Novel automobile brake clearance adjusting arm device

A technology for automobile braking and clearance adjustment, applied in the direction of brake parts, slack adjusters, etc., can solve the problems of changes in assembly size, large amount of freedom of adjustment arms, and short service life of brake adjustment arms.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

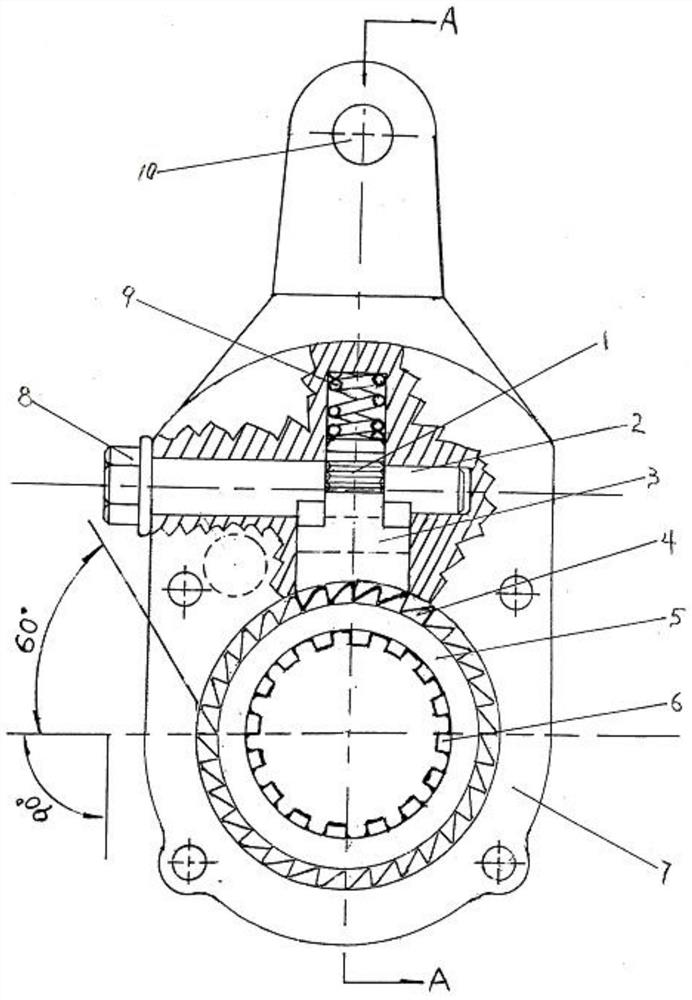

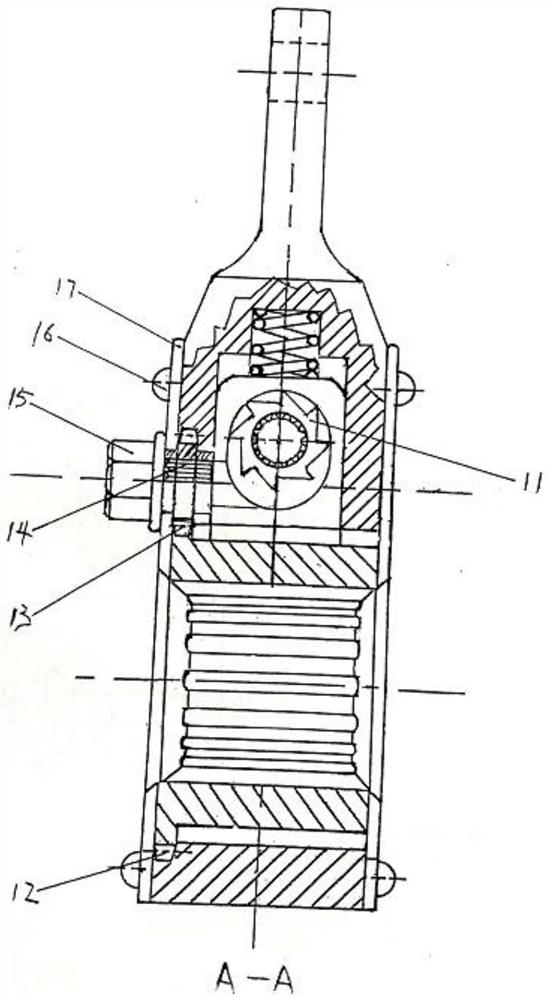

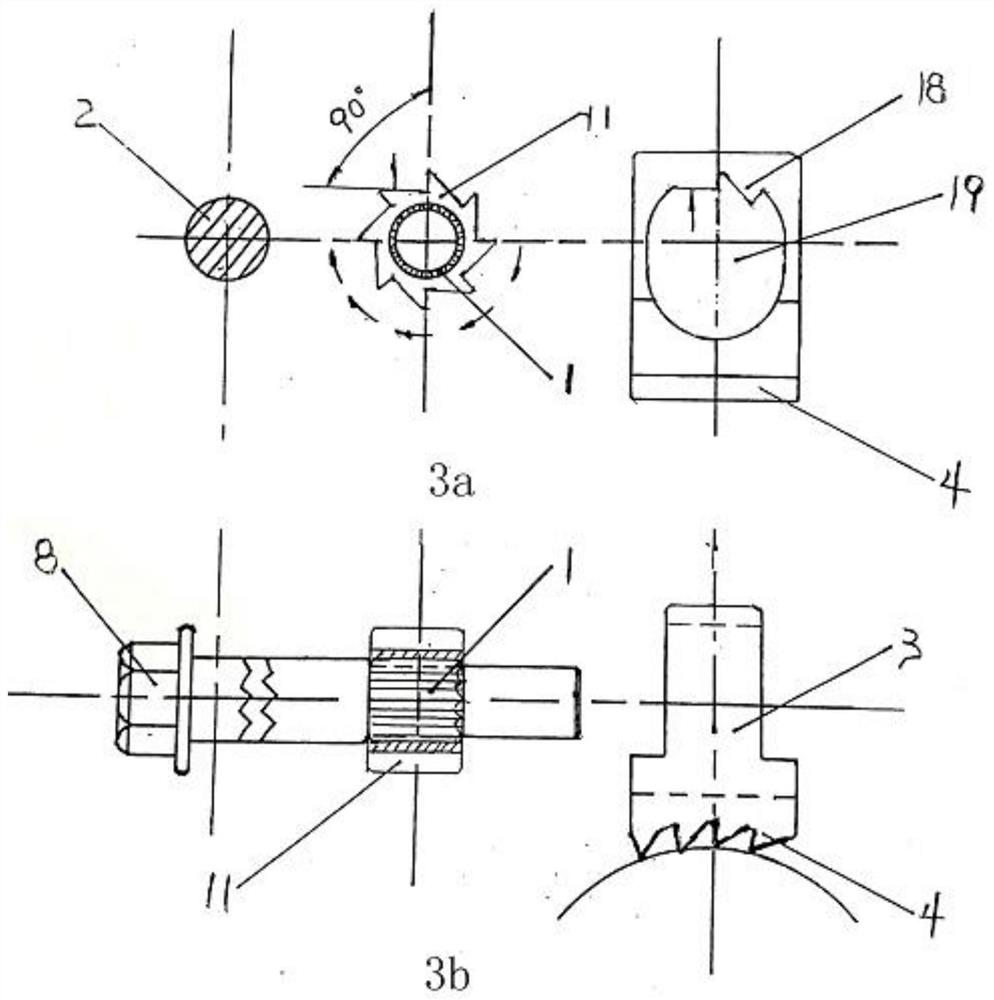

Embodiment 1

[0023] Type I device;

[0024] Refer to the attached Figures 1 to 4 , the detailed description of this embodiment is designed for large buses and heavy trucks. The embodiment of the present invention is a new type of automobile brake gap adjustment arm device, which includes a spline tooth 1 provided on the reverse adjustment rod, and a reverse adjustment rod 2 , ratchet block 3, ratchet 4, ratchet gear 5, camshaft spline teeth 6, adjustment arm housing 7, reverse adjustment hexagonal cap 8, return spring 9, adjustment arm brake connection hole 10, upper reverse adjustment rod The ratchet teeth 11 are set, and the forward gear 12 and the forward pinion 13 arranged at one end of the ratchet gear 5 are arranged on the forward adjustment rod and assembled through the assembly spline 14; the forward adjustment rod adjusts the hexagonal cap 15. The cover plate 17 is fixed on the adjustment arm housing 7 by the rivet 16, an oval hole is set on the ratchet block, and a triangular b...

Embodiment 2

[0027] Type II device;

[0028] according to Figure 5-6 , respectively set the following parts, reverse adjustment rod 2, reverse adjustment hexagonal cap 8, reverse adjustment rod middle section is provided with assembly square shaft 20, double-headed cam block 21, ratchet block side is provided with special-shaped hole 22, the reverse adjustment rod 2 set The double-headed cam block 21 is assembled with an assembly square shaft. The double-headed cam block 21 is arranged in the special-shaped hole 22. When the reverse adjustment hexagonal cap 8, the reverse adjustment rod 2, and the double-headed cam block 21 are reversely rotated, The double-headed cam block 21 rotates in the special-shaped hole 22 on the ratchet block 3, and the cam head gradually pushes the ratchet block 3 upwards, and the cam head rotates 90° and pushes upwards to the highest point. The ratchet and the ratchet on the ratchet gear start to move upward and disengage, and the cam head rotates 180° to form...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com