Patents

Literature

34results about How to "Rapid force" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Control system of electrosparking equipment

ActiveCN104209607ANo frequent replacementTake advantage ofElectrical-based auxillary apparatusControl systemElectrical discharge machining

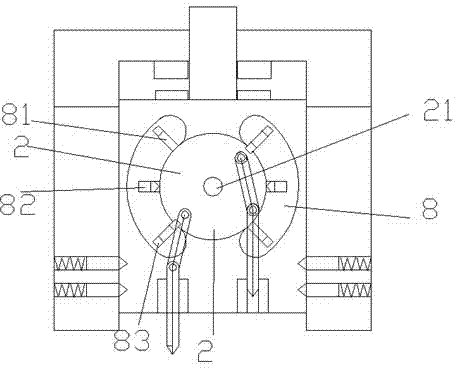

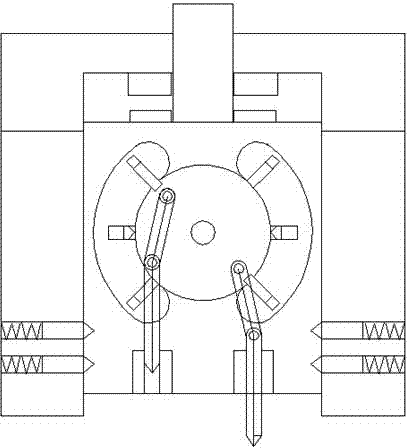

The invention provides a control system of electrosparking equipment. The control system comprises a controller, a main frame, an electrosparking head device (10), a front-and-rear moving motor (202), a front-and-rear moving block (200) and a left-and-right moving motor (201), wherein the front-and-rear direction and the left-and-right direction are perpendicular to each other in a horizontal plane; the front-and-rear moving motor (202) is fixedly connected with the main frame and is capable of driving the front-and-rear moving block (200) to move back and forth on the main frame; the left-and-right moving motor (201) is fixedly connected with the front-and-rear moving block (200) and is capable of driving the electrosparking head device (10) to move left and right on the front-and-rear moving block (200).

Owner:TANGSHAN ZHENGFENG IRON & STEEL CO LTD

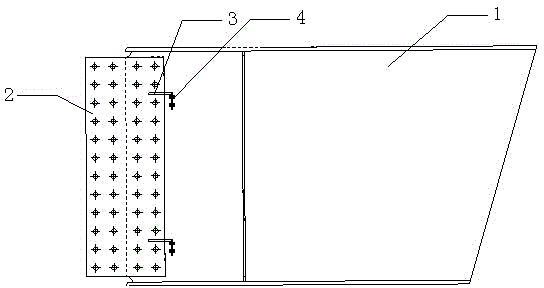

Locating-plate-based quick installation method for steel structure roof beam

InactiveCN106285015ASimple structureEasy to manufactureBuilding material handlingEngineeringMaterial Perforation

Owner:MCC5 GROUP CORP SHANGHAI

Machining process using electric spark machining equipment control system

InactiveCN104259601ANo frequent replacementTake advantage ofElectric circuitsControl systemForward backward

The invention relates to a machining process using a electric spark machining equipment control system. The system comprises a controller, a main frame, an electric spark machining head device (10), a forward-backward-direction moving motor (202), a forward-backward-direction moving block (200) and a leftward-rightward-direction moving motor (201). The forward and backward direction and the leftward and rightward direction are vertical to each other in a horizontal plane. The forward-backward-direction moving motor (202) is fixedly connected with the main frame and can drive the forward-backward-direction moving block (200) to move forwards and backwards on the main frame. The leftward-rightward-direction moving motor (201) is fixedly connected with the forward-backward-direction moving block (200) and can drive the electric spark machining head device (10) to move leftwards and rightwards on the forward-backward-direction moving block (200).

Owner:ZHEJIANG NORMAL UNIVERSITY

Electrosparking method

InactiveCN104259599ANo frequent replacementTake advantage ofElectrical-based machining electrodesEngineeringMechanical engineering

Owner:YANTAI POWER SUPPLY COMPANY OF STATE GRID SHANDONG ELECTRIC POWER +2

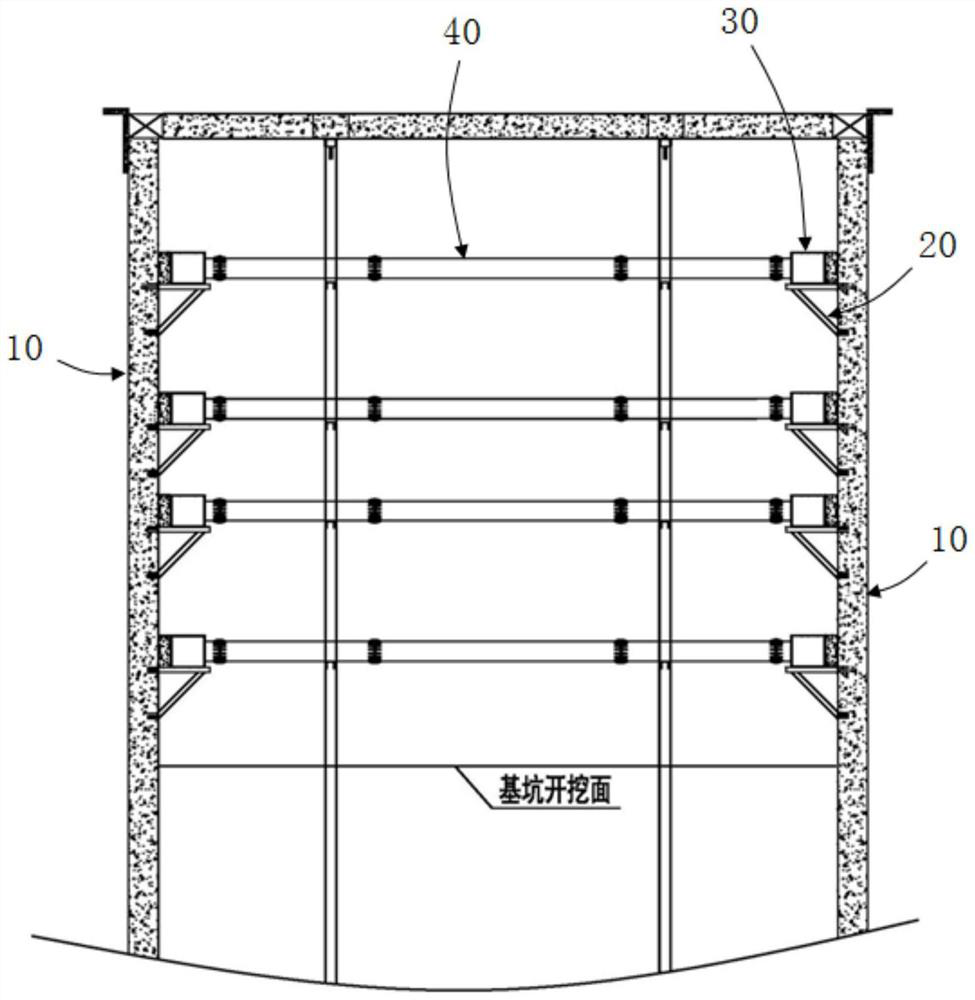

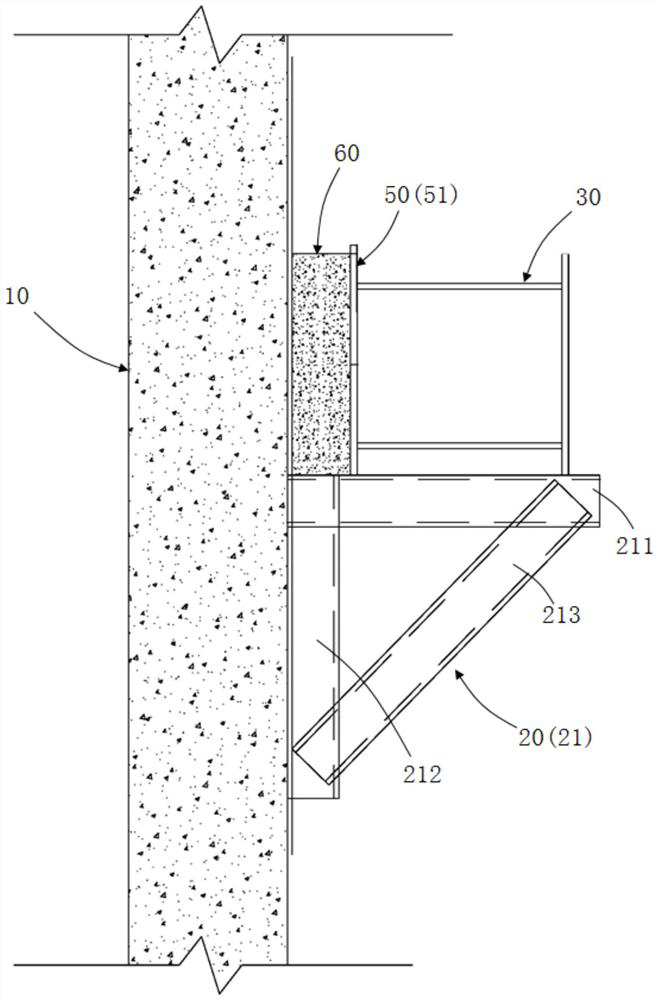

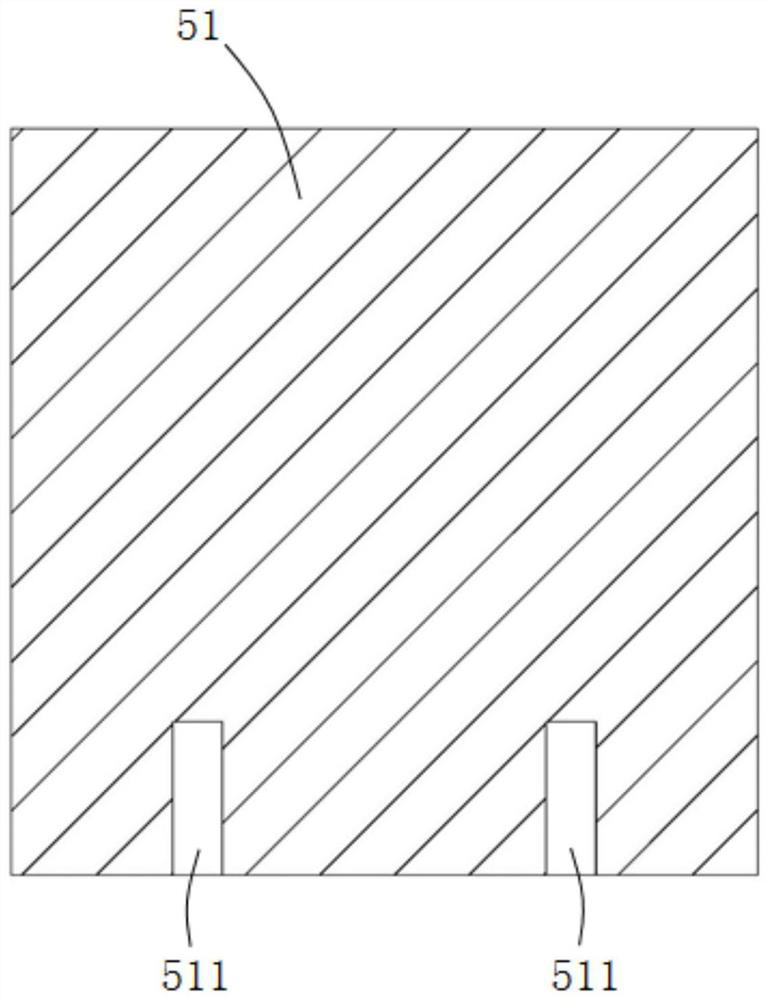

Connecting joint of steel support and underground diaphragm wall and correcting mold and construction method of connecting joint of steel support and underground diaphragm wall

ActiveCN114032914ASolve the problem of poor forming flatnessFast formingArtificial islandsHydro energy generationSupporting systemSlurry wall

The invention provides a connecting joint of a steel support and an underground diaphragm wall and a correcting mold and a construction method of the connecting joint of the steel support and the underground diaphragm wall, the connecting joint of the steel support and the underground diaphragm wall comprises the underground diaphragm wall, a supporting bracket and a steel supporting system, and the correcting mold is arranged on the supporting bracket and is connected between the underground diaphragm wall and the steel support system. Therefore, the correcting mold is arranged among the underground diaphragm wall, the supporting bracket and the steel support system, and a grouting material is injected between the correcting mold and the underground diaphragm wall, so that the uneven position of the wall surface of the underground diaphragm wall is filled, and the strength of the joint is rapidly formed; the node is uniformly stressed when an axial force compensation system is loaded, so that the steel support end part mounting node which does not need to pre-embed a steel plate, saves the time required by post-embedded parts and chiseling and leveling of an underground diaphragm wall and accelerates the forming speed of a support system is formed.

