Method for integrally forming C sandwich panel antenna housing

A flat-panel antenna and integrated technology, applied in the field of radome, can solve the problems of increasing cost and increasing the number of tanks, and achieve the effect of ensuring smoothness, reducing production cost and less operation steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

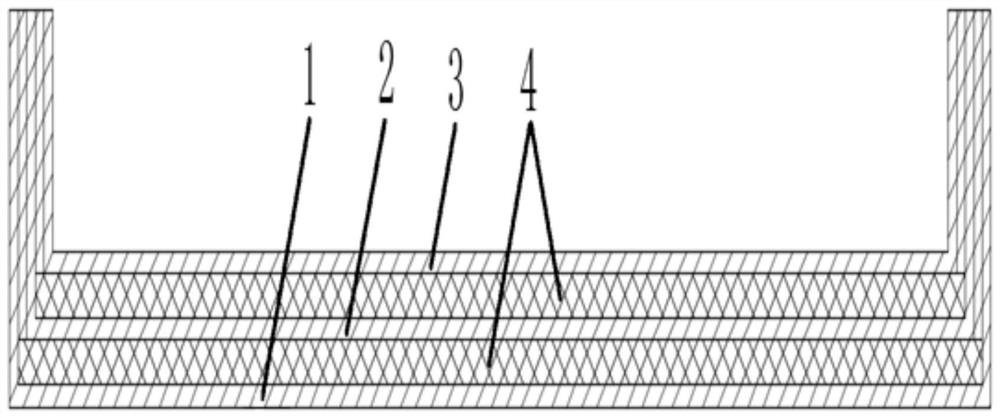

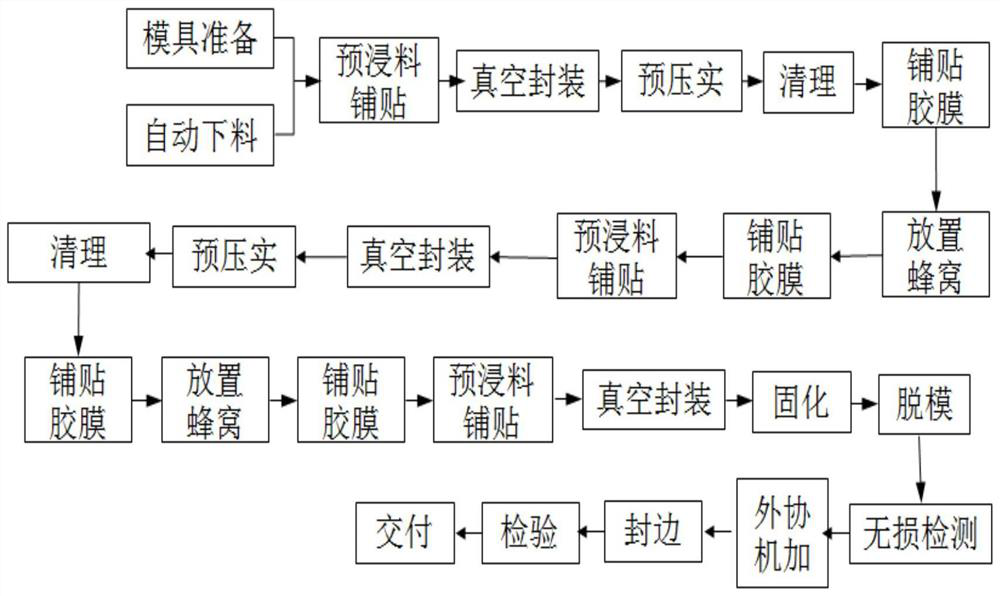

[0033] A method for integrally forming a C-sandwich flat-panel radome, comprising the steps of:

[0034] (1) Prepreg preparation: use the CPD module of Catia software to make the blanking diagram of the skin layer, and then use the automatic blanking machine to cut the prepreg sheet according to the blanking diagram; and the prepreg The material is a mixture of glass fiber or quartz fiber and epoxy resin or cyanic acid resin or double horse resin;

[0035](2) Mold pretreatment: Clean the mold with gasoline first, then wash it with acetone for 3 times, remove the mold oil seal, then confirm that the molding surface of the mold is not damaged, and finally confirm the engraved line, and spray Loctite on the mold before each use 770-NC mold release agent (spray 8-10 times for new molds, 3-5 times for used molds, 10-15 minutes between each spraying, ensure that the mold release agent sprayed last time is cured and dry before spraying the next time) ;

[0036] (3) Paving the outer...

Embodiment 2

[0043] A method for integrally forming a C-sandwich flat-panel radome, comprising the steps of:

[0044] (1) Prepreg preparation: use the CPD module of Catia software to make the blanking diagram of the skin layer, and then use the automatic blanking machine to cut the prepreg sheet according to the blanking diagram; and the prepreg The material is a mixture of glass fiber or quartz fiber and epoxy resin or cyanic acid resin or double horse resin;

[0045] (2) Mold pretreatment: Clean the mold with gasoline first, then wash it twice with acetone, remove the mold oil seal, then confirm that the molding surface of the mold is not damaged, and finally confirm the engraved line, and spray Loctite on the mold before each use 770-NC mold release agent (spray 8-10 times for new molds, 3-5 times for molds after use, with an interval of 10-15 minutes between each spray, and ensure that the mold release agent sprayed last time is cured and dry before spraying the next time );

[0046]...

Embodiment 3

[0053] A method for integrally forming a C-sandwich flat-panel radome, comprising the steps of:

[0054] (1) Prepreg preparation: use the CPD module of Catia software to make the blanking diagram of the skin layer, and then use the automatic blanking machine to cut the prepreg sheet according to the blanking diagram; and the prepreg The material is a mixture of glass fiber or quartz fiber and epoxy resin or cyanic acid resin or double horse resin;

[0055] (2) Mold pretreatment: Clean the mold with gasoline first, then wash it with acetone for 3 times, remove the mold oil seal, then confirm that the molding surface of the mold is not damaged, and finally confirm the engraved line, and spray Loctite on the mold before each use 770-NC mold release agent (spray 5-10 times for new molds, 3-5 times for molds after use, with an interval of 10-15 minutes between each spray, and ensure that the mold release agent sprayed last time is cured and dried before spraying the next time ); ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com