Full-automatic cutting and drilling integrated machine for aluminum hub

A fully automatic, all-in-one technology, used in maintenance and safety accessories, metal processing machinery parts, precision positioning equipment, etc., can solve the problems of inconvenient processing and loading and unloading, large investment, high labor intensity, etc. The effect of smooth conveying and improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The specific implementation of the present invention will be described in detail below in conjunction with the accompanying drawings. The described embodiments are only illustrations and explanations of the present invention, and do not constitute the only limitation of the present invention.

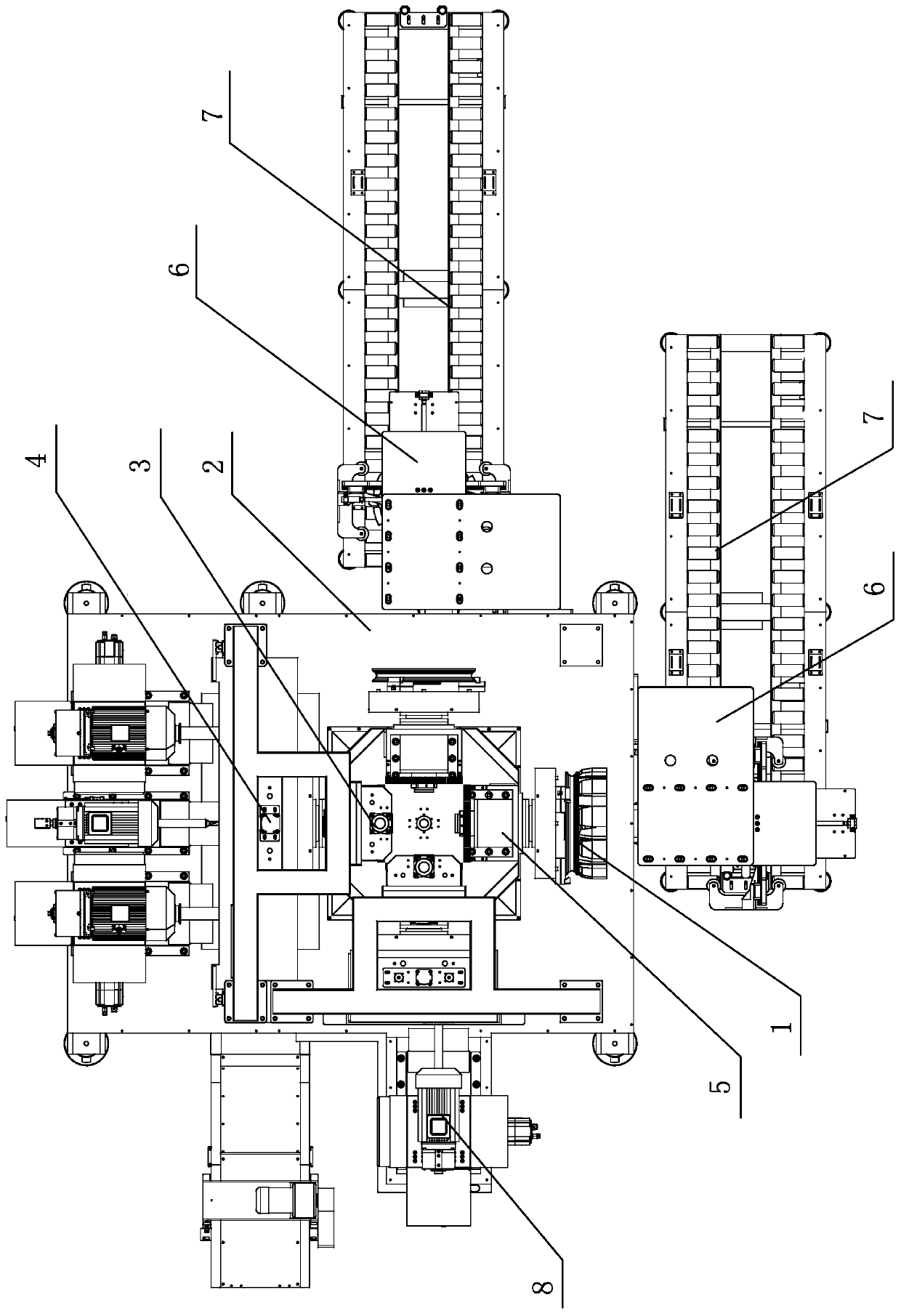

[0040] like Figure 1 to Figure 11 As shown, the present invention includes a cutting drill, an automatic feeding device 6 and an automatic unloading device 7; A power head device 8.