Owner:CHINA CONSTR EIGHT ENG DIV CORP LTD

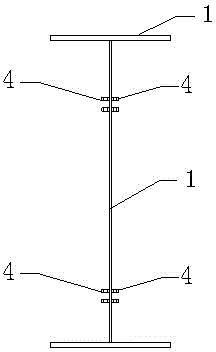

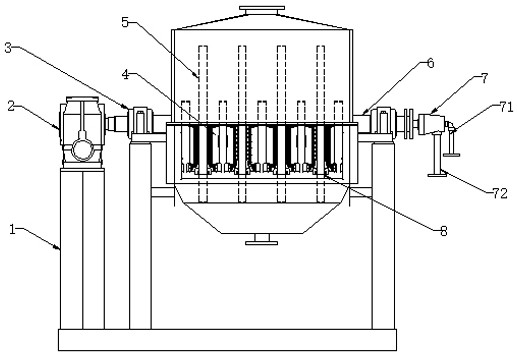

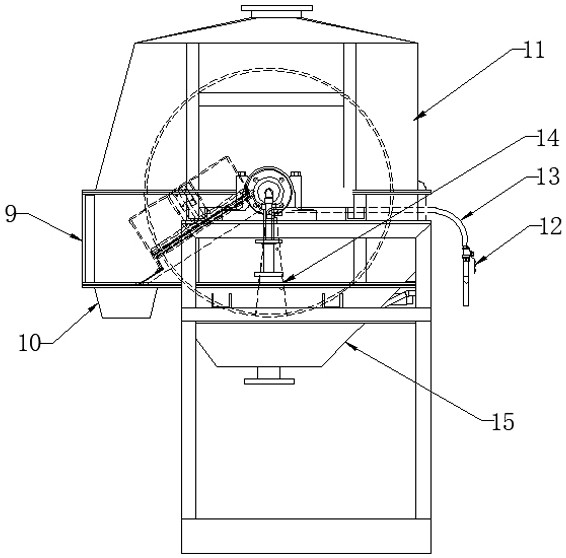

Electrosparking device

ActiveCN104259600ANo frequent replacementTake advantage ofElectrical-based machining electrodesElectrical-based auxillary apparatusEngineeringMechanical engineering

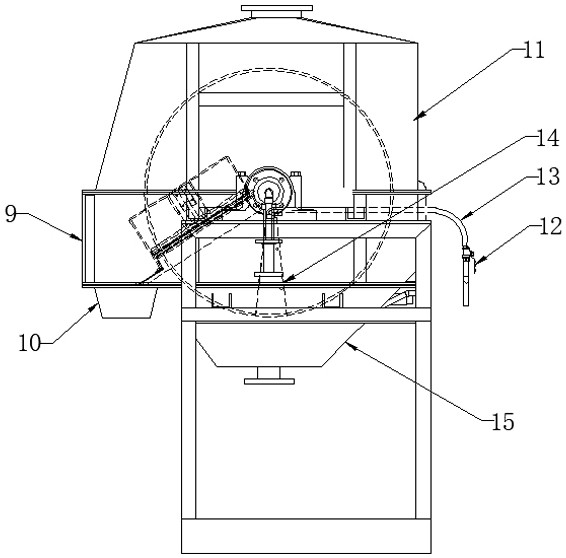

Disclosed is an electrosparking device which comprises an electrosparking head (10), a lifting device (101), an upright (102), a workbench (103), a workpiece (105) and a machining medium supplying device (104). The lifting device (101) can move up and down along the upright (102) to raise and lower the electrosparking head (10), the machining medium supplying device (104) is borne on the workbench (103), and the workpiece (105) is disposed in a machining medium in the machining medium supplying device (104).

Owner:TANGSHAN ZHENGFENG IRON & STEEL CO LTD

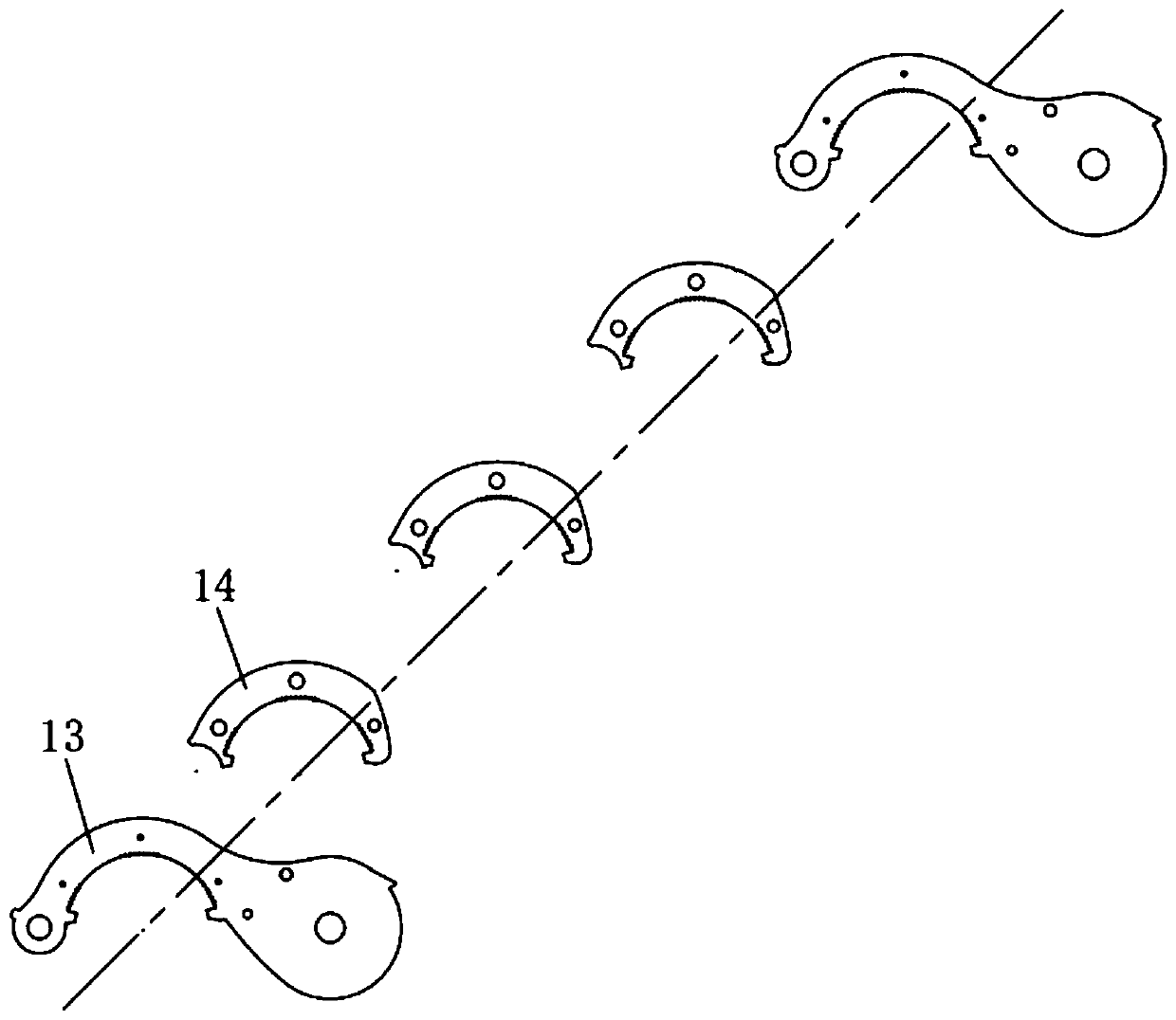

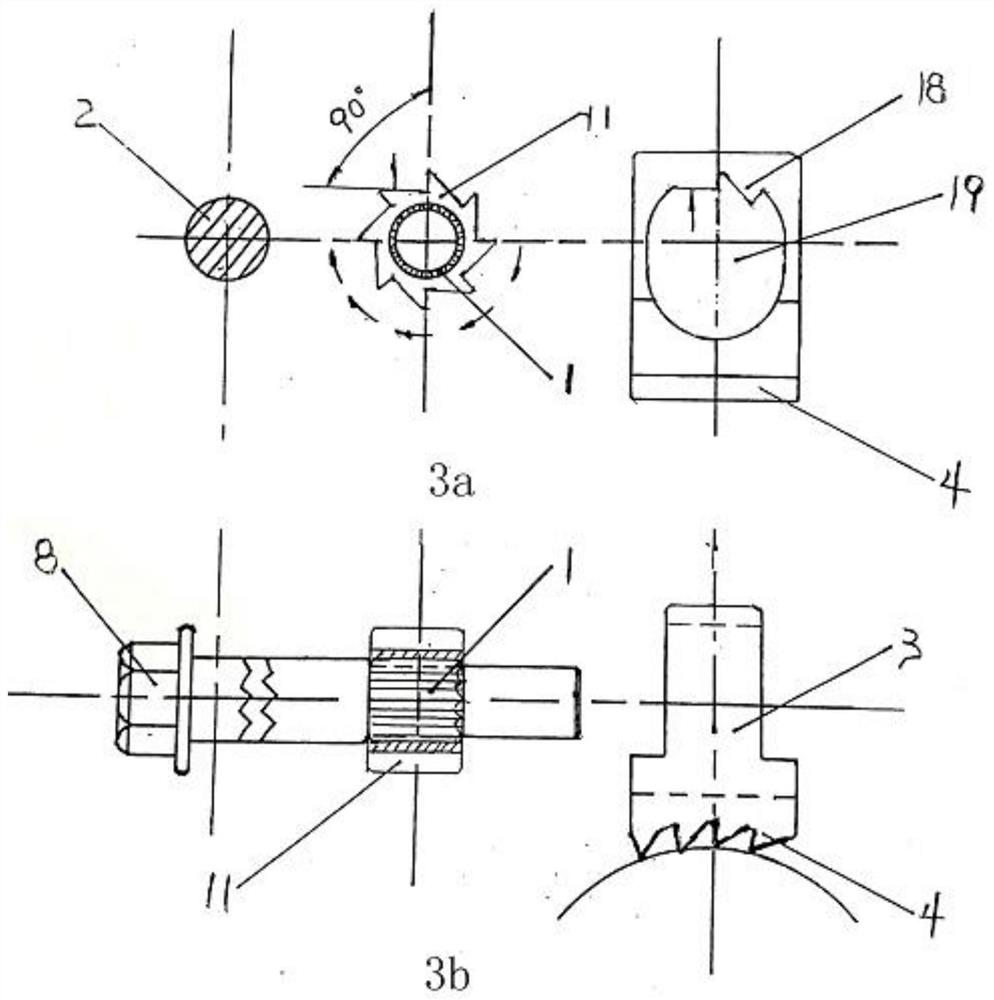

Gear type traceless pipe wrench and method

The invention discloses a gear type traceless pipe wrench and a method. The traceless pipe wrench comprises a jaw and a wrench handle, wherein the jaw comprises an upper jaw assembly and a lower jaw assembly, and the wrench handle comprises a rocking handle assembly; one end of the upper jaw assembly is hinged to the rocking handle assembly, the other end of the upper jaw assembly is hinged to thelower jaw assembly, and a large gear is fixedly arranged at the other end of the lower jaw assembly; a small gear is arranged at the hinged position of the upper jaw assembly and the rocking handle assembly; a return ratchet wheel is arranged on the right side of the small gear; and the upper jaw assembly and the lower jaw assembly each comprise a clamping part, and a rubber pad is arranged on the inner side wall of each clamping part. The working method of the traceless pipe wrench completes the construction of a pipe through a plurality of steps. According to the traceless pipe wrench, thegear combination is arranged, so that the holding force of the traceless pipe wrench is large in the construction process, and the slipping probability is small; the rubber pads are arranged, so thatthe surface of the pipe is effectively protected; and the return ratchet wheel is arranged, so that the jaw of the traceless pipe wrench can loosen the pipe when the traceless pipe wrench returns, thetraceless pipe wrench does not break away from the pipe, the force can be quickly applied when the pipe is screwed, and time and labor are saved.

