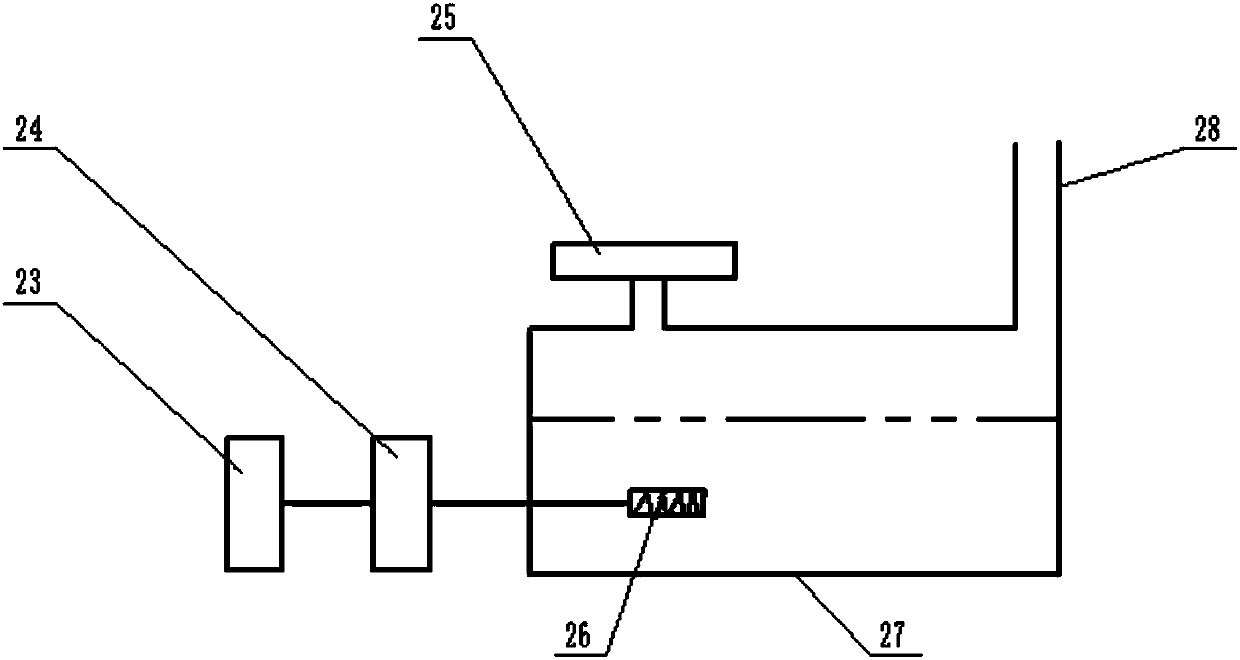

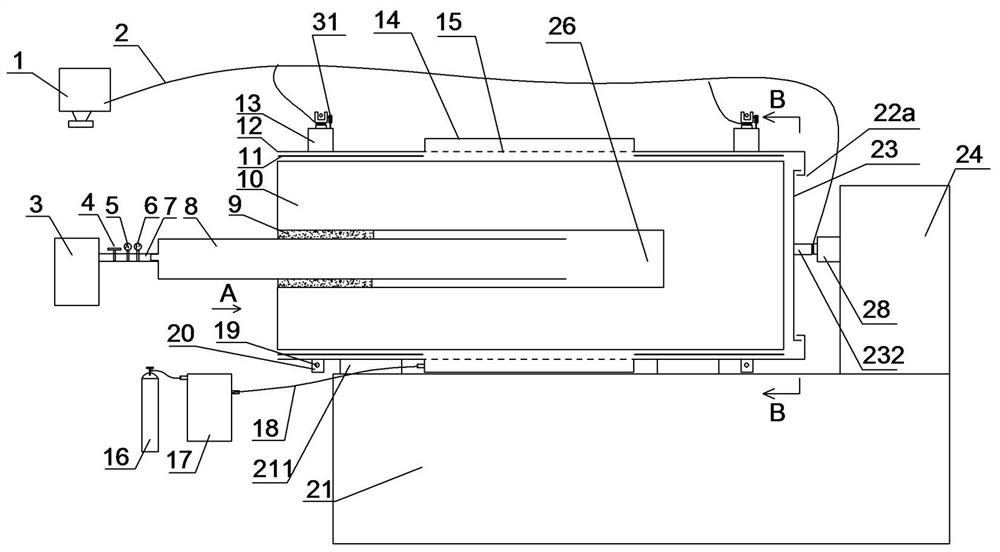

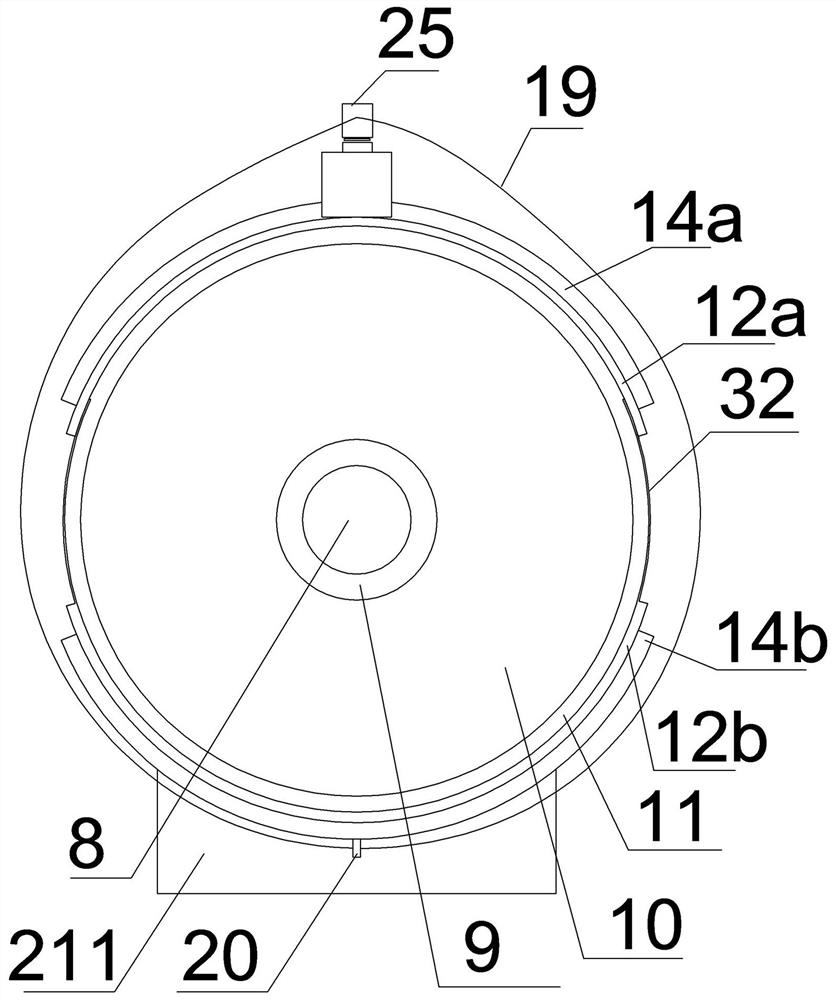

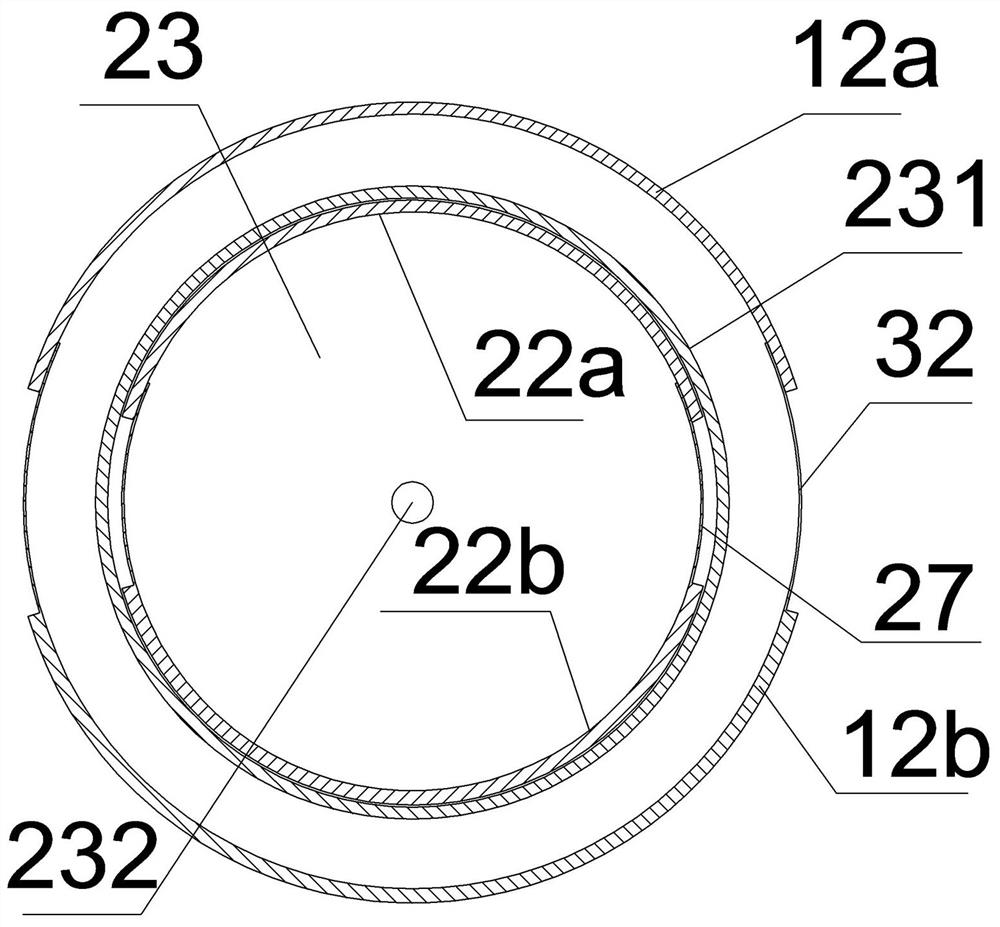

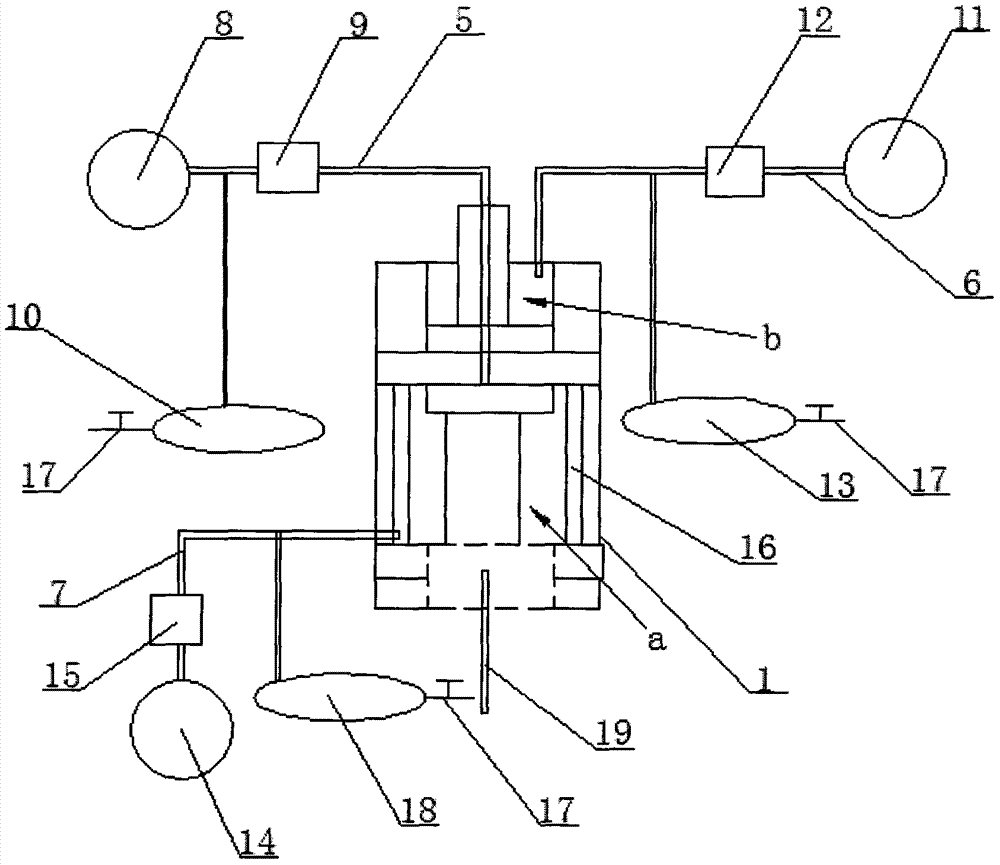

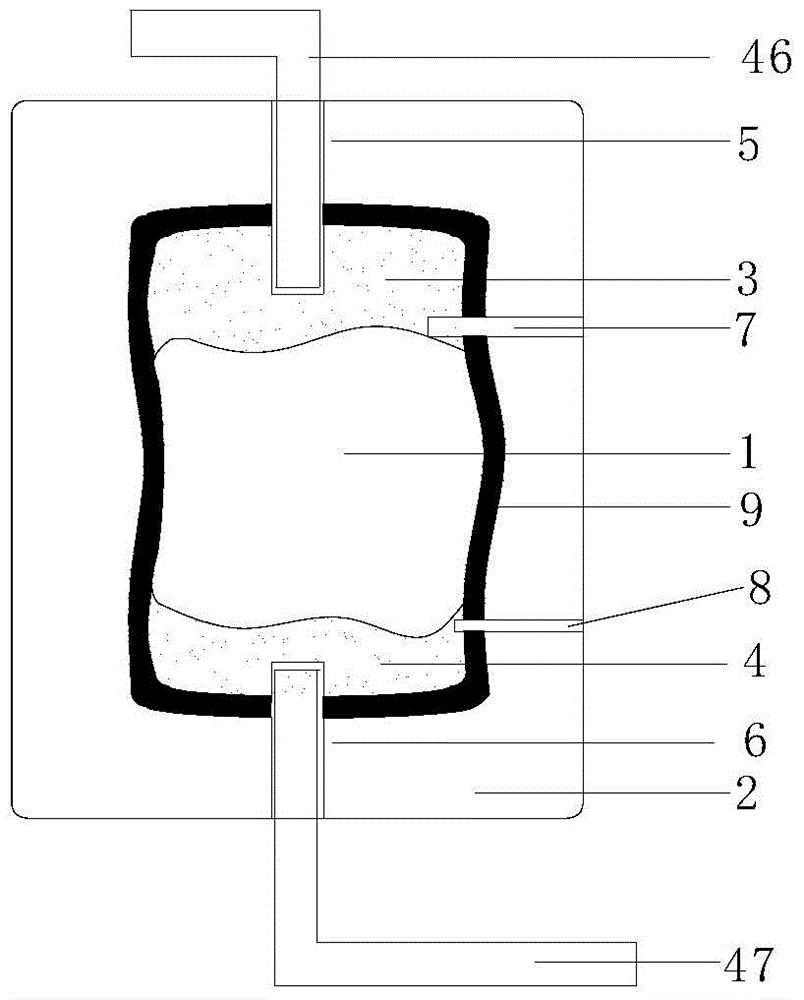

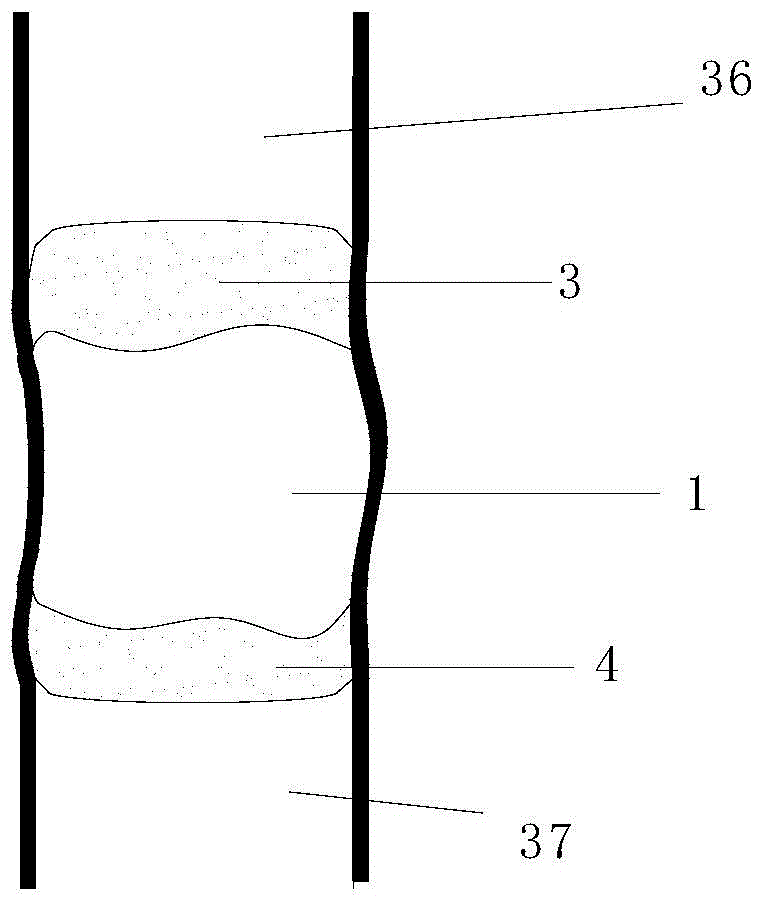

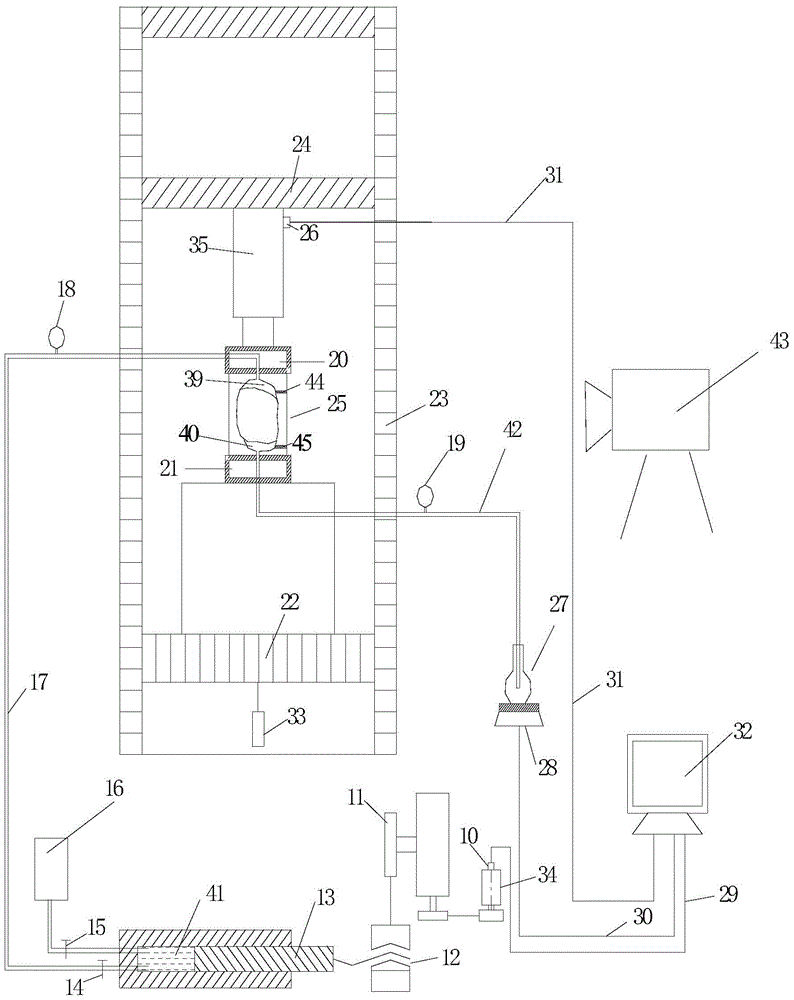

The invention discloses a triaxial seepage stress temperature creep coupling experimental device based on a digital image. The triaxial seepage stress temperature creep coupling experimental device comprises a triaxial pressure chamber (1), a digital image observing system and a triaxial pressure chamber heating system, wherein a pore pressure applying system, a stable-pressure axial applying system and a surrounding pressure applying system are mounted on the triaxial pressure chamber (1); the pore pressure applying system comprises a pore pressure fluid injection tube (5), one end of the pore pressure fluid injection tube is connected with a first pressure pump (8); the first pressure pump (8) is used for providing pore pressure energy, the pressure value is measured by a digital pressure meter (9), and the pressure meter (9) is mounted on the pore pressure fluid injection tube (5). The triaxial seepage stress temperature creep coupling experimental device can be used for accurately and automatically measuring creep deformation by searching the influences of the surrounding pressure, the axial pressure, the hole pressure, the temperature and the creep deformation on coal permeability.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

Coal permeability testing device and use method thereof

PendingCN107515185ASimple structureSimple and fast operationAnalysing solids using sonic/ultrasonic/infrasonic wavesPermeability/surface area analysisRock coreGas cylinder

Owner:HENAN POLYTECHNIC UNIV

Pressure-bearing broken residual coal permeability evolution and spontaneous combustion characteristic testing device

InactiveCN105259091AMake up for the technical status quo that cannot bear the pressureComprehensive test functionPermeability/surface area analysisTemperature controlLine tubing

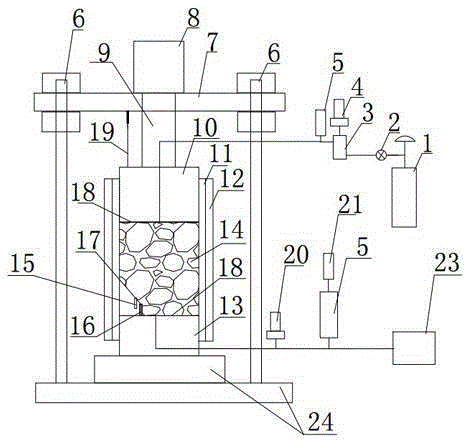

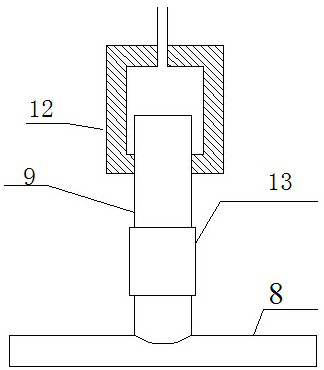

The invention relates to a pressure-bearing broken residual coal permeability evolution and spontaneous combustion characteristic testing device. A coal sampling mill comprises a coal sampling mill cavity, a piston pressure head and a lower plug head. The coal sampling mill cavity is fixed to a supporting frame of the pressure-bearing broken residual coal permeability evolution and spontaneous combustion characteristic testing device. The coal sampling mill cavity is of a cylindrical hollow structure. The piston pressure head is arranged at the upper portion of the coal sampling mill cavity. The lower plug head is arranged at the lower portion of the coal sampling mill cavity. A heating temperature control device is arranged on the periphery of the coal sampling mill cavity. A first sensor and a second sensor are arranged inside the coal sampling mill cavity. A pressure control system is arranged on the top of the coal sampling mill cavity. A gas inlet formed inside the piston pressure head is provided with a pipeline to be connected with a pressure testing system. A gas outlet formed inside the lower plug head is provided with a pipeline to be connected with a gas detection unit. Axial loading stress and temperature control are adopted for solving the technical problem that a traditional coal spontaneous combustion testing device cannot achieve stress load.

