Power module encapsulating structure

A packaging structure and power module technology, applied in the field of power electronics, can solve the problems of difficult automation and consistency of process methods and control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

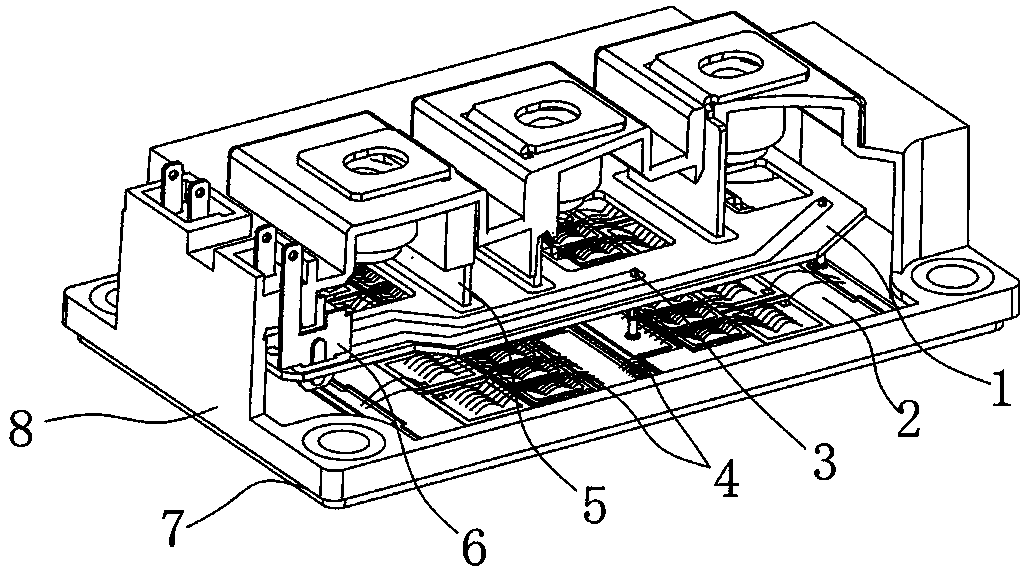

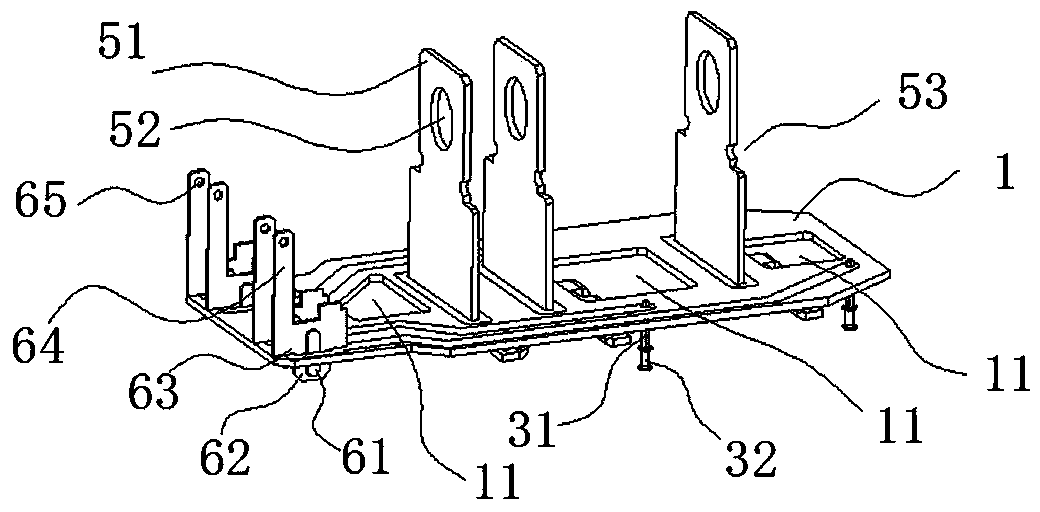

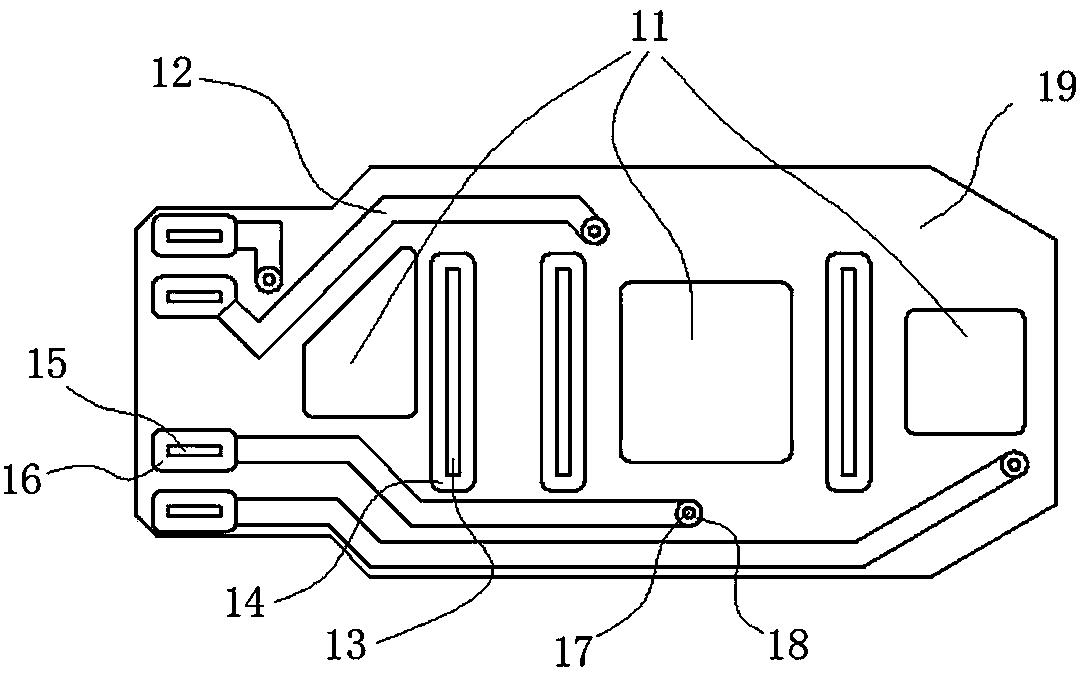

[0029] Example: figure 1 As shown, in the power module, the DBC2 with the chip and the bonding wire is welded to the substrate 7, and the circuit board 1 on which the power terminal 5, the signal terminal 6 and the signal lead frame 3 are fixed passes through the power terminal pin and the signal lead frame After the feet are welded to the DBC, the whole module is fixed and closed through the shell. There is an opening on the casing, and the power terminal and the signal terminal protrude through the opening to connect with the external application terminal. In this structure, there are 2 signal terminals leading to the gates of the upper tube and the lower tube respectively, and 2 signal terminals respectively leading to the emitters of the upper tube and the lower tube. The signal terminal is connected with the corresponding signal lead frame through the circuit design of the circuit board, and the signal lead frame is welded and connected with the corresponding position on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com