Automatic correction device for leather cutting machine

A technology of automatic correction and leather cutting machine, which is applied in the directions of transportation and packaging, winding strips, and thin material processing, etc., can solve the problems of unstable work efficiency, high labor intensity of workers, and deviation of leather materials, and achieves high performance. Efficient production, reducing the number of defective products, and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] In order to facilitate the understanding of those skilled in the art, the present invention will be further described below in conjunction with the accompanying drawings.

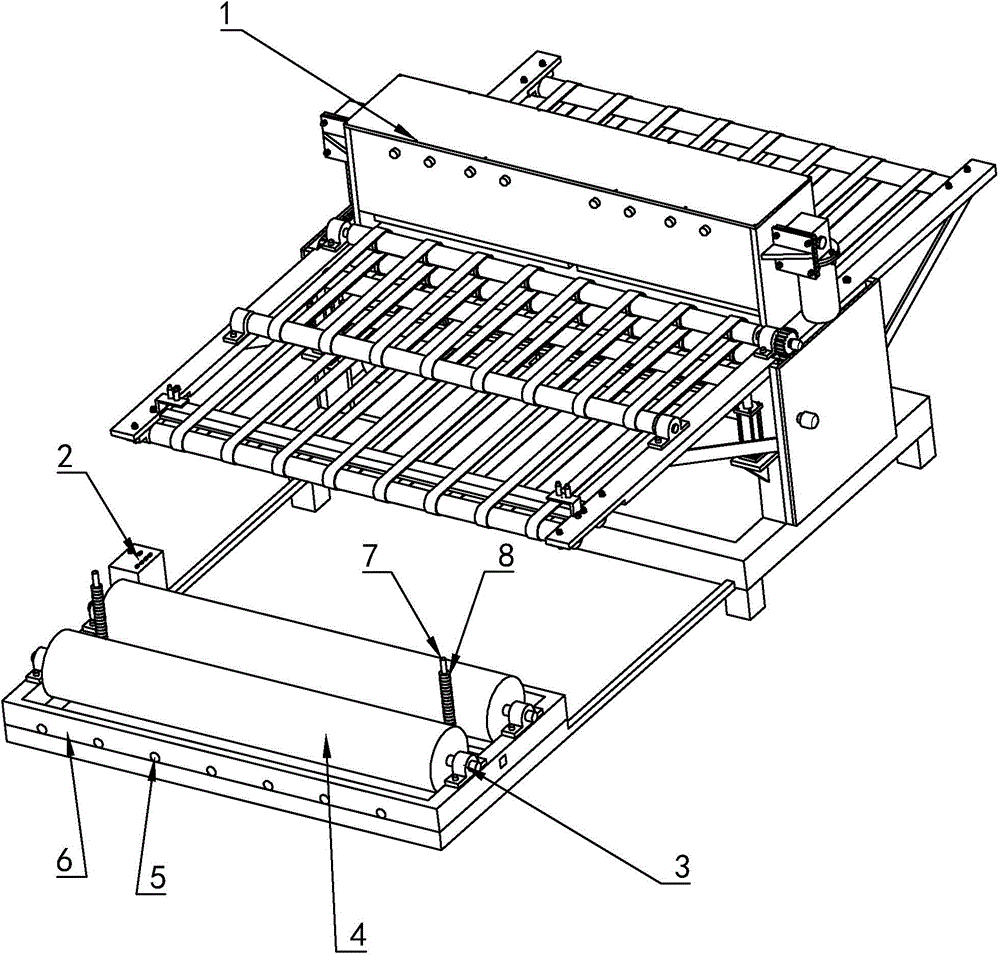

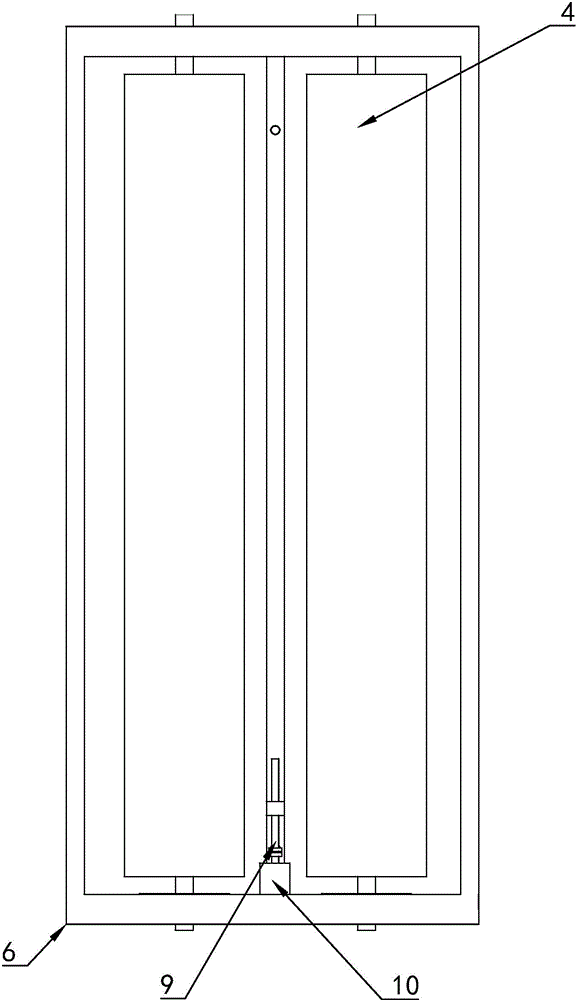

[0012] Such as figure 1 , 2 The automatic correction device for a skin cutting machine shown mainly includes a control device 2, a roller 4, a support frame 6, and a motor 10; the support frame 6 is provided with two rollers 4, which are connected and fixed to the support through a bearing 3 On the upper surface of the frame 6, a control device 2 is provided on one side of the support frame 6, and a pulley 5 is provided at the bottom of the support frame 6, and a steel structure frame is provided at the bottom of the pulley 5, so that the support frame 6 can move on the steel structure frame, and the roller The two ends of the gap between 4 are provided with guide pillars 7, and the guide pillars 7 are fixed on the steel structure frame, and the motor 10 is arranged on the steel structure frame, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com