Connecting joint of steel support and underground diaphragm wall and correcting mold and construction method of connecting joint of steel support and underground diaphragm wall

An underground diaphragm wall and connection node technology, which is applied in excavation, artificial islands, sheet pile walls, etc., can solve the cumbersome installation of buried slabs and plug welding procedures, which affect the rapid formation of support systems, and the difficulty of post-embedded reinforcement planting, etc. problems, to achieve the effect of reducing foundation pit excavation and exposure time, reducing chisel leveling, and meeting safety and quality requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

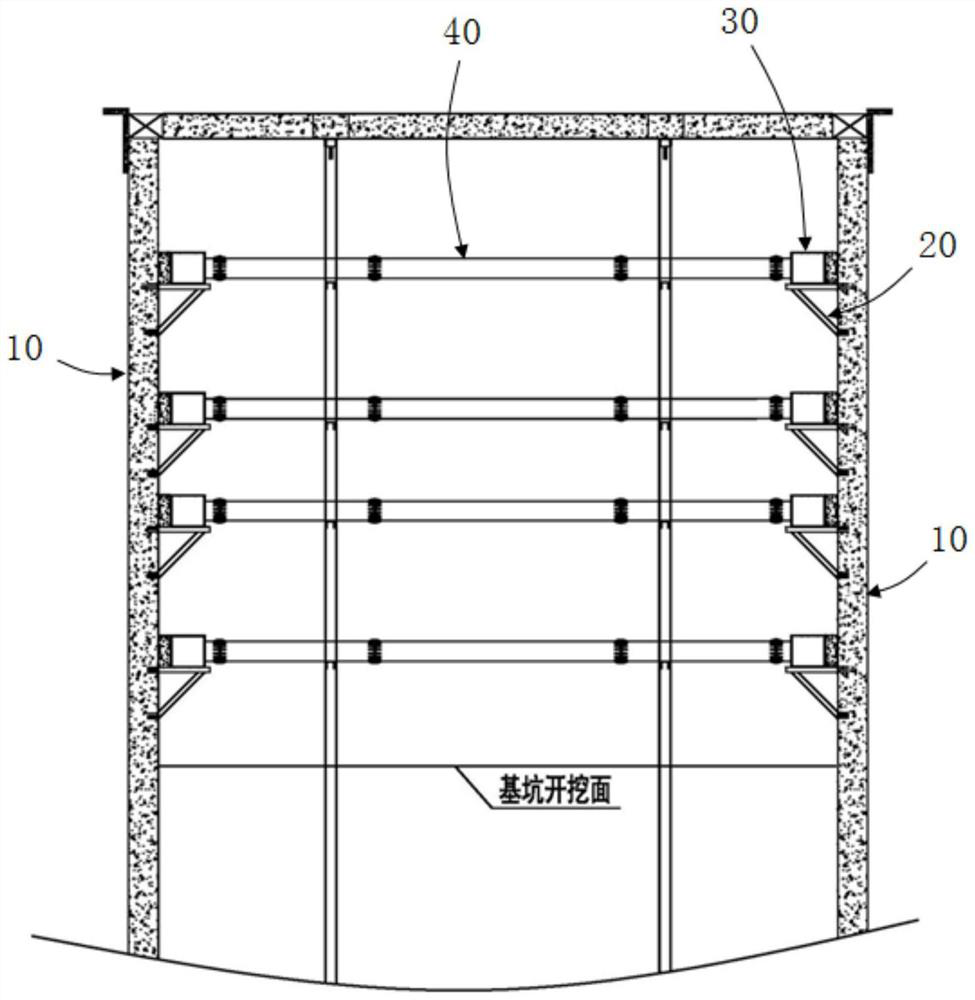

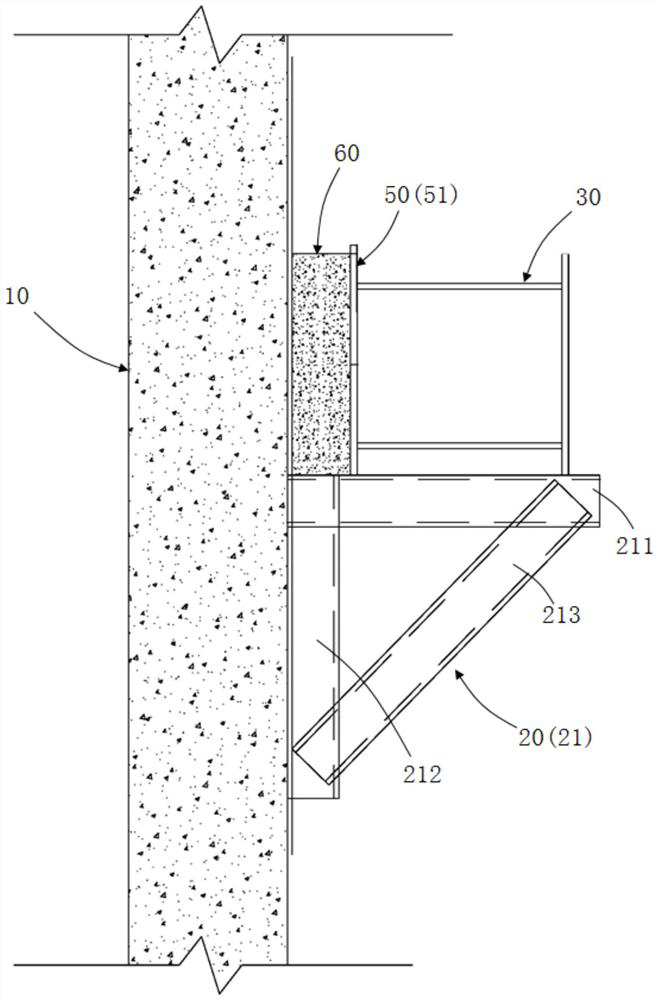

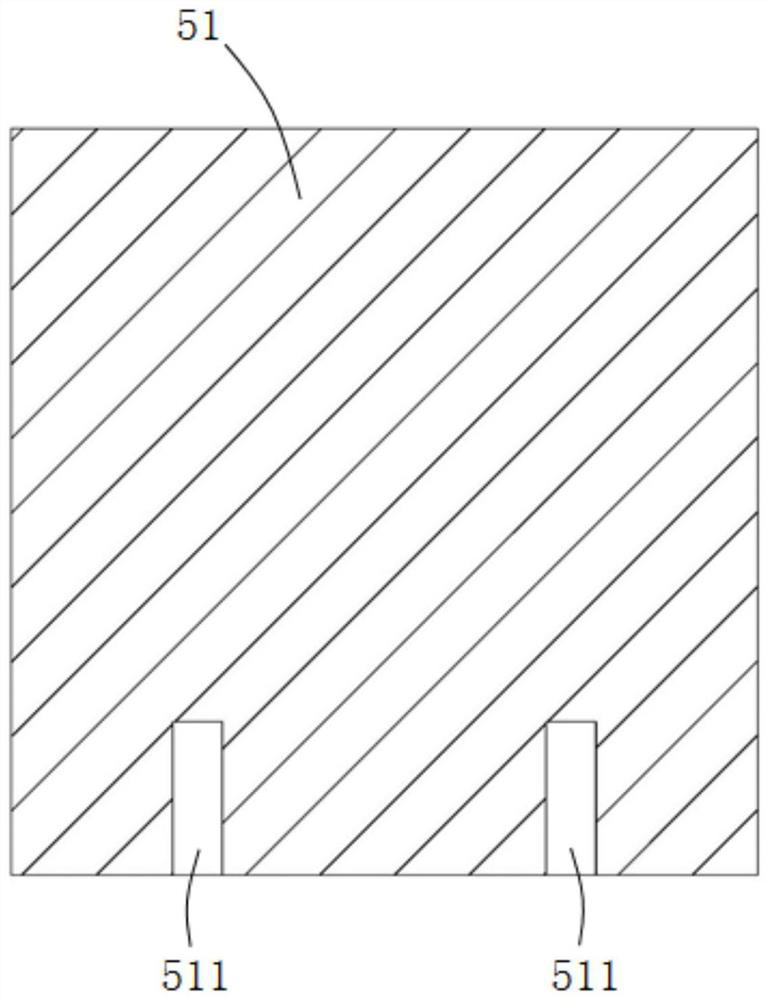

[0034] For the benefit of the understanding of the present invention, the following combination Figure 1 to Figure 4 and examples are described.

[0035] Such as figure 1 , figure 2, the present invention provides a connection node between a steel support and an underground diaphragm wall, which includes an underground diaphragm wall 10 , a support bracket 20 , a steel support system and a correction mold 50 . The steel support system is arranged between the two underground diaphragm walls 10, the support bracket 20 is arranged on the opposite wall surface of the underground diaphragm wall 10, the two ends of the steel support system pass through the The supporting brackets 20 are fixed to form a supporting system.

[0036] In the embodiment of the present invention, the steel support system includes a purlin 30 and a steel support 40, wherein the purlin 30 is fixed on the bearing platform of the support bracket 20; the two ends of the steel support 40 Parts are respecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com