Owner:威海港华燃气有限公司

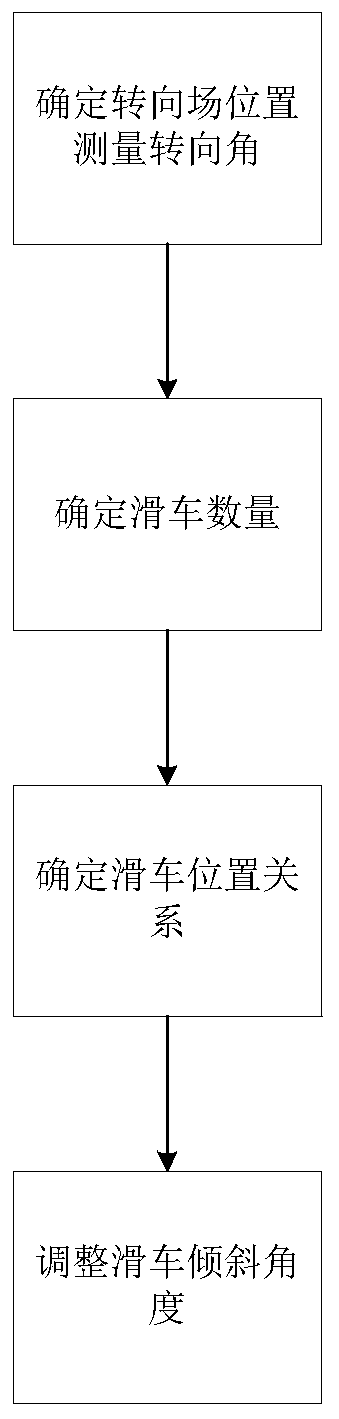

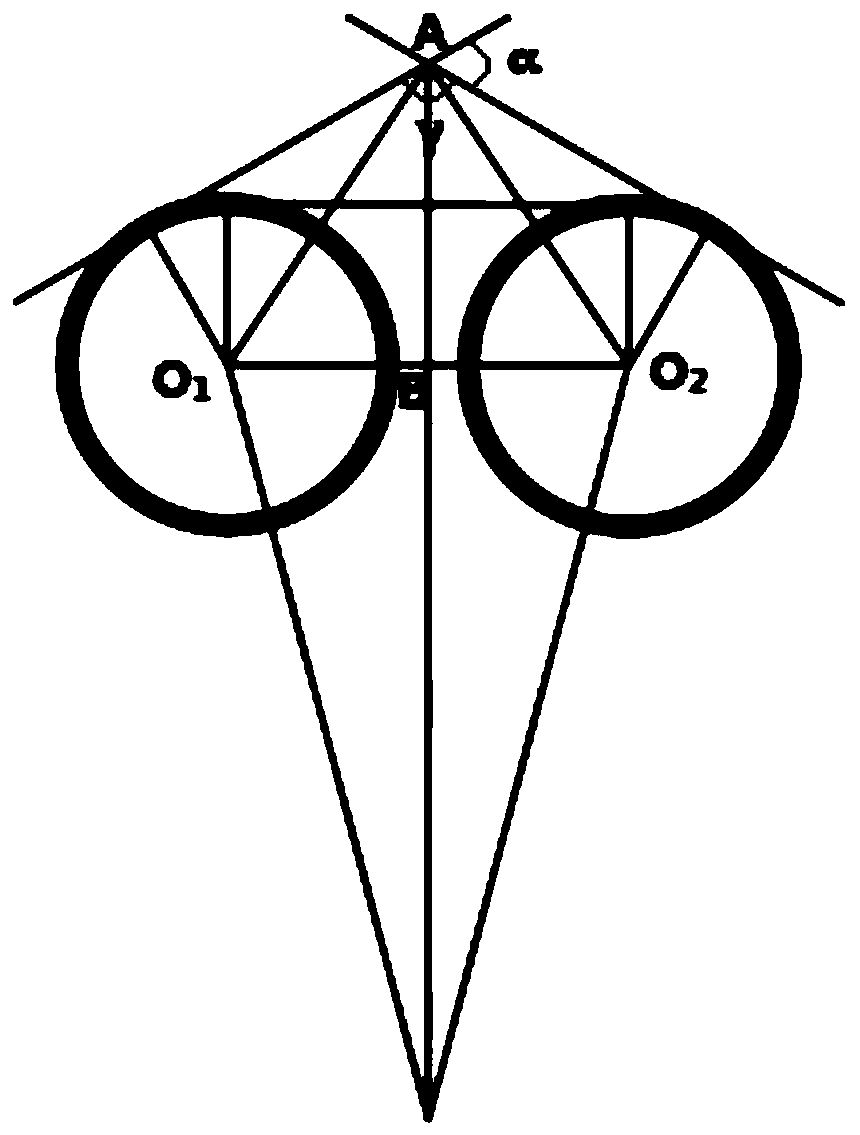

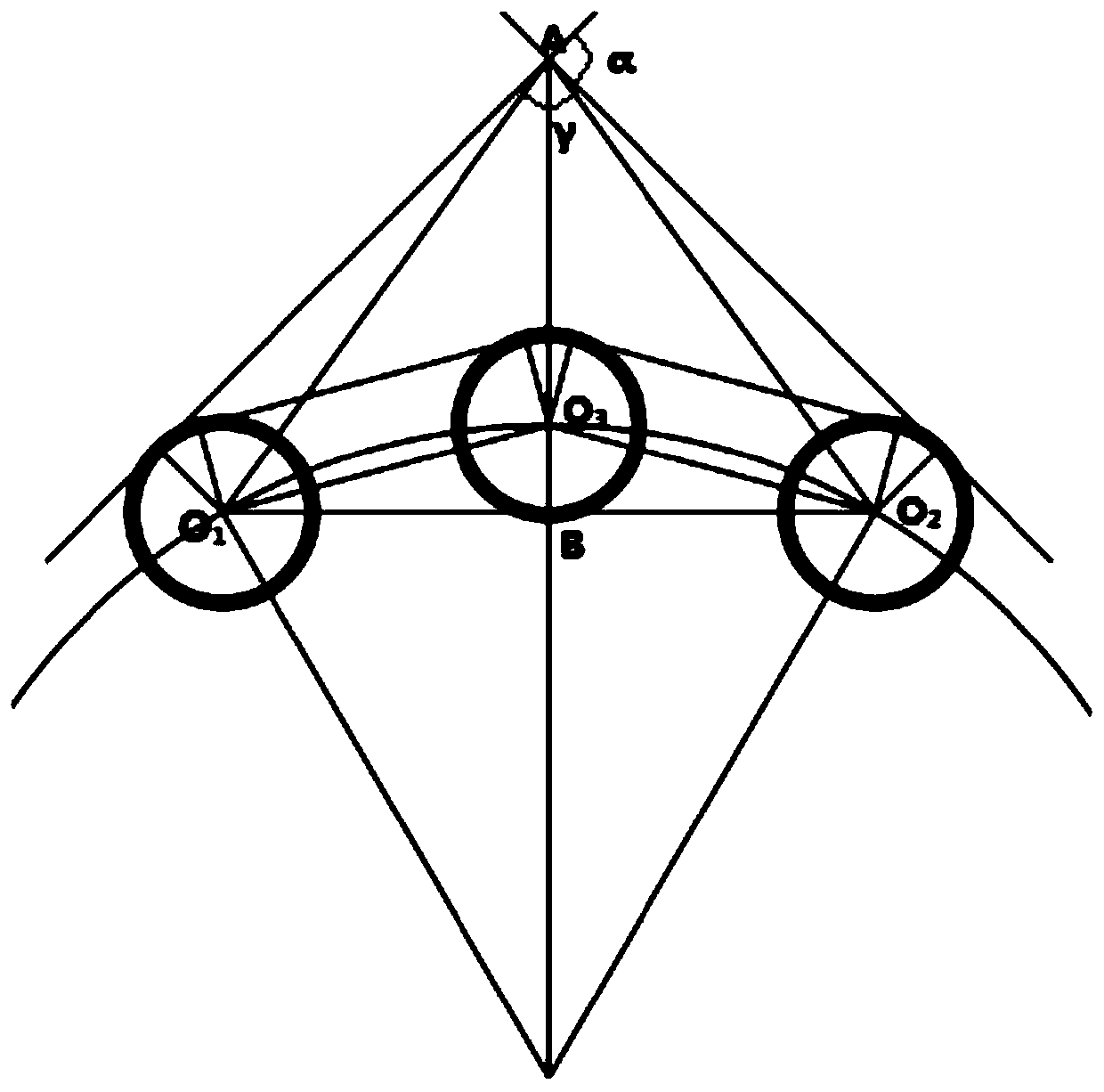

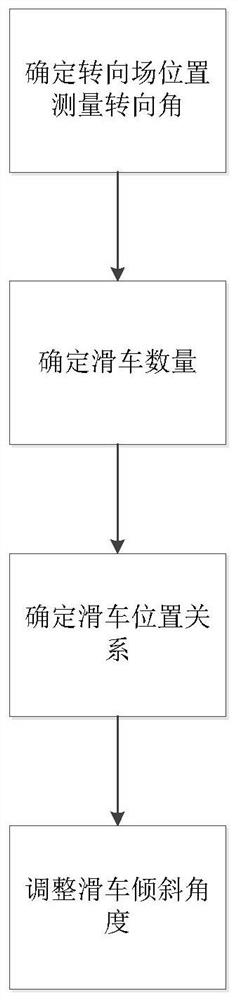

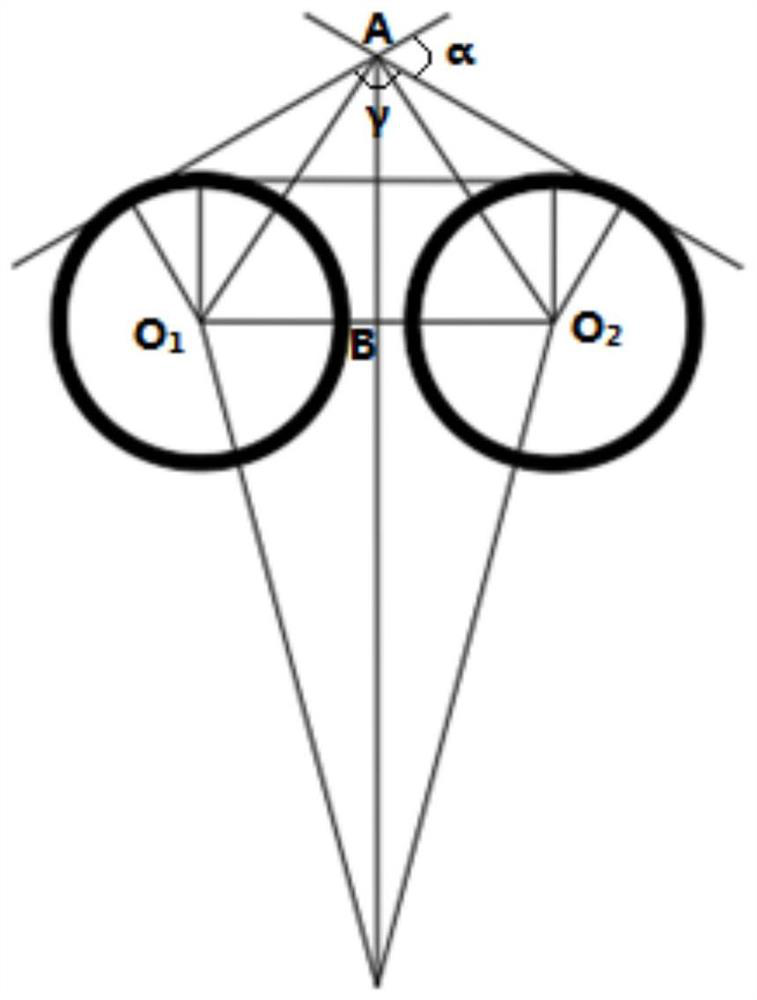

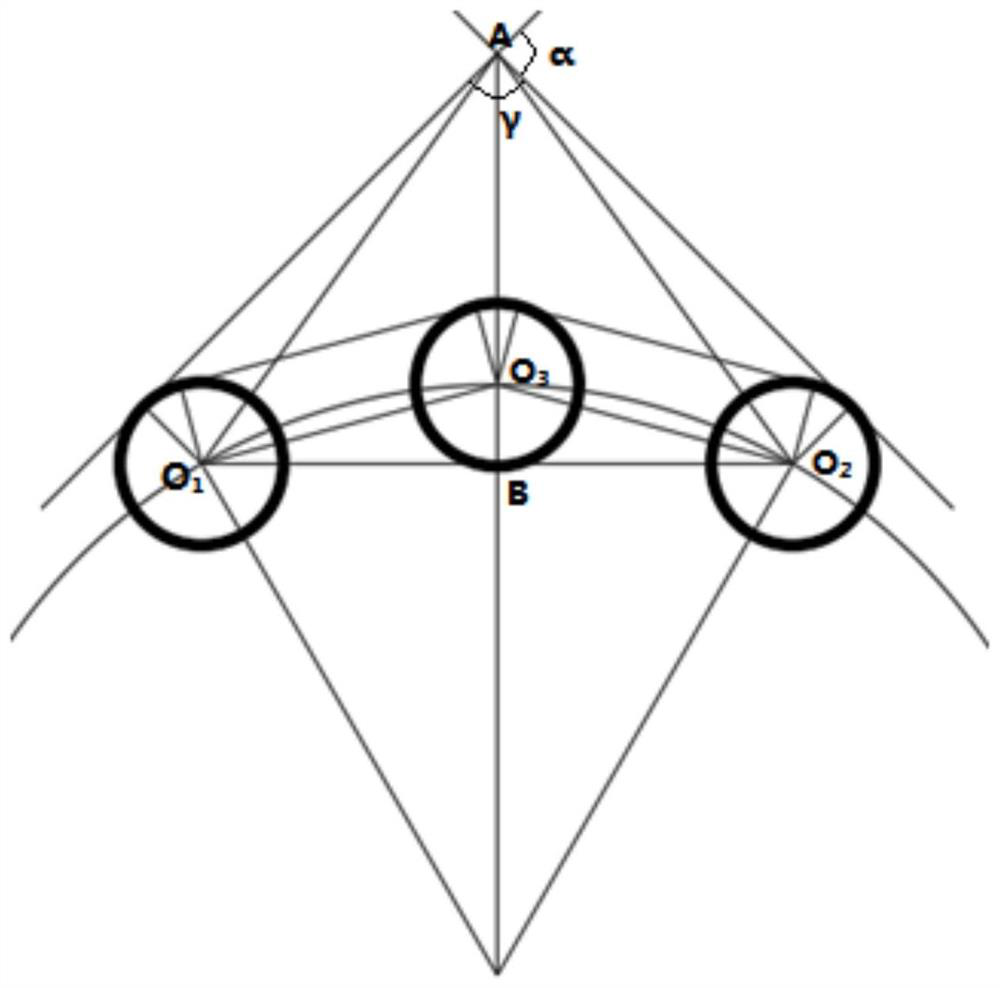

Multi-tackle arrangement method for steering field

ActiveCN110752550AEven by forceImprove stabilityApparatus for overhead lines/cablesSteering angleControl engineering

The invention discloses a multi-tackle arrangement method for a steering field, comprising the following steps: step 1, determining the position of the steering field according to the positions of a traction field and a tension field, and measuring a steering angle alpha; step 2, determining the number of tackles in the steering field according to the steering angle alpha; and step 3, determiningthe positional relationship of each tackle according to the steering angle alpha and the number of tackles. After the steering angle is determined, the number of tackles can be quickly determined andthe relative position of each tackle can be further determined, so that when the steering field is arranged, only a small number of individual tackles need to be carried, which significantly reduces the transportation and installation costs. The steering field can be arranged flexibly and normatively according to the actual steering angle. On the premise of meeting the requirements of special terrains in mountainous areas, the envelop angles of the tackles are equal, and the tackles are stressed uniformly, so that the operational safety of the steering field is improved, and the tackles and cables are effectively protected.

Owner:SICHUAN POWER TRANSMISSION & TRANSFORMATION CONSTR

Control system of electrosparking device

InactiveCN104209609ANo frequent replacementTake advantage ofElectrical-based auxillary apparatusControl systemEmbedded system

The invention provides a control system of an electrosparking device. The control system comprises a controller, an electrosparking head (10), a lifting device (101), an upright column (102), a workbench (103), a workpiece (105) and a processing medium supplying device (14), wherein the lifting device (101) is capable of moving up and down along the upright column (102) so as to enable the electrosparking head (10) to ascend and descend; the processing medium supplying device (104) is supported on the workbench (103); the workpiece (105) is put in a processing medium in the processing medium supplying device (104).

