Carbon brush automatic processing machine

An automatic processing and carbon brush technology, which is applied in metal processing equipment, automatic grinding control devices, manufacturing tools, etc., can solve the problems of large labor costs and low carbon brush processing efficiency, reducing labor costs, improving processing Maintenance-friendly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

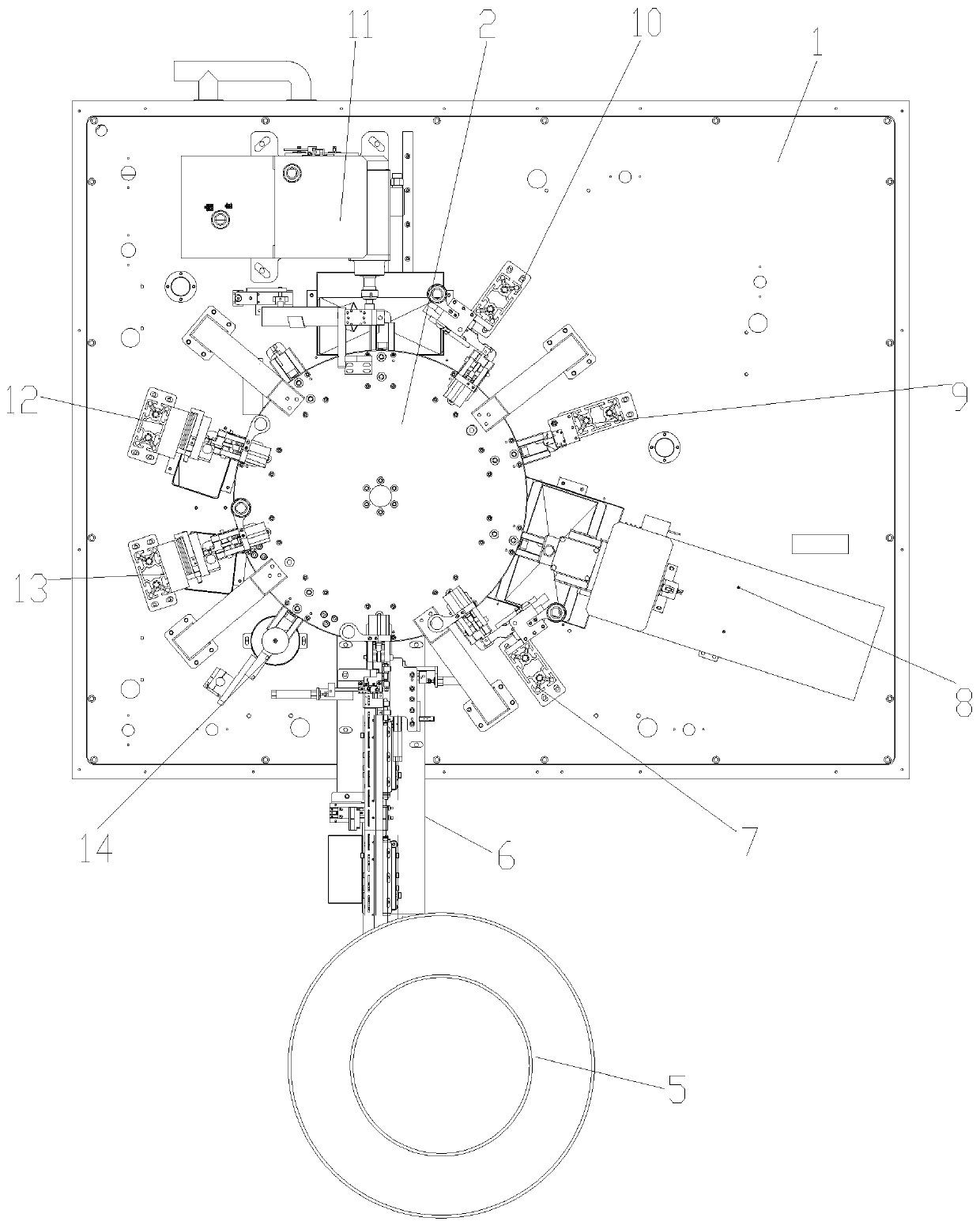

