Coal mine roadway with water seepage warning function

A coal mine roadway and function technology, applied in the directions of drainage, mining equipment, mining devices, etc., can solve the problem of local leakage of coal mine roadway without corresponding solutions, affecting the construction progress, difficult water seepage and other problems, to avoid adverse effects, The effect of increasing buoyancy and increasing drainage volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

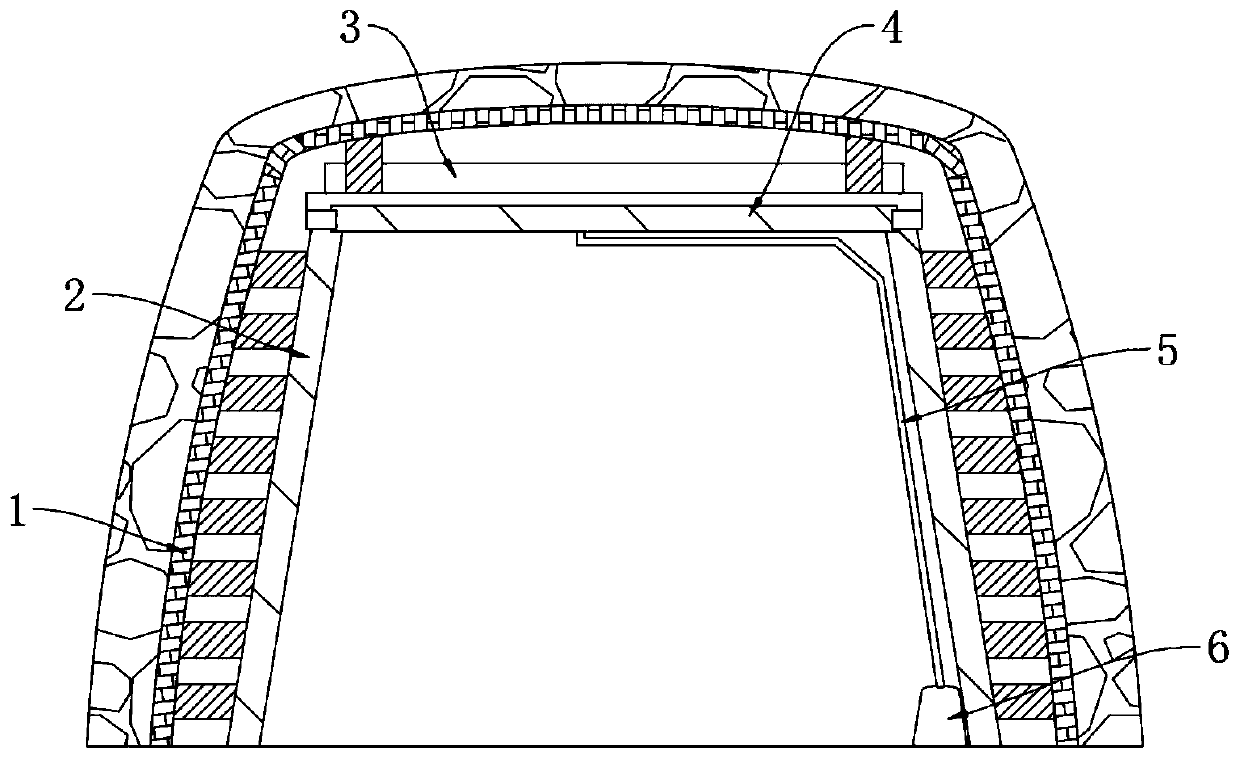

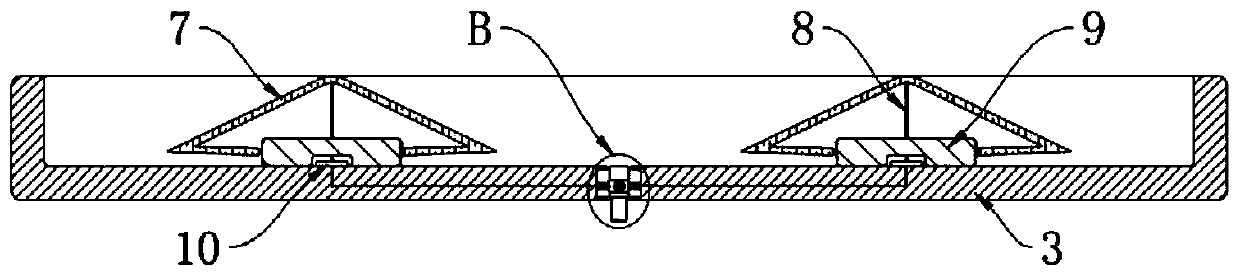

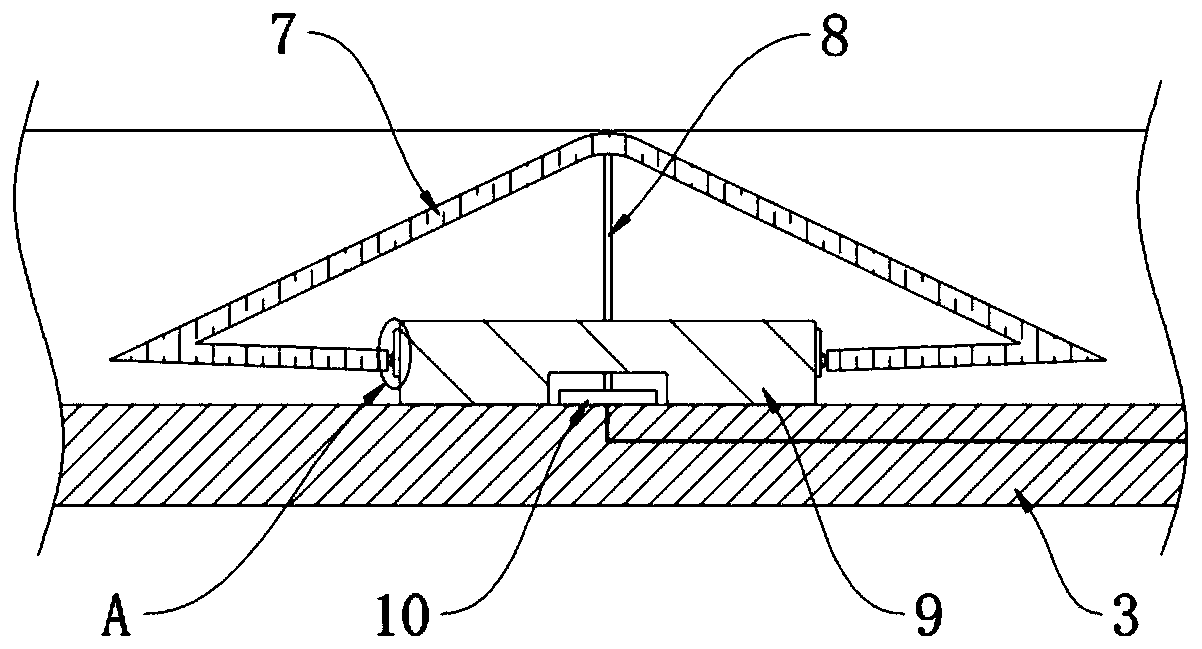

[0032] refer to Figure 1-6 , a coal mine roadway with a water seepage warning function, including an anchor net 1 fixedly arranged on the inner wall of the roadway, the anchor net 1 supports a roof 4 through a support layer 2, and a water collection tank 3 is placed between the anchor net 1 and the roof 4, Two electrode plates 9 are symmetrically arranged on the inner bottom wall of the water collection tank 3, and each electrode plate 9 is slidably connected with a drainage bracket 7, and the bottom wall of each electrode plate 9 is provided with a rectangular groove, and each rectangular groove Electrode sheets 10 are placed inside, and each electrode sheet 10 is connected to the corresponding drainage bracket 7 through a traction rope 8, and the traction rope 8 passes through the electrode sheet 10, and a sealing ring is provided at both ends of the perforation on the electrode sheet 10 ;

[0033] The middle part of the sump 3 is provided with a drainage alarm mechanism. ...

Embodiment 2

[0041] refer to Figure 7-9 , the difference between this embodiment and Embodiment 1 is that a sealing box 15 is also provided in the installation groove, and the annular joint 12 and the buzzer 13 are all located in the sealing box 15, and the bottom end of the connecting piece 14 is connected to the sealing box 15 The inner bottom wall is fixedly connected, and the top seal of the connecting piece 14 runs through the top wall of the sealing box 15 and is movably connected with a water blocking ball 16. There are a plurality of water holes 20, and the top of the limit cylinder 19 is provided with a plurality of first air holes 17 and second air holes 18, and a check valve is installed on the second air holes 18;

[0042] There is no communication port 1401 on the connecting piece 14, it is only a cylindrical body, and the connecting piece 14 is made of two-way memory alloy;

[0043] The cross-sectional area of the sealing box 15 is less than the cross-sectional area of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com