Automatic clothes hanger bending forming machine

A technology for bending and forming machines, applied in applications, household appliances, manufacturing tools, etc., to achieve the effect of high automation level, high production efficiency and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

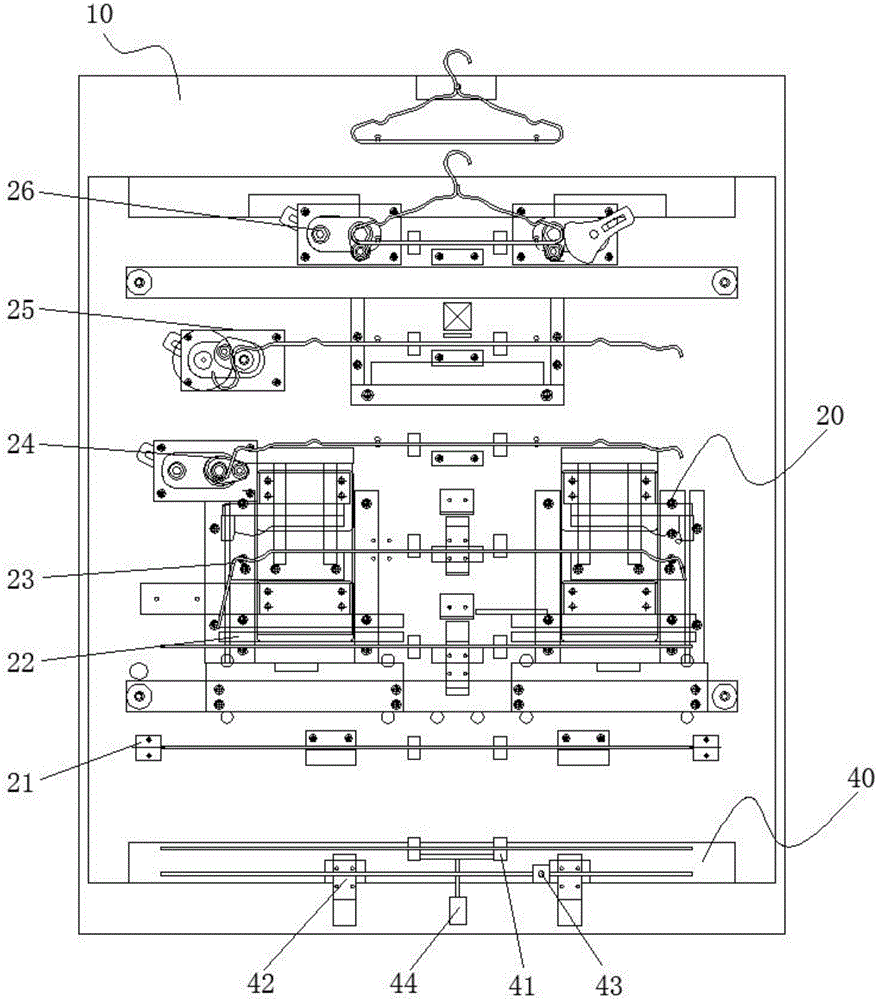

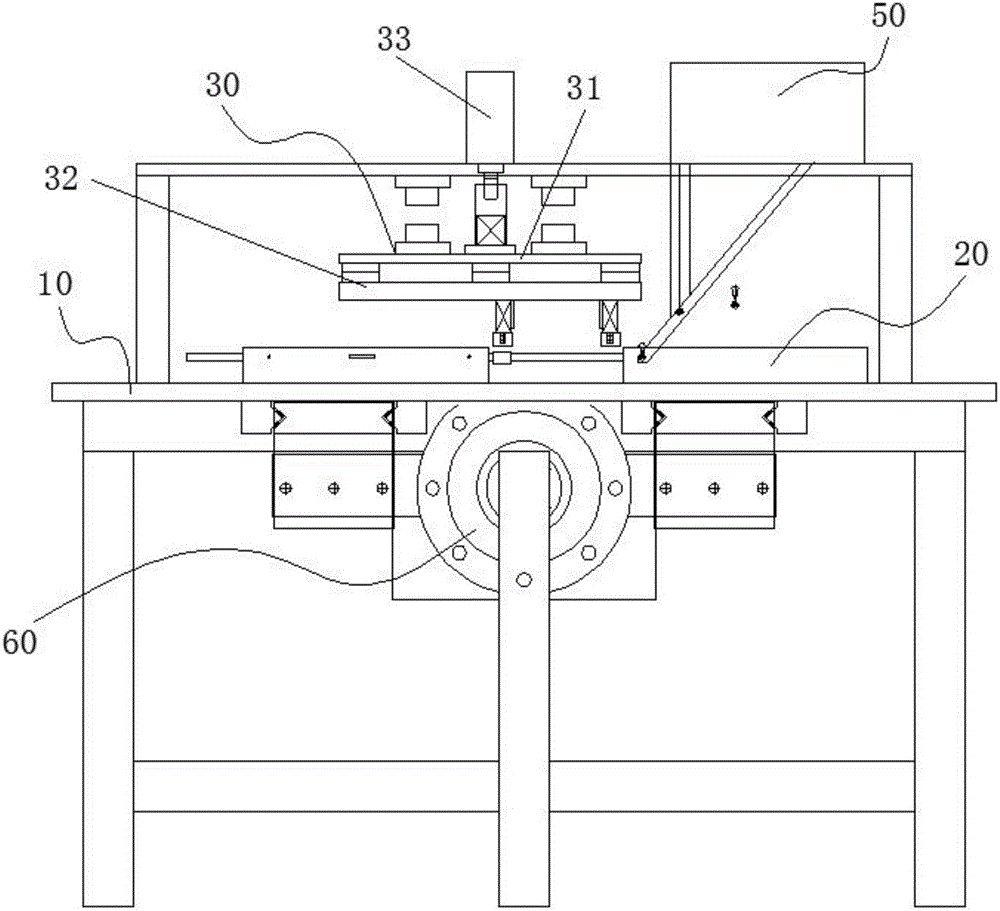

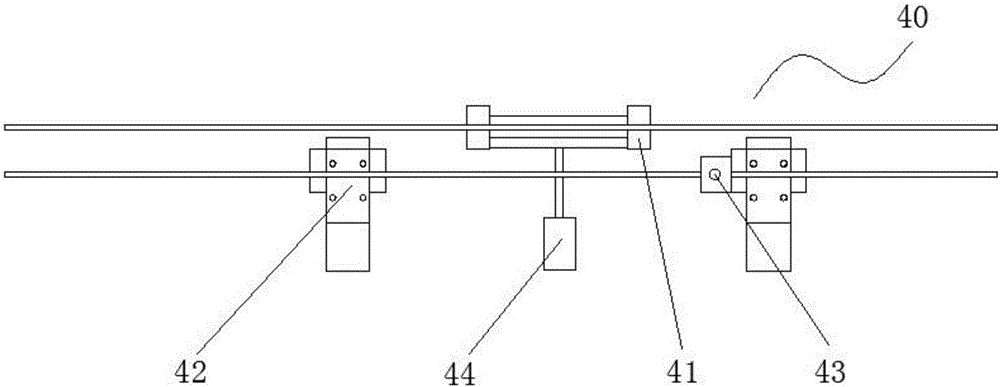

[0037] see Figure 1-Figure 12 . figure 1 It is a structural schematic diagram of the bending and forming mechanism of the clothes hanger automatic bending and forming machine of the present invention. figure 2 It is a structural schematic diagram of the automatic bending and forming machine for clothes hangers of the present invention. image 3 It is a schematic diagram of the structure of the feeding mechanism. Figure 4 It is a schematic diagram of the structure of the conveying mechanism. Figure 5 Is the structural schematic diagram of the chamfering unit. Figure 6 It is a structural schematic diagram of the punching and printing unit. Figure 7 It is a schematic diagram of the structure of the pressing unit. Figure 8 It is a structural schematic diagram of the hook forming unit. Figure 9 It is a side view of the hook molding unit. Figure 10 It is a structural schematic diagram of the hook bending unit. Figure 11 is a schematic diagram of the bending unit. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com