Owner:HENAN POLYTECHNIC UNIV

Triaxial seepage device for changing humidity of gas and positive pressure of outlet end

The invention discloses a triaxial seepage device for changing the humidity of gas and positive pressure of an outlet end. The triaxial seepage device comprises a triaxial pressure system, wherein a gas supply system is connected with the air inlet end of the triaxial pressure system through a pipeline; the air outlet end of the triaxial pressure system is connected with a positive pressure adjusting system through a pipeline; the positive pressure adjusting system is connected with a flow determining system through a pipeline; a pressure loading system is connected with the triaxial pressuresystem; a vacuum degassing system is connected to a part between the positive pressure adjusting system and the flow determining system through a pipeline. The technical problems that the triaxial seepage device cannot change the humidity of the gas, cannot simulate the influence of the change of gas humidity of a coal mining site on coal permeability and the like are solved.

Owner:GUIZHOU UNIV

Solvent extraction, wetting inversion, and impulse fracturing triune coal permeability-improvement method

InactiveCN108266222AEffective crackingChange hydrophilicityFluid removalGas removalFrequency conversionSolvent

The invention provides a solvent extraction, wetting inversion, and impulse fracturing triune coal permeability-improvement method. According to the method, gas extraction pipes and grouting pipes aremounted in constructed drilled holes, the grouting pipes are externally connected with impulse water injecting pumps and frequency-conversion motors, and the externally-connected impulse water injecting pumps are further utilized to mix extraction solvents, wetting inversion agents and water according to a certain proportion, so that an extraction inversion solvent is formed and injected into thedrilled holes for coal seam permeability-improvement operation, and then the gas extraction pipes are used for discharging the extraction inversion solvent and then conduct gas extraction. Accordingto the solvent extraction, wetting inversion, and impulse fracturing triune coal permeability-improvement method, the advantages of the extraction solvent, the wetting inversion agent and impulse fracturing are brought into full play, the method is simple and efficient, and the permeability-improvement of a coal seam can be greatly improved.

Owner:CHINA UNIV OF MINING & TECH

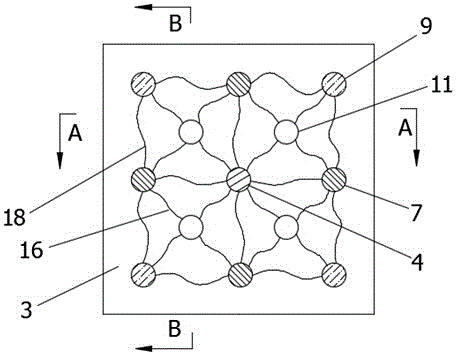

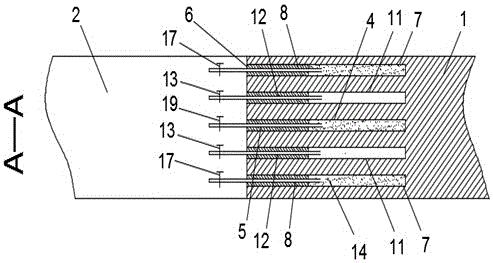

Spalling permeability increasing method for rapid excavation of underground seam gateway

ActiveCN104912588AImprove breathabilityThe production is conducive toFluid removalGas removalSlurryGrout