Owner:STATE GRID CORP OF CHINA +1

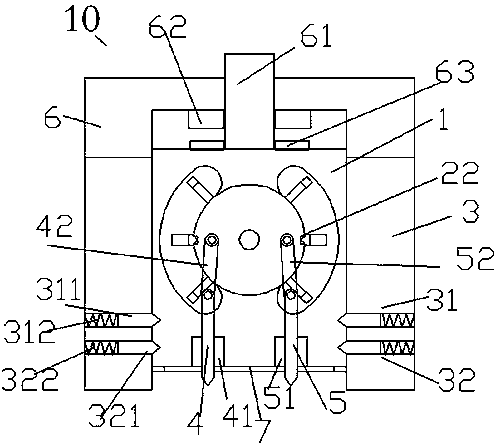

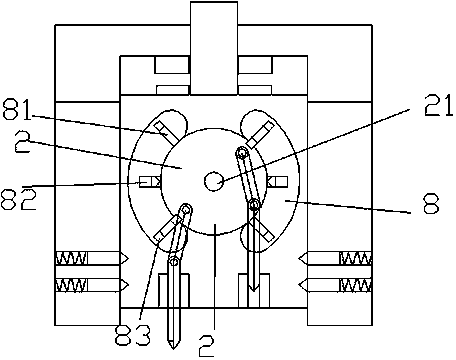

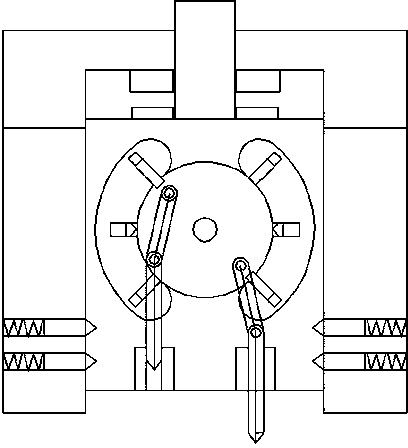

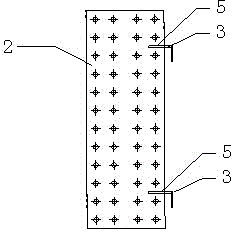

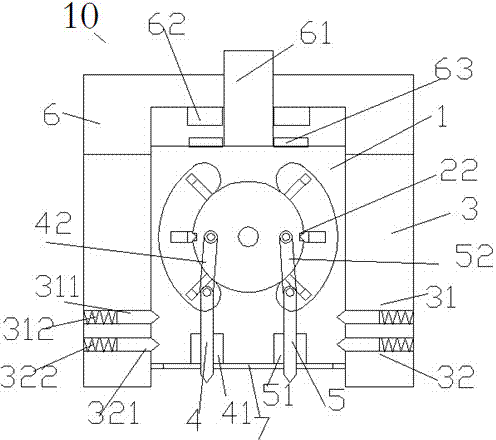

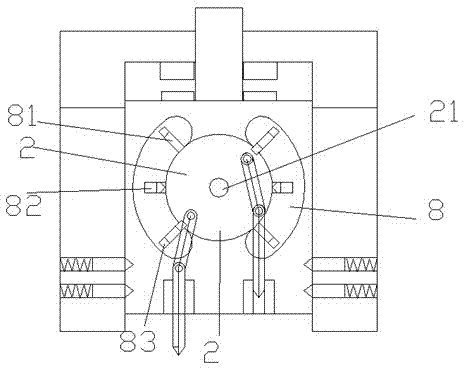

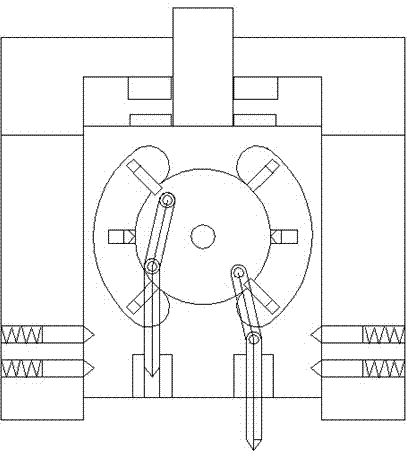

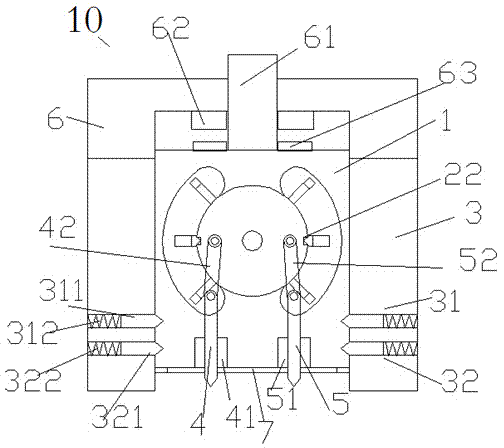

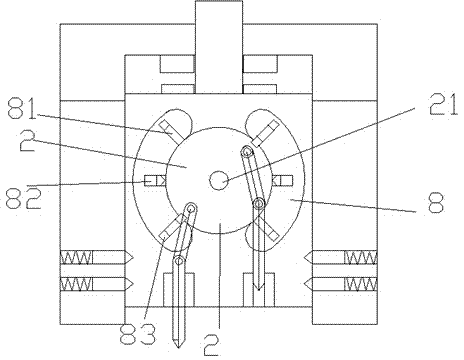

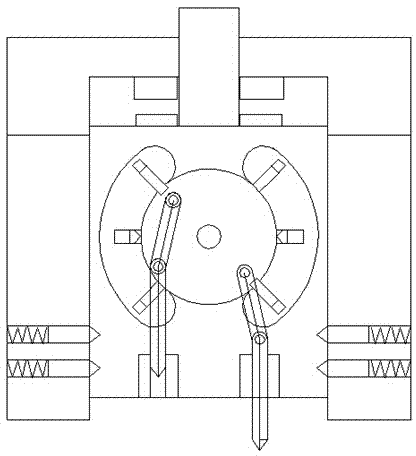

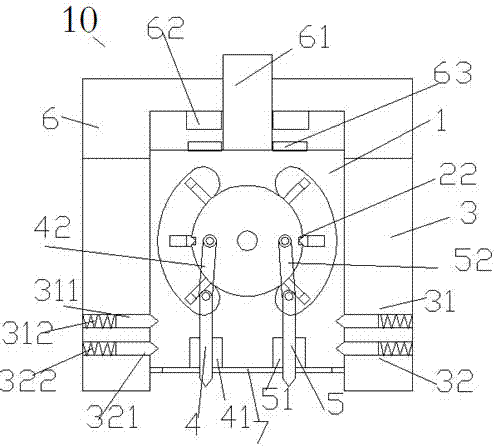

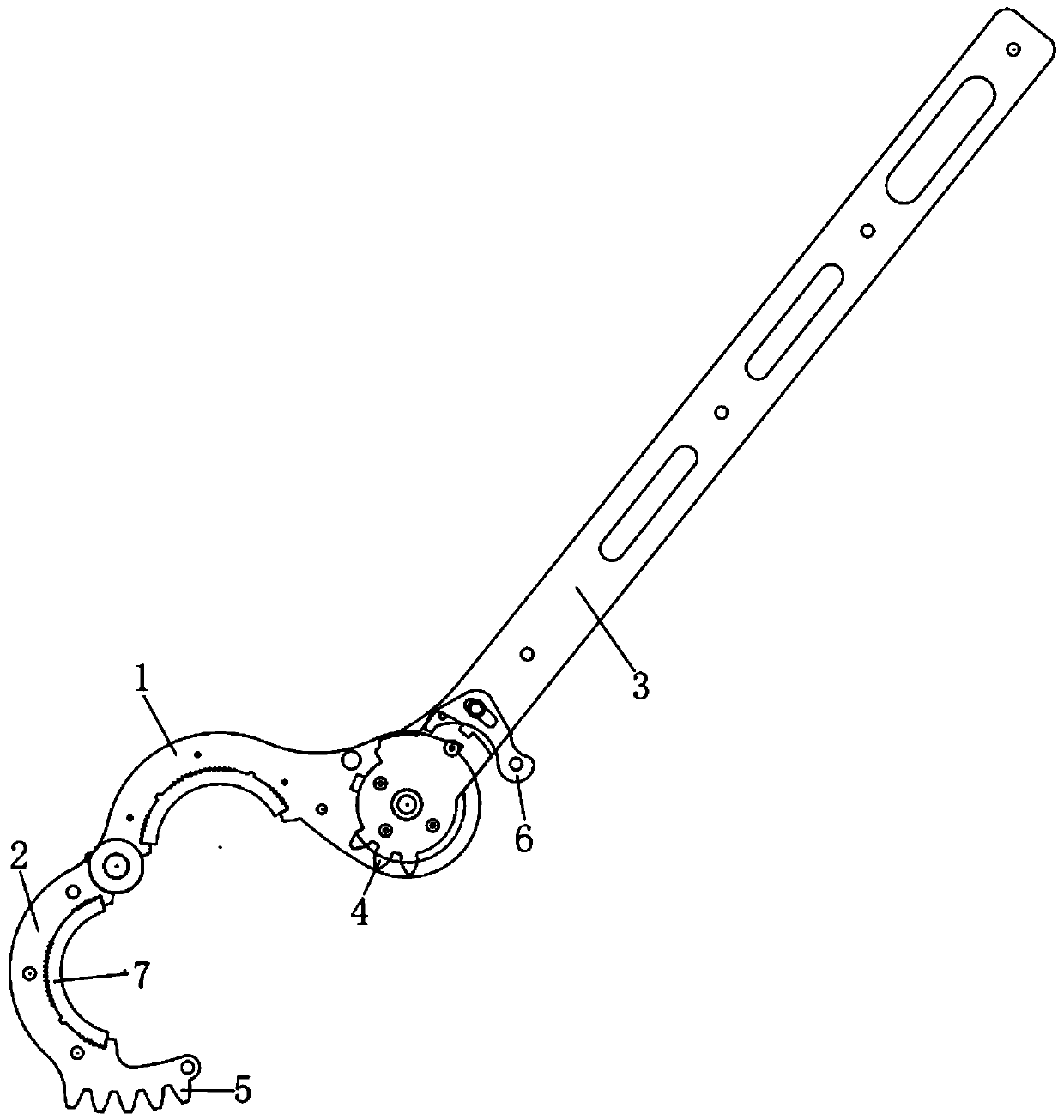

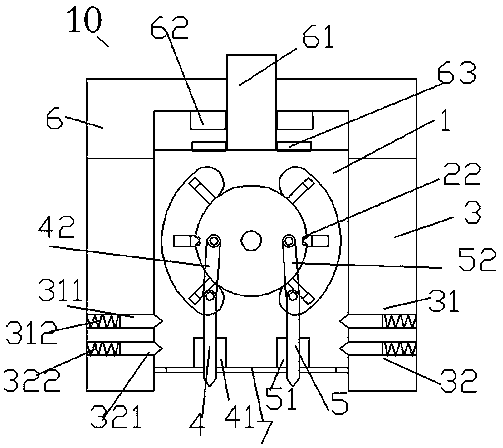

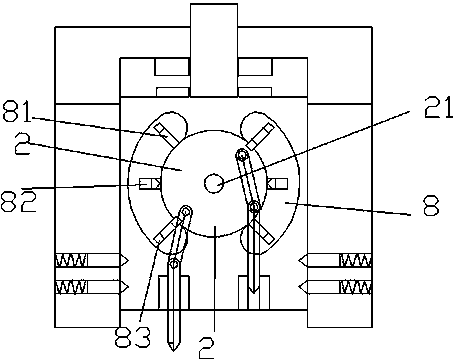

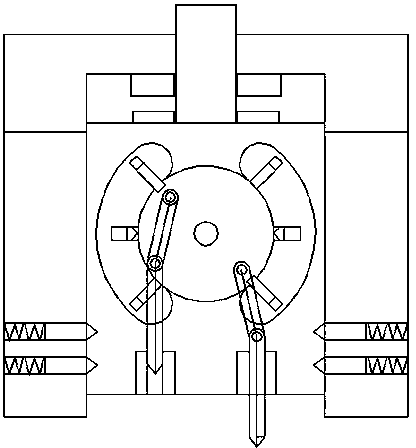

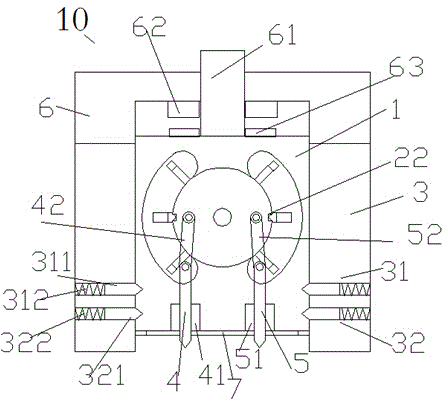

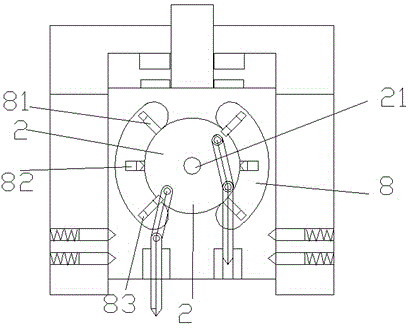

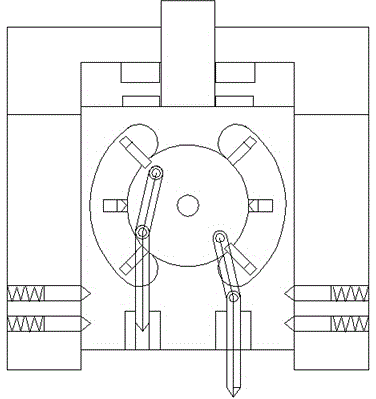

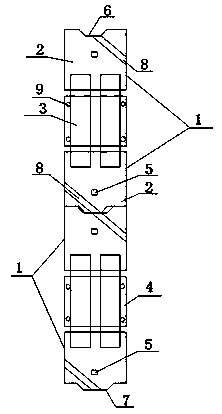

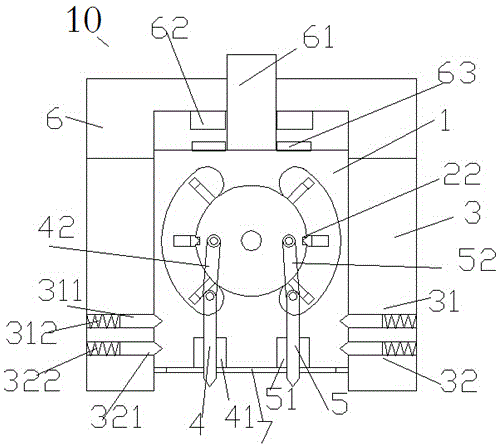

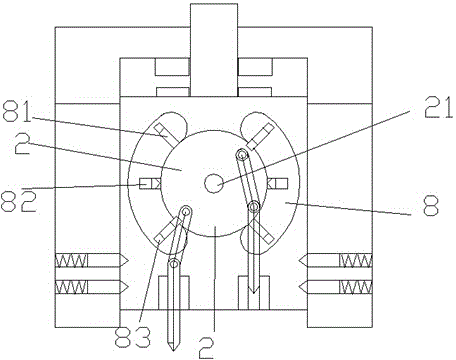

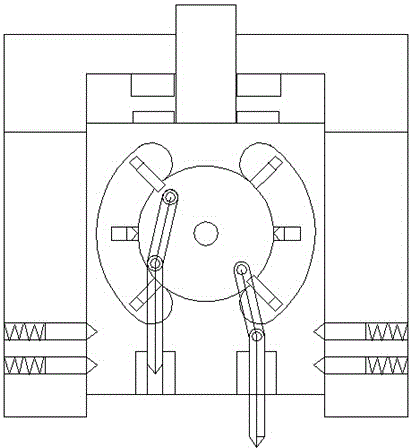

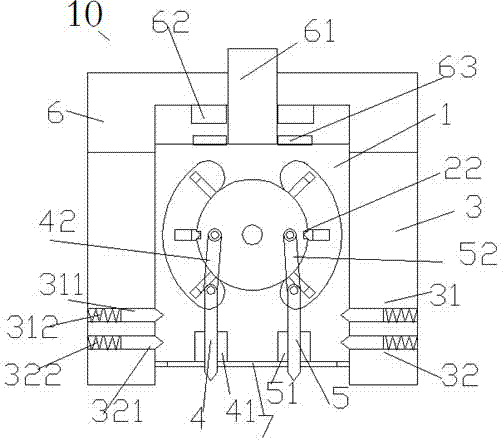

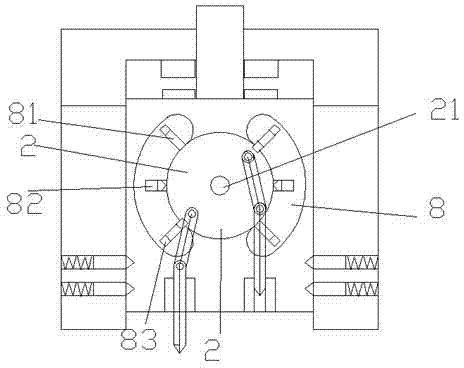

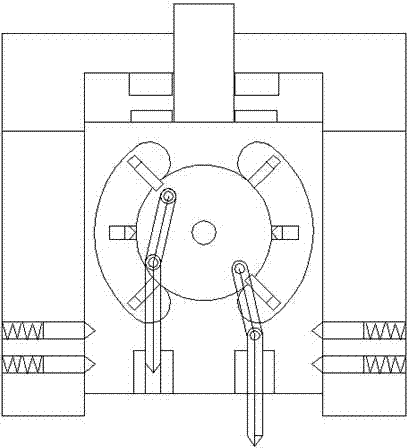

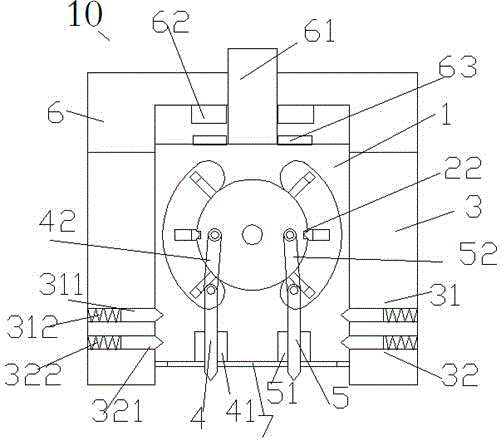

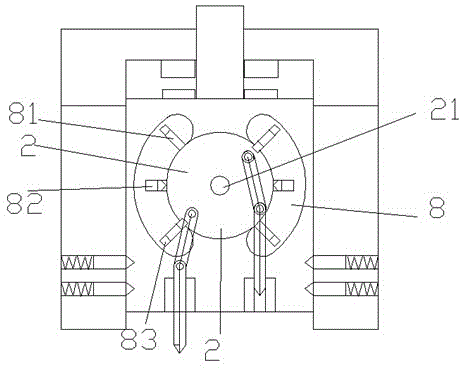

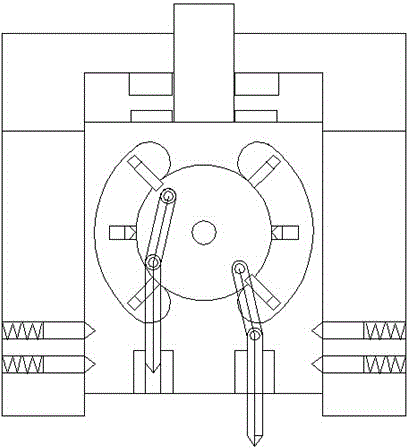

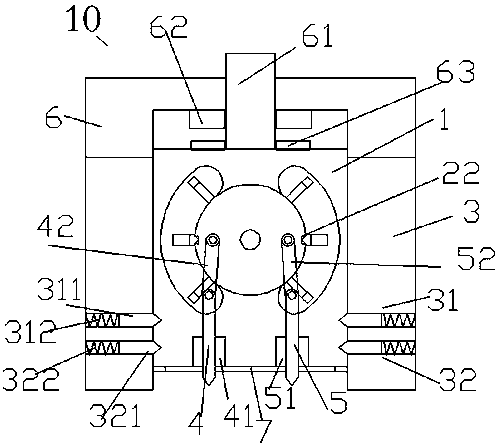

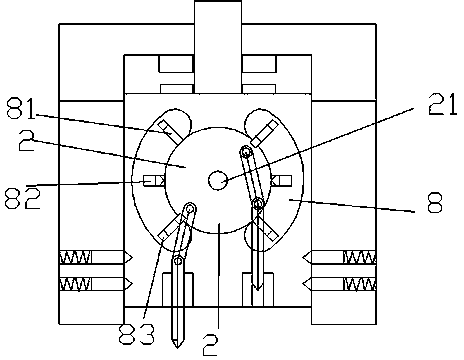