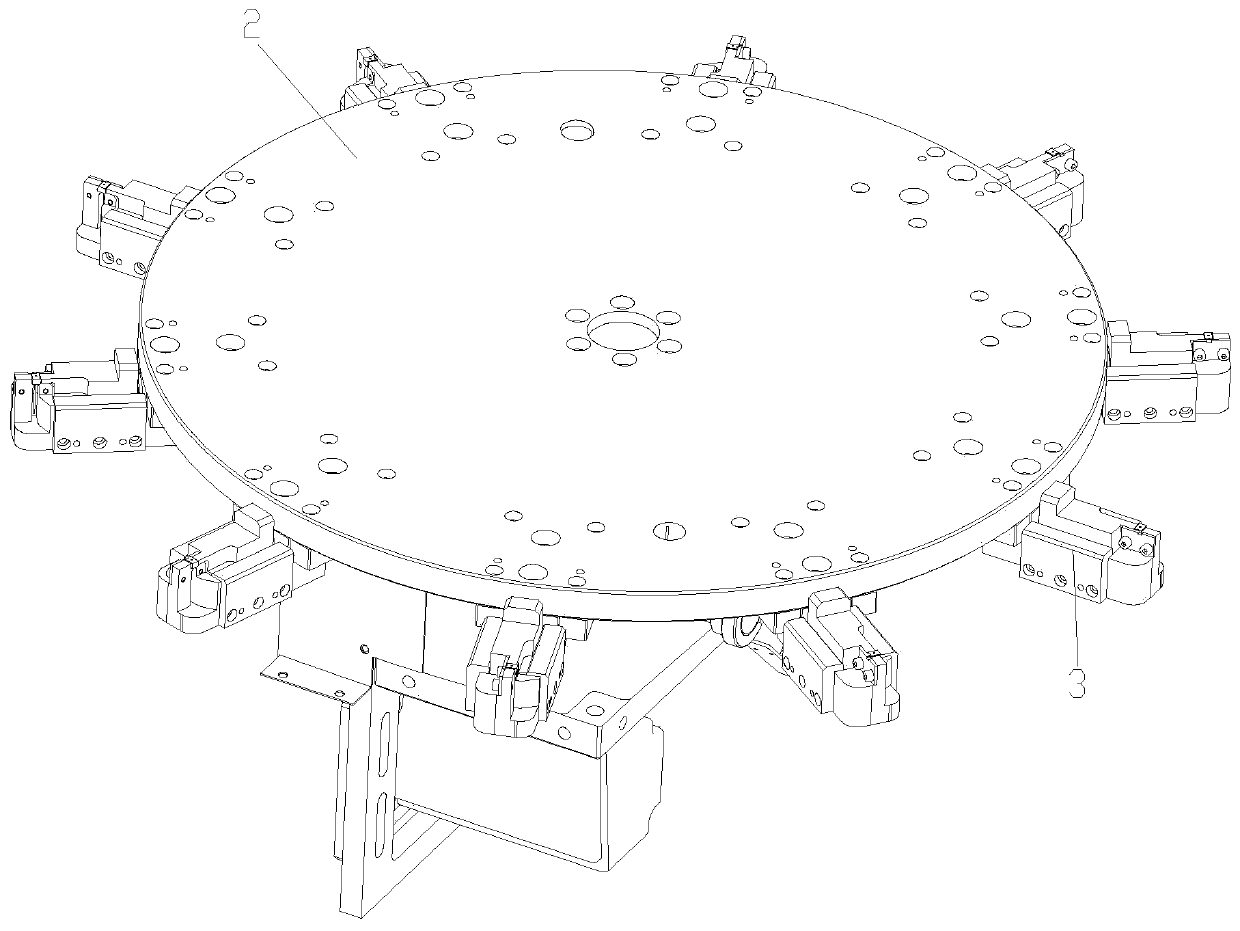

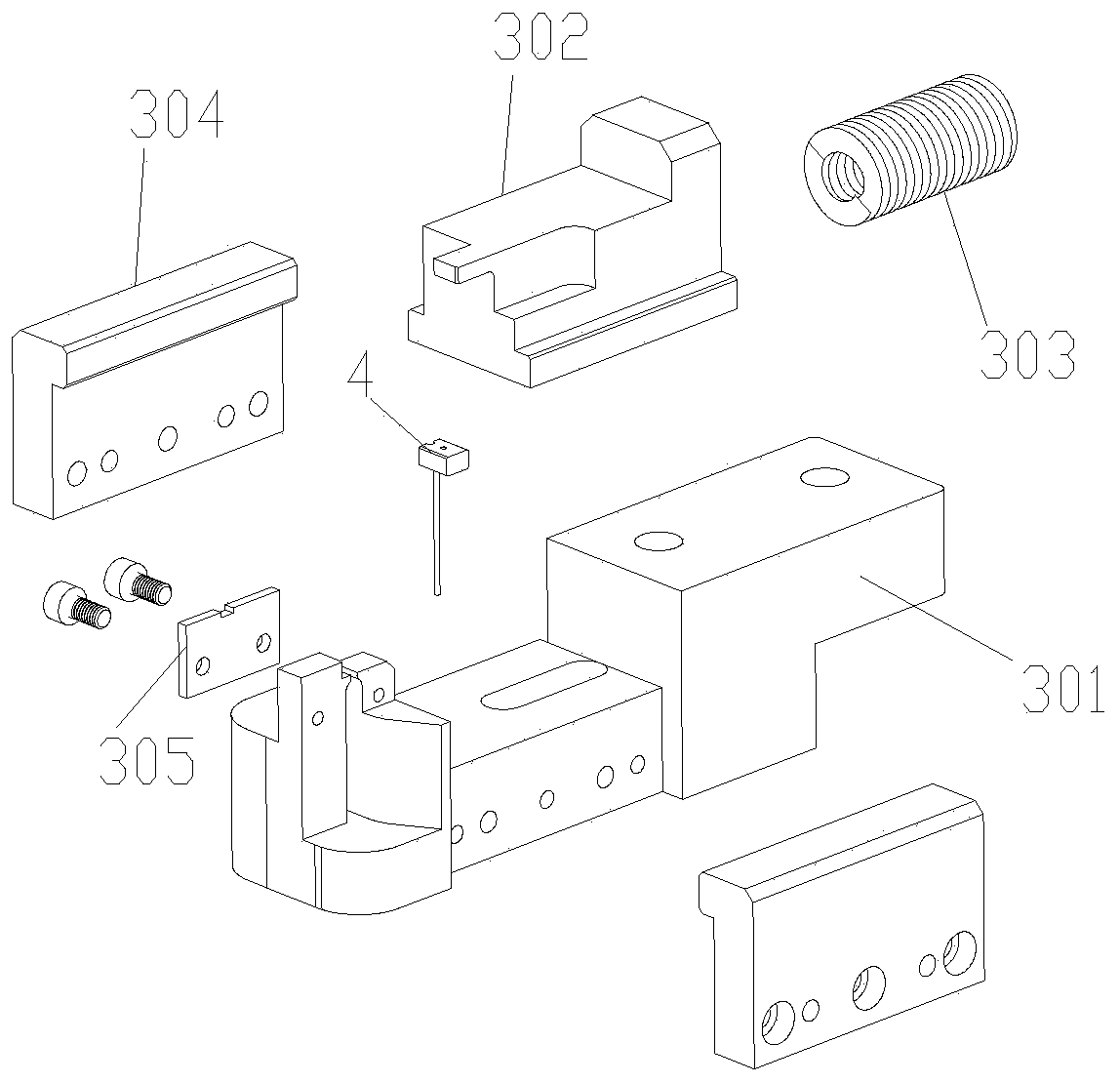

[0030] Such as Figure 1-13 As shown, an automatic carbon brush processing machine provided by the embodiment of the present invention includes a workbench 1, which is a rectangular platen with mounting holes on the surface, suitable for the installation of various components. A turntable 2 is installed on the workbench 1. The principle of the turntable 2 is that the bottom has a cam divider, and the raised divider can drive the turntable body installed on the top to rotate. The outer edge of the turntable 2 is equipped with a carrier 3 in an annular array, and a carbon brush 4 is installed inside the carrier 3. A vibrating plate 5 is also arranged on the outer side of the workbench 1. The principle of the vibrating plate 5 is that there is a The pulse electromagnet can make ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com