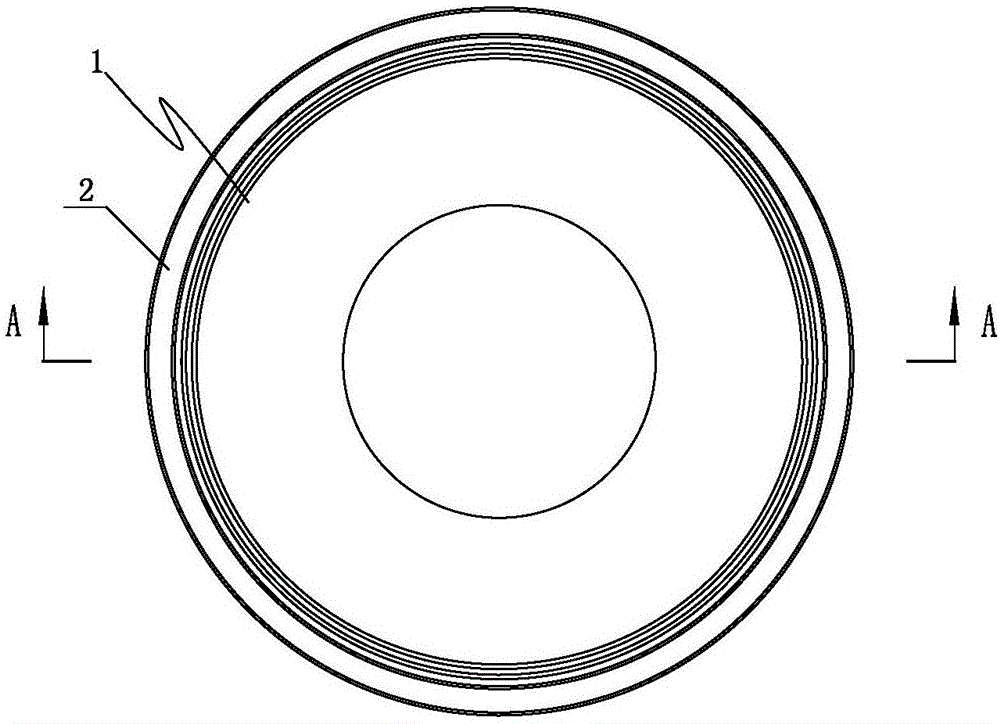

Vacuum non-stick pan and production method thereof

A non-stick pan and vacuum technology, which is applied to special materials of cooking utensils, the structure of cooking utensils, cooking utensils, etc., can solve the problems of long cooking time, low heating efficiency, and high cost, and achieves reduced energy consumption, low cost, and preparation. easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

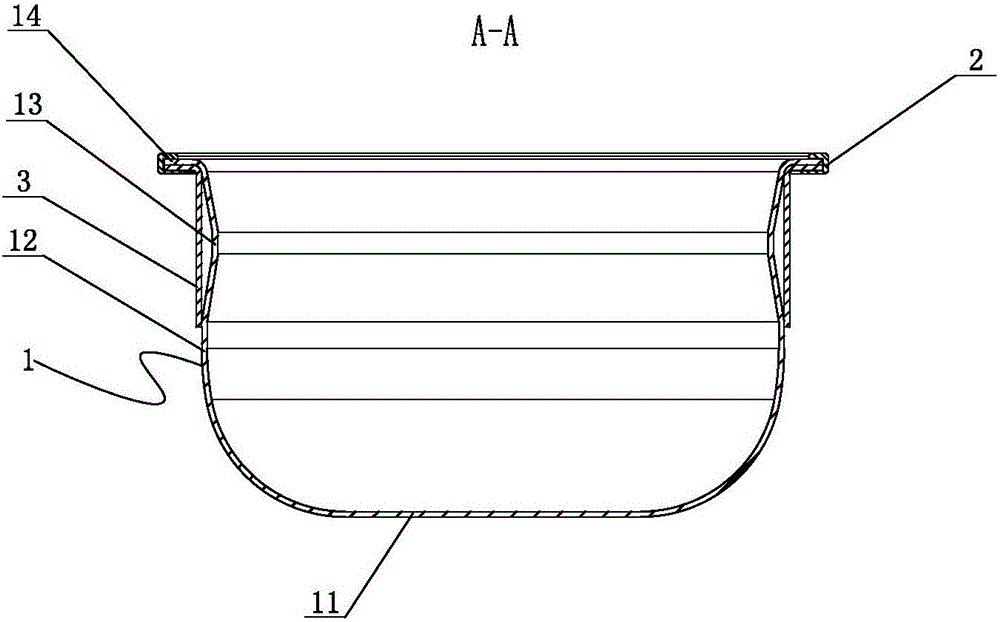

[0026] A method for preparing a vacuum non-stick pan. After a spherical inner pot 1 is formed, an annular insulating layer 3 is inserted into the inner body 12, so that the upper end of the insulating layer 3 is attached to the lower end of the pot edge 14, and the outer portion of the insulating layer 3 The lower end is welded on the gallbladder body 12, and then the surface of the spherical pot gallbladder 1 is enameled and bounded using the powder-sprinkling method.

[0027] The powdering method is to sprinkle dry top glaze powder on the hot bottom glaze, so that enamelling and firing are combined into one operation; in this way, the gas in the annular cavity formed between the insulation layer 3 and the neck 13 reacts with the glaze Or it is more fully oxidized with the substrate, and the unreactive gas is easily discharged, so that the vacuum degree can be effectively guaranteed.

Embodiment 2

[0029] A method for preparing a vacuum non-stick pan. After a spherical inner pot 1 is formed, an annular insulating layer 3 is inserted into the inner body 12, so that the upper end of the insulating layer 3 is attached to the lower end of the pot edge 14, and the outer portion of the insulating layer 3 The lower end is welded on the tank body 12, and then the substrate (spherical pot tank 1) is sprayed with Teflon at high temperature. During the spraying process, the gas in the annular cavity formed between the insulation layer 3 and the neck 13 It reacts with Teflon or oxidizes fully with the substrate, and the non-reactive gas is easily discharged, so that the vacuum degree can be effectively guaranteed, and finally baked and wrapped.

[0030] The high-temperature spraying refers to spraying when the temperature of the substrate is 600-800°C (650°C in this example, but also 600°C, 700°C, 750°C or 800°C, etc.).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com