Silica gel injection molding device for breast paste production

A technology of silica gel and chest stickers, which is applied in the field of production and processing, can solve the problems of inconvenient mold replacement, inconvenient packing of finished products, troubles, etc., and achieve the effects of convenient packing, enhanced stability, and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

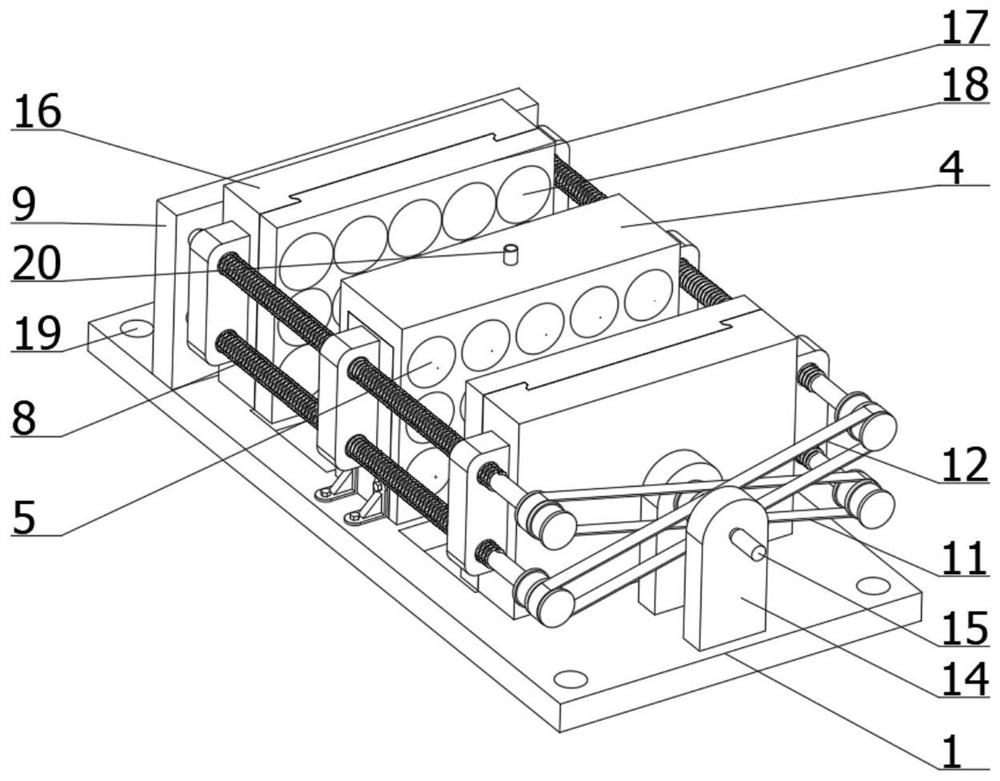

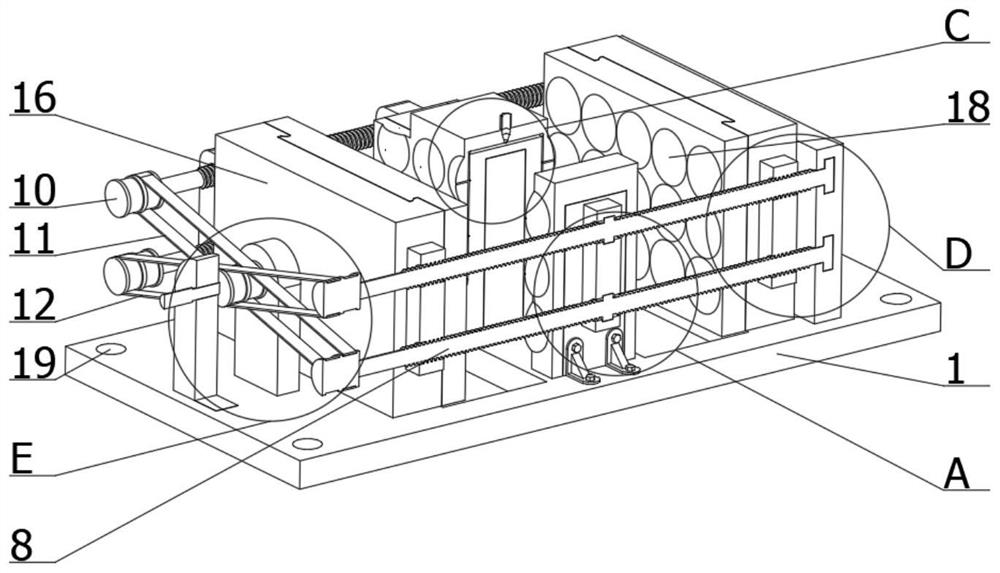

[0034] see figure 2 , 4 , 5, 6 and 7, a silicone injection molding device for breast stickers production, including a base plate 1, a fixing block 2 positioned on the upper surface of the base plate 1, and a reinforcing rib 3 on one side of the fixing block 2, the number of reinforcing ribs 3 is multiple, A plurality of reinforcing ribs 3 are symmetrically distributed, one side of the fixed block 2 is movably connected with a punch 4, both sides of the punch 4 are provided with bumps 5, the inner side of the bump 5 is provided with an injection hole 6, and the punch 4 One side is fixedly connected with a connection block 7, and the inside of the connection block 7 is movably connected with a reverse double-threaded screw rod 8, and one end of the upper surface of the bottom plate 1 is fixedly connected with a fixed plate 9, and one end of the reverse double-threaded screw rod 8 is connected to the fixed plate 9. Fitting, the upper surface of punch 4 is fixedly connected with...

Embodiment 2

[0037] see figure 1 and 8 , this embodiment is further optimized on the basis of Embodiment 1, specifically, the number of reverse double-flight screws 8 is multiple, and the multiple reverse double-flight screws 8 are distributed in a rectangular array.

