Multifunctional winding and arranging all-in-one machine

An all-in-one, multi-functional technology, applied in the direction of conveying filamentous materials, coating, thin material processing, etc., it can solve the problems that winding equipment and carbon yarn equipment cannot be controlled synchronously, the workshop area is large, etc., and achieve synchronous control. , space saving, reasonable structure setting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to make the purpose, technical solutions and advantages of the embodiments of the present invention more clear, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention.

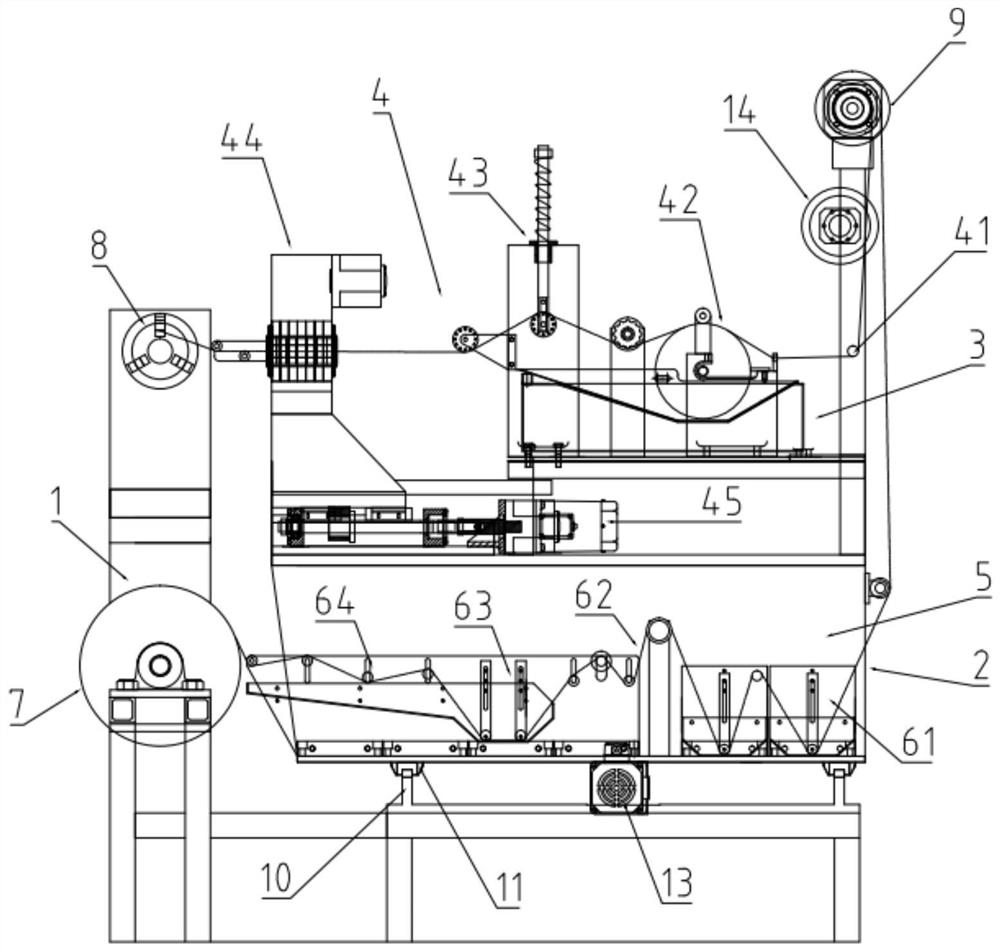

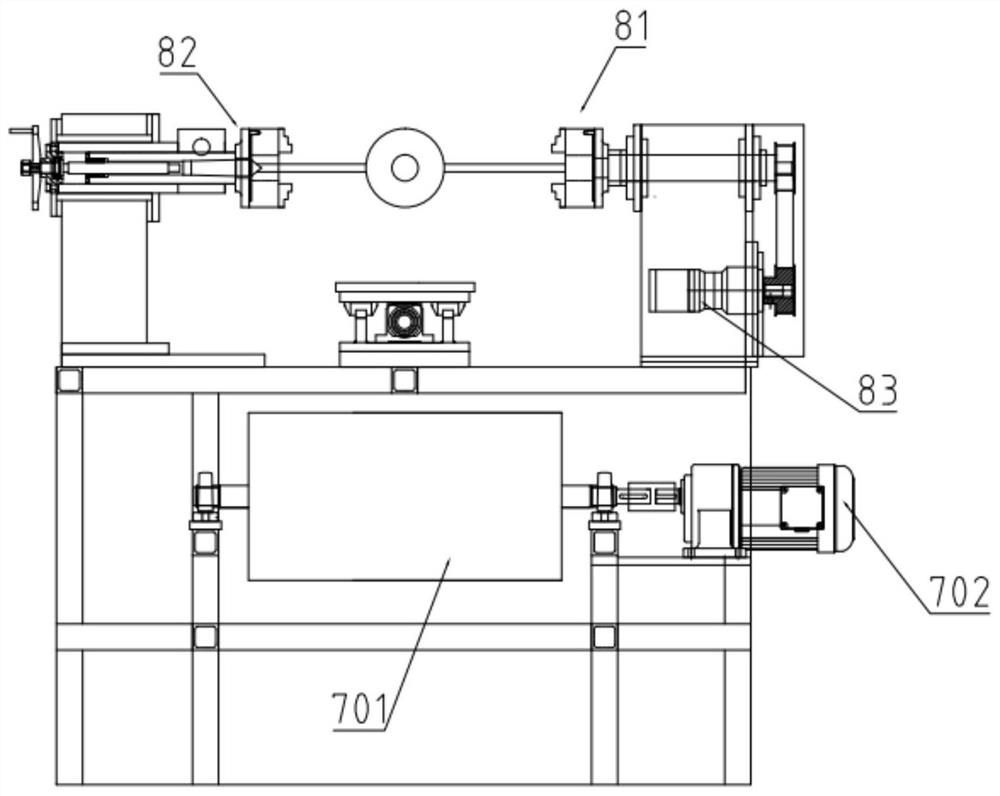