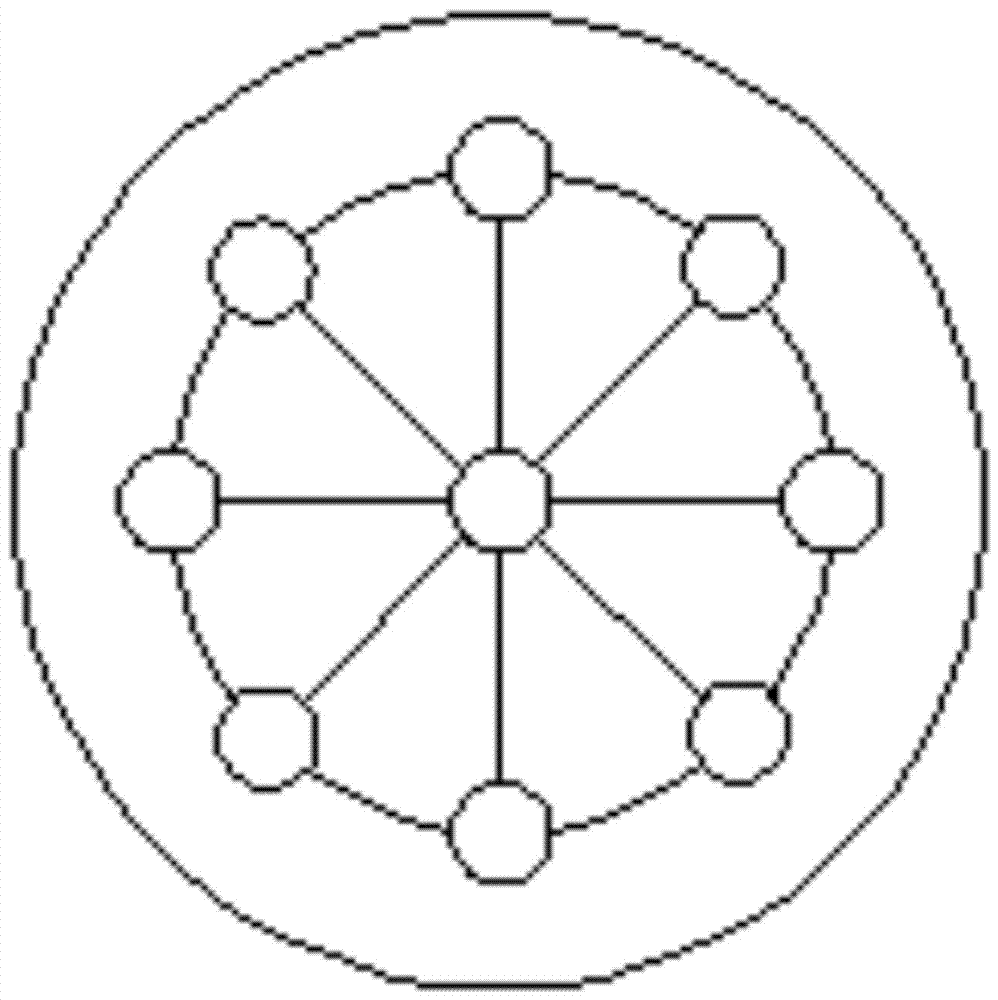

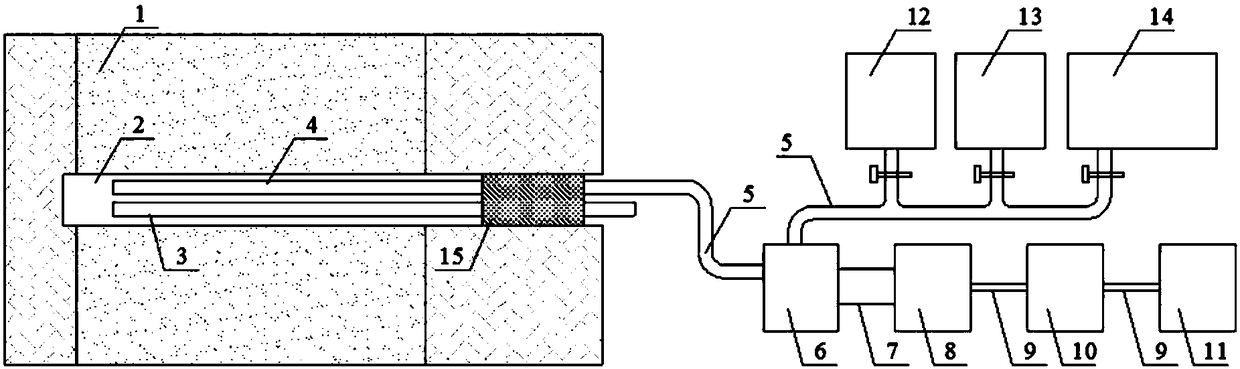

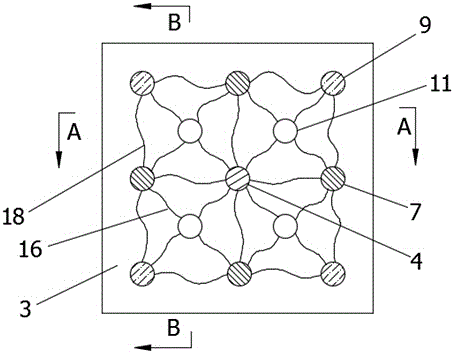

The invention discloses a spalling permeability increasing method for rapid excavation of an underground seam gateway. The method is particularly suitable for advancing pre-pumping of a high-gas low-permeability seam gateway. A first spalling hole is constructed in the head-on geometric center position of the seam gateway, and second spalling holes are formed in the positions over, under, left and right the first spalling hole; third spalling holes are constructed in the positions over and under the second spalling holes horizontal to the first spalling hole, and exhausting and mining holes are constructed in the center points of the connecting lines of the first spalling hole and the third spalling holes; after drilling is finished, quick lime grout is injected into the third spalling holes in a crossing manner, and the spalling holes are control holes of one another; and through spalling pressure generated by the holes, net-shaped cracks are generated between the holes, so that the coal permeability is greatly improved, the gas exhausting and mining efficiency is improved, and the excavation speed of the seam gateway is improved; and the method is simple in technology, convenient to operate, wide in grout source, cheap and low in cost.

Owner:TAIYUAN UNIV OF TECH

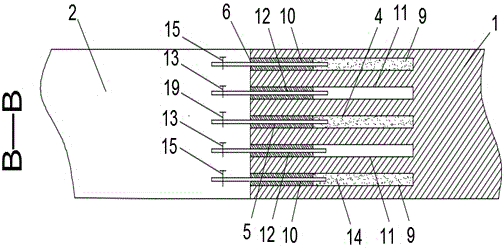

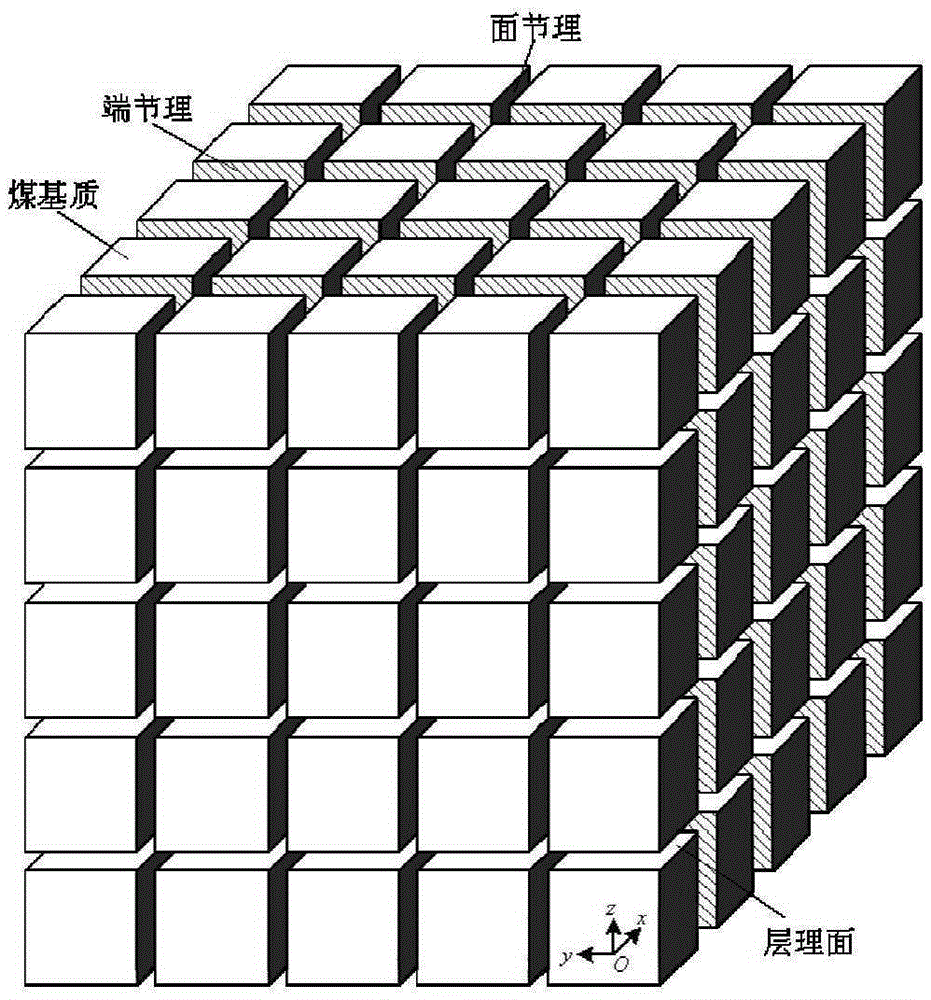

Method for calculating anisotropic absolute permeability of coal

InactiveCN105260597AHigh precisionSpecial data processing applicationsTheoretical computer scienceCoal

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

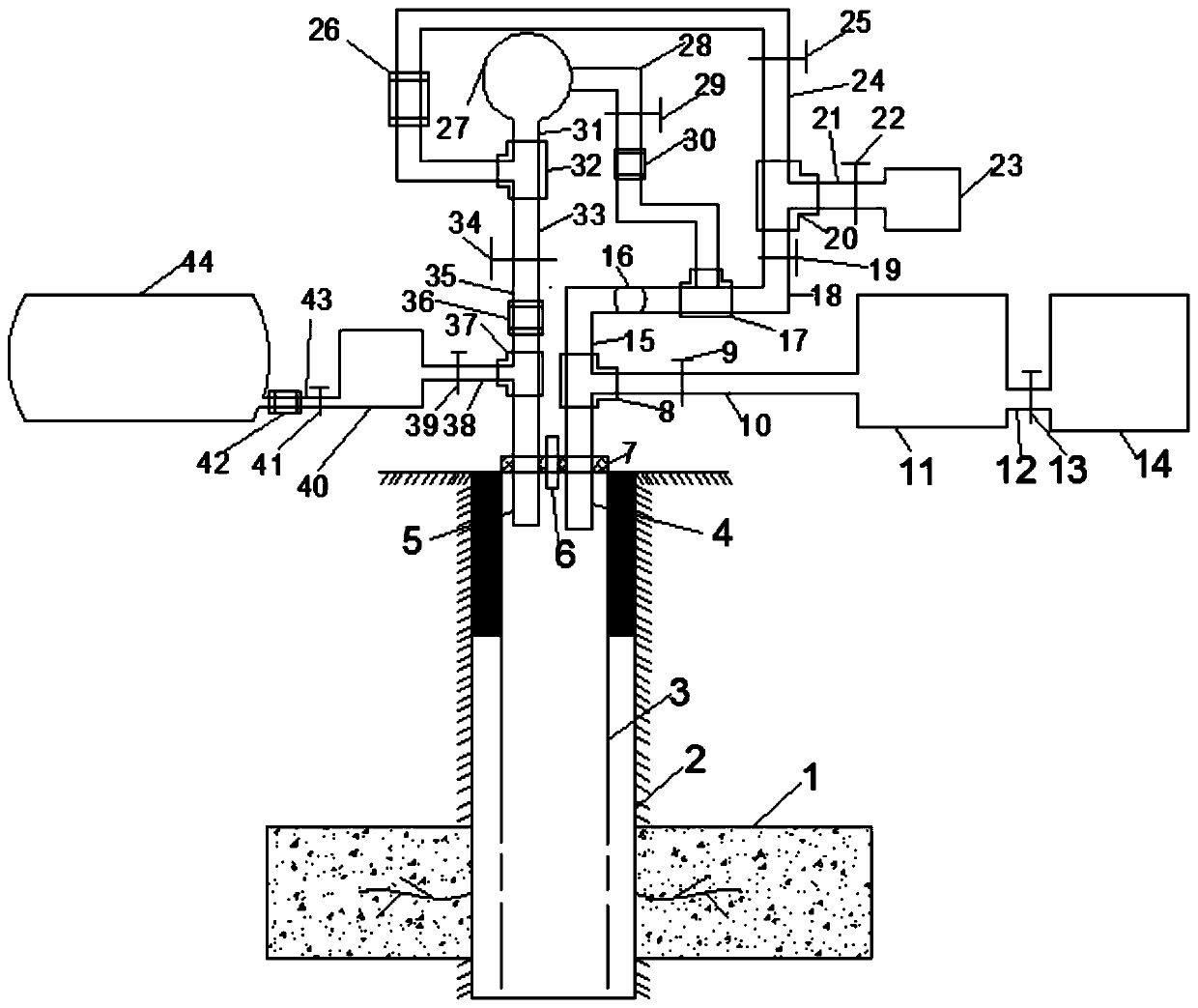

Device for measuring mining influenced coal permeability and using method thereof

InactiveCN106840996AAccurate monitoring of permeability trendsAccurate measurementPermeability/surface area analysisProduct gasGas concentration

The invention discloses a device for measuring a mining influenced coal permeability and a using method thereof. In the mining process of a high gas coal seam, gas in coal in the front of a stope permeates into a stope space by fractures under the influence of mining, and in order to measure a gas permeability condition in the mined coal, the device for measuring the mining influenced coal permeability is in urgent need. The left side of a detachable plug I is connected with a gas pipeline I; the left side of the gas pipeline I is connected with a gas storage tank; a gas pressure stabilizer I, a gas pressure sensor I and a gas flow meter I are sequentially arranged on the right side of the gas pipeline I. Experiments for measuring the gas permeability in the coal under conditions of different mining stresses, different mining heights, different gas concentrations and different gas pressures can be developed, and a gas permeability change rule of the coal in the front of the underground stope under the influence of mining is researched. The invention is used for the device and method for measuring the permeability of the coal under the influence of mining.

