Zinc oxide melting gasification device

A technology of melting gasification and zinc oxide, applied in the direction of zinc oxide/zinc hydroxide, etc., can solve problems such as energy waste, and achieve the effects of low energy consumption, high processing efficiency, and efficient heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

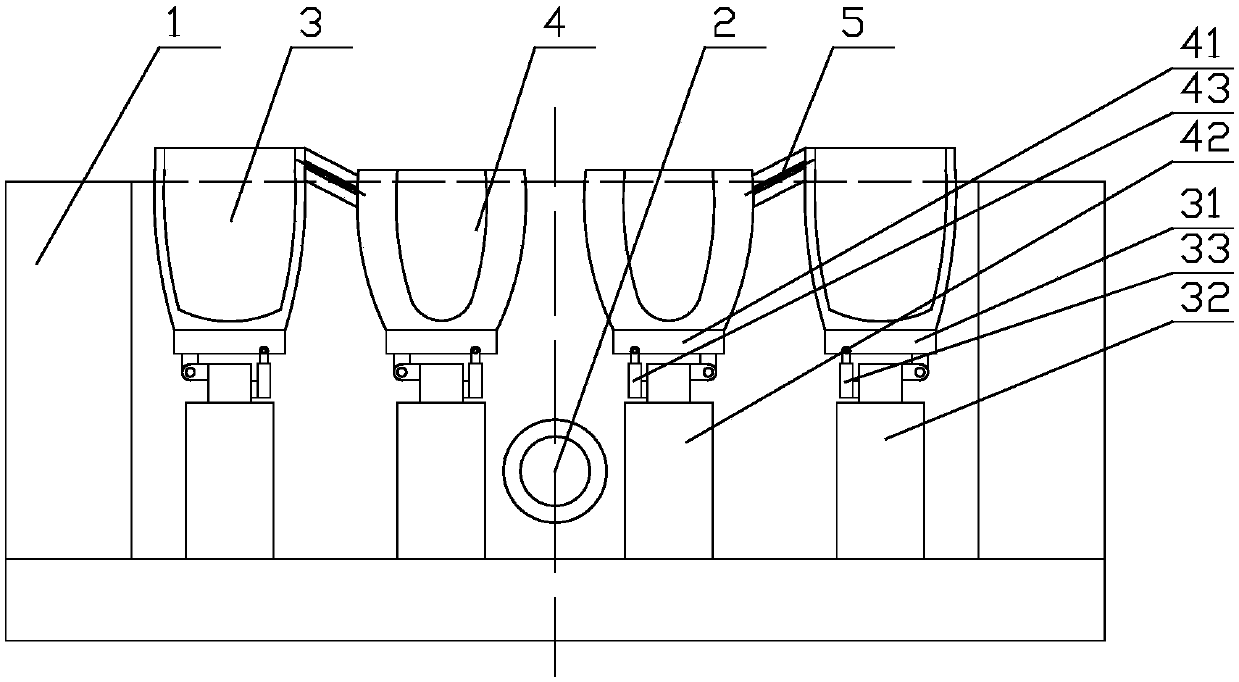

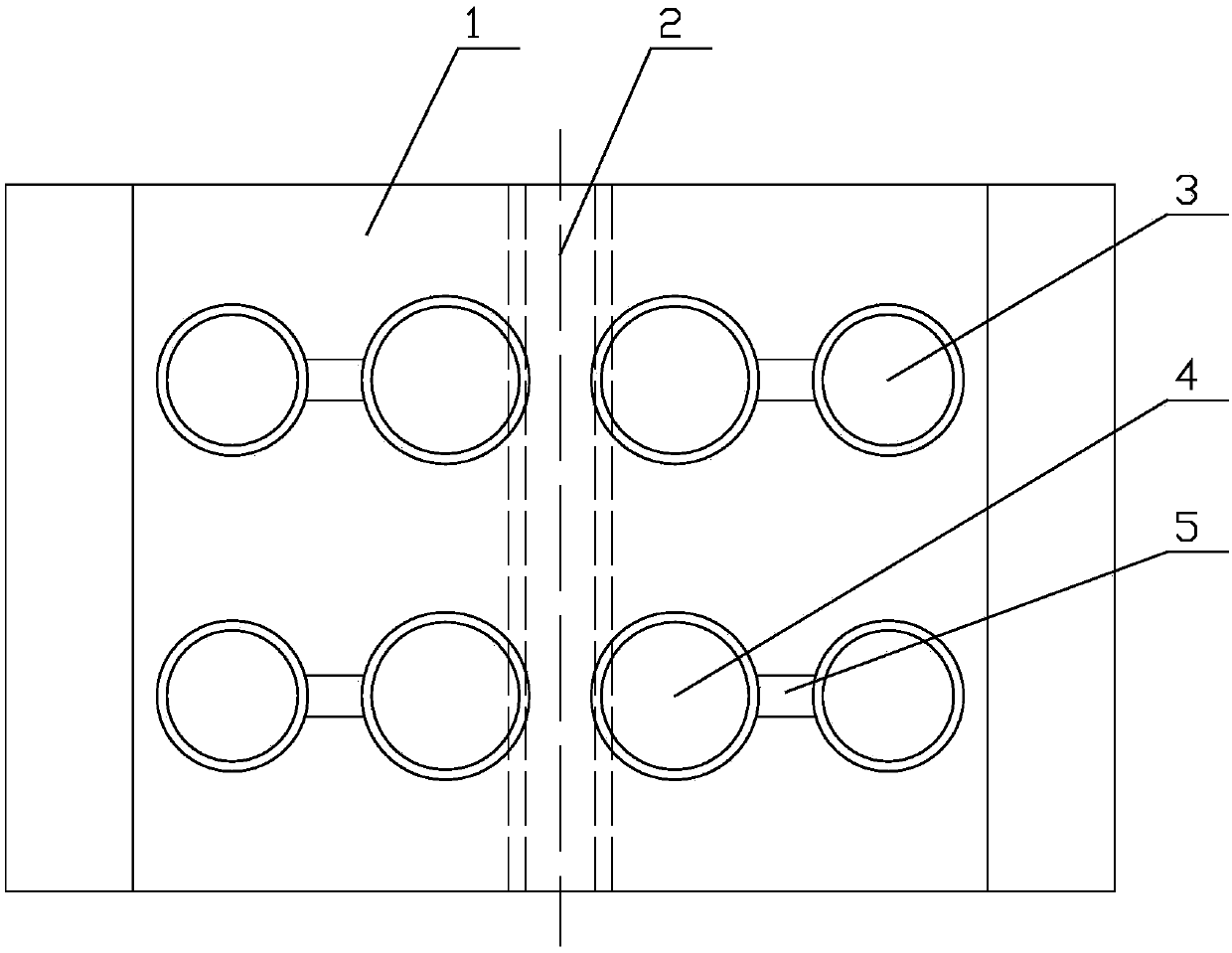

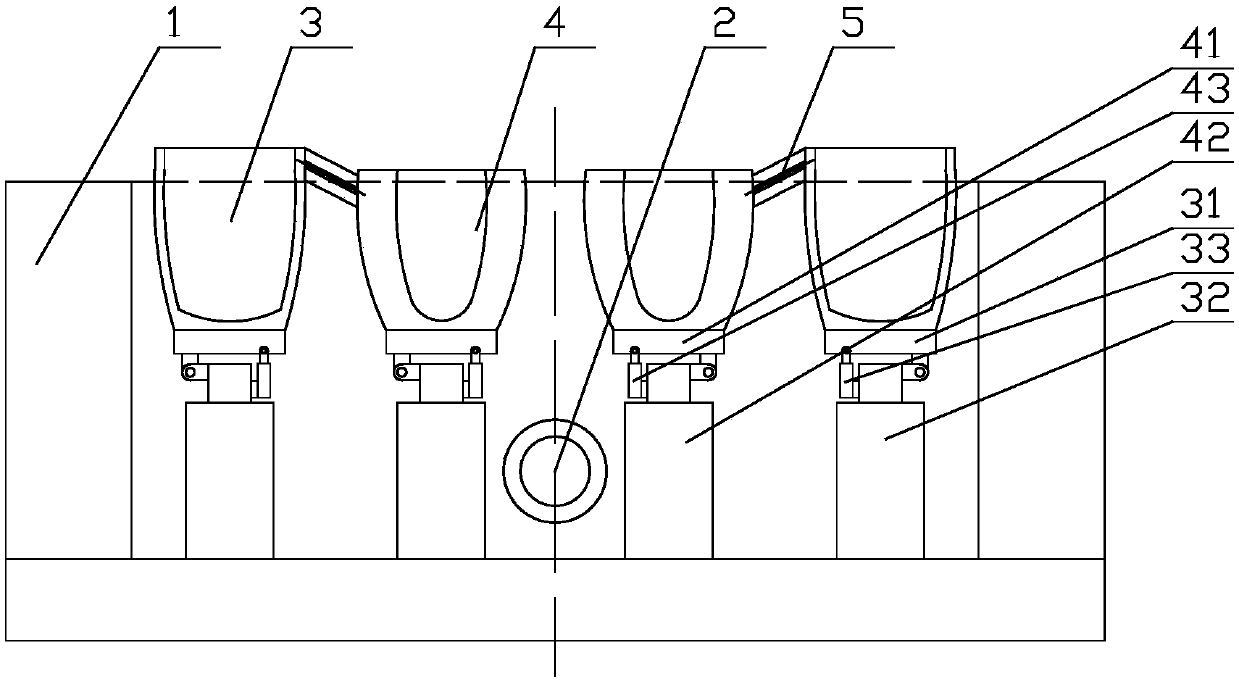

[0013] The invention as Figure 1-2 As shown, it includes a heating pool 1, a heat source pipeline 2, several melting crucibles 3 and several gasification crucibles 4;

[0014] The heat source pipeline 2 is connected to the bottom of the heating pool 1, and several gasification crucibles 4 are symmetrically distributed on both sides of the heat source pipeline 2; the melting crucible 3 is arranged on the gasification crucible 4 away from the One side of the heat source pipeline 2, and the top edge is higher than the top edge of the gasification crucible 4; when in use, the gasification crucible and the melting crucible on both sides of the heat source pipeline can be efficiently heated at the same time. The distance between the heat source pipes is greater than the distance between the gasification crucible and the heat source pipes, so the temperature at the bottom of the melting crucible will be lower than that at the bottom of the gasification crucible, so that one heat sou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com