Horn processing jig and processing method thereof

A processing method and speaker technology, applied in electrical components, sensors, etc., can solve the problems of low processing efficiency, assembly errors, and low product position accuracy, and achieve the effect of improving assembly accuracy and high processing efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described in detail below with reference to the examples and drawings, but the implementation of the present invention is not limited thereto.

[0036] Such as Figure 1-6 Shown:

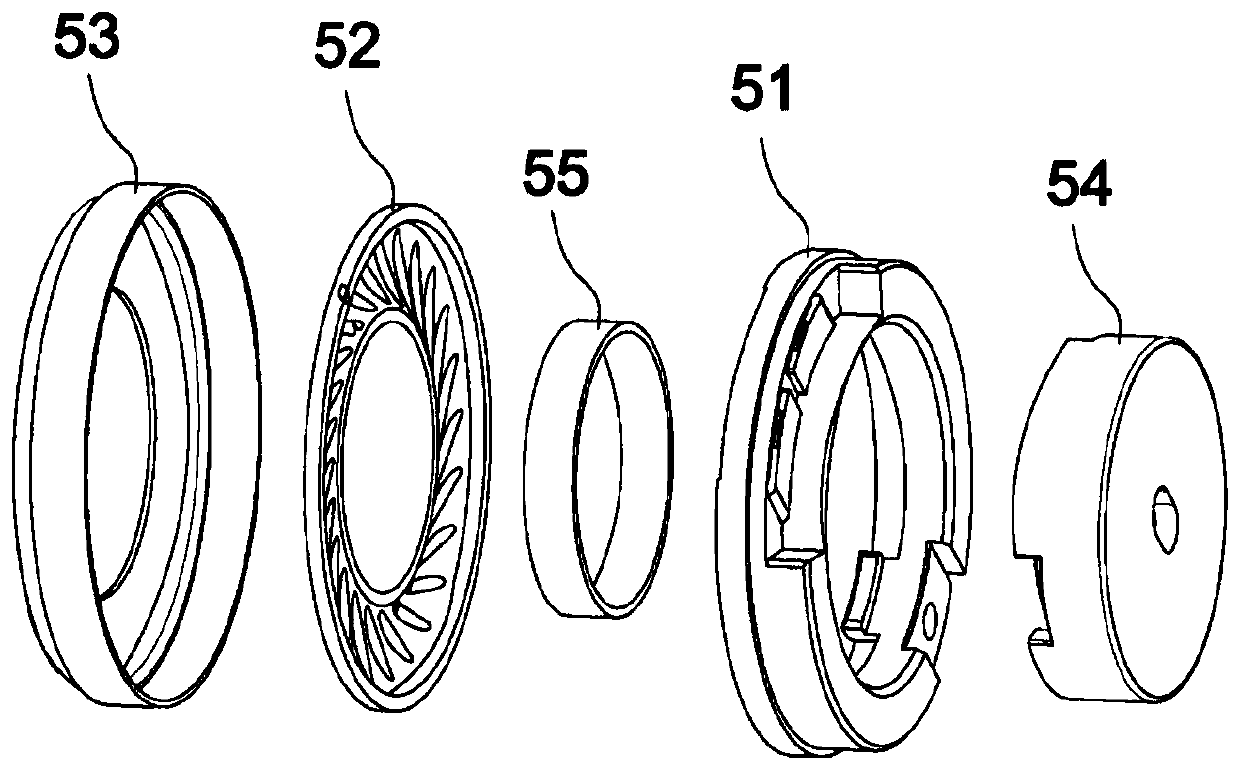

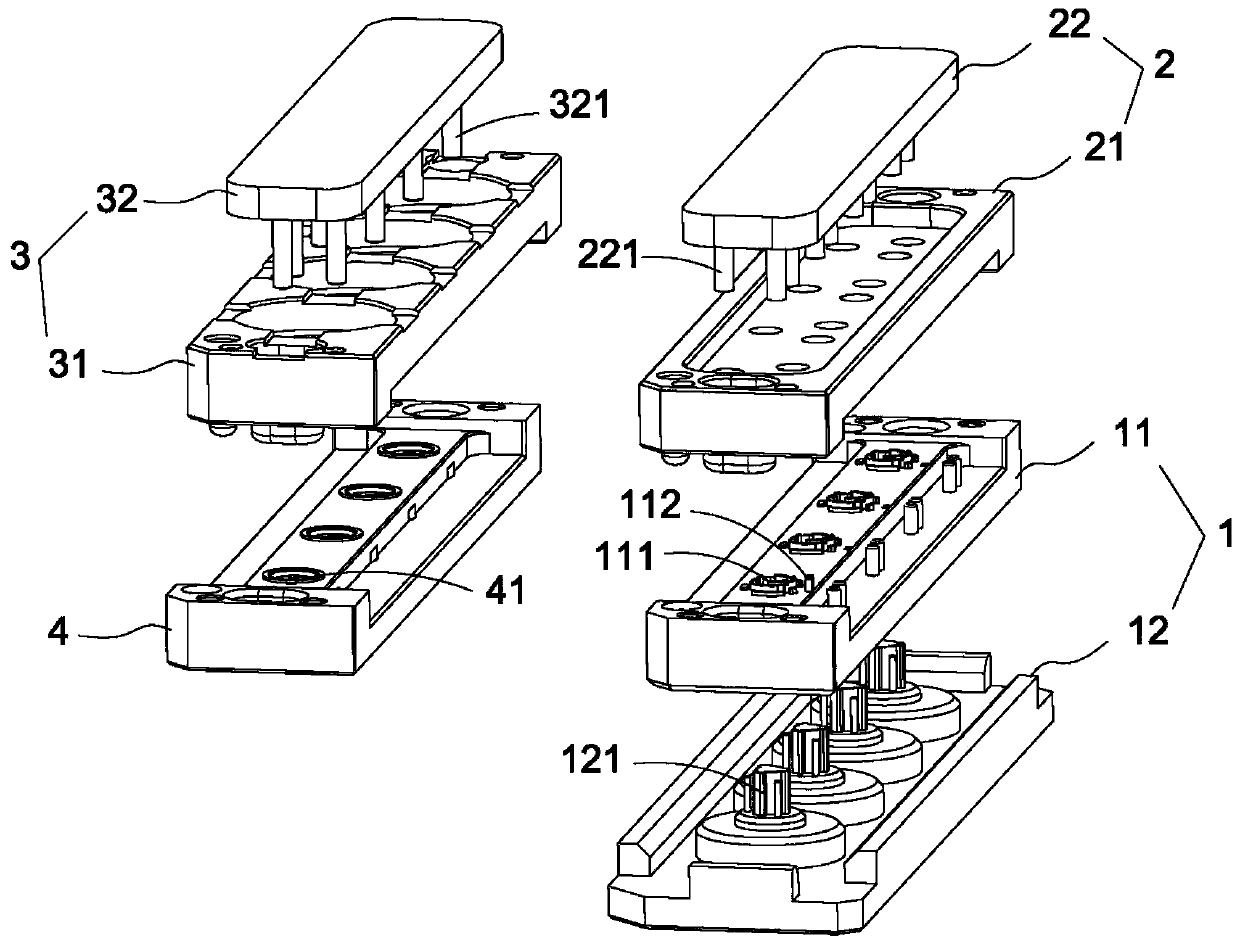

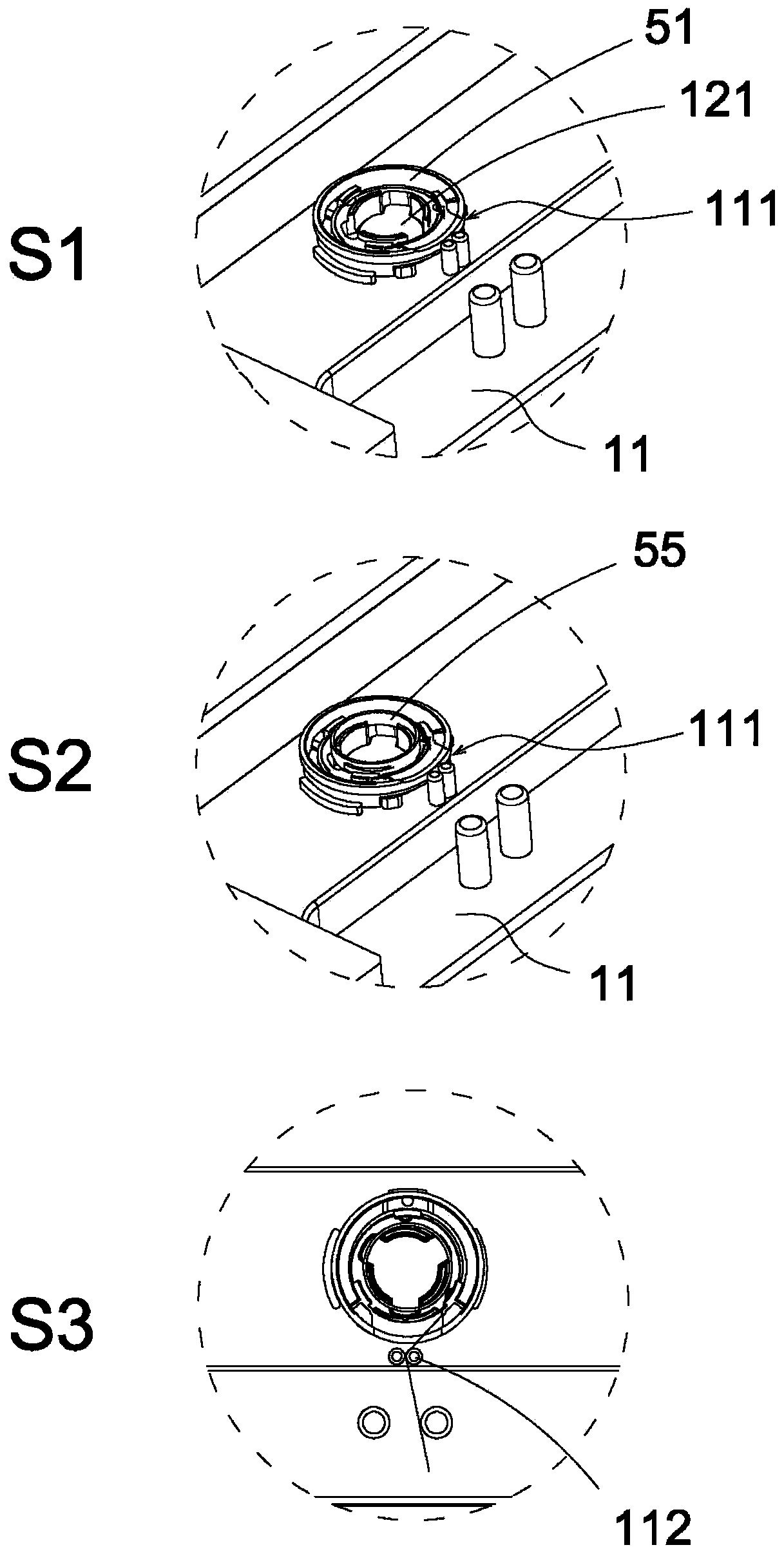

[0037] A horn processing jig, comprising a main assembly module 1, a diaphragm assembly module 2, a front cover assembly module 3, and a magnetic circuit carrier 4, the main assembly module 1 is provided with a bracket groove for accommodating a bracket 51 111, and the bracket top strip 121 for ejecting the bracket 51, the diaphragm assembly module 2 is provided with a diaphragm groove 211 for accommodating the diaphragm 52, and a diaphragm top strip 221 for ejecting the diaphragm 52 , the front cover assembly module 3 is provided with a front cover groove 311 for accommodating the front cover 53 and a front cover top bar 321 for ejecting the front cover 53, and the lower end of the magnetic circuit carrier plate 4 is provided with a magnetic circuit 54 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com