Owner:HEILONGJIANG UNIVERSITY OF SCIENCE AND TECHNOLOGY

Tectonic coal permeability tester

InactiveCN104964905AAvoid damageSimple samplingPermeability/surface area analysisThermodynamicsRock core

The invention discloses a tectonic coal permeability tester, which can simultaneously realize steady-state method and non-steady-state method permeability tests on irregular tectonic coal. The tectonic coal permeability tester comprises a core arranging chamber in which a sample is arranged, wherein two ends of the core arranging chamber are respectively provided with vents; two ends of the sample are planes, and space between the periphery of the sample and the inner wall of the core arranging chamber is filled with glass cement; one end of the core arranging chamber is connected with a pressure regulating valve by a pipeline, and the pressure regulating valve is communicated to a gas source; a flowmeter I and an upper stream container which are connected with each other in parallel are connected between the pressure regulating valve and the core arranging chamber; the other end of the core arranging chamber is respectively connected with a flowmeter II, a vacuum pump, and a downstream container through pipelines; a differential pressure gauge is connected between the vents in the two ends of the core arranging chamber. According to the tester, sampling is easy, a sample clamp holder is prevented from pressing and damaging the sample, and the tested permeability is more close to reality; the steady-state and non-steady-state tests can be performed, so the test range is wider, meanwhile the porosity of the sample can be tested, and acquired data are more.

Owner:CHINA UNIV OF MINING & TECH

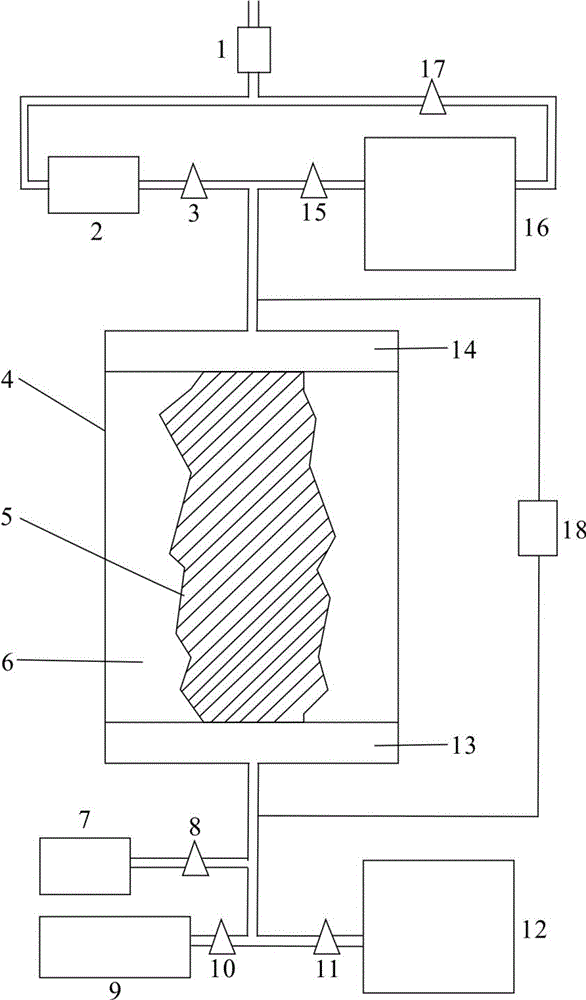

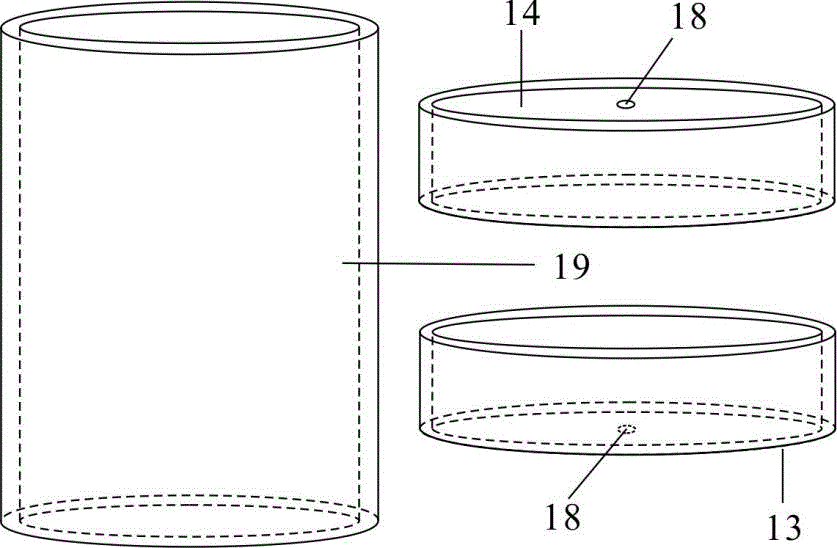

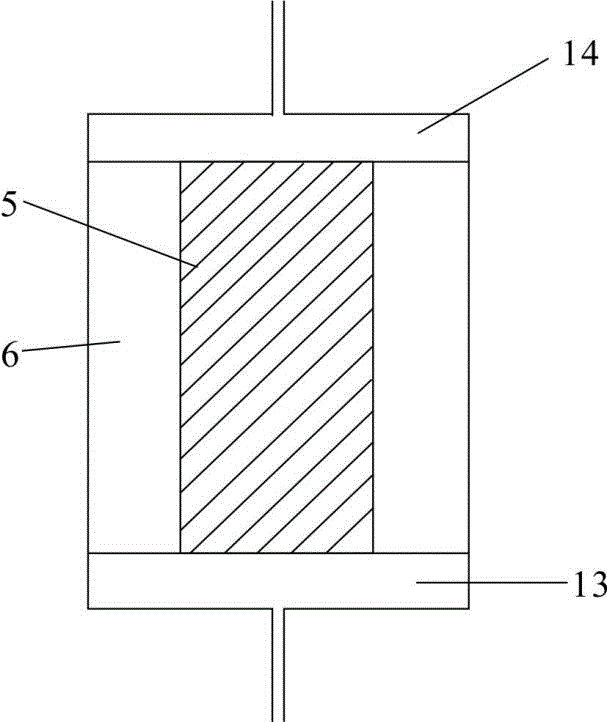

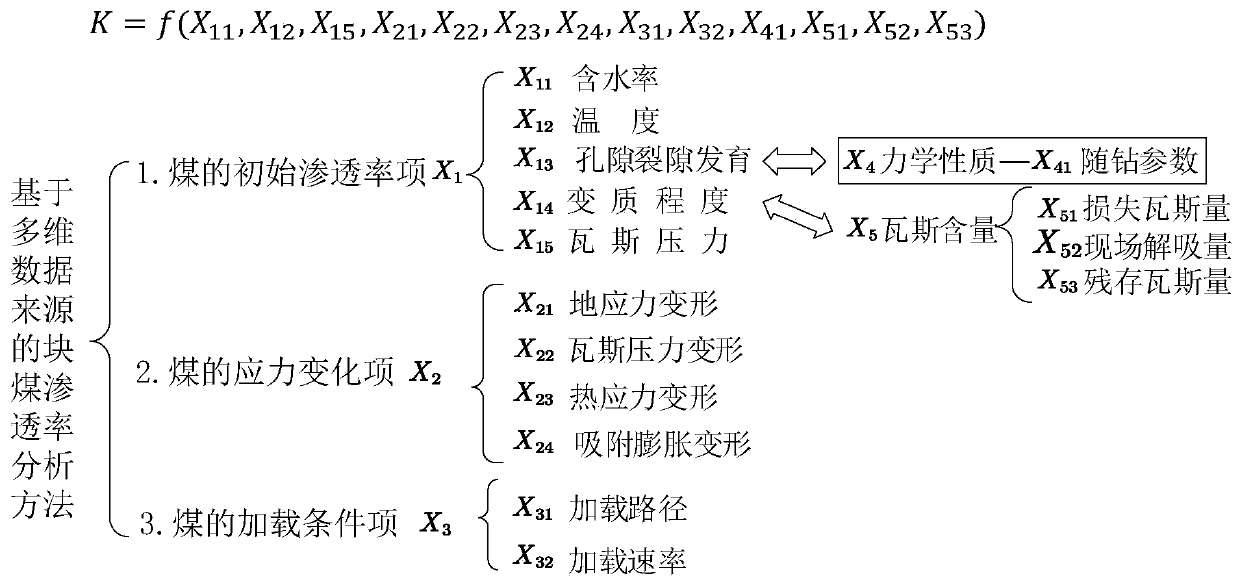

Multi-dimensional data source lump coal permeability analysis method, measurement device and method

ActiveCN111398130AMeet extractionMachine learningPermeability/surface area analysisThermodynamicsMeasurement device

The invention discloses a multi-dimensional data source lump coal permeability analysis method. A permeability model is established, influence factors of lump coal permeability are identified, and themulti-dimensional data source lump coal permeability analysis method is established so that an analysis result is more accurate. Meanwhile, the invention discloses a multi-dimensional data source lump coal permeability measurement device and method. The device comprises an adsorption and desorption system, an electro-hydraulic servo triaxial seepage test device, a gas source system, a vacuumizingsystem, a gas collection device and the like, deformation can be measured and used for analyzing the change rule of permeability, the relation between parameters while drilling and mechanical properties is established and serves as a permeability prediction sample, and the desorption rule of gas-containing coal under the high-temperature coupling of the constant-temperature environment and the middle line of the sample is studied, and finally, the data of the lump coal permeability influence factor under laboratory conditions is obtained so as to accurately analyze and measure the permeability of the lump coal.

Owner:TAIYUAN UNIV OF TECH

Large-temperature-difference freeze-thaw cycle method for production increase of surface borehole

InactiveCN109779590AImprove water absorptionGood cracking effectFluid removalGas removalHigh concentrationFreezing thawing

The invention discloses a large-temperature-difference freeze-thaw cycle method for production increase of a surface borehole. Firstly, magnetized water is injected into a gas extraction pipe of the surface borehole in a pulsating manner; high-pressure nitrogen drives the magnetized water to enter the coal body; liquid nitrogen freezing is carried out on the magnetized water for many times and themagnetized water and high-temperature nitrogen are melted; the freezing expansion force of the magnetized water and the direct large-temperature-difference effect of the liquid nitrogen and the high-temperature nitrogen are utilized to jointly crack the coal body; by means of interaction of high-temperature and high-pressure nitrogen, liquid nitrogen and magnetized water, an ultra-large temperature difference effect is formed, the coal cracking effect is achieved, finally, the coal cracking effect and the crack expansion range can be effectively improved, the coal permeability is increased, and therefore large-flow, high-concentration and long-time gas extraction through ground drilling is achieved.

Owner:XUZHOU UNIV OF TECH

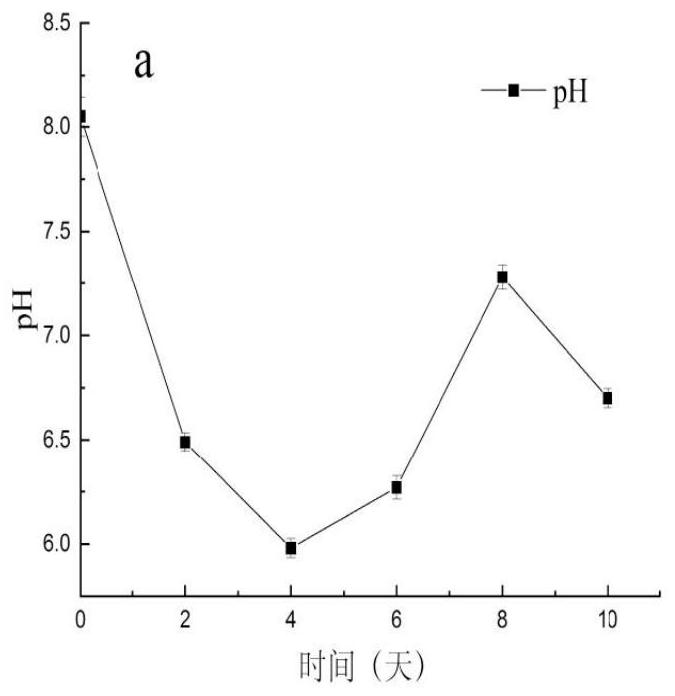

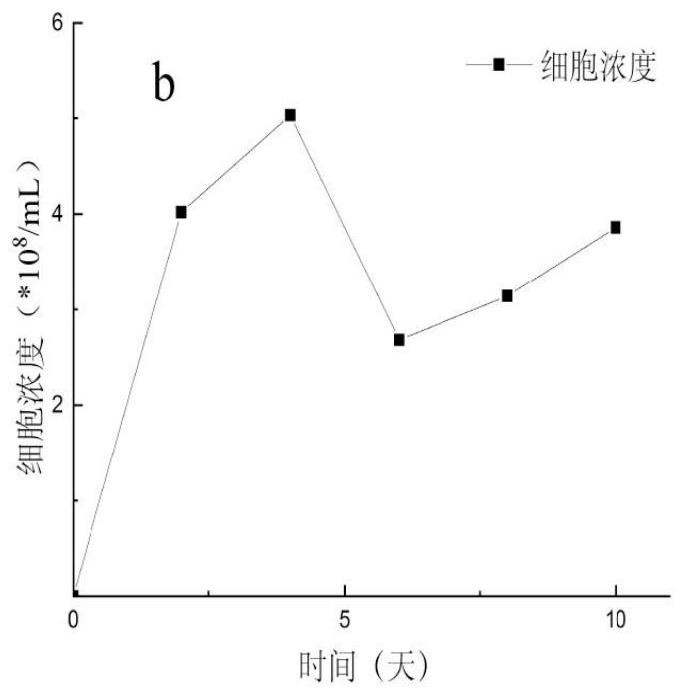

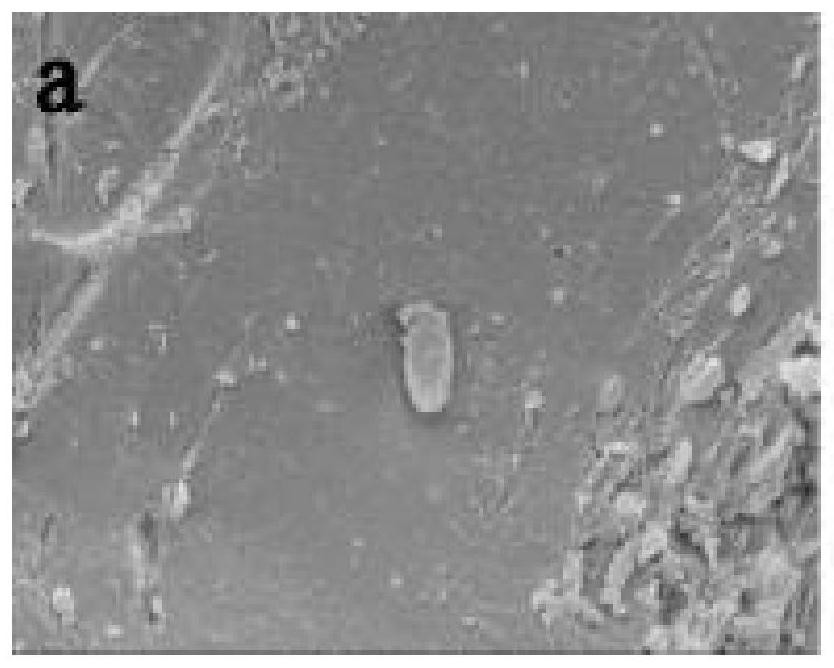

A method of changing coal permeability by using hydrogen-producing acetogenic bacteria

