Titanium and titanium alloy surface carbon nanomaterial modified ti-al-si-c coating and preparation method thereof

A ti-al-si-c, carbon nanomaterial technology, applied in metal material coating process, coating, hot dip plating process and other directions, can solve problems such as coating cracks, achieve easy production and processing, excellent high temperature performance, The effect of promoting the application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

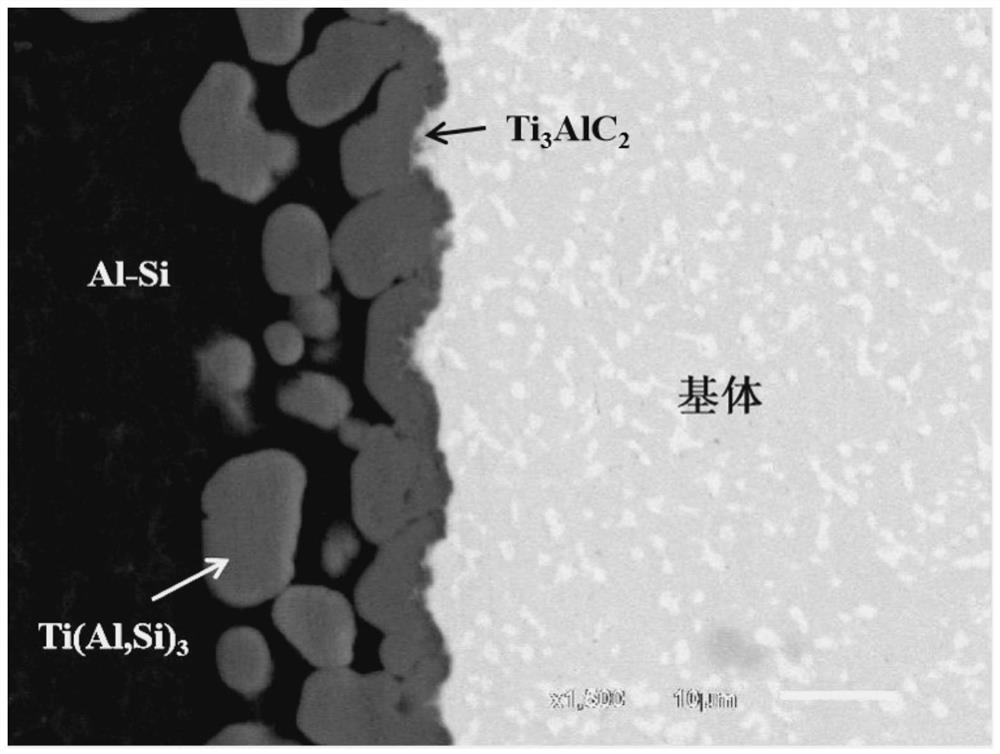

Embodiment 1

[0034](1) Configuration of added slurry: 5 parts of graphene powder are dispersed in 95 parts of N-methylpyrrolidone as a suspension, and the suspension is ultrasonically dispersed for 30 min. Subsequently, polyvinylidene fluoride with a mass of 0.5% of the suspension was added as a thickener, stirred evenly and then placed in the oven at 80 °C for 30 min to obtain the added slurry.

[0035] (2) Take step (1) The added slurry obtained by the configuration is uniformly applied to the inner surface of the silica quartz vessel enlarged in proportion to 1.2 times according to the shape of the TC4 titanium alloy workpiece, the thickness of the slurry layer is 100μm, and then dried in the vacuum drying box and placed for use.

[0036] (3) The surface of the TC4 titanium alloy workpiece is polished and smoothed, and the pickling alkali wash removes the surface oxide scale and oil stain, and then dried in the vacuum drying box and placed for use.

[0037] (4) Under the condition of inert ...

