Novel integrated circuit (IC) package manufacturing process

A manufacturing process and a new type of technology, applied in the field of IC packaging technology, can solve the problems of slow packaging speed and poor packaging precision, and achieve the effects of rigorous production, improved moisture-proof function, and improved density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] The present invention is described in further detail below:

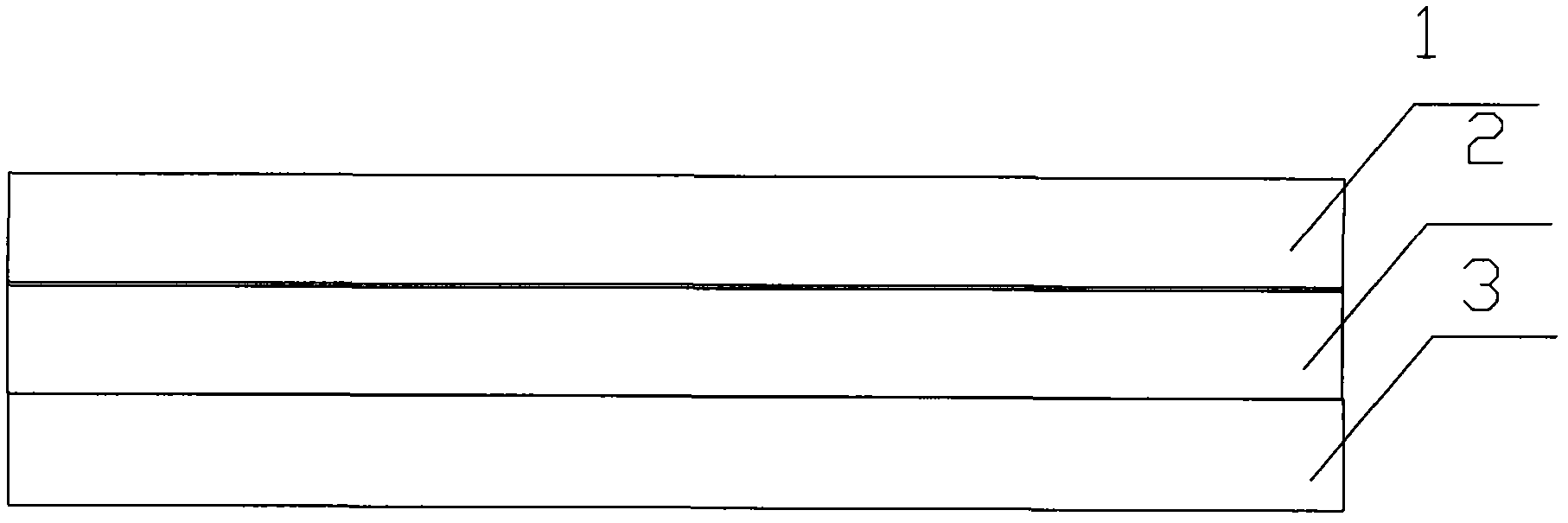

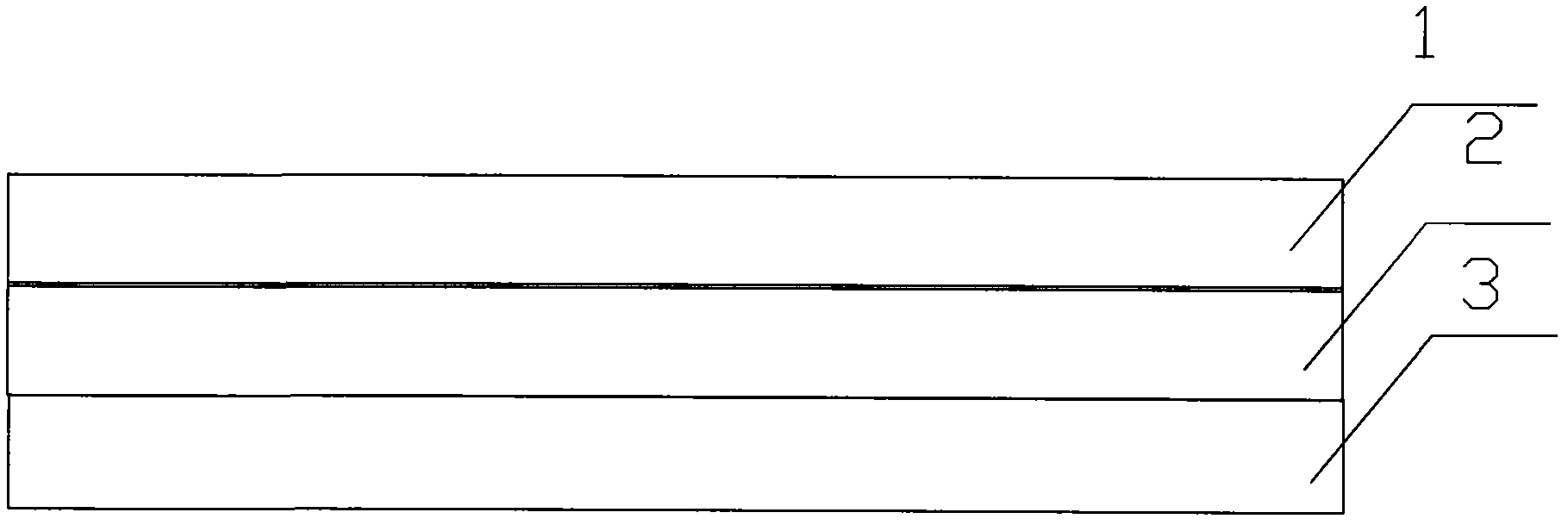

[0056] Such as figure 1 Shown is the layer structure schematic diagram of the product made by the present invention, and the technological process of production is as follows:

[0057] Step 1, making IC carrier board 3;

[0058] Step 2, preparing the packaging cover plate 2;

[0059] Step 3: Put 50Um resin-type pure glue on the reverse side of the package cover, and press it onto the IC carrier through mechanical integral pressing; in this pressing step, the temperature needs to be controlled at 170-180 degrees, and the time should be controlled within 30 minutes.

[0060] Step 4, use ±0.05mm high-precision engraving machine to engrave and shape,

[0061] Step 5, bind the IC carrier board 3 through the binding machine,

[0062] Step 6, cover the front of the packaging cover plate 2 with 50Um resin type pure glue,

[0063] In step 7, the encapsulation glass 1 is mechanically laminated on the encapsulation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com