Owner:CHINA UNIV OF MINING & TECH

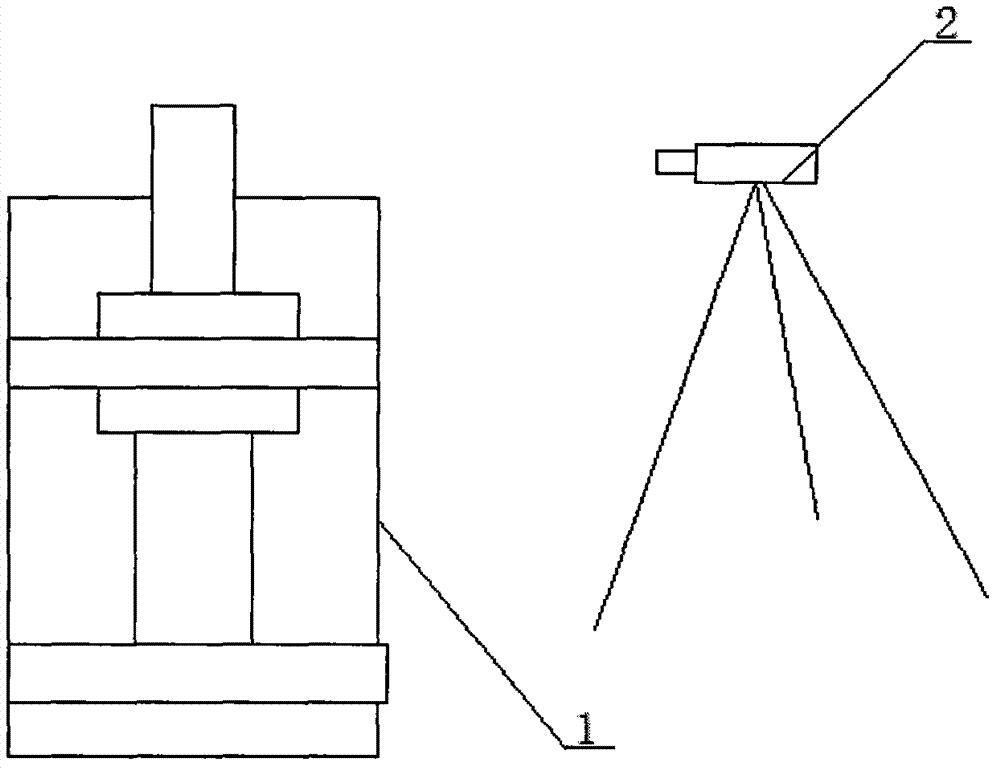

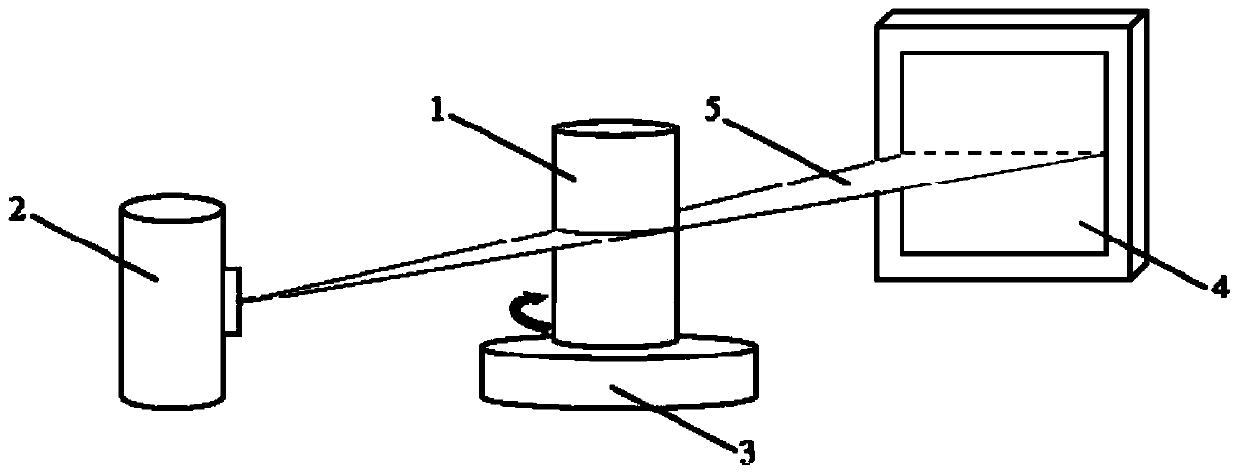

Method of Predicting Coal Permeability under Stress Loading Condition Based on CT Scanning

ActiveCN109211666BGuaranteed accuracyReduce testing costsMaterial strength using tensile/compressive forcesPermeability/surface area analysisTerrainNumerical models

A method for predicting coal permeability under a stress loading condition on the basis of a CT scan, which solves the technical problem of the calculation of the permeability of deformed coal, the method comprising the steps of: A. making a coal sample specimen, and conducting a uniaxial compression experiment while simultaneously performing a CT scan on the coal sample specimen; B. using a digital terrain model method to perform threshold segmentation to obtain a threshold value of the coal sample specimen, and importing a CT scan image into modeling software to establish a three-dimensional numerical model; C. importing the three-dimensional numerical model into finite element analysis software and setting a seepage condition; D. applying a plurality of pressure gradient values ▽P to the three-dimensional numerical model, setting an initial flow velocity v0, and adjusting the parameters ▽P and v0 to obtain a plurality of seepage models; E. importing the seepage models into finite element software for simulation calculation to obtain calculation results; F. importing the calculation results into data processing software, extracting a seepage velocity equidistantly along a seepage direction to obtain a relationship between the seepage velocity and the pressure gradient, and calculating permeability.

Owner:SHANDONG UNIV OF SCI & TECH

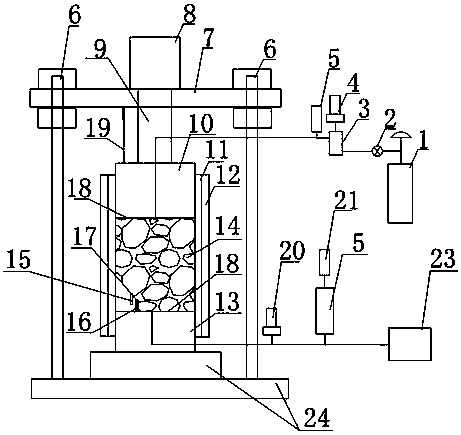

A refined simulation device and method for gas variable negative pressure drainage system

ActiveCN110108614BSufficient dataAccurate dataFuel testingPermeability/surface area analysisThermodynamicsEngineering

The invention discloses a refinement simulation device and method for a gas variable negative pressure drainage system. The device includes a base, a sample cylinder placed on the base, and coal filled in the sample cylinder. The simulation device of the invention can simulate extraction The pressure of the coal seam and the pressure of the gas can provide different extraction negative pressures and pressures of the coal body for the experiment, and provide sufficient and accurate data for the experiment; the simulation device can provide different conditions for the experiment when used The permeability data of the coal under the coal body provide sufficient and accurate data for the gas variable negative pressure drainage system.

Owner:HENAN UNIV OF URBAN CONSTR

The three-in-one gas drainage method of drilling, blasting and pumping

A three-in-one gas drainage method of drilling, blasting and pumping is most suitable for regional gas drainage in high-gas and low-permeability coal seams. On the coal seam in front of the coal mining or excavation face, the drainage holes and blasting holes are alternately arranged in the same layer or through the layer; the construction operation is performed on the drainage holes one by one, and the cutting and gas extraction are carried out; the blasting holes are constructed one by one, And carry out the blasting operation, through the sharpening action of the blasting gas in the blasting hole, a columnar compressed crushing ring and a penetrating blasting fracture body along the direction of the blasting hole and the drainage hole connecting the center line are formed around the blasting hole, so that the ground stress is transferred, the coal body The air permeability increases, and the internal pressure of the coal body is relieved, which is beneficial to the discharge of gas in the coal body. The gas permeability of the coal body can be increased by about 20-50 times, the gas drainage volume of a single hole can be increased by 5-10 times on average, the gas drainage concentration is ≥50%, the gas drainage rate of the mining face is ≥80%, and the drilling and blasting pumping pressure relief After anti-reflection, the pre-gas extraction time can be shortened by half, and the number of gas drainage drilling holes can be reduced by 20-30%. Realize the safe, efficient and uniform extraction of high-gas and low-permeability outburst coal seam gas.

Owner:CHINA UNIV OF MINING & TECH

Test device for permeability evolution and spontaneous combustion characteristics of pressure-bearing broken coal

InactiveCN105259091BMake up for the technical status quo that cannot bear the pressureComprehensive test functionPermeability/surface area analysisTemperature controlCoal spontaneous combustion