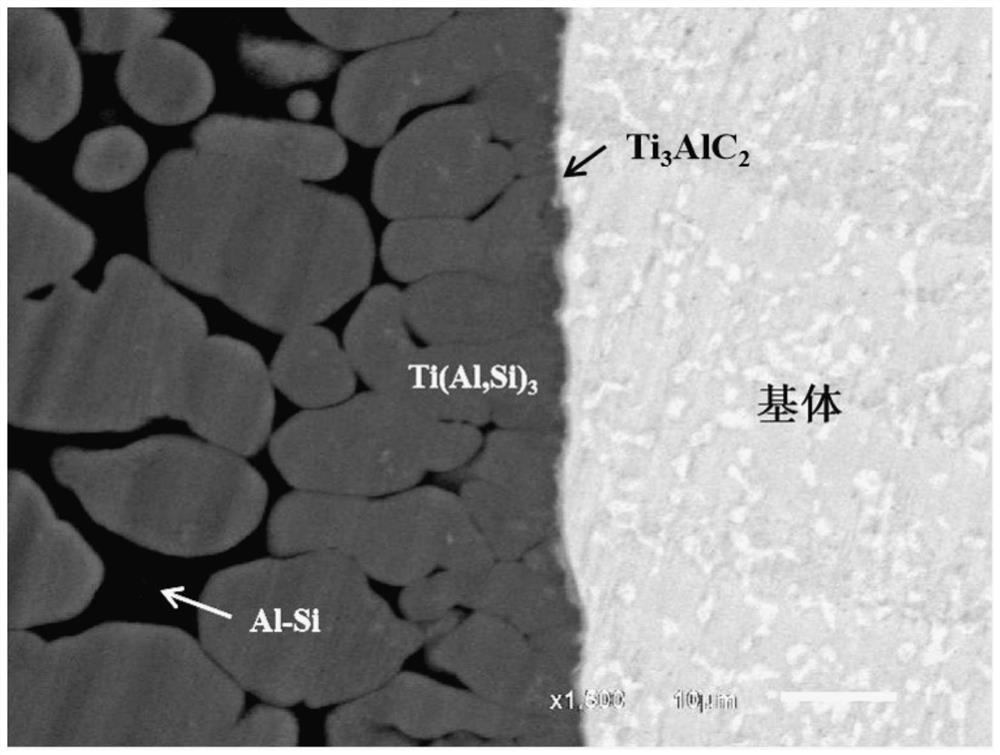

Embodiment 2

[0041] (1) Configuration of added slurry: 5 parts of graphene powder are dispersed in 95 parts of N-methylpyrrolidone as a suspension, and the suspension is ultrasonically dispersed for 30 min. Subsequently, polyvinylidene fluoride with a mass of 0.5% of the suspension was added as a thickener, stirred evenly and then placed in the oven at 80 °C for 30 min to obtain the added slurry.

[0042] (2) Take step (1) The added slurry obtained by the configuration is uniformly applied to the inner surface of the silica quartz vessel enlarged in proportion to 1.2 times according to the shape of the TC4 titanium alloy workpiece, the thickness of the slurry layer is 100μm, and then dried in the vacuum drying box and placed for use.

[0043] (3) The surface of the TC4 titanium alloy workpiece is polished and smoothed, and the pickling alkali wash removes the surface oxide scale and oil stain, and then dried in the vacuum drying box and placed for use.

[0044] (4) Under the condition of inert ...

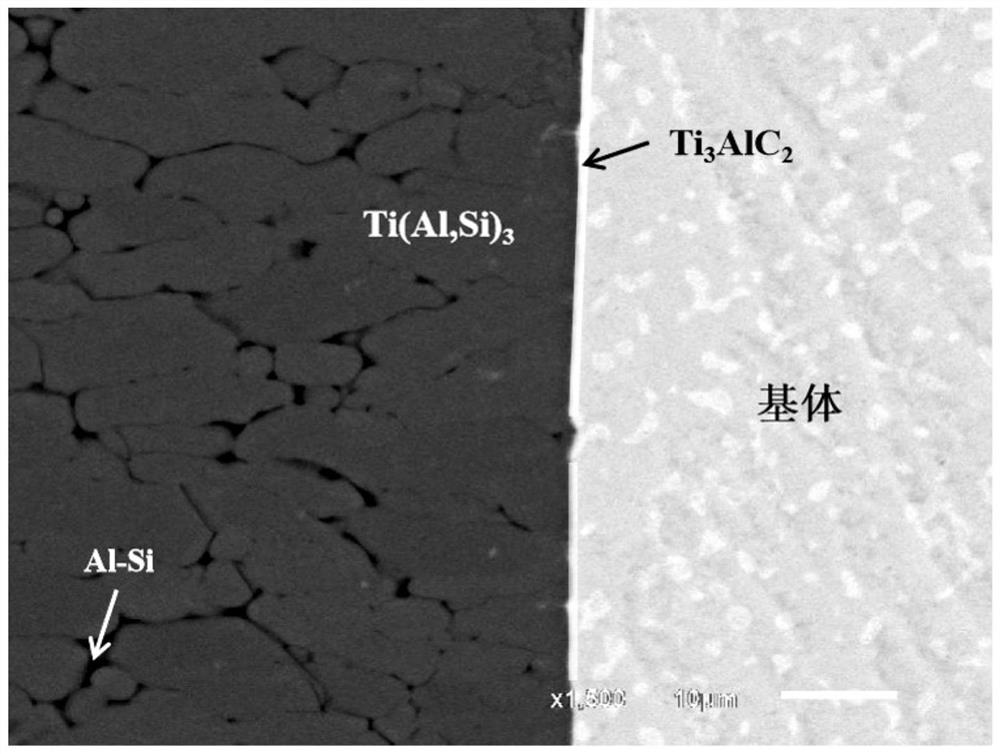

Embodiment 3

[0048] (1) Configuration of added slurry: 5 parts of graphene powder are dispersed in 95 parts of N-methylpyrrolidone as a suspension, and the suspension is ultrasonically dispersed for 30 min. Subsequently, polyvinylidene fluoride with a mass of 0.5% of the suspension was added as a thickener, stirred evenly and then placed in the oven at 80 °C for 30 min to obtain the added slurry.

[0049] (2) Take step (1) The added slurry obtained by the configuration is uniformly applied to the inner surface of the silica quartz vessel enlarged in proportion to 1.2 times according to the shape of the TC4 titanium alloy workpiece, the thickness of the slurry layer is 100μm, and then dried in the vacuum drying box and placed for use.

[0050] (3) The surface of the TC4 titanium alloy workpiece is polished and smoothed, and the pickling alkali wash removes the surface oxide scale and oil stain, and then dried in the vacuum drying box and placed for use.

[0051] (4) Under the condition of inert...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com