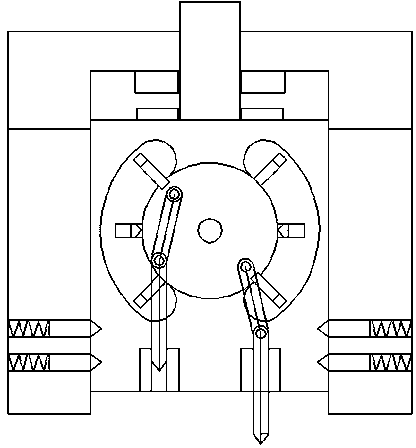

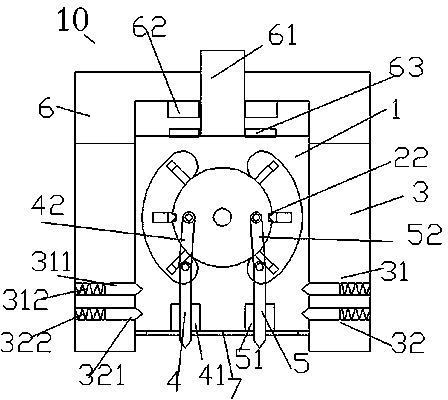

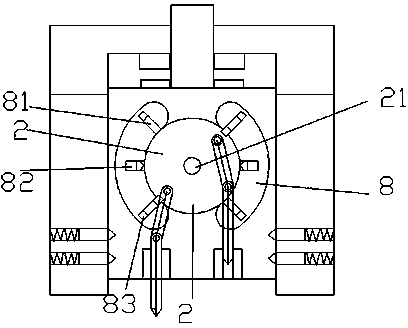

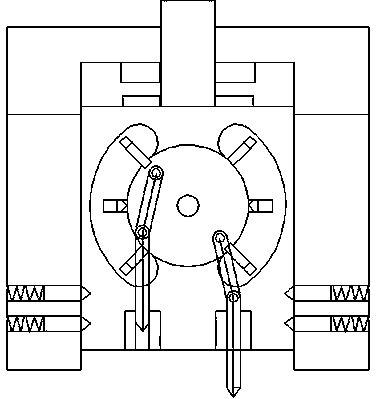

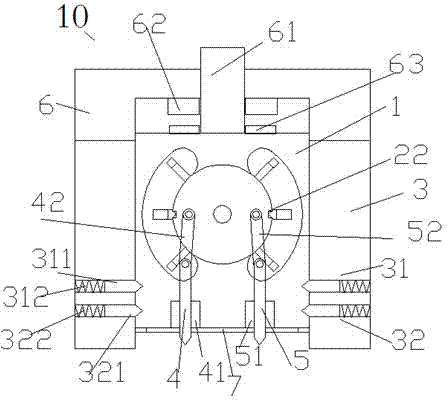

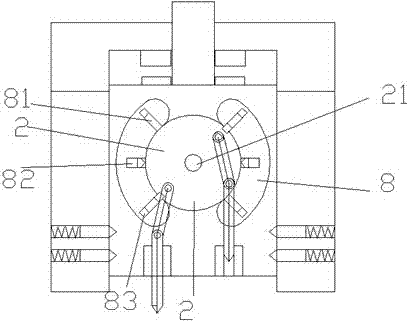

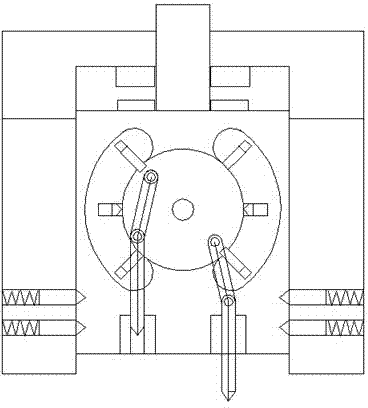

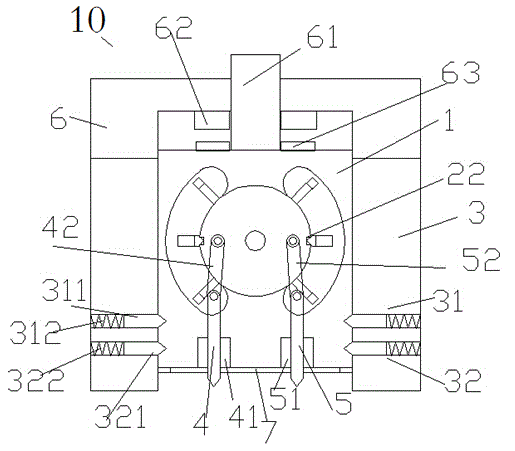

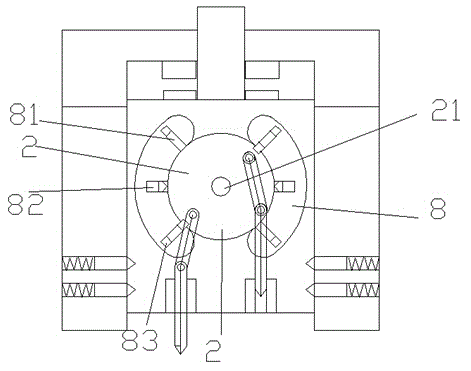

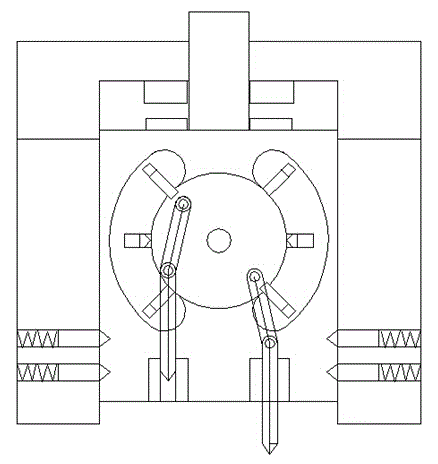

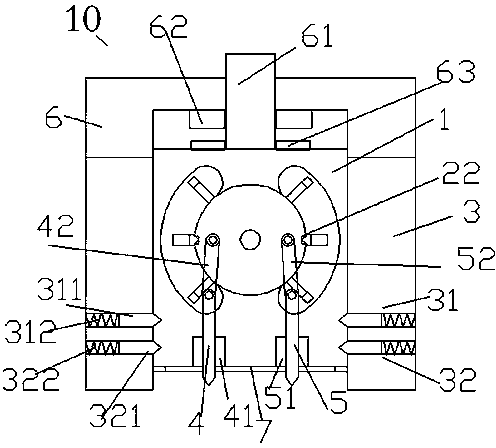

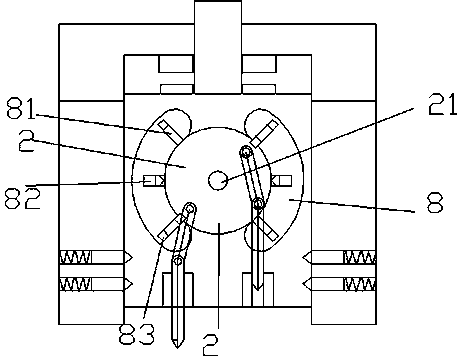

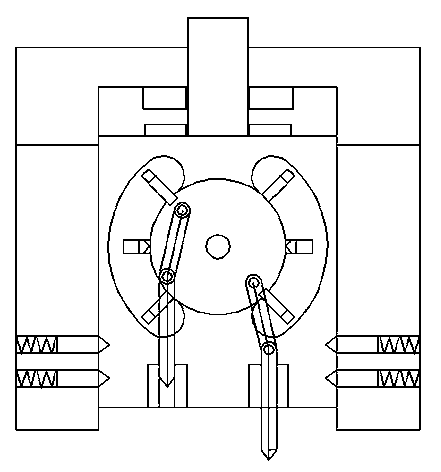

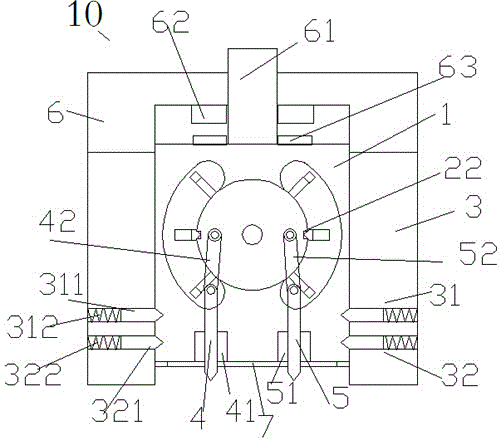

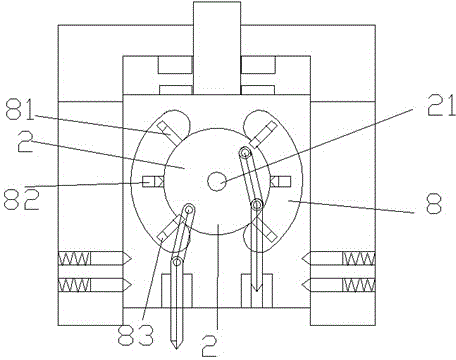

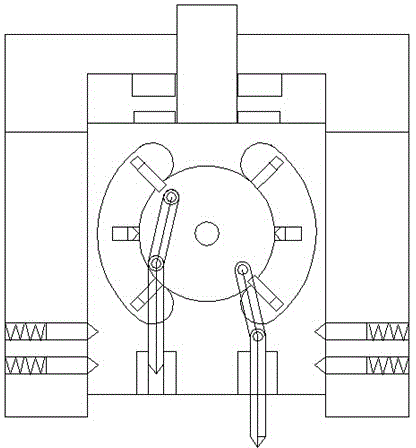

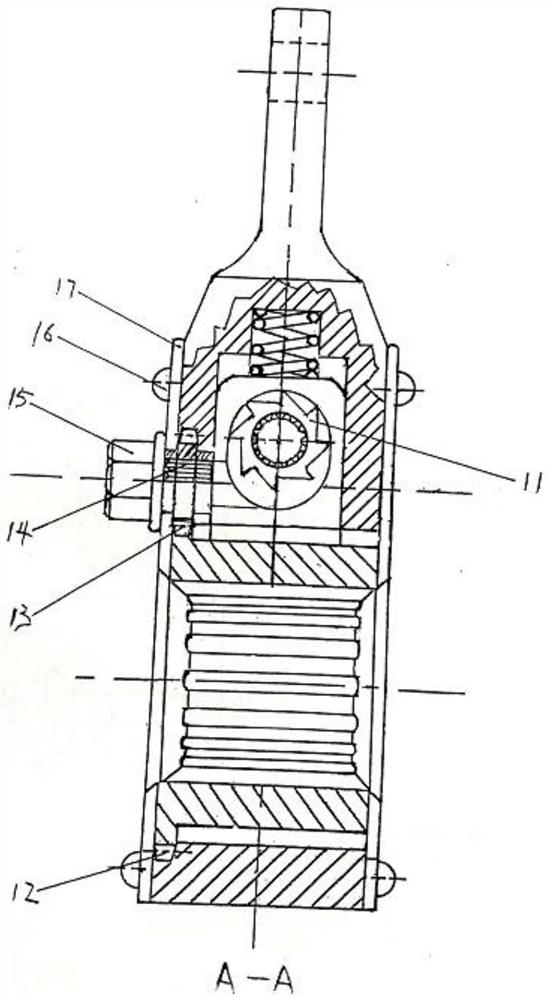

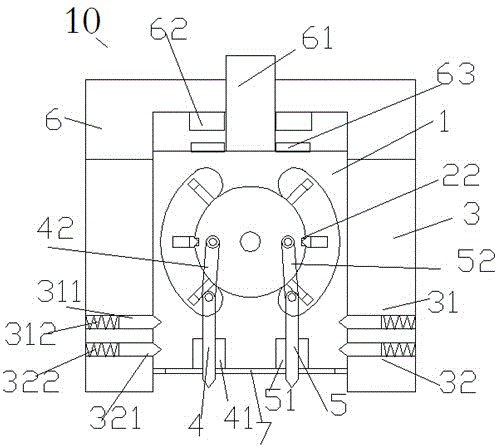

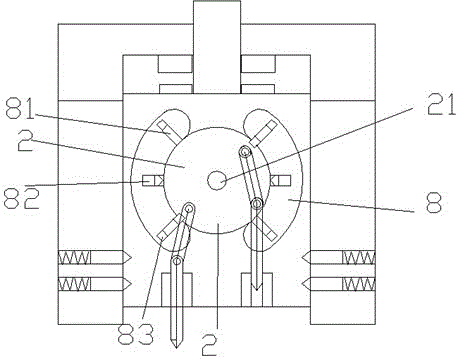

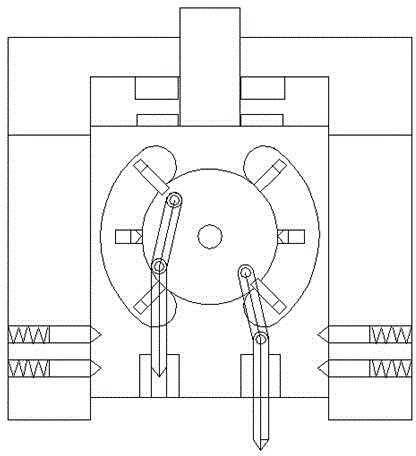

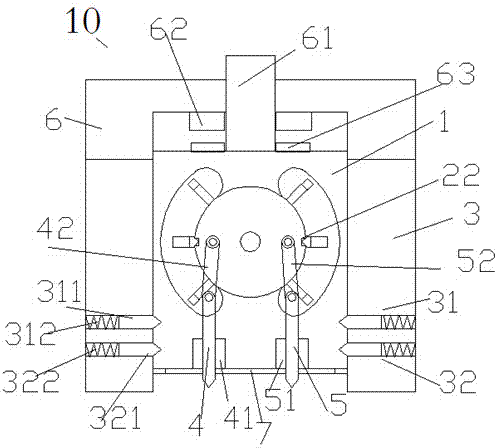

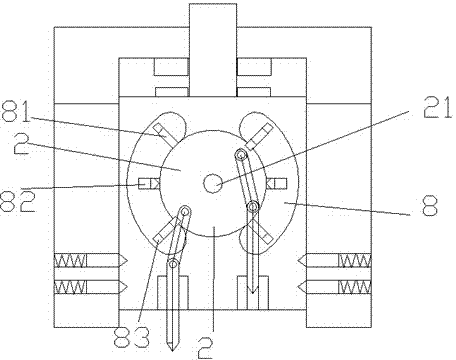

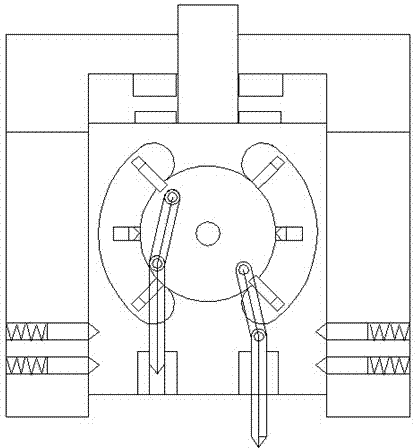

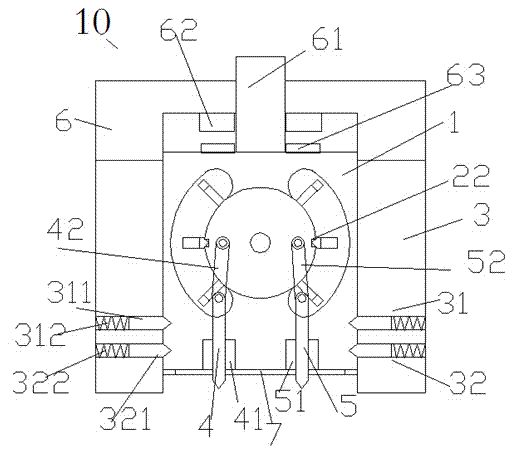

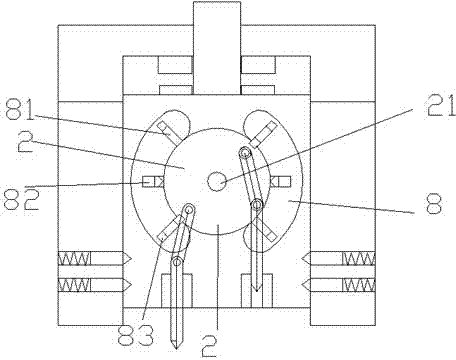

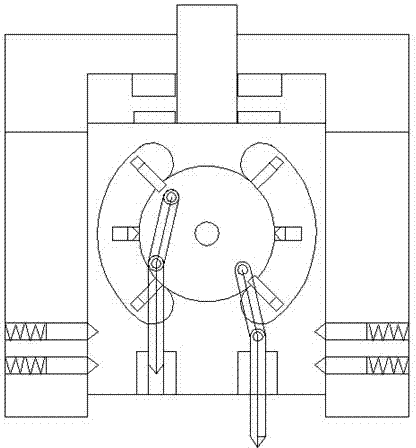

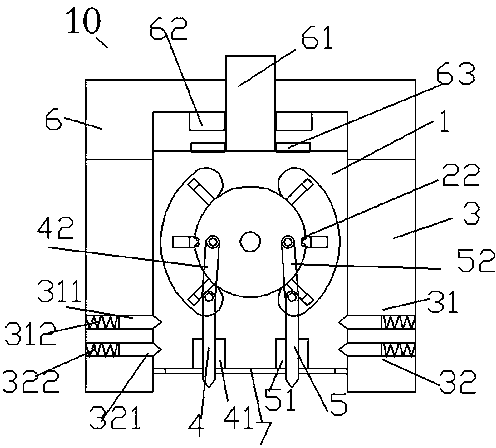

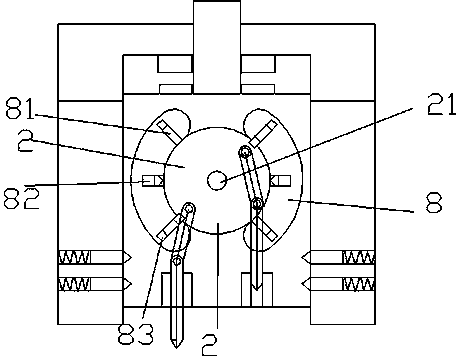

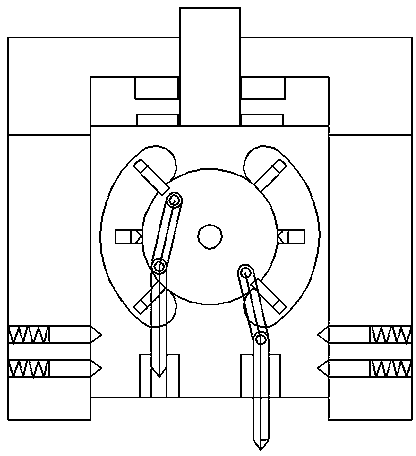

Electrosparking head device