Owner:HENAN POLYTECHNIC UNIV

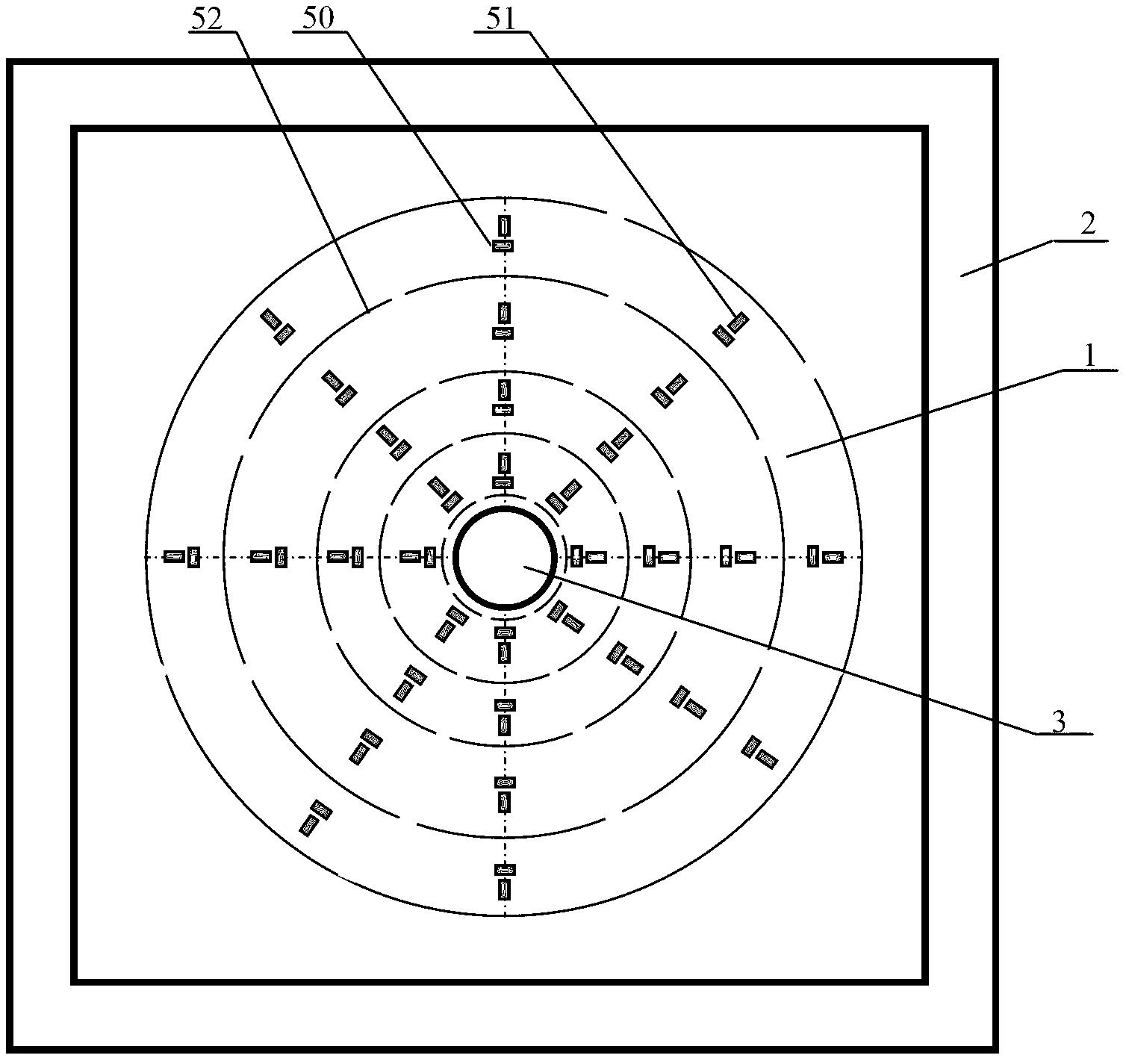

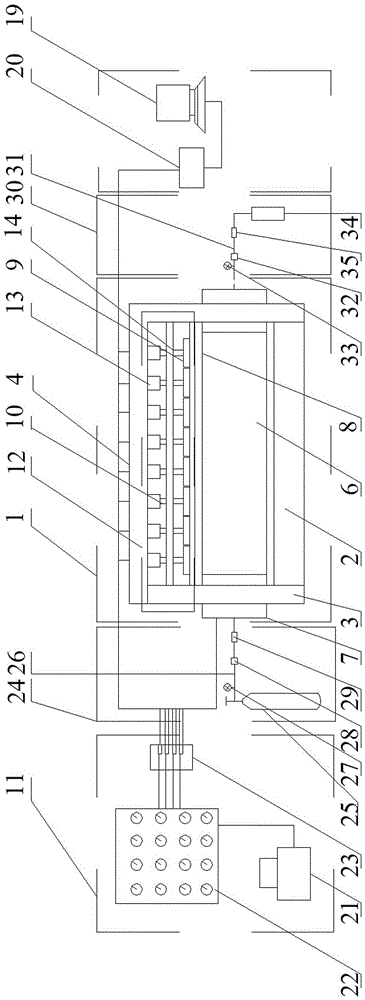

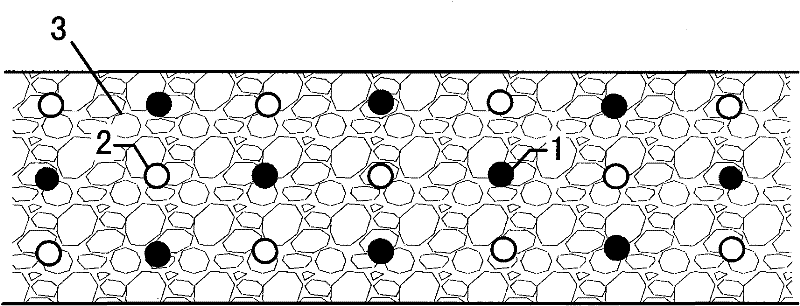

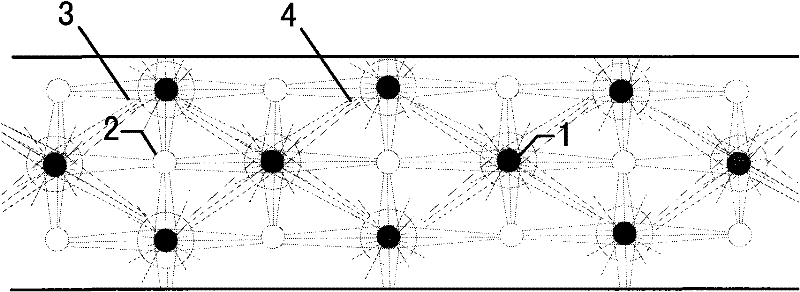

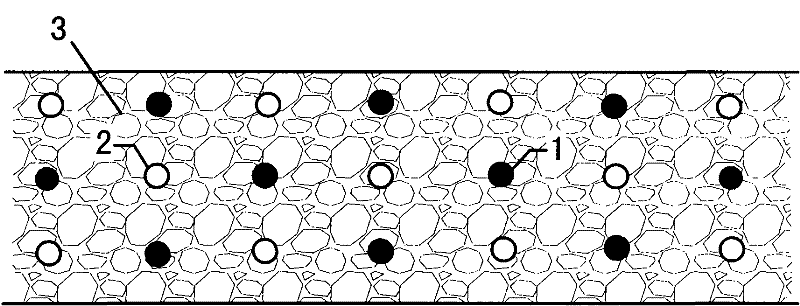

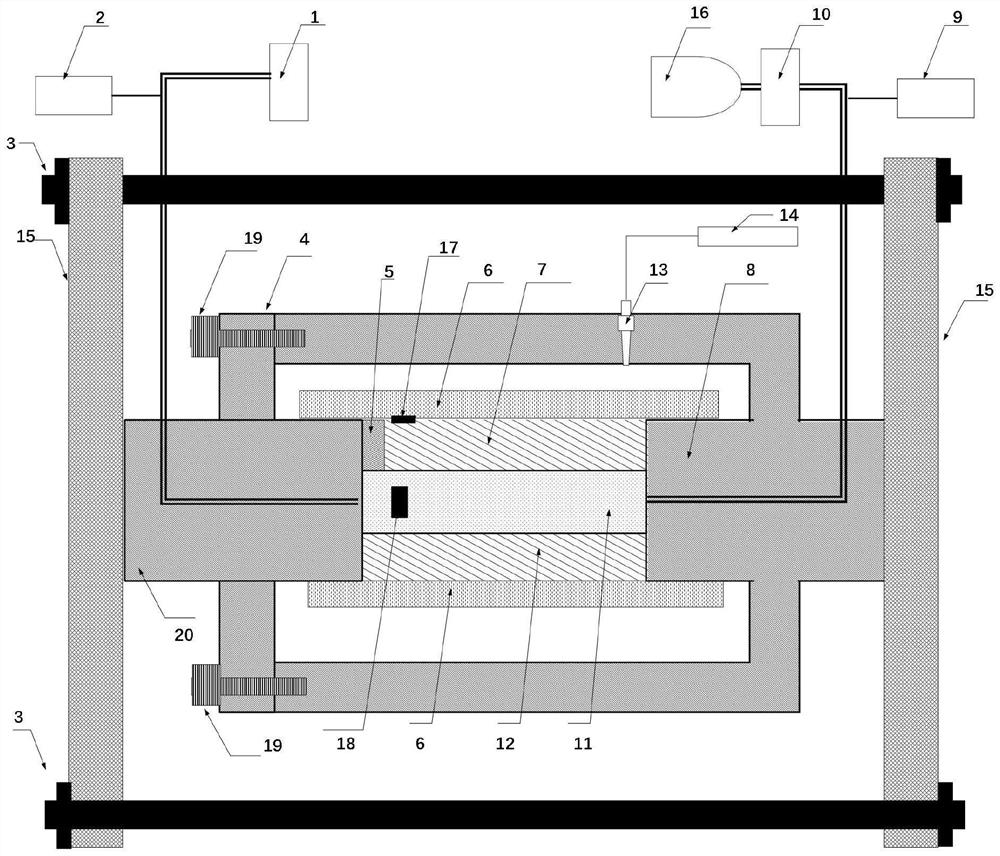

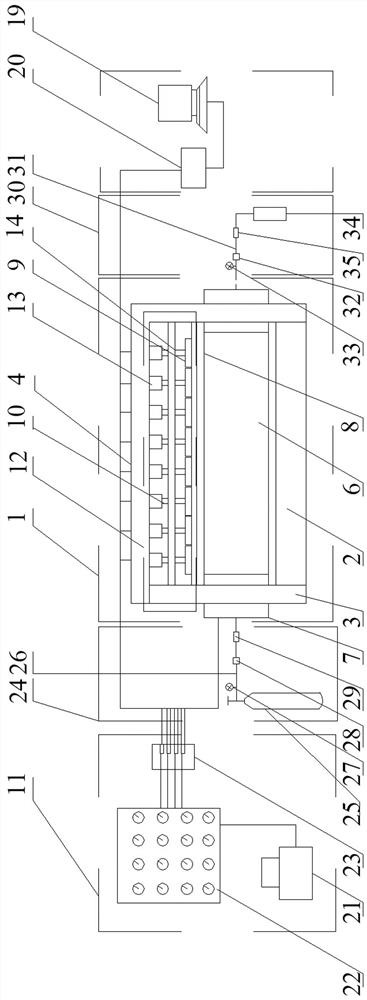

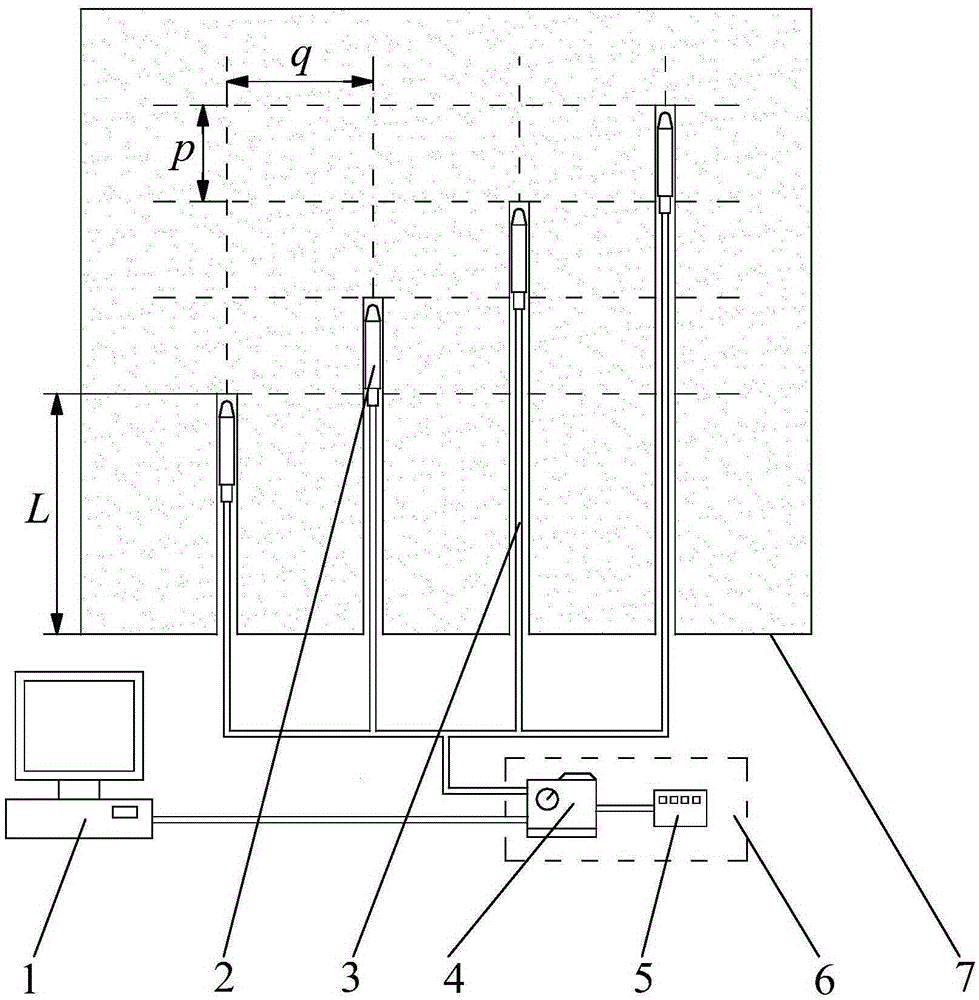

Physical simulation test system and method for gas-bearing coal for permeation enhancement, displacement and multiphase seepage

ActiveCN109372571BClear division of laborEasy to operateSurveyFluid removalAxial pressureClassical mechanics

The invention discloses an anti-reflection displacement and multiphase seepage flow physical simulation experiment system and experiment method for coal containing methane. The system comprises a model counter-force and sealing system for coal and rock specimen manufacturing and loading experiments, a stress loading system used for exerting axial pressure, a fluid injection system used for performing anti-reflection and displacement treatment on a specimen and a numerical control system used for monitoring physical and mechanics parameters inside the specimen. The anti-reflection measures suchas blasting fracturing and hydraulic fracturing and displacement measures such as injection of CO2, N2 and the like of deep methane adsorbed coal can be simulated; and the physical and mechanics parameters such as the coal stress, the strain, the temperature and the gas pressure can be monitored in real time by sensors arranged inside the specimen, so that the rules and mechanisms of adsorption and desorption, seepage and migration of the methane in the coal and rock under the condition of high crustal stress can be studied.

Owner:SHANDONG UNIV +1

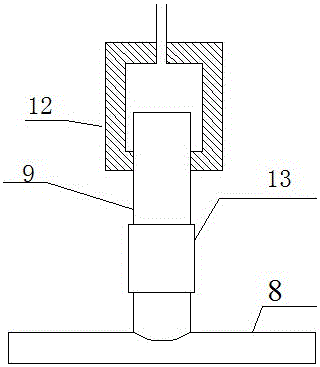

A test system and method for coal permeability characteristics

InactiveCN103940719BSimple structureEasy to assemblePermeability/surface area analysisAxial pressureHydraulic pump

The invention discloses a coal body permeability characteristic testing system. The coal body permeability characteristic testing system comprises an electronic universal testing machine, a permeability characteristic testing device, a vibration detecting device, a first gas system, a confining pressure hydraulic system and a computer, wherein the permeability characteristic testing device consists of a lane simulating mechanism and a lane ambient environment simulating mechanism; the lane simulating mechanism comprises a baffle, a breathable plate, a coal rock sample and a U-shaped clamping sleeve; the lane ambient environment simulating mechanism comprises a base, a cylinder tube, a lower pressing head, an upper half concave surface pressing head, an upper half convex surface pressing head and a piston; the first gas system comprises a first gas tank, a first pressure reduction valve and a first gas pressure meter; the confining pressure hydraulic system comprises a confining pressure liquid tank, a hydraulic pump, a unidirectional valve, a confining pressure hydraulic meter and a confining pressure liquid overflow valve. The invention also provides a coal body permeability characteristic testing method. According to the coal body permeability characteristic testing system and method, the axial pressure, the confining pressure and the methane gas pressure are controllable, the gas permeability characteristics influenced by disturbance of a lane coal rock body and a coal mine deep part coal rock body can be tested, and the testing precision is high.

