Polyurethane waterproof coiled material production and processing method

A technology of polyurethane waterproofing and processing method, which is applied in the direction of coating, device for coating liquid on the surface, etc., can solve the problems of inability to produce and process polyurethane waterproofing membranes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

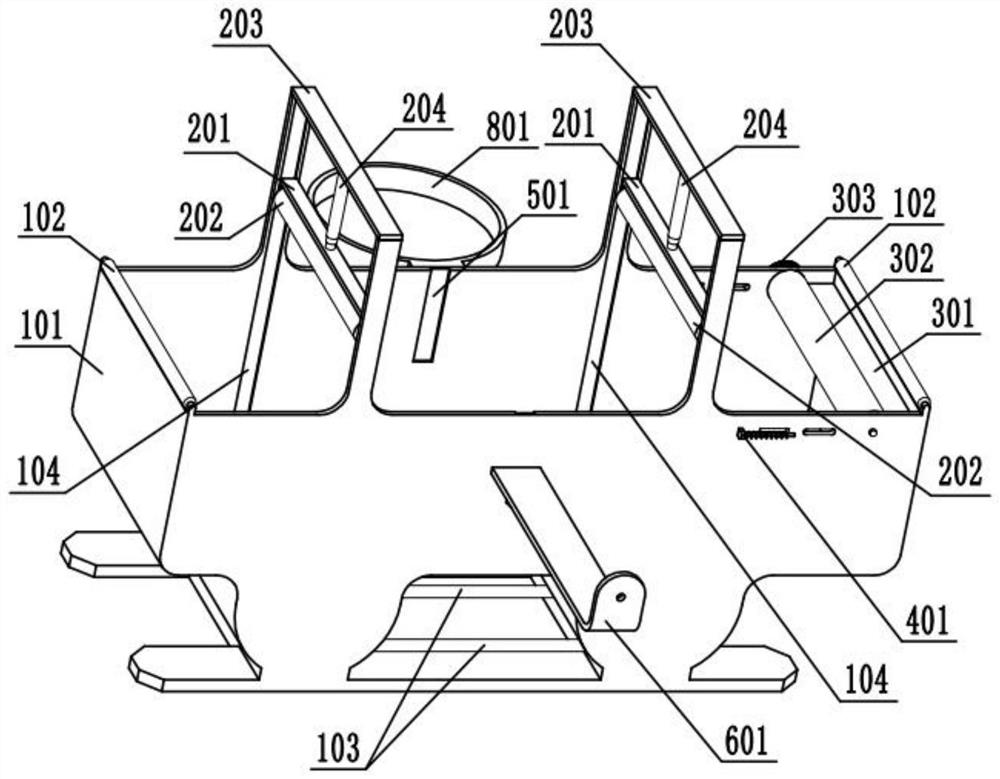

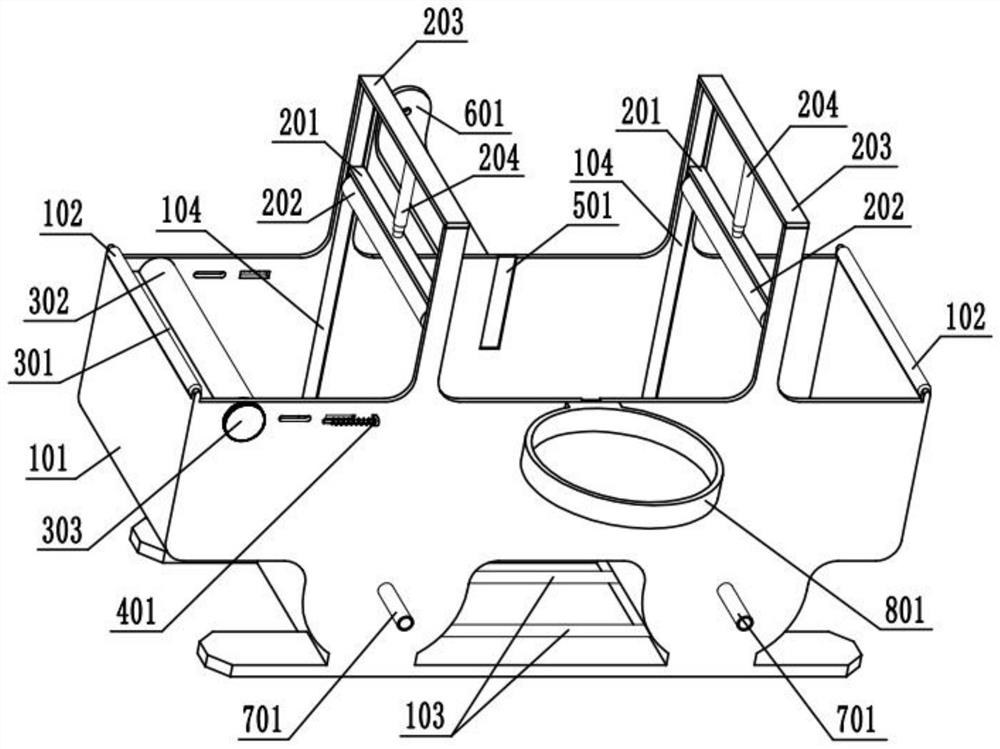

[0024] The present invention will be further described in detail below in conjunction with the accompanying drawings.

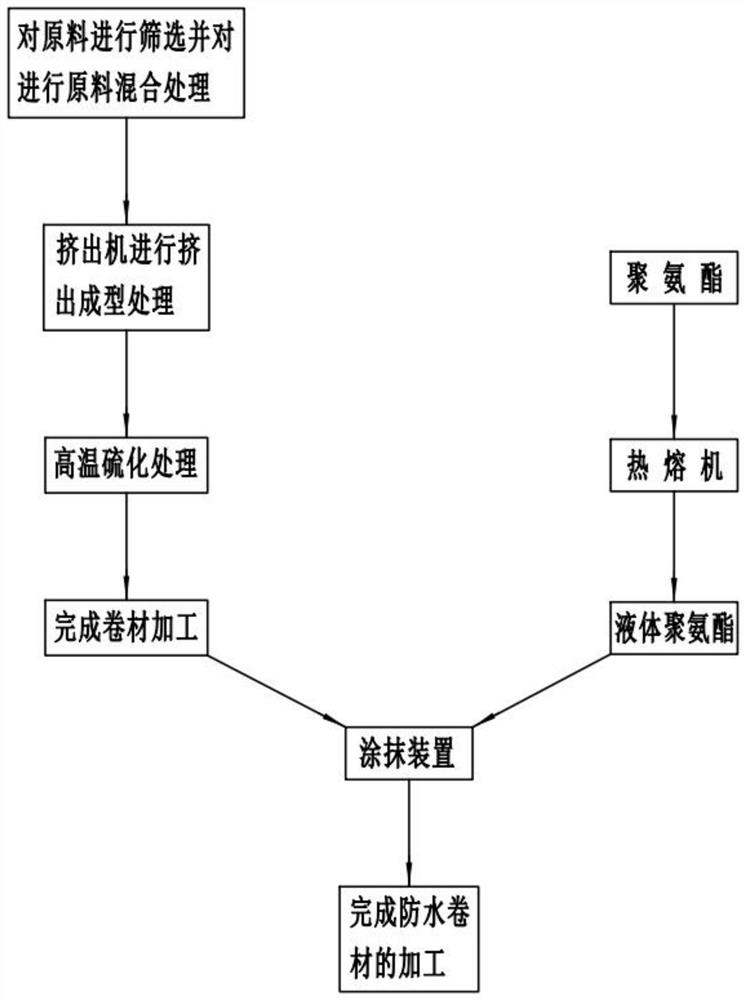

[0025] Attached below figure 1 In detail, a method for producing and processing a polyurethane waterproofing membrane, the processing method comprises the following steps:

[0026] Step 1: Screening the raw materials, and mixing the qualified raw materials;

[0027] In step 2, the raw materials that have been mixed with the slurry are added to the extruder, the raw materials are subjected to extrusion molding, and then the extruded raw materials are subjected to high-temperature vulcanization treatment to complete the processing of the coil;

[0028] Step 3, adding the polyurethane into the hot melt machine, and processing the solid polyurethane into liquid polyurethane;

[0029] Step 4: Add the liquid polyurethane into the coating device, and let the processed roll material pass through the coating device to complete the processing of the polyurethane wate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com