Processing method of camera decoration ring

A processing method and technology of decorative circles, applied in image communication, color TV parts, TV system parts, etc., can solve the problems of low production efficiency and high production cost, meet production needs and realize mass production Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

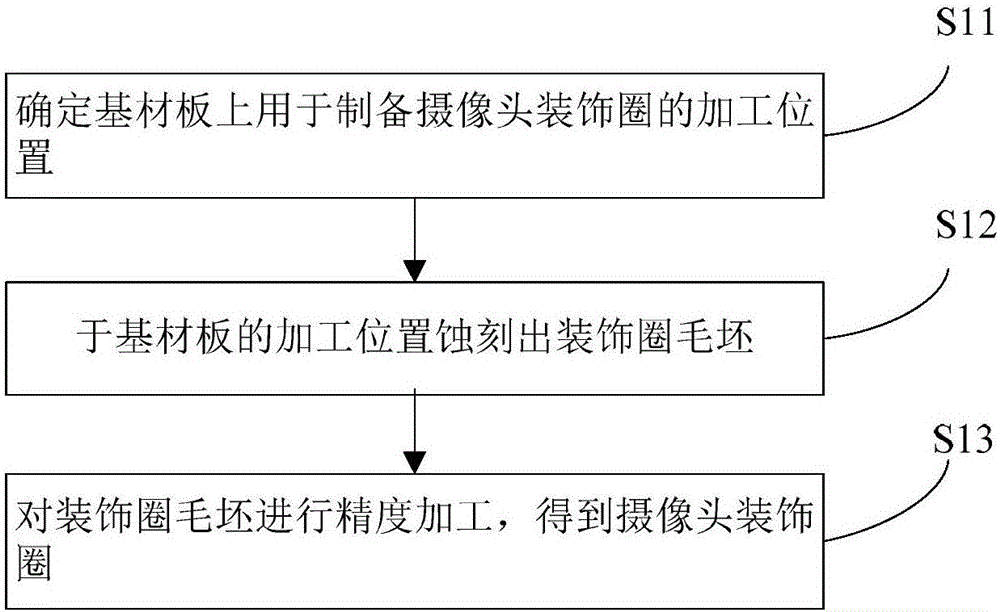

Embodiment 1

[0024] refer to figure 1 , a method for processing a camera decoration ring, comprising: providing a base plate, wherein the base plate is a metal base plate, preferably a stainless steel base plate, and positioning holes are provided on both sides of the base plate.

[0025] Step S11 , determining a processing position on the base plate for preparing the camera trim ring.

[0026] In this step, the processing position on the base plate for preparing the camera trim ring can be determined by means of exposure and development. In particular, when it is necessary to process batches of camera decorative rings on the base plate, the determination of batch processing positions can be effectively realized by means of exposure and development, and the production efficiency can be effectively improved. Wherein, how many camera decoration rings need to be processed on the substrate board can be determined according to the size of the substrate board and actual production needs.

[00...