Owner:XIAN UNIV OF SCI & TECH

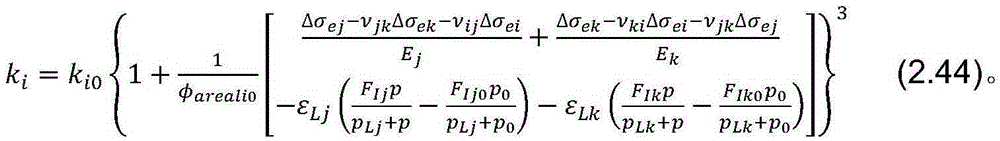

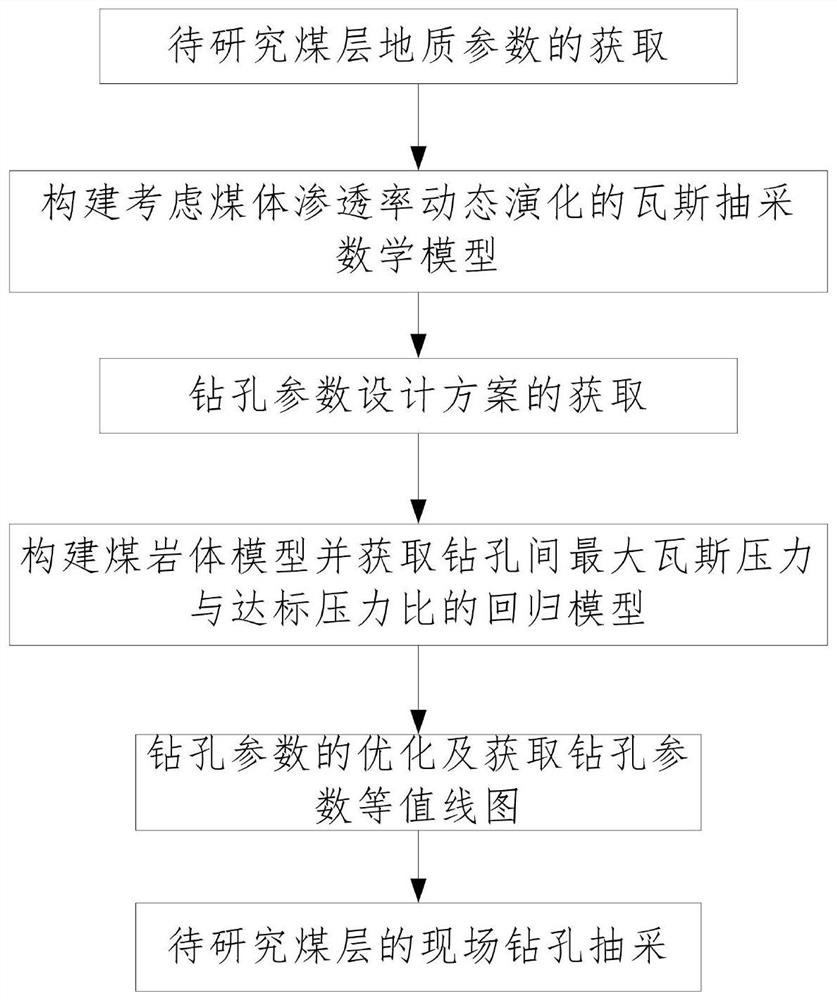

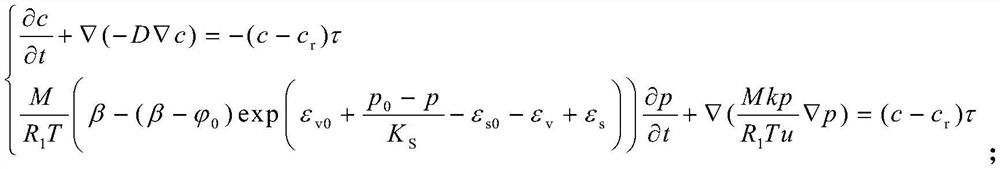

Drilling optimization method for extracting coal seam gas by drilling

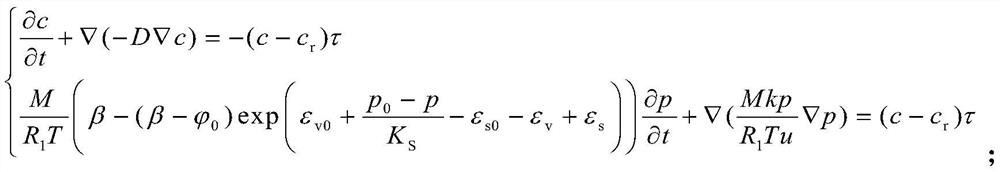

InactiveCN114386283AAccurately judge the sampling complianceAddressing OverdrainingSurveyConstructionsThermodynamicsMathematical model

The invention discloses a drilling optimization method for extracting coal seam gas by drilling. The drilling optimization method comprises the following steps: 1, acquiring geological parameters of a coal seam to be researched; 2, constructing a gas extraction mathematical model considering the dynamic evolution of the coal permeability; 3, acquiring a drilling parameter design scheme; 4, constructing a coal-rock mass model, and obtaining a regression model of the maximum gas pressure between the drill holes and the standard pressure ratio; 5, optimizing the drilling parameters and acquiring a contour map of the drilling parameters; and 6, on-site drilling extraction of the coal seam to be researched. The method is simple in step and reasonable in design, the drilling parameters are optimized based on the ratio of the maximum gas pressure between the drill holes to the standard pressure, the extraction negative pressure, the drill hole diameter and the drill hole interval are optimized, it is guaranteed that coal seam gas extraction reaches the standard on the premise that the gas extraction effect is improved and the construction cost is reduced, coal seam gas extraction is accurate, and the coal seam gas extraction efficiency is improved. And a theoretical basis and technical guidance are provided for on-site extraction drilling hole arrangement.

Owner:XIAN UNIV OF SCI & TECH

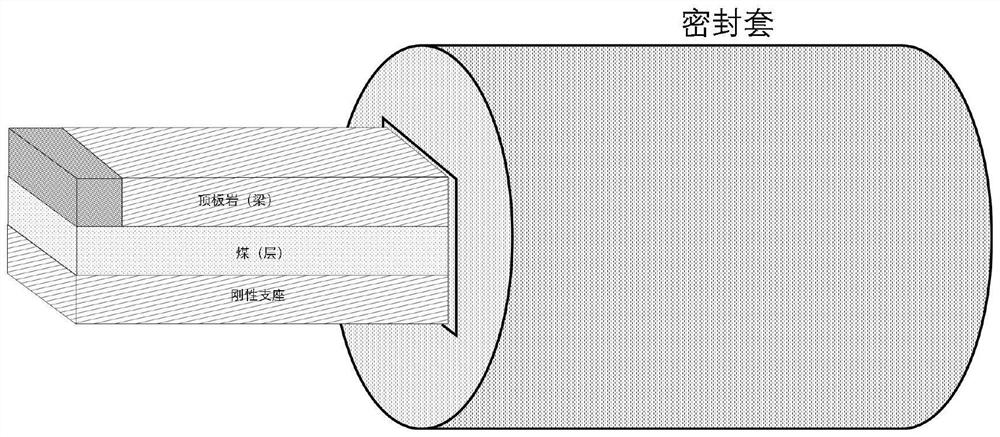

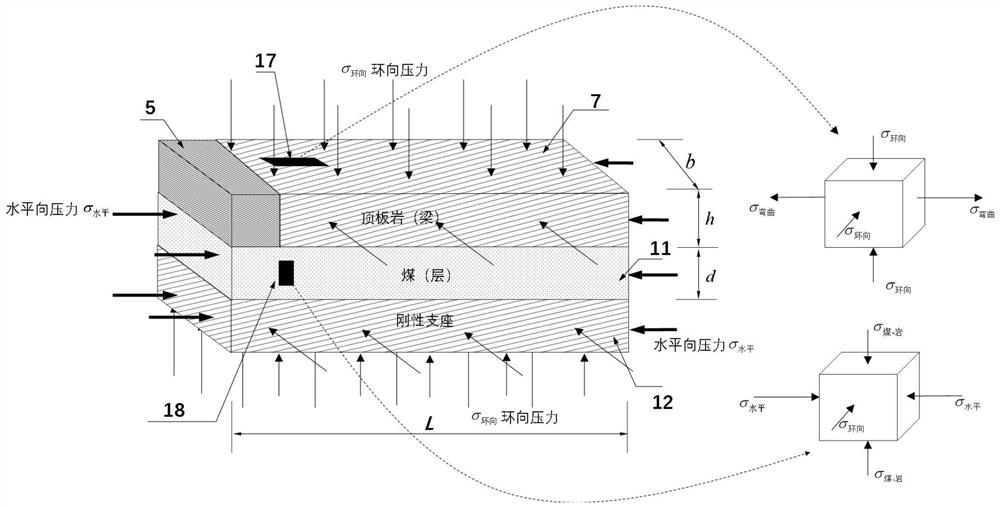

Test method for evaluating influence of rock deformation on permeability of coal body

PendingCN114720350AShorten the timeReduce trial and error costsMaterial strength using tensile/compressive forcesPermeability/surface area analysisMathematical modelClassical mechanics

The invention discloses a test method for evaluating the influence of rock deformation on coal permeability, which comprises the following steps of: applying boundary conditions for limiting displacement to a coal-rock combination sample by setting the structure of a seepage holder, and simulating the interaction condition of coal and a top plate in the coal reservoir gas development process; the method comprises the following steps: testing the deflection and coal deformation of a roof rock of a coal-rock combination under different pressure drop conditions, comparing the deflection and the coal deformation to determine the boundary condition of the coal-rock combination, and simulating the real stress state of coal and a roof in the coal reservoir gas development process and the deformation condition of the coal and the roof after stress; a basis is provided for establishing a mathematical model for finely describing the permeability of the coal reservoir, and the model is used for accurately guiding a coal reservoir gas development project, so that the time is saved, and the trial and error cost is reduced.

Owner:SHANDONG UNIV OF SCI & TECH +2

Triaxial Seepage Stress-Temperature-Creep Coupling Experimental Device Based on Digital Image

InactiveCN104849194BPrecise creep deformationReduce manpower consumptionPermeability/surface area analysisAxial pressurePore water pressure

The invention discloses a digital image-based triaxial seepage stress temperature creep coupling experiment device, which comprises a triaxial pressure chamber (1), a digital image observation system and a triaxial pressure chamber heating system, the triaxial pressure chamber (1) A pore pressure application system, an axial pressure application system with stabilizing pressure and a confining pressure application system are installed on it; the pore pressure application system includes a pore pressure fluid injection pipe (5), and the pore pressure fluid injection pipe (5 ) is connected to the first pressure pump (8), the pore pressure energy is provided by the first pressure pump (8), and the pressure value is measured by a digital pressure gauge (9), and the pressure gauge (9) is installed in the pore pressure fluid Injection tube (5). The invention can use the device to study the influence of confining pressure, axial pressure, pore pressure, temperature and creep deformation on coal permeability; it can accurately and automatically measure creep deformation and reduce manpower consumption.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