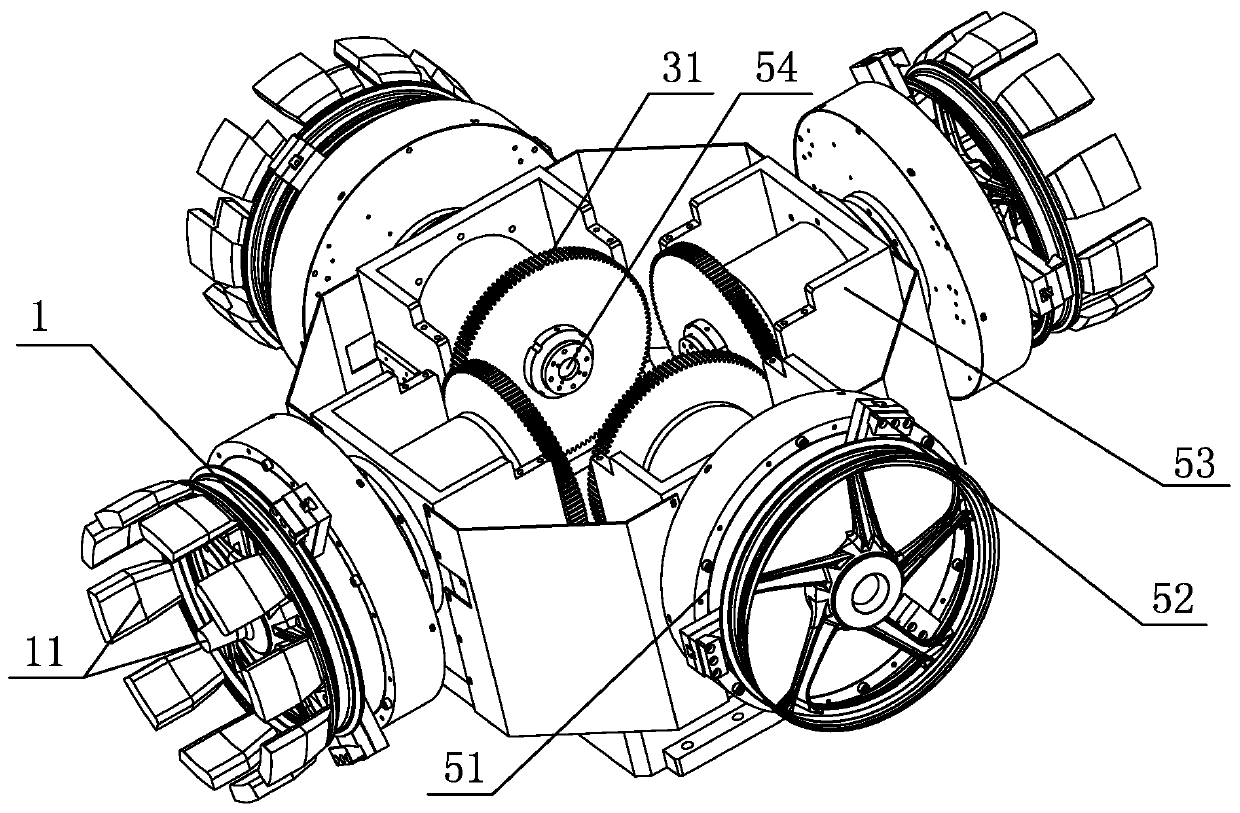

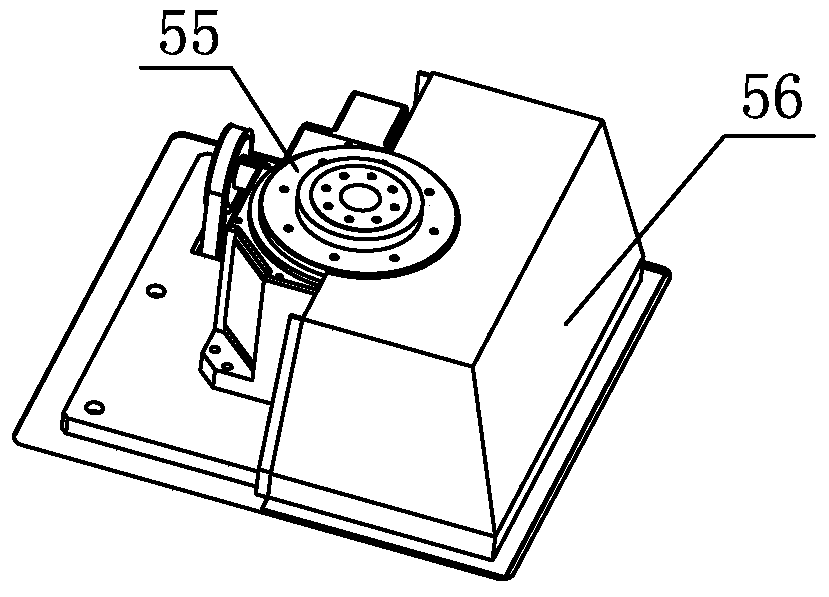

[0041] The workpiece clamping device 5 includes a rotary table mechanism and four chuck mechanisms; the rotary table mechanism includes a table, a cam indexer 55 and an indexing drive motor, and the bed is provided with a motor installation cavity, and the indexing drive motor passes through the mounting plate The support is installed in the inner cavity of the motor, and the cam indexer is fixedly installed on the top surface of the bed. The input shaft of the cam indexer is connected to the rota...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com