Control system of electrosparking equipment

A processing equipment and control system technology, applied in the field of EDM equipment control system, can solve the problems of increasing cost, prolonging the production process, and cumbersome process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

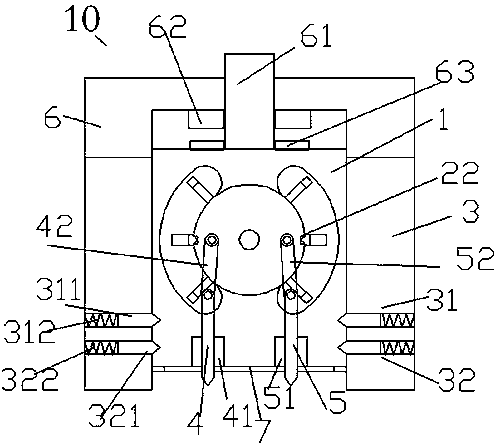

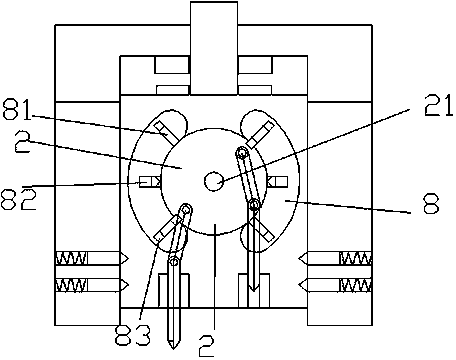

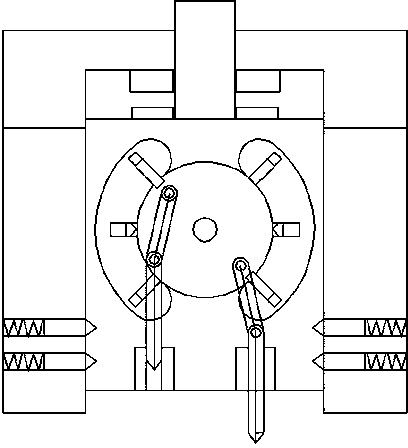

[0030] Refer below Figure 1-6 , describe the present invention in detail.

[0031]A control system for electric discharge machining equipment, which includes a controller, a main frame, an electric discharge machining head device 10, a front and rear moving motor 202, a front and rear moving block 200, and a left and right moving motor 201, and the front and rear directions and the left and right directions are In the direction perpendicular to each other in the horizontal plane, the front and rear direction moving motor 202 is fixedly connected with the main frame, which can drive the front and rear direction moving block 200 to move back and forth on the main frame, and the left and right direction moving motor 201 is fixedly connected with the front and rear direction moving block 200, which can drive The EDM head device 10 moves left and right on the front and rear moving block 200;

[0032] Described electrical discharge machining head device 10 comprises lower frame 3,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com