Glue sealing floor

A floor and rubber sealing technology, which is applied to floors, buildings, building structures, etc., can solve the problems of floor extrusion, sound, deformation, uplift, and rot, and achieve the effects of reducing waste, reducing costs, and good environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

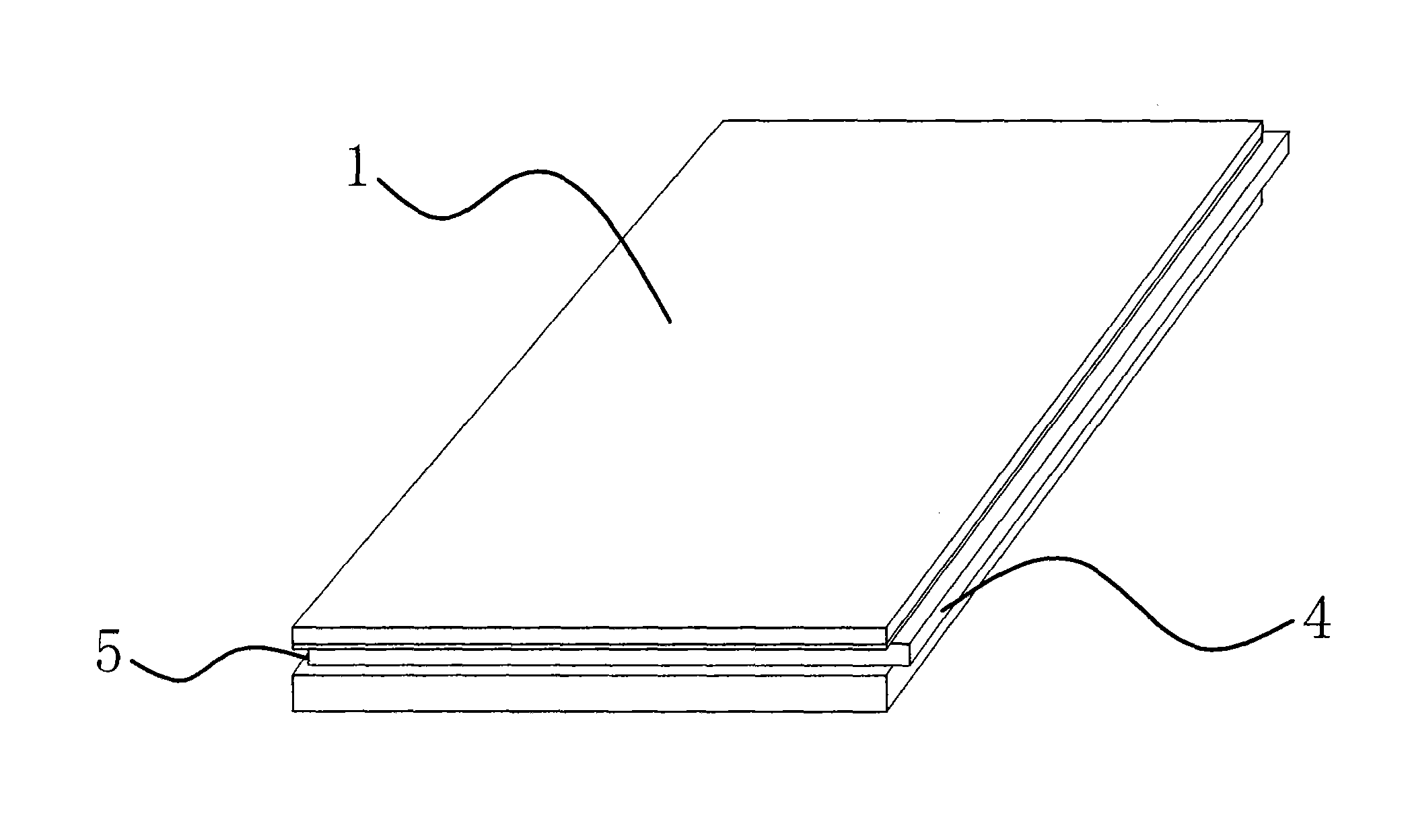

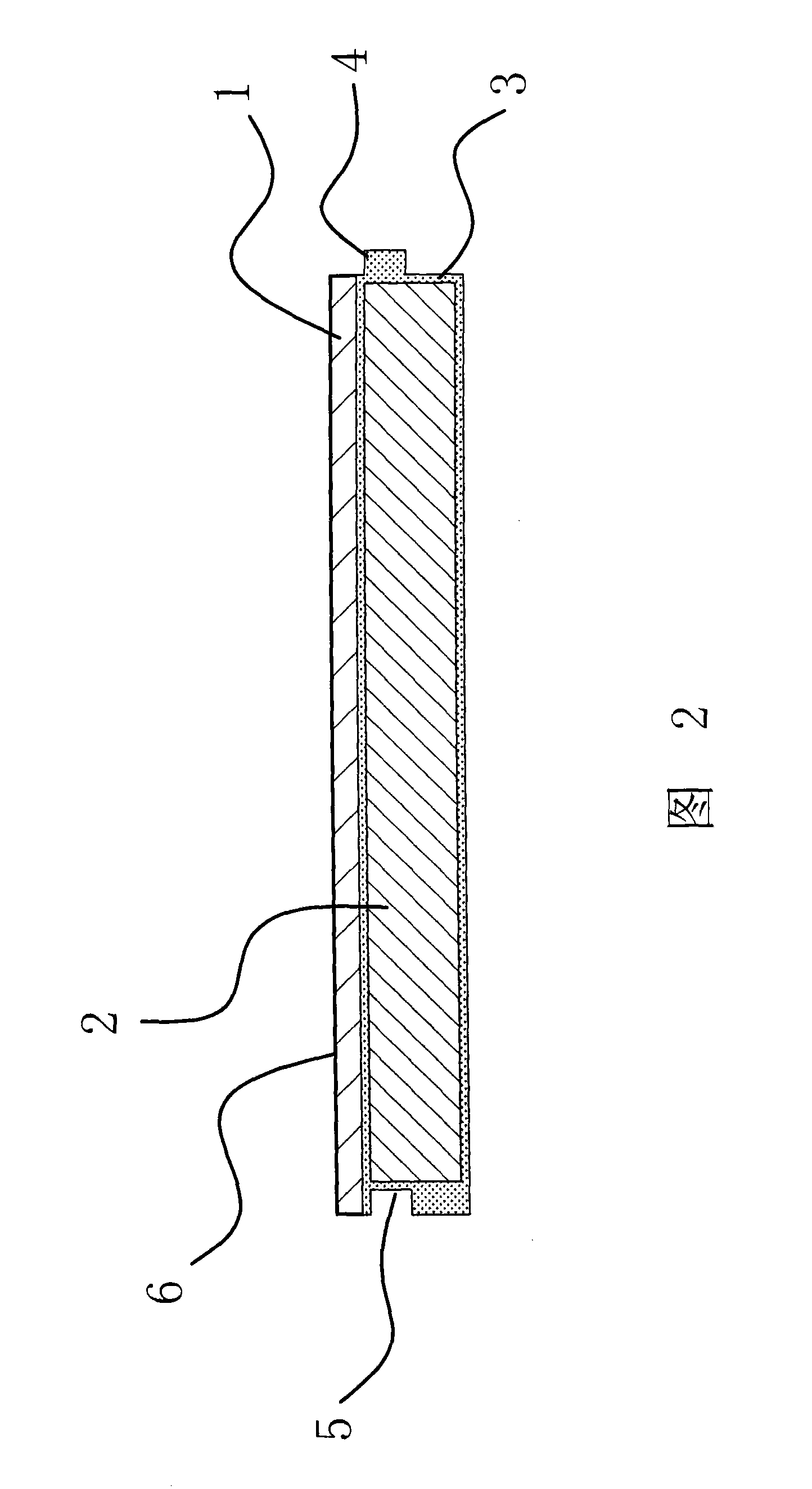

[0033] Such as figure 1 , shown in Figure 2 and Figure 4, the rubber-sealed floor includes a panel 1, a core board 2, a plastic layer 3 and a paint layer 6.

[0034] The panel 1 is made of natural high-quality wood, and in this embodiment, the natural high-quality wood is selected from Mandshurica mandshurica. In addition, the panel 1 can also be made of hard wood such as teak, rosewood and camphor wood. The core board 2 is made of cheap fast-growing wood, and in this embodiment, the cheap fast-growing wood is Chinese fir. In addition, the core board 2 can also be selected from pine, paulownia and birch.

[0035] When processing the panel 1 and the core board 2, the selected wood is all artificially dried to make the wood reach the standard moisture content, and then the wood is sliced according to the size required by the design to obtain a standard size board. Both the panel 1 and the core panel 2 after processing are single panels.

[0036] Due to the thermoplasticity...

