Drilling machine

A technology of drilling machine and drilling device, which is applied in boring/drilling, drilling/drilling equipment, metal processing machinery parts, etc. The effect of increasing efficiency, improving accuracy, and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

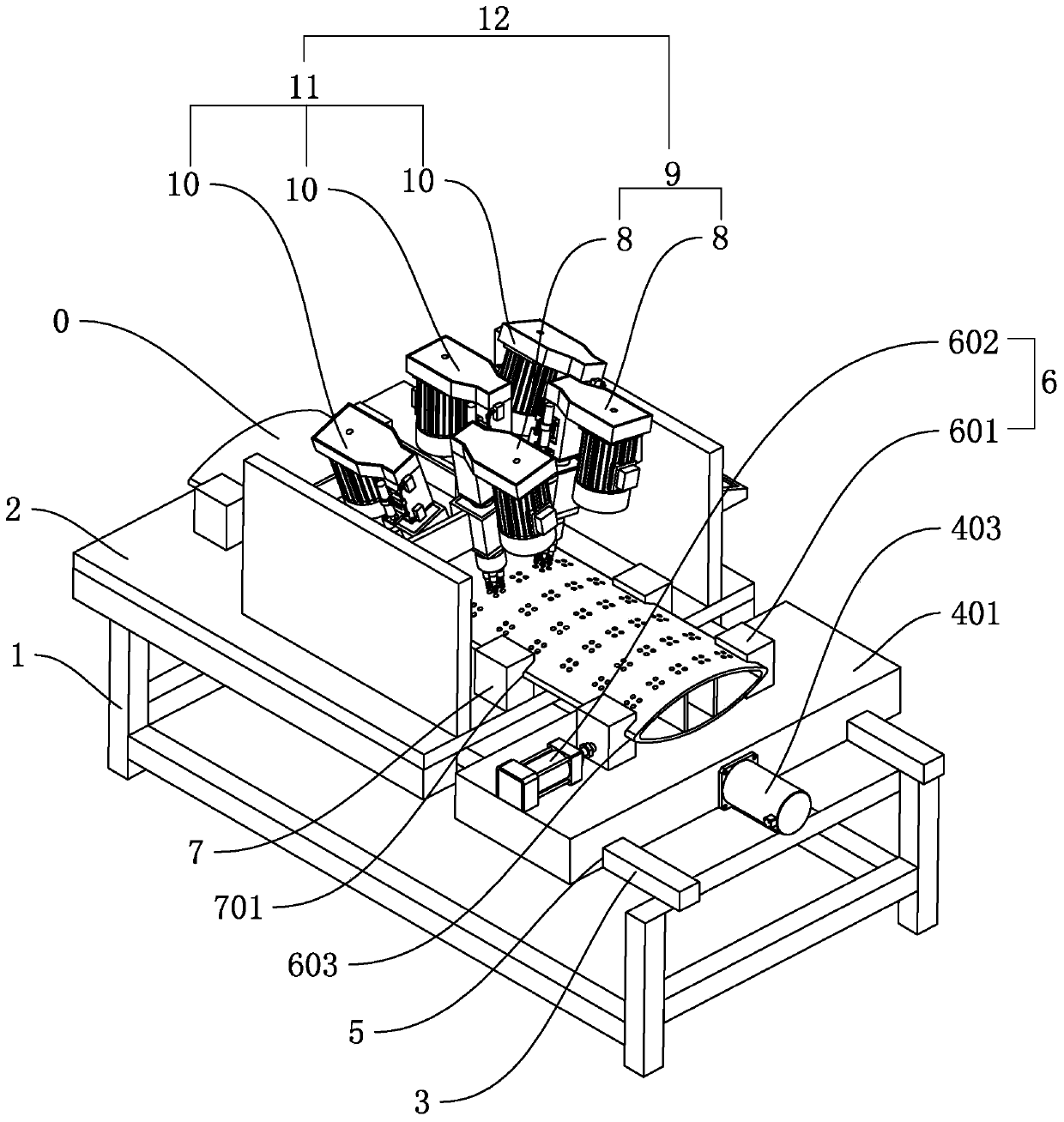

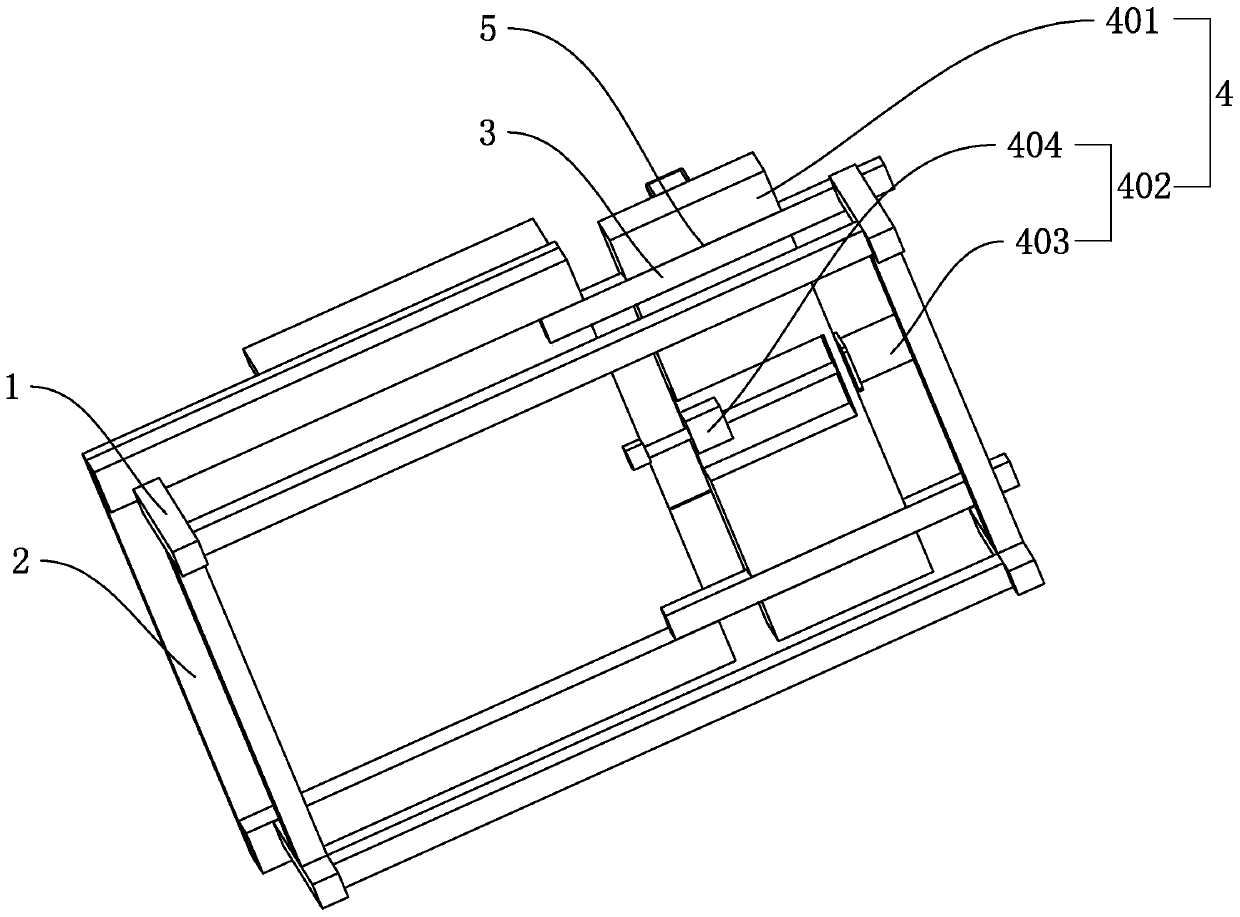

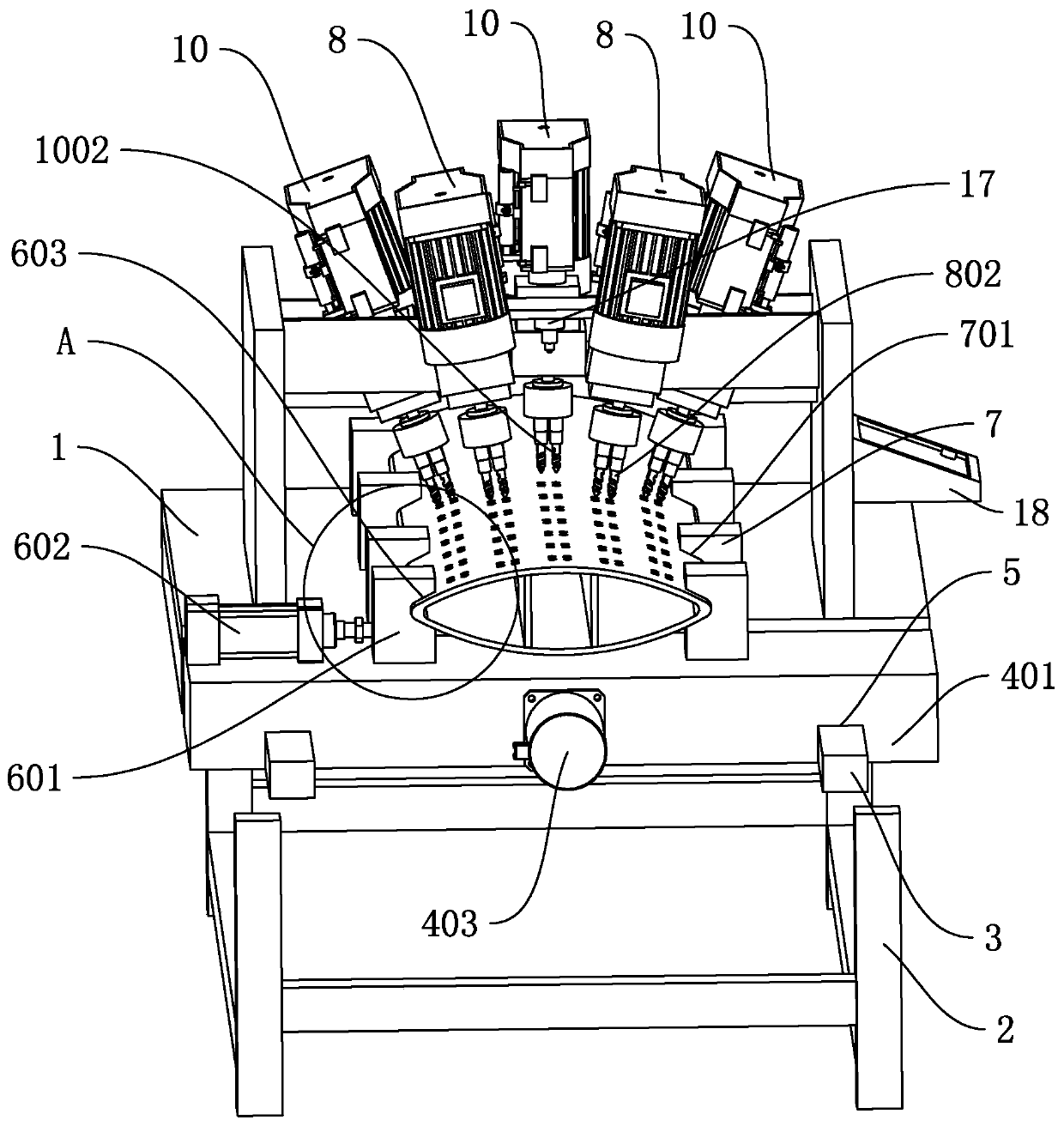

[0036] Embodiment: a kind of drilling machine, with reference to figure 1 and figure 2 , including a frame 1, the frame 1 is provided with a horizontal workbench 2, a push mechanism 4 and a drilling device 12, the surface of the workbench 2 is rectangular, and one end of the workbench 2 is provided with a The slide rail 3, the push mechanism 4 includes a loading plate 401, and a pushing drive member 402 that drives the loading plate 401 to slide back and forth on the workbench 2. The shape of the loading plate 401 is a cuboid, and the bottom surface is provided with a Move the matching chute 5, the loading plate 401 slides in the length direction of the workbench 2 through the chute 5, the push drive 402 includes a reciprocating drive motor 403, a ball screw 404, and the ball screw 404 is installed on the loading plate At the bottom of 401, the reciprocating drive motor 403 is fixedly installed on the frame 1, the reciprocating drive motor 403 is connected with the ball screw ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com