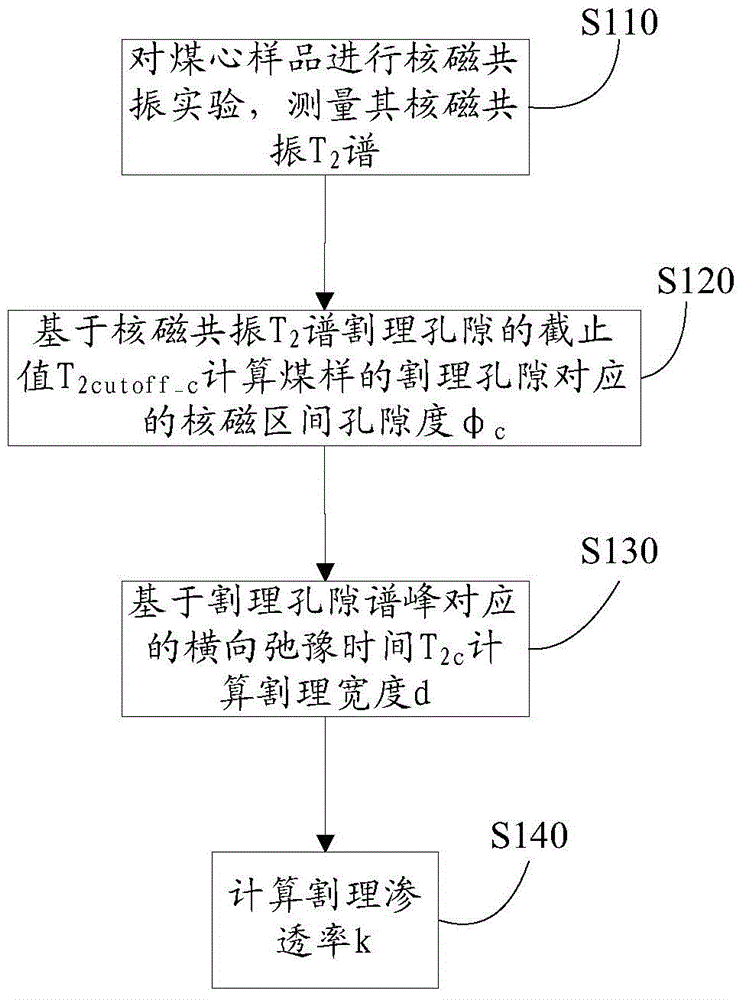

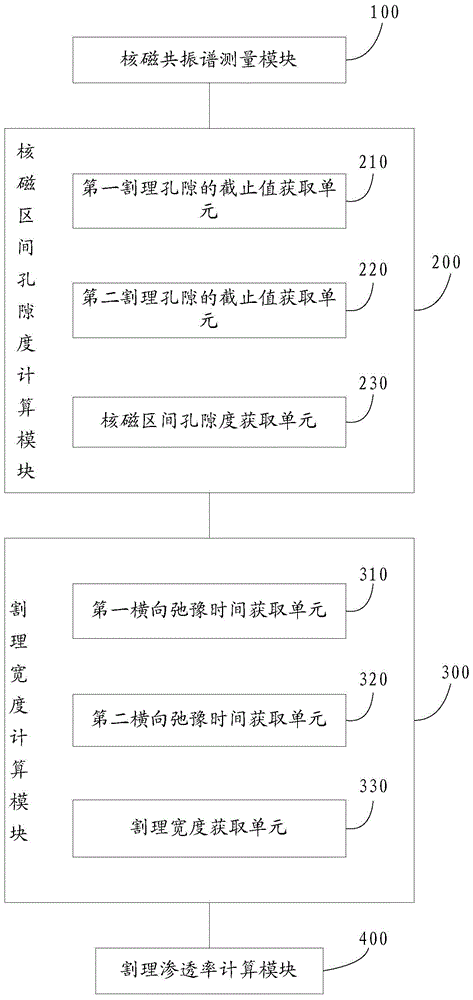

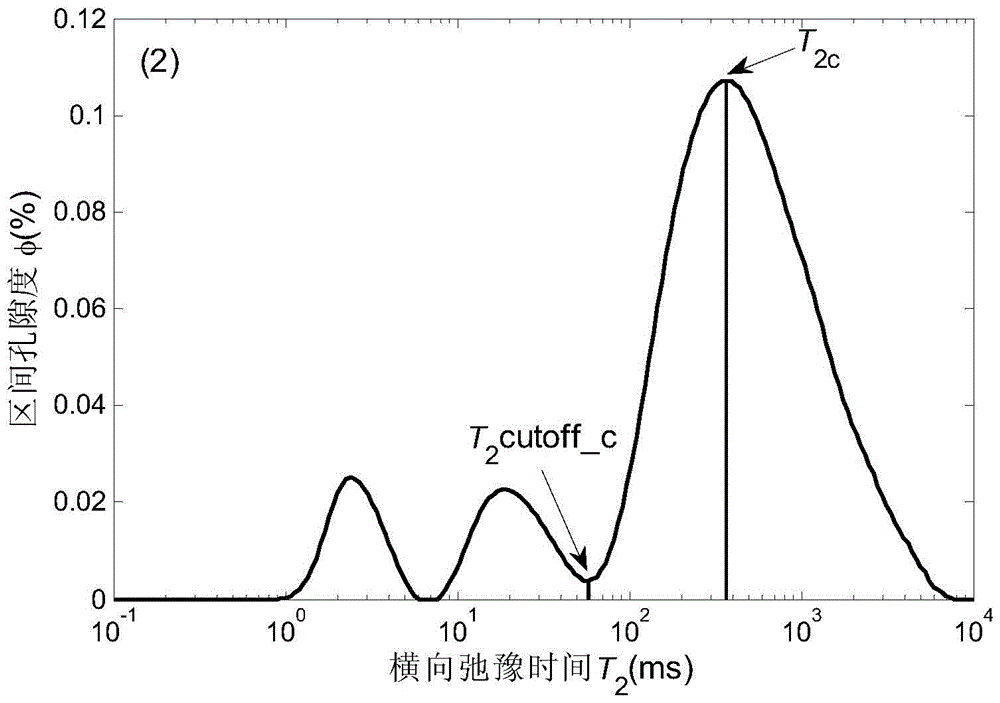

A method and system for calculating the permeability of coal and rock cleats

ActiveCN103674803BRealize computingAnalysis using nuclear magnetic resonancePermeability/surface area analysisPorosityNMR - Nuclear magnetic resonance

The invention relates to the technical field of coalbed methane exploration and development and discloses a method and a system for calculating coal rock cleat permeability. According to the method and system for calculating coal rock cleat permeability provided in the invention, the method comprises the following steps: performing a nuclear magnetic resonance experiment on a coal core sample to obtain a nuclear magnetic resonance T2 spectrum, and calculating nuclear magnetic interval porosity Phi c which corresponds to the cleat porosity of the coal sample based on a cutoff value T2cutoff-c of the cleat porosity of the nuclear magnetic resonance T2 spectrum under different conditions; calculating the cleat width d based on transverse relaxation time T2 c which corresponds to a cleat porosity spectral peak under different conditions; and finally, calculating to obtain the cleat permeability k through a formula, so that the calculation of the coal rock cleat permeability is realized.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

A method of expansion cracking and anti-permeability for rapid tunneling of underground coal seam roadway

ActiveCN104912588BImprove breathabilityThe production is conducive toFluid removalGas removalSlurryCoal

The invention discloses a spalling permeability increasing method for rapid excavation of an underground seam gateway. The method is particularly suitable for advancing pre-pumping of a high-gas low-permeability seam gateway. A first spalling hole is constructed in the head-on geometric center position of the seam gateway, and second spalling holes are formed in the positions over, under, left and right the first spalling hole; third spalling holes are constructed in the positions over and under the second spalling holes horizontal to the first spalling hole, and exhausting and mining holes are constructed in the center points of the connecting lines of the first spalling hole and the third spalling holes; after drilling is finished, quick lime grout is injected into the third spalling holes in a crossing manner, and the spalling holes are control holes of one another; and through spalling pressure generated by the holes, net-shaped cracks are generated between the holes, so that the coal permeability is greatly improved, the gas exhausting and mining efficiency is improved, and the excavation speed of the seam gateway is improved; and the method is simple in technology, convenient to operate, wide in grout source, cheap and low in cost.

Owner:TAIYUAN UNIV OF TECH

Coal permeability enhancement method for microwave hot air coupled heat injection

ActiveCN106869991BEasy to crackImprove anti-reflection effectFluid removalGas removalGas analysisConverters

A coal body anti-reflection method using microwave hot air coupled heat injection. First, drill holes into the coal seam, connect the microwave antenna to the inner end of the coaxial waveguide, and send it into the drill hole together. Then connect the waveguide converter, rectangular waveguide and microwave generator to the outer end of the coaxial waveguide in sequence. Then connect the heater with a pipe and pass it into the drill hole. After the equipment is installed, high-pressure hot air is delivered to the borehole, and the microwave is turned on for radiation. Microwave radiation can effectively promote gas desorption, and the thermal stress generated can damage the coal body and produce micro-cracks. At the same time, high-pressure hot air will flow rapidly along the coal seam cracks, blowing away the coal debris in the cracks, and expanding the coal seam cracks. Combining the two, microwaves not only produce a radiation effect on the coal body, but also have the effect of further heating the wind flow, making it easier to dredge the pores of the coal body, achieving a good effect of increasing the transparency of the coal body and promoting gas analysis.

Owner:CHINA UNIV OF MINING & TECH

A device for measuring the permeability of coal body affected by mining and its application method

InactiveCN106840996BAccurate monitoring of permeability trendsAccurate measurementPermeability/surface area analysisMining engineeringGas concentration

The invention discloses a device for measuring a mining influenced coal permeability and a using method thereof. In the mining process of a high gas coal seam, gas in coal in the front of a stope permeates into a stope space by fractures under the influence of mining, and in order to measure a gas permeability condition in the mined coal, the device for measuring the mining influenced coal permeability is in urgent need. The left side of a detachable plug I is connected with a gas pipeline I; the left side of the gas pipeline I is connected with a gas storage tank; a gas pressure stabilizer I, a gas pressure sensor I and a gas flow meter I are sequentially arranged on the right side of the gas pipeline I. Experiments for measuring the gas permeability in the coal under conditions of different mining stresses, different mining heights, different gas concentrations and different gas pressures can be developed, and a gas permeability change rule of the coal in the front of the underground stope under the influence of mining is researched. The invention is used for the device and method for measuring the permeability of the coal under the influence of mining.

Owner:HEILONGJIANG UNIVERSITY OF SCIENCE AND TECHNOLOGY

Laboratory method for rapid determination of coal body permeability in front of underground working face of coal mine

ActiveCN103940723BSafe and stable production workAvoid disasterPermeability/surface area analysisStress distributionMonitoring system

The invention discloses a method for determining permeability of a working surface front coal body of an underground coal mine, and belongs to the field of preventing and controlling disasters of a coal mine excavation working surface. The method comprises the following steps of firstly determining a coal mine mining-induced stress monitoring system on the spot to obtain a mining-induced stress distribution curve of the working surface front coal body, and combining with a working surface advancing speed to draw a changing curve of mining-induced stress of a coal body unit, which is at a certain distance from the front part of the working surface, in a working surface advancing process; encoding an axle stress loading and confining pressure unloading synchronization servo control program by utilizing Visual C++, and introducing in a true three-axis permeability testing system computer controller, so as to simulate a mining-induced stress changing process of the coal body unit having the certain distance with the front part of the working surface along with the advancing of the working surface by utilizing a true three-axis permeability test; finally obtaining a permeability value and the changing rule of the permeability value of the coal body unit along with the advancing of the working surface. According to the method for determining the permeability of the working surface front coal body of the underground coal mine, the permeability of the coal body in front of the tunneling working surface and the stope face can be precisely and quickly determined.

Owner:SHANDONG UNIV OF SCI & TECH

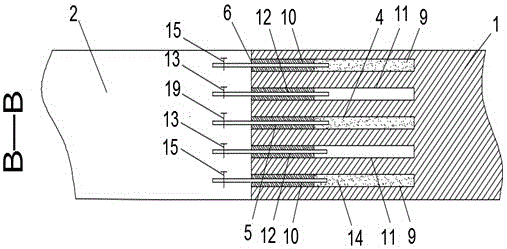

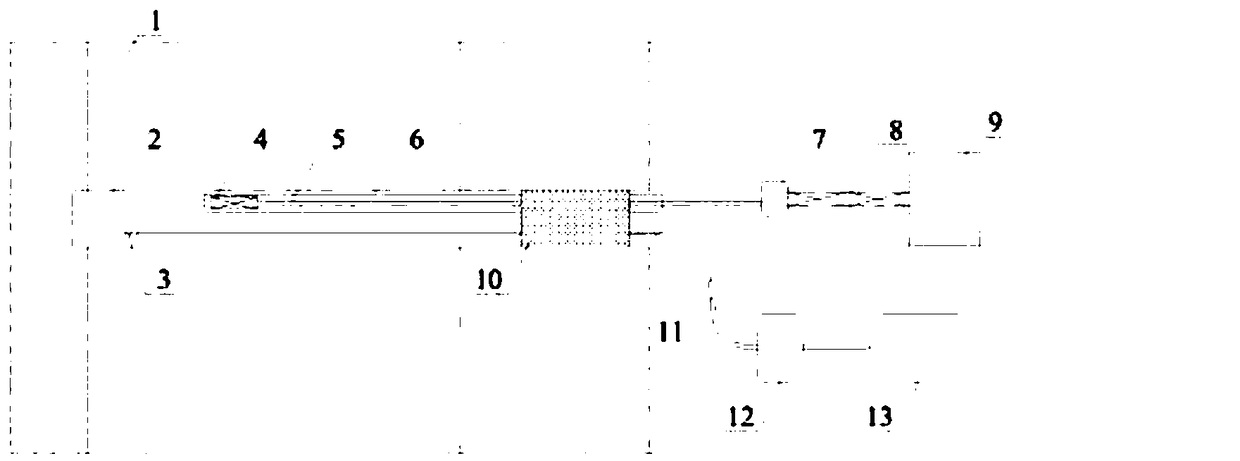

Low-permeability coal high-pressure gas cycle pulse fracturing anti-reflection experimental device

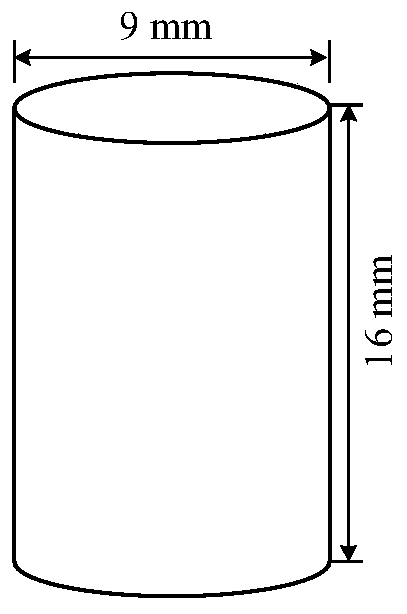

InactiveCN103234890BLow costEasy to operatePermeability/surface area analysisCoal briquetteGraduated cylinder

The invention relates to a low-permeability coal high-pressure gas cycle pulse fracturing anti-reflection experimental device belonging to the field of low-permeability coal seam reinforcement anti-reflection technology. The coal can be impacted by high-pressure gas for a plurality of times in a circulating way through a power electric induction electronic control valve so as to be fractured for increasing permeability; and the device is simple to operate, low in cost and obvious in anti-reflection effect. The low-permeability coal high-pressure gas cycle pulse fracturing anti-reflection experimental device comprises a coal sample, a blasting cylinder mechanism, a triaxial loading system, a high pressure gas impact system and a coal permeability measurement system, wherein the coal sample consists of coal briquettes and a protecting layer; the blasting cylinder mechanism consists of an upper cylinder cover, a lower cylinder cover, a cylinder barrel, an upper pressure head and a lower pressure head; the triaxial loading system consists of an axial compression loading system and a confining pressure loading system; the high pressure gas impact system consists of a gas explosion gun, the power electric induction electronic control valve, a high-pressure gas storage tank, a multi-ported valve, an air compressor and a gas source cylinder; and the coal permeability measurement system comprises a methane gas cylinder, a water tank and a measuring cylinder arranged outside the blasting cylinder mechanism.

Owner:LIAONING TECHNICAL UNIVERSITY

A raw coal transparent pouring part, preparation method and permeability test device

ActiveCN104198354BHigh transparencyTestable permeability coefficientPreparing sample for investigationPermeability/surface area analysisAxial pressurePore water pressure

The invention discloses a raw coal transparent pouring part, a preparation method and a permeability testing device. The permeability testing device includes a test piece, an axial pressurization system, a hydraulic loading system, a high-speed camera, and a data acquisition system; the shaft Axial pressure is applied to the test piece by the pressurization system, hydraulic pressure is applied from the top of the test piece by the hydraulic loading system, and the drainage pipeline discharges the permeated water from the lower part of the test piece into the flat-bottomed flask on the electronic balance. The data is sent to the controller, and the high-speed camera shoots the seepage process of the aqueous solution with milky white dye in the coal fissures in real time, so as to realize the visual observation of the seepage path of the raw coal fissures. The invention can realize the visual observation of the seepage path of the raw coal fissures, and obtain the permeability coefficient of the raw coal under different stress states.

Owner:HUNAN UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com