[0038] Specifically, the other ends of the plurality of reverse double-flight screws 8 are fixedly connected with driven rollers 10 .

[0039] Specifically, a plurality of driven rollers 10 are adapted to the second transmission belt 12 and the driving pulley 13 via the first transmission belt 11 .

[0040] Specifically, support plates 14 are movably connected to both sides of the drive wheel 13 , and the bottom ends of the support plates 14 are fixedly connected to the bottom plate 1 .

[0041] Specifically, one side of the driving wheel 13 is fixedly connected with a rotating rod 15 , and the other end of the rotating rod 15 is penetrated and movably connected with a support plate 14 .

[0042] Specifically, the middle ...

Embodiment 3

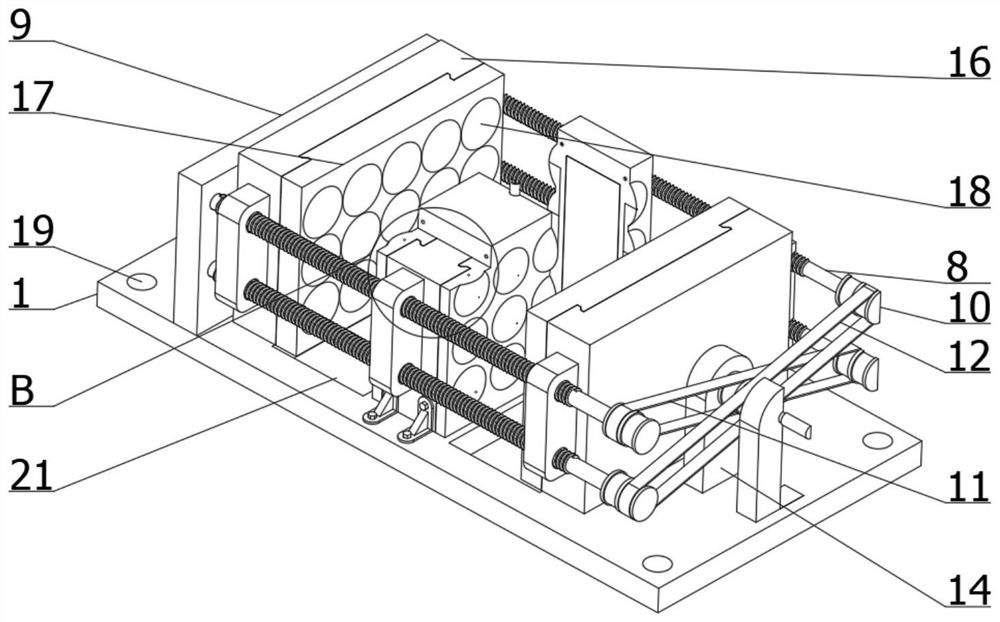

[0046] see image 3 , this embodiment is optimized as follows on the basis of example 1 or example 2, specifically, the corners of the bottom plate 1 are provided with mounting holes 19, the number of mounting holes 19 is multiple, and the multiple mounting holes 19 are rectangular Distributed in an array, the inside of the bottom plate 1 is symmetrically provided with blanking holes 21 .

[0047] In this embodiment, the bottom plate 1 can be stably fixed and installed through a plurality of mounting holes 19, and the product can automatically drop to the collection box after demolding through the blanking hole 21, so that it is more convenient for boxing.

[0048] In summary: in the present invention, the fixed block 2 can be fixed and limited by a plurality of reinforcing ribs 3, the punch 4 can be limited by the fixed block 2, and the feeding hole 20 can be connected with the feeding pipeline, thereby One side of a plurality of bumps 5 flows through the injection hole 6, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com