InactiveCN104209610BNo frequent replacementTake advantage ofElectrical-based auxillary apparatusEngineeringElectrical discharge machining

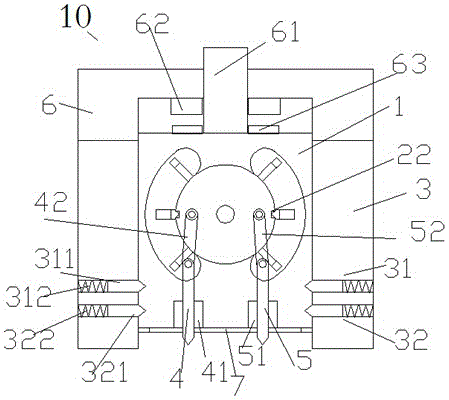

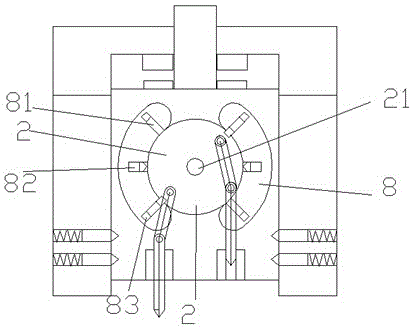

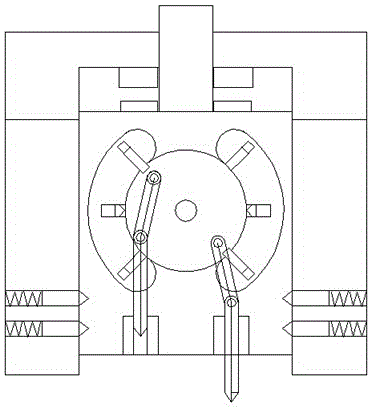

The invention provides an electrosparking head device which comprises a lower rack (3), an upper rack (6) and an inner rack (1), wherein the upper rack (6) is positioned above the lower rack (3); the inner rack (1) is positioned in a chamber formed by the lower rack (3) and the upper rack (6) and can slide up and down; the inner side of the upper part of the upper rack and the upper side of the inner rack (1) are respectively provided with an electromagnetic coil (62) and a magnet (63) which are coupled with each other so as to drive the inner rack (1) to slide; the lower parts of two side walls of the lower rack are symmetrically provided with an upper wedge surface locating pin (31) and a lower wedge surface locating pin (32) in each side wall; the lower parts of two sides of the inner rack (1) are respectively, correspondingly and symmetrically provided with an upper cotterway and a lower cotterway; when the inner rack (1) is in an upper working state, the upper wedge surface locating pin (31) is matched with the upper cotterway.

