Double-side driven glass micro-nozzle processing device and processing method

A processing device, glass micro technology, applied in glass production, glass molding, glass manufacturing equipment, etc., can solve the problems of uncontrollable length of micro nozzle, different lengths at both ends, and deviation of breaking point from heat source, etc., to improve production The effect of efficiency and material utilization, good applicability and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

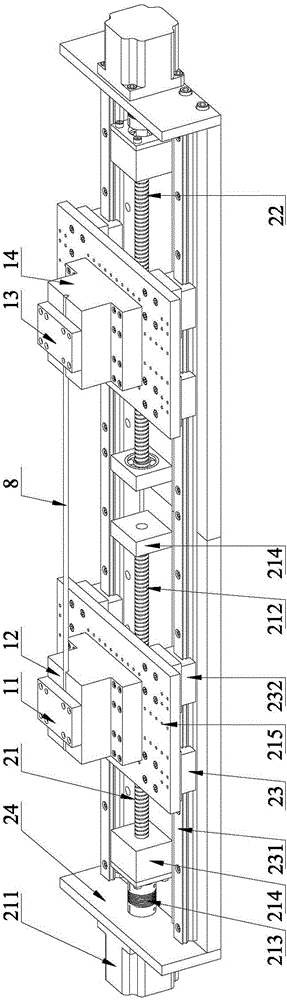

[0041] The invention discloses a double-end driven glass micro-nozzle processing method: by setting two symmetrically arranged drive mechanisms, the glass tube clamping devices at both ends of the glass tube are driven to move in opposite directions at the same time, so as to realize the drawing of the glass tube During the process, two micro-nozzles with symmetrical structure are formed at both ends of the break point.

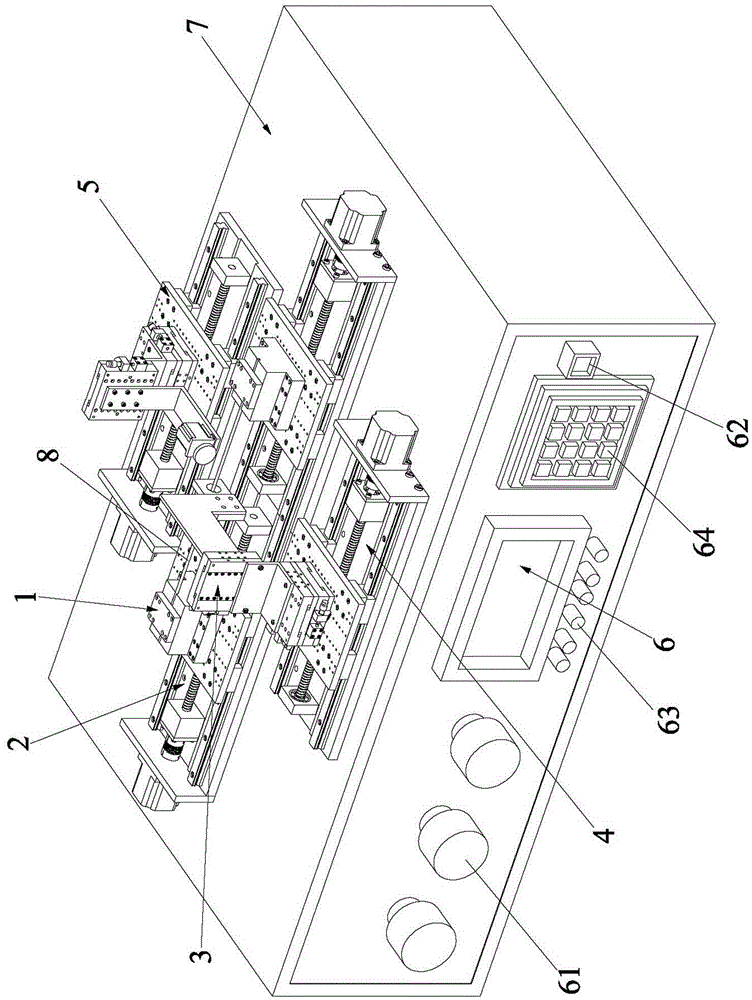

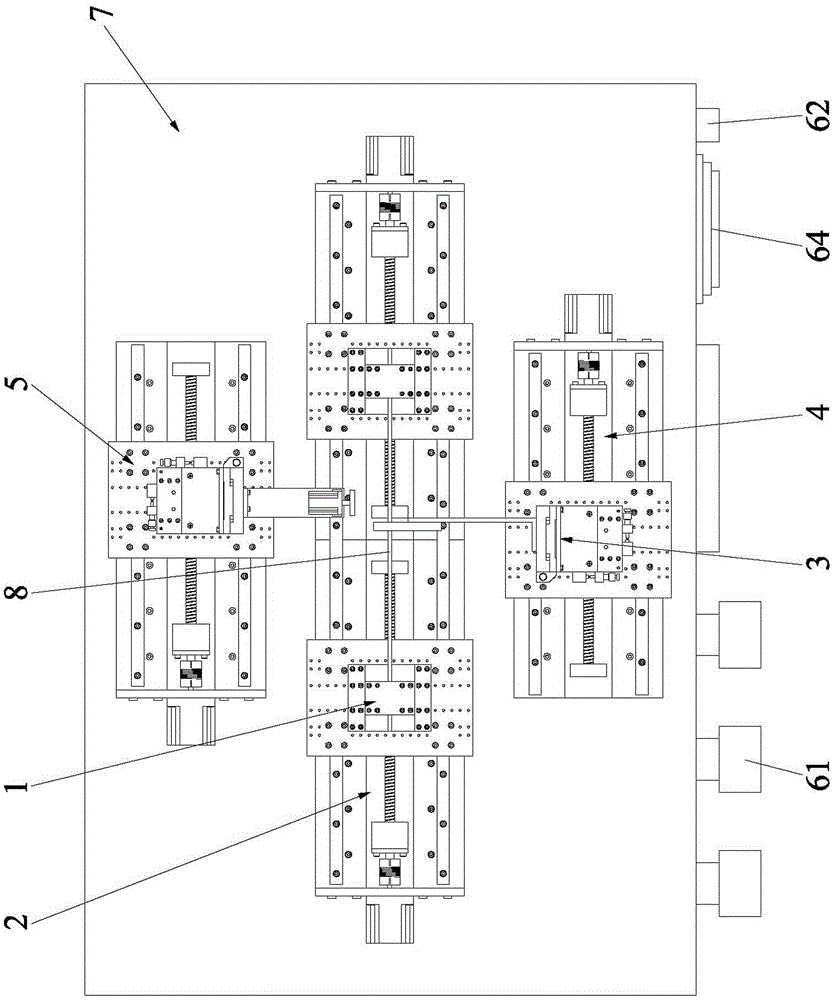

[0042] The invention also discloses a double-end driven glass micro-nozzle processing device, see Figure 1 to Figure 6 shown, is the preferred embodiment of the present invention. The processing device includes a glass tube clamping device 1 , a glass tube drawing motion device 2 , a heater device 3 , a forging motion device 4 , a grinding device 5 , a control device 6 and a base 7 . in:

[0043] The glass tube cla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com