Machining process using electric spark machining control system

A technology of control system and processing technology, applied in electric processing equipment, metal processing equipment, circuits, etc., can solve the problems of prolonged production process, cumbersome process, increased cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

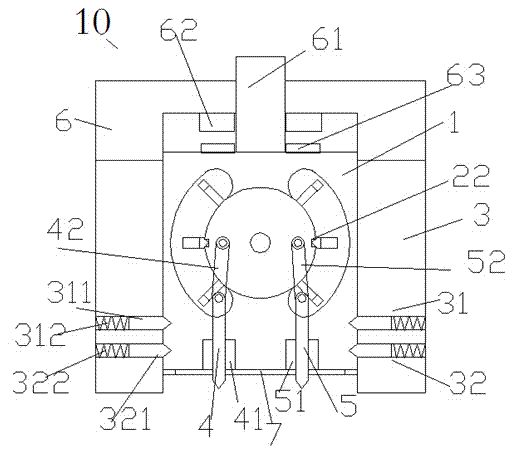

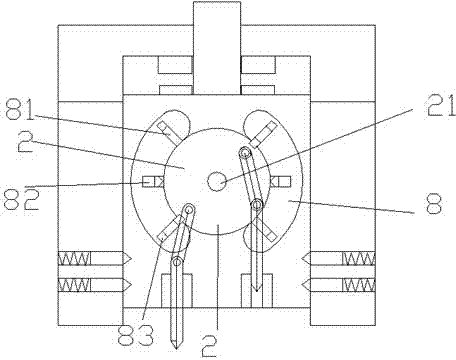

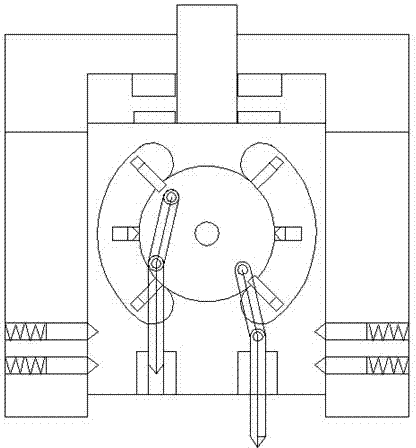

[0034] Refer below Figure 1-5 , describe the present invention in detail.

[0035] A processing technology using an electric discharge machining control system, the electric discharge machining control system includes a controller and an electric discharge machining head device 10, and the electric discharge machining head device 10 includes a lower frame 3, an upper frame 6 and an inner frame 1. The upper frame 6 is above the lower frame 3, and the inner frame 1 is located in the cavity formed by the lower frame 3 and the upper frame 6, and can slide up and down.

[0036] Wherein, the upper inner side of the upper frame 6 and the upper side of the inner frame 1 are respectively provided with coupled electromagnetic coils 62 and magnets 63 to drive the sliding of the inner frame 1; The lower part of the side wall is symmetrically provided with an upper wedge surface positioning pin 31 and a lower wedge surface positioning pin 32 in each side wall, and the lower parts of both...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com