Owner:SHANGHAI MUNICIPAL ELECTRIC POWER CO +1

Precast cushion block coupling beam structure erected in soft soil layer tunnel, and construction method

PendingCN111101970AImprove structural rigidityRapid forceUnderground chambersTunnel liningSocial benefitsArchitectural engineering

The invention belongs to the technical field of tunnel construction, and particularly relates to a precast cushion block coupling beam structure erected in a soft soil layer tunnel, and a constructionmethod. The precast cushion block coupling beam structure erected in the soft soil layer tunnel comprises a plurality of precast concrete cushion blocks connected end to end, wherein each precast concrete cushion block comprises two symmetrical concrete cushion blocks; each two concrete cushion blocks are connected through a support steel member; steel plates are fixedly connected above the support steel members; a plurality of lock foot guide pipe guiding holes are reserved in the concrete cushion blocks; and the outer surfaces of the concrete cushion blocks are roughened. The precast cushion block coupling beam structure provided by the invention solves the safety problems such as sedimentation, and is remarkable in effect, high in operability, and remarkable in economic benefit and social benefit.

Owner:JINAN URBAN CONSTR GRP +2

A control system of an electric discharge machining device

InactiveCN104209609BNo frequent replacementTake advantage ofElectrical-based auxillary apparatusElectricityElectric discharge

Owner:STATE GRID CORP OF CHINA +1

Processing technology utilizing electrosparking device control system

InactiveCN104289772ANo frequent replacementTake advantage ofElectrical-based machining electrodesElectrical-based auxillary apparatusControl systemEmbedded system

Disclosed is a processing technology utilizing an electrosparking device control system. A device comprises an electrosparking head (10), a lifting device (101), a stand column (102), a workbench (103), a workpiece (105) and a processing medium providing device (104). The lifting device (101) can vertically move along the stand column (102), therefore, the electrosparking head (10) can ascend and descend, the processing medium providing device (104) is borne on the workbench (103), and the workpiece (105) is arranged in processing media in the processing medium providing device (104).

Owner:YANTAI POWER SUPPLY COMPANY OF STATE GRID SHANDONG ELECTRIC POWER +2

A Machining Technology Utilizing the Control System of Electric Discharge Machining Device

InactiveCN104289772BNo frequent replacementTake advantage ofElectrical-based machining electrodesElectrical-based auxillary apparatusControl systemEmbedded system

Disclosed is a processing technology utilizing an electrosparking device control system. A device comprises an electrosparking head (10), a lifting device (101), a stand column (102), a workbench (103), a workpiece (105) and a processing medium providing device (104). The lifting device (101) can vertically move along the stand column (102), therefore, the electrosparking head (10) can ascend and descend, the processing medium providing device (104) is borne on the workbench (103), and the workpiece (105) is arranged in processing media in the processing medium providing device (104).

Owner:YANTAI POWER SUPPLY COMPANY OF STATE GRID SHANDONG ELECTRIC POWER +2

A kind of electric discharge machining equipment

InactiveCN104209608BNo frequent replacementTake advantage ofElectrical-based auxillary apparatusElectric dischargeEngineering

The invention relates to electric spark machining equipment. The electric spark machining equipment comprises a main frame, an electric spark machining head device (10), a front-back moving motor (202), a front-back moving block (200) and a left-right moving motor (201), wherein a front-back direction is vertical to a left-right direction in a horizontal plane; the front-back moving motor (202) is fixedly connected with the main frame, and can be used for driving the front-back moving block (200) to move forwards and backwards on the main frame; the left-right moving motor (201) is fixedly connected with the front-back moving block (200), and can be used for driving the electric spark machining head device (10) to move leftwards and rightwards on the front-back moving block (200).

Owner:江华瑶族自治县金牛开发建设有限公司

A multi-tackle layout method for steering field

ActiveCN110752550BEven by forceReduce transportation and installation costsApparatus for overhead lines/cablesSteering angleControl engineering

The invention discloses a multi-tackle arrangement method for a steering field, comprising the following steps: step 1, determining the position of the steering field according to the positions of a traction field and a tension field, and measuring a steering angle alpha; step 2, determining the number of tackles in the steering field according to the steering angle alpha; and step 3, determiningthe positional relationship of each tackle according to the steering angle alpha and the number of tackles. After the steering angle is determined, the number of tackles can be quickly determined andthe relative position of each tackle can be further determined, so that when the steering field is arranged, only a small number of individual tackles need to be carried, which significantly reduces the transportation and installation costs. The steering field can be arranged flexibly and normatively according to the actual steering angle. On the premise of meeting the requirements of special terrains in mountainous areas, the envelop angles of the tackles are equal, and the tackles are stressed uniformly, so that the operational safety of the steering field is improved, and the tackles and cables are effectively protected.

Owner:SICHUAN POWER TRANSMISSION & TRANSFORMATION CONSTR

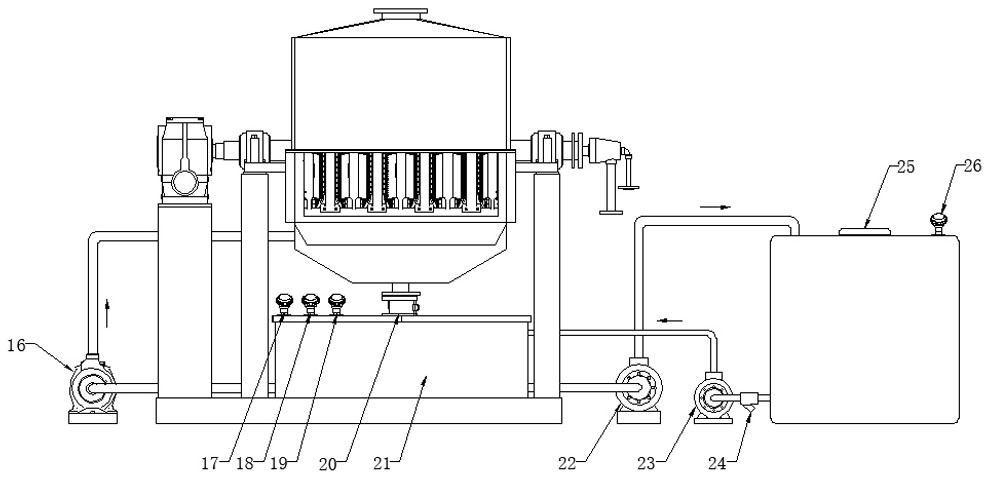

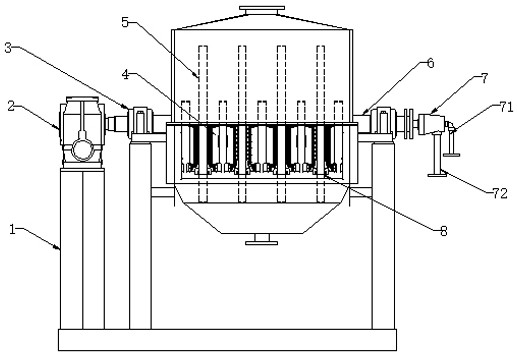

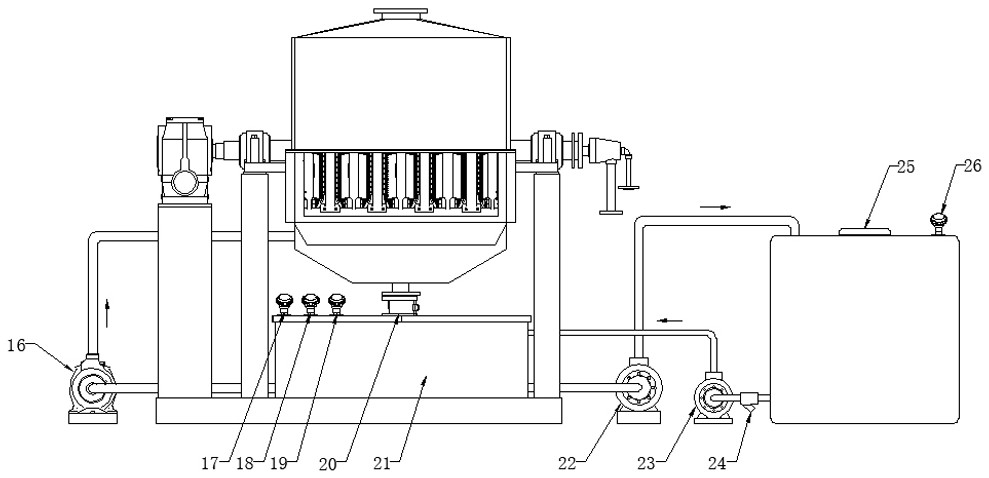

Disc scraper drying device

ActiveCN112209464AExtended service lifeAvoid cloggingSpecific water treatment objectivesWater distributersCircular discLiquid storage tank

The invention discloses a disc scraper drying device. The device comprises a frame, a rotating shaft rotatably installed on the frame, at least one disc coaxially fixed to the rotating shaft, a scraper supporting plates in one-to-one correspondence with the discs and movably arranged on the frame, a main scraper fixed to the scraper supporting plates, a main scraper driving device used for drivingthe scraper supporting plates to act to adjust the attaching force between the main scraper and the discs, a liquid storage tank used for containing feed liquid, a liquid inlet pump pumping the feedliquid in the liquid storage tank into the material distribution device, a material distribution device outputting the feed liquid in the liquid storage tank to the surfaces of the two ends of the disc, a rotary driving device driving the rotating shaft to rotate, a heating device heating the disc, and a discharging hopper located under the lower end of the main scraper. The gap between the main scraper and the disc is automatically adjusted by the main scraper driving device, the adjusting efficiency is high, the surface of the adjusted disc surface is stressed uniformly, the service life ofthe disc is long, discharging is smooth, and solid materials are dried thoroughly and uniformly.

Owner:SUZHOU ZHANQING ENVIRONMENT PROTECTION TECHCO LTD

A processing method using electric discharge machining equipment

InactiveCN104259598BNo frequent replacementTake advantage ofElectrical-based machining electrodesForward backwardEngineering

Owner:江阴泛函电气自动化有限公司

Electrosparking head device

InactiveCN104209610ANo frequent replacementTake advantage ofElectrical-based auxillary apparatusElectrical discharge machiningMagnet

The invention provides an electrosparking head device which comprises a lower rack (3), an upper rack (6) and an inner rack (1), wherein the upper rack (6) is positioned above the lower rack (3); the inner rack (1) is positioned in a chamber formed by the lower rack (3) and the upper rack (6) and can slide up and down; the inner side of the upper part of the upper rack and the upper side of the inner rack (1) are respectively provided with an electromagnetic coil (62) and a magnet (63) which are coupled with each other so as to drive the inner rack (1) to slide; the lower parts of two side walls of the lower rack are symmetrically provided with an upper wedge surface locating pin (31) and a lower wedge surface locating pin (32) in each side wall; the lower parts of two sides of the inner rack (1) are respectively, correspondingly and symmetrically provided with an upper cotterway and a lower cotterway; when the inner rack (1) is in an upper working state, the upper wedge surface locating pin (31) is matched with the upper cotterway.

Owner:SHANGHAI MUNICIPAL ELECTRIC POWER CO +1

Machining method using electric spark machining equipment

InactiveCN104259598ANo frequent replacementTake advantage ofElectrical-based machining electrodesForward backwardEngineering

The invention relates to a machining method using electric spark machining equipment. The electric spark machining equipment comprises a main frame, an electric spark machining head device (10), a forward-backward-direction moving motor (202), a forward-backward-direction moving block (200) and a leftward-rightward-direction moving motor (201). The forward and backward direction and the leftward and rightward direction are vertical to each other in a horizontal plane. The forward-backward-direction moving motor (202) is fixedly connected with the main frame and can drive the forward-backward-direction moving block (200) to move forwards and backwards on the main frame. The leftward-rightward-direction moving motor (201) is fixedly connected with the forward-backward-direction moving block (200) and can drive the electric spark machining head device (10) to move leftwards and rightwards on the forward-backward-direction moving block (200).