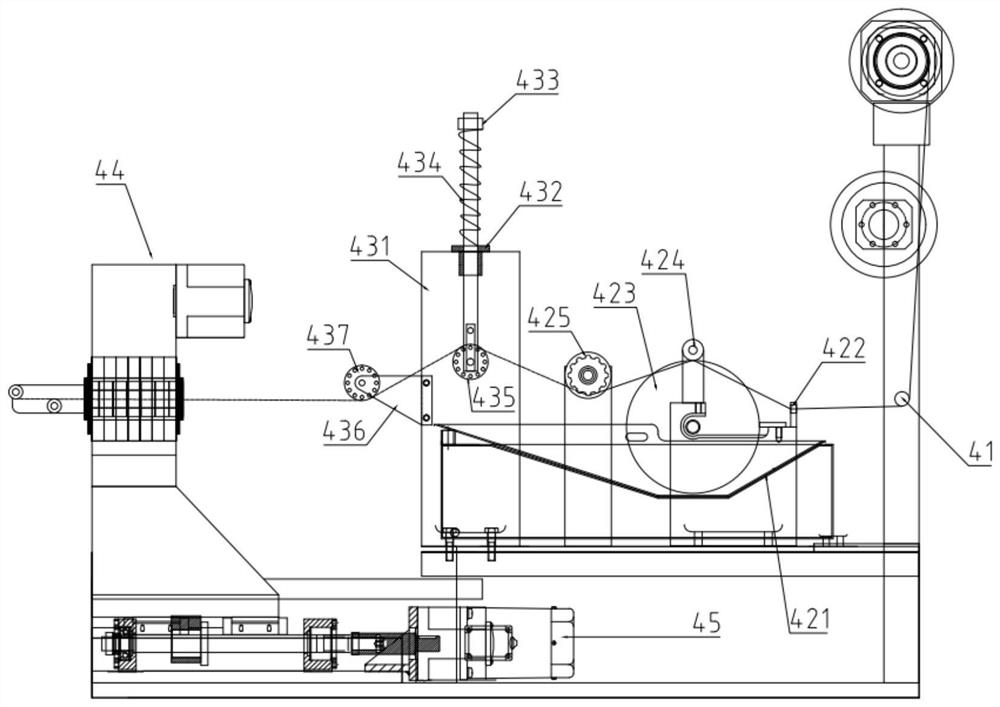

[0034] Such as Figure 1-4 In the illustrated embodiment, a multifunctional winding and arranging machine includes a fixed frame 1 and a movable frame 2 that can move along the first direction on the fixed frame 1; the movable frame 2 is divided into upper and lower layers, and the upper layer is The winding operation area 3 is provided with a winding device 4, and the lower layer is an arrangement operation area 5, which is provided with an arrangement device 6; the fixed frame 1 is in an "L" shape, and the longitudinal frame body of the fixed frame 1 is respectively provided with hot rollers The winding device 7 and the mold clamping device 8, the position o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com