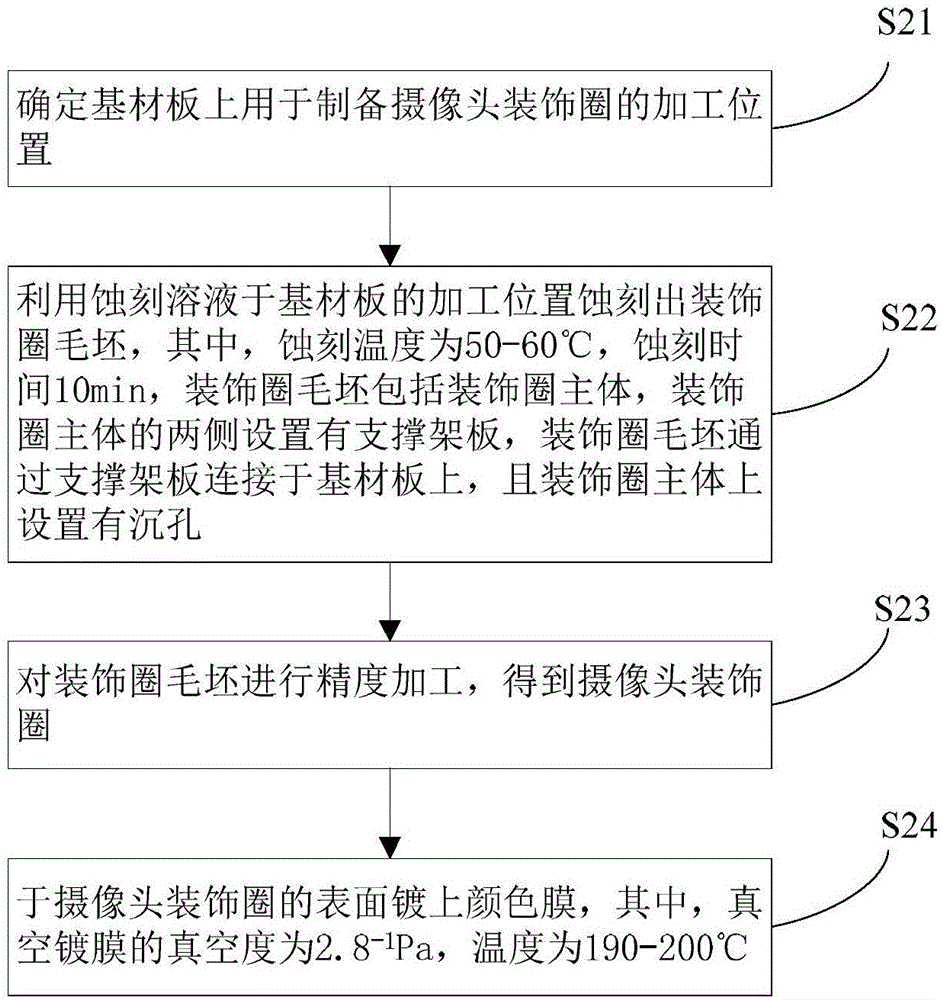

Embodiment 2

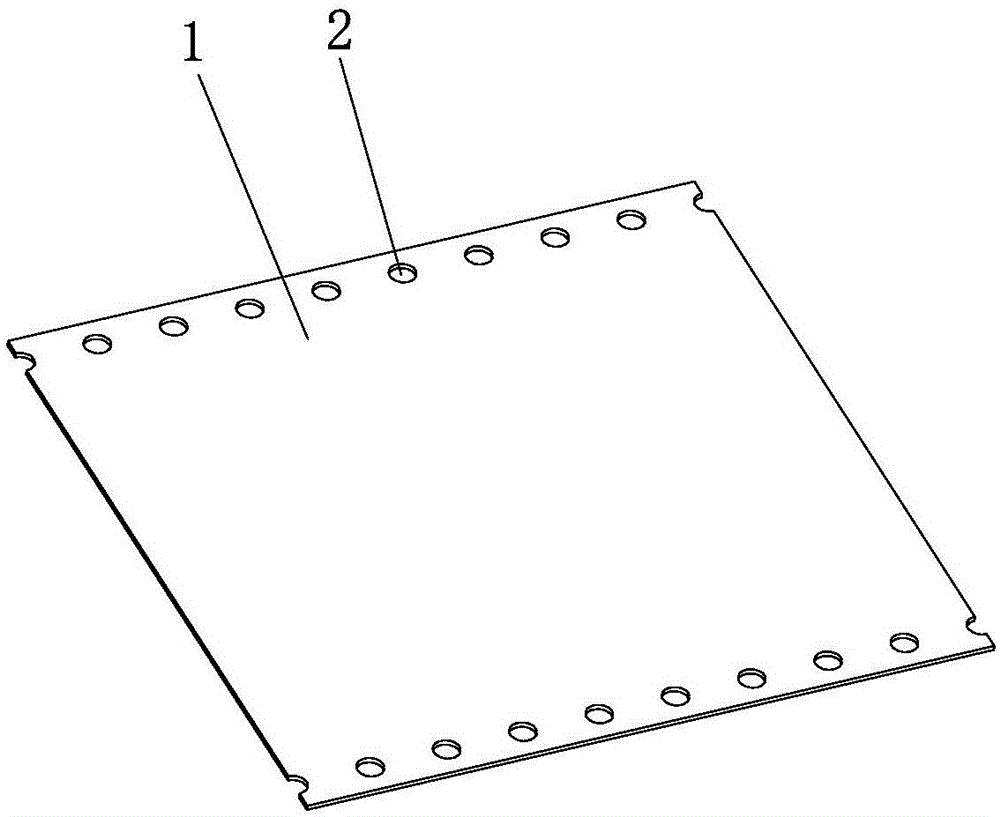

[0033] refer to figure 2 , a method for processing a camera trim ring, comprising: providing a base plate, wherein the base plate is a metal base plate, preferably a stainless steel base plate; refer to image 3 , The two sides of the base plate 1 are provided with positioning holes 2, so as to facilitate the positioning of the base plate during processing.

[0034] Step S21 , determining a processing position on the base plate for preparing the camera trim ring.

[0035] In this step, the processing position on the base plate for preparing the camera trim ring can be determined by means of exposure and development. In particular, when it is necessary to process batches of camera decorative rings on the base plate, the determination of batch processing positions can be effectively realized by means of exposure and development, and the production efficiency can be effectively improved. Wherein, how many camera decoration rings need to be processed on the substrate board can ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com