Owner:江阴泛函电气自动化有限公司

An electric discharge machining device

ActiveCN104259600BNo frequent replacementTake advantage ofElectrical-based machining electrodesElectrical-based auxillary apparatusElectric dischargeMechanical engineering

Owner:TANGSHAN ZHENGFENG IRON & STEEL CO LTD

Electric spark machining equipment

InactiveCN104209608ANo frequent replacementTake advantage ofElectrical-based auxillary apparatusElectrical discharge machiningElectric spark

The invention relates to electric spark machining equipment. The electric spark machining equipment comprises a main frame, an electric spark machining head device (10), a front-back moving motor (202), a front-back moving block (200) and a left-right moving motor (201), wherein a front-back direction is vertical to a left-right direction in a horizontal plane; the front-back moving motor (202) is fixedly connected with the main frame, and can be used for driving the front-back moving block (200) to move forwards and backwards on the main frame; the left-right moving motor (201) is fixedly connected with the front-back moving block (200), and can be used for driving the electric spark machining head device (10) to move leftwards and rightwards on the front-back moving block (200).

Owner:江华瑶族自治县金牛开发建设有限公司

A Machining Technology Utilizing EDM Control System

ActiveCN104259602BNo frequent replacementTake advantage ofElectric circuitsElectricityMachine control

The invention relates to a machining process using an electric spark machining control system. The system comprises a controller and an electric spark machining head device (10). The electric spark machining head device (10) comprises a lower frame (3), an upper frame (6) and an inner frame (1). The upper frame (6) is located above the lower frame (3). The inner frame (1) is located in a cavity formed by the upper frame (6) and the lower frame (3) and can slide up and down.

Owner:MAINTENANCE COMPANY OF STATE GRID XINJIANG ELECTRIC POWER COMPANY +1

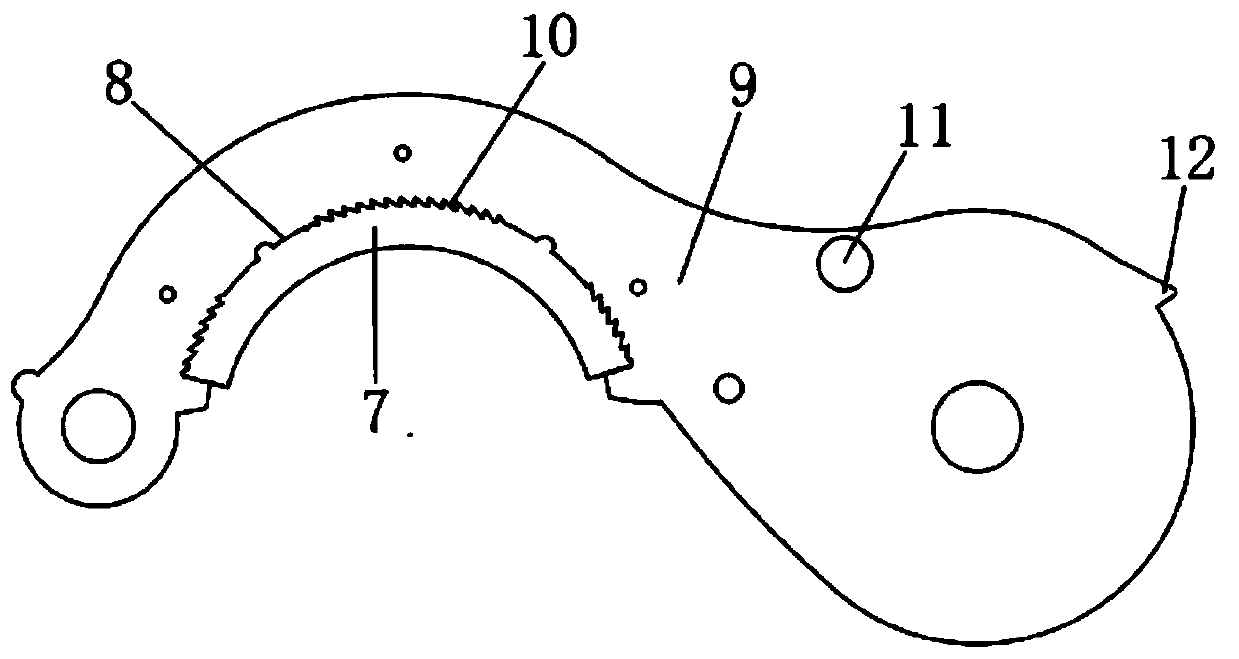

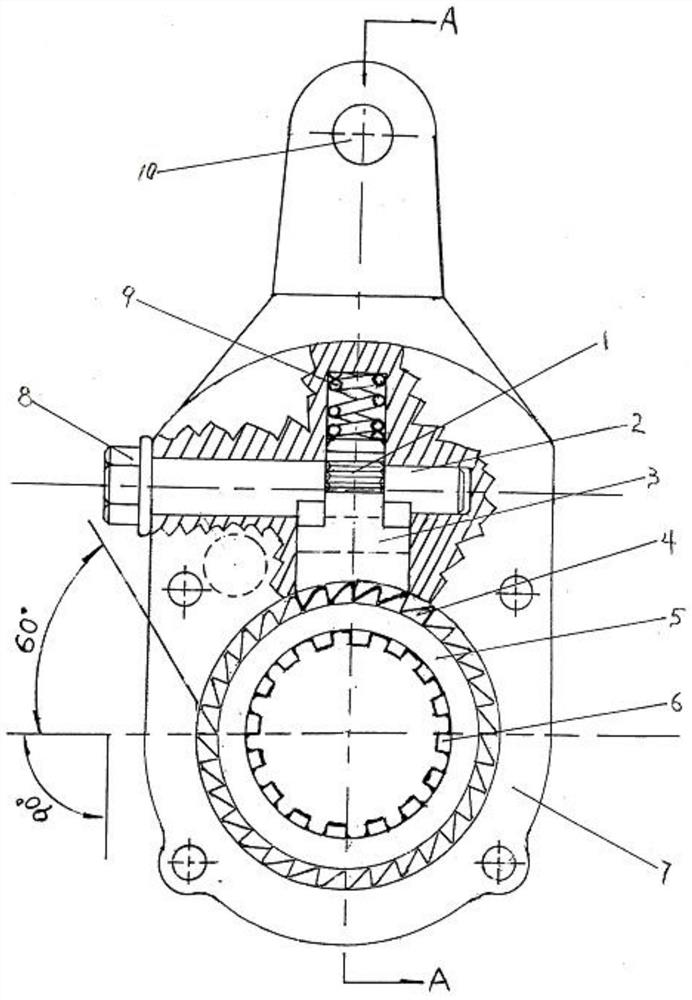

Novel automobile brake clearance adjusting arm device

PendingCN113847366AExtended service lifeImprove the forceBraking membersSlack adjustersRatchetGear drive

The invention discloses a novel automobile brake clearance adjusting arm device. The device comprises an adjusting arm shell, a ratchet wheel, a ratchet block, a forward adjusting rod, a reverse adjusting rod, a return spring, an ejection structure, a forward large gear and a forward small gear, a ratchet wheel hole is formed in the adjusting arm shell, a profiled groove is formed at the top of the inner side of the adjusting arm shell, and the ratchet wheel is rotationally installed in the ratchet wheel hole; the ratchet wheel is in transmission connection with a camshaft; the reverse adjusting rod is rotationally connected into the adjusting arm shell, ejection ratchet teeth are fixed to the reverse adjusting rod, an elliptical hole is formed in the ratchet block, the ejection ratchet teeth are located in the elliptical hole, and a plurality of ratchets are arranged at the bottom of the ratchet block and meshed with ratchets of the ratchet wheel; the profiled groove is formed at the inner side of the adjusting arm shell, the return spring is fixed in the profiled groove, and the bottom end of the return spring abuts against the ratchet block; and the forward adjusting rod rotates in the adjusting arm shell and is connected with the forward small gear, one end of the ratchet wheel is provided with the forward large gear, and the forward small gear is in transmission connection with the forward large gear.

Owner:浙江睿安汽配有限公司

A processing method using an electric discharge machining device

InactiveCN104209606BNo frequent replacementTake advantage ofElectrical-based auxillary apparatusElectric dischargeEmbedded system

The invention provides a processing method using an electrosparking device. The device comprises an electrosparking head (10), a lifting device (101), an upright column (102), a workbench (103), a workpiece (105) and a processing medium supplying device (104), wherein the lifting device (101) can move up and down along the upright column (102) so as to enable the electrosparking head (10) to ascend and descend; the processing medium supplying device (104) is supported on the workbench (103); the workpiece (105) is put in a processing medium in the processing medium supplying device (104).

Owner:江阴市赛英电子股份有限公司

A control system for electric discharge machining

ActiveCN104259603BNo frequent replacementTake advantage ofElectric circuitsElectrical-based auxillary apparatusElectricityMachine control

Disclosed is an electrosparking control system which comprises a controller and an electrosparking head device (10). The electrosparking head device (10) comprises a lower rack (3), an upper rack (6) and an inner rack (1), the upper rack (6) is positioned above the lower rack (3), and the inner rack (1) is positioned in a cavity formed by the lower rack (3) and the upper rack (6) and can slide up and down.

Owner:STATE GRID CORP OF CHINA +1

Disc scraper drying device

ActiveCN112209464BExtended service lifeAvoid cloggingSpecific water treatment objectivesWater distributersCircular discAdhesion force

The invention discloses a disc scraper drying device, which comprises a frame, a rotatable rotating shaft mounted on the frame, at least one disc coaxially fixed on the rotating shaft, and a movable disc corresponding to the disc one by one. The scraper support plate set on the frame, the main scraper fixed on the scraper support plate, the main scraper driving device for driving the scraper support plate to adjust the adhesion force between the main scraper and the disc, and the liquid storage for containing the material liquid tank, the liquid inlet pump that can pump the liquid in the liquid storage tank into the distributing device, the distributing device that can output the liquid in the liquid to the surface of both ends of the disc, the rotary drive device that drives the rotating shaft to rotate, and heats the disc. The heating device and the discharge hopper located directly below the lower end of the main scraper, the gap between the main scraper and the disc in the present invention is automatically adjusted by the main scraper drive device, the adjustment efficiency is high, and the force on the surface of the disc after adjustment is uniform, and the disc The service life is long, the discharge is smooth, and the solid material is completely and evenly dried.

Owner:淮安湛清生态环境材料有限公司

Machining process using electric spark machining control system

ActiveCN104259602ANo frequent replacementTake advantage ofElectric circuitsElectricityMachine control

The invention relates to a machining process using an electric spark machining control system. The system comprises a controller and an electric spark machining head device (10). The electric spark machining head device (10) comprises a lower frame (3), an upper frame (6) and an inner frame (1). The upper frame (6) is located above the lower frame (3). The inner frame (1) is located in a cavity formed by the upper frame (6) and the lower frame (3) and can slide up and down.

Owner:MAINTENANCE COMPANY OF STATE GRID XINJIANG ELECTRIC POWER COMPANY +1

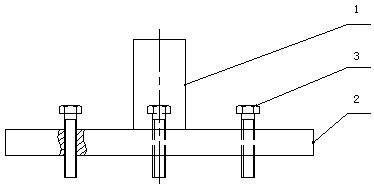

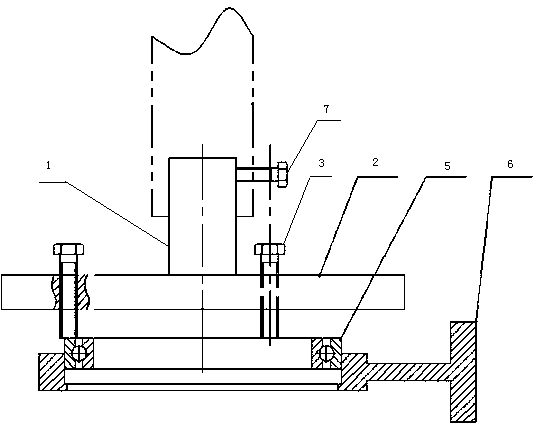

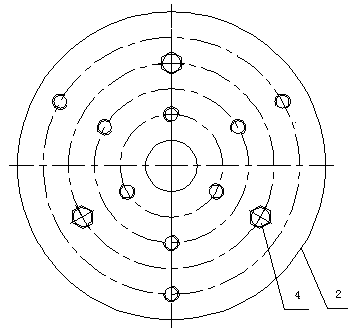

Bearing assembly tool

InactiveCN109500775AReduce labor intensityEven by forceMetal-working hand toolsIsoetes triquetraEngineering

The invention discloses a bearing assembly tool. The tool comprises a connecting rod fixedly connected with one end of a press machine, and a positioning disc; the connecting rod is fixedly connectedwith the positioning disc, a plurality of positioning bolt holes are formed in the positioning disc, positioning bolts for applying force to a bearing are arranged in the positioning bolt holes, the positioning bolt holes are arranged in a concentric circle mode, the plurality of positioning bolt holes on the same concentric circle are uniformly distributed, the positioning disc is provided with three positioning bolt holes on the same concentric circle, and the three positioning bolt holes are arranged in an equilateral triangle shape; and the connecting rod is fixedly connected with one endof the press machine through a tightening bolt, the positioning bolts are connected with the positioning disc in a screwing mode through the positioning bolt holes, the sizes of the positioning boltsare the same, and when the positioning bolts are screwed in the positioning bolt holes, the bottom surface of one positioning bolt is flush with the bottom surface of another positioning bolt. The bearing assembly tool can reduce labor intensity of workers and is uniform in stress, and has the advantages of being rapid in installation, accurate in positioning function, high in working precision, suitable for various diameter bearings and the like.

Owner:SHANGHAI DATUN ENERGY

Processing method using electrosparking device

InactiveCN104209606ANo frequent replacementTake advantage ofElectrical-based auxillary apparatusEngineeringElectrical discharge machining

The invention provides a processing method using an electrosparking device. The device comprises an electrosparking head (10), a lifting device (101), an upright column (102), a workbench (103), a workpiece (105) and a processing medium supplying device (104), wherein the lifting device (101) can move up and down along the upright column (102) so as to enable the electrosparking head (10) to ascend and descend; the processing medium supplying device (104) is supported on the workbench (103); the workpiece (105) is put in a processing medium in the processing medium supplying device (104).

Owner:江阴市赛英电子股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com