Follow-up auxiliary anode electrolytic wire cut machining system and method

An auxiliary anode and cutting system technology, applied in electric processing equipment, metal processing equipment, circuits, etc., can solve problems such as stray corrosion, affecting the machining accuracy of electrolytic wire cutting, and achieve high-quality machining accuracy, simple structure, strong flexibility sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

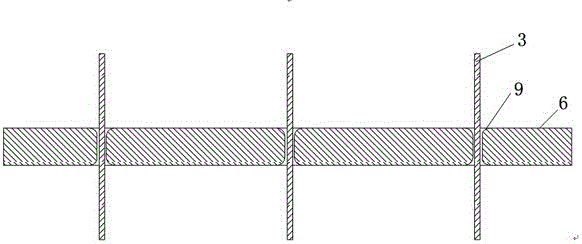

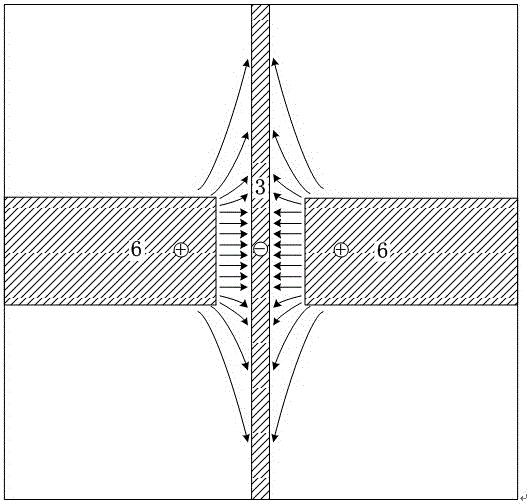

[0023] figure 1 In the process, due to the existence of stray corrosion, there is a problem of stray corrosion fillet in the kerf, which affects the machining accuracy.

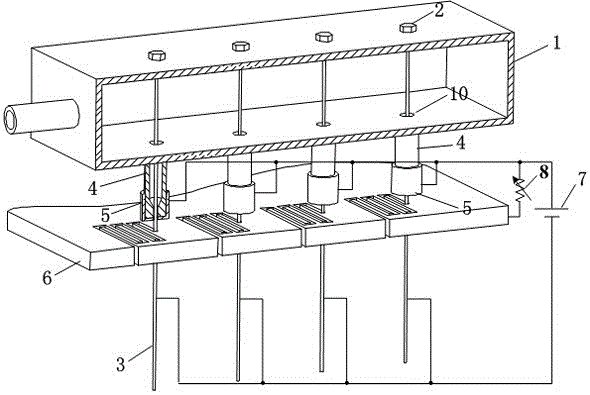

[0024] image 3 , Figure 4 In the schematic diagram of the follow-up auxiliary anode multi-wire (fine) electrolytic wire cutting processing device shown, the auxiliary anode (5) is integrated with the insulating nozzle (4), and the auxiliary anode (5) follows the processing position during the processing.

[0025] combine image 3 , Figure 4 The implementation process of the present invention is described:

[0026] Step 1, prepare the auxiliary anode 5 that moves with the tool electrode wire;

[0027] Step 2. Fix the workpiece anode 6, tool electrode wire 3, and auxiliary anode 5 on the fixture in sequence, and the auxiliary anode 5 and tool electrode wire 3 follow, position, and clamp;

[0028] Step 3, the positive pole of the processing power supply 7 is connected to the auxiliary anode 5 and one en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com