Embodiment 2

[0040] The structural principles, processing and usage methods of this embodiment are basically the same as those of Embodiment 1. The difference lies in that the outer surface of the processed core plate 2 in this embodiment is provided with a plastic layer 3 wrapping the core plate 2 inside it. The embedding structure includes a plastic rib 4 formed by the plastic layer 3 on one side of the core board 2 , and a plastic groove 5 formed by the plastic layer 3 on the other side of the core board 2 opposite to the rib 4 .

Embodiment 3

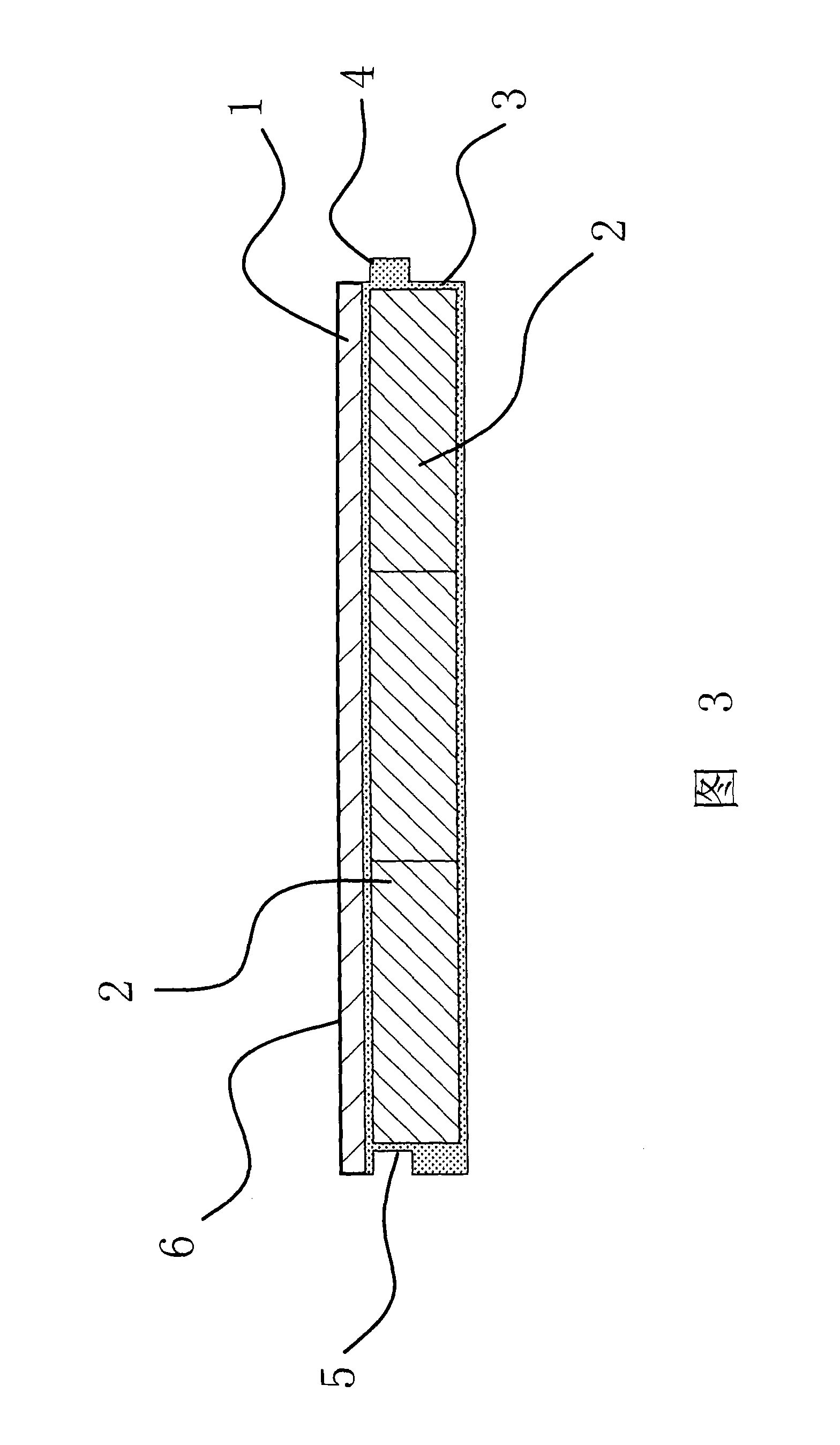

[0042] This embodiment is basically the same as the first embodiment in terms of its structural principles, processing, and use methods, as shown in Figure 5. The difference is that in this embodiment, the side processing of the core plate 2 is performed in the first and second embodiments. The ribs 4 and grooves 5 mentioned in the above, and then wrap the outer surface of the processed core board 2 with a plastic layer 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com