Laser cladding and on-line machining repair method for positioning groove of rough rolling stand roll

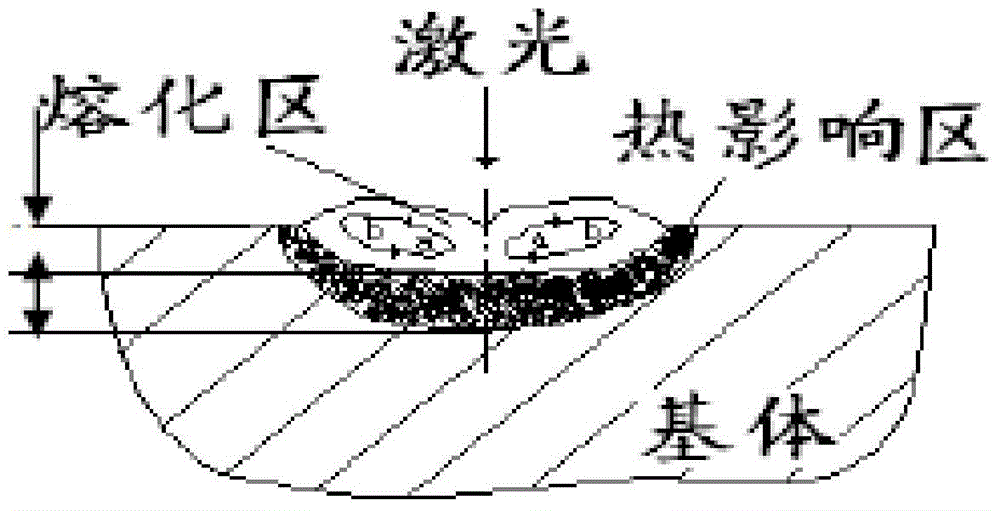

A laser cladding and repair method technology, which is applied in the direction of metal rolling racks, metal rolling mill stands, metal processing equipment, etc., can solve the failure of rack roll bearing installation and positioning accuracy, and the impact on the service life of rack rolls. Problems such as the decline in the accuracy of equipment functions, to achieve the effect of restoring equipment accuracy, prolonging the service life of equipment, and protecting against wear and corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The specific implementation process of the present invention:

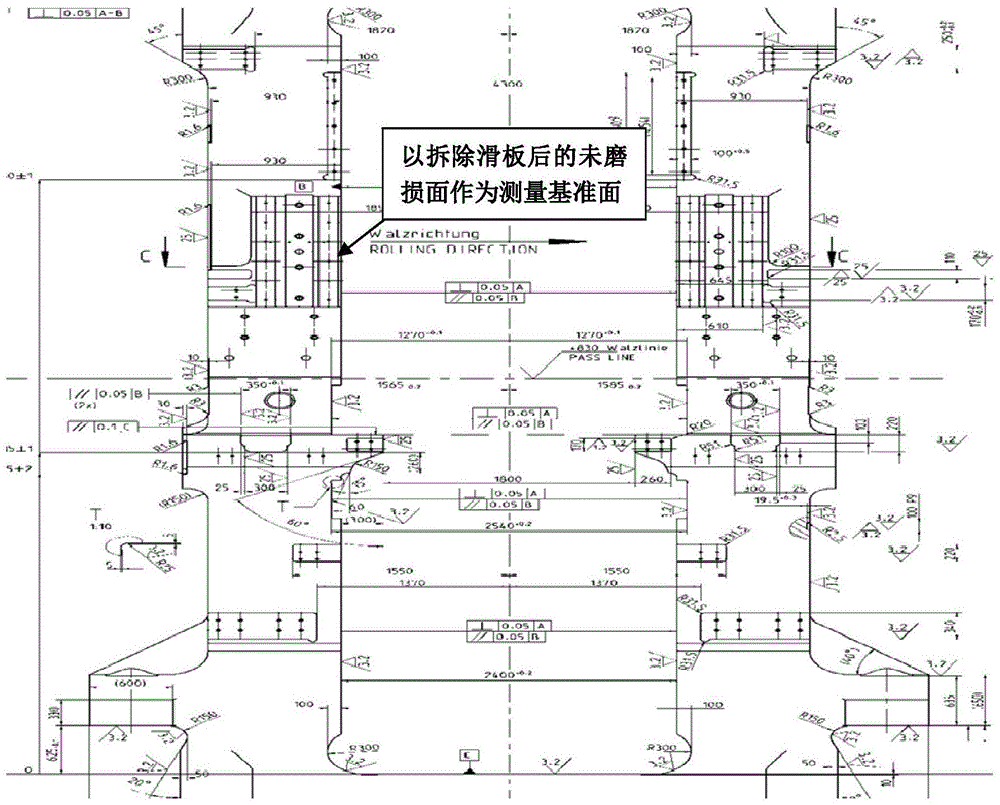

[0032] Step 1. Construction platform construction and equipment import

[0033] Carry out safety confirmation before construction, handle construction procedures and fire certificates. Construction platform specifications δ80×1800×6000-2 pieces are built in the rolling center, and box girders are used to support the box girder welding under the track below the rolling mill. In order to prevent construction personnel from falling, 20# channel steel and checkered plate are used to lay the gap, and 50# angle steel and φ16~20 round steel are used to weld the protective railing around, and a ladder is built when necessary. Import the 2500 mobile boring and milling machine from the entrance side Adjustments are made on the rack platform.

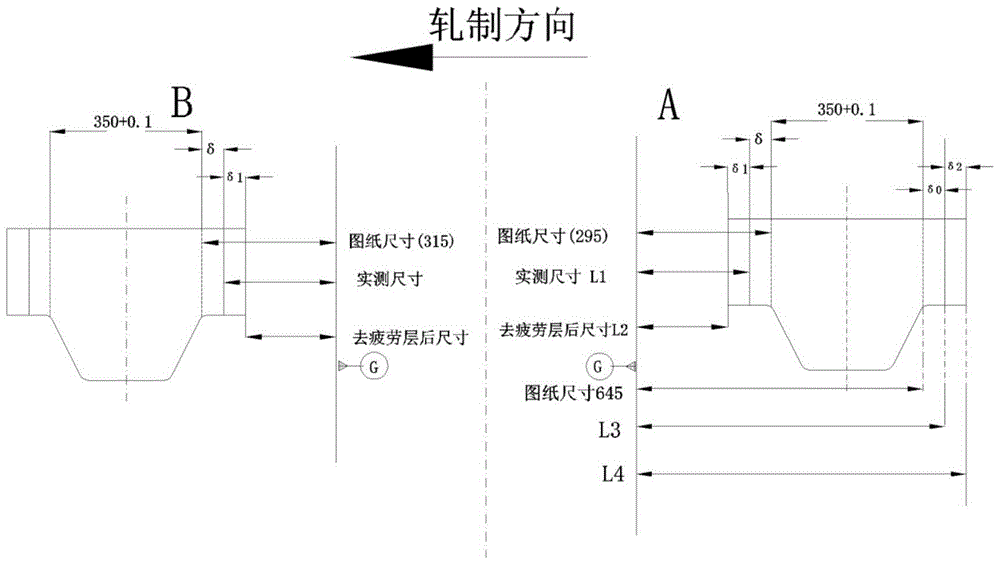

[0034] Step 2. Rough machining to remove the fatigue layer on all sides of the inner side of the positioning groove

[0035] Rough machining removes the fatigue layer on the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com