Phase change material temperature-sensitive coating as well as composite retarder and preparation method thereof

A temperature-sensitive aftercoating and phase-change material technology, applied in the field of composite inhibitors, can solve the problems of short resistance life, inability to effectively control the spontaneous combustion area of goaf, poor stability, etc., to achieve increased hardness, inhibition of spontaneous combustion of coal, and prevention of fire the enlarged effect of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] The preparation of the temperature-sensitive cell coat of the phase change material includes the selection of the phase change material of the cell coat shell, the enhancement of the strength of the phase change material and the improvement of the ignition point, and the steps of putting the frozen inhibitor particles into the mixed cell coat phase change material.

[0025] Among them, the choice of temperature-sensitive cell coat shell materials.

[0026] After comparison and analysis, the physical properties of petrolatum, stearic acid and paraffin are compared, stearic acid and paraffin are selected as phase change materials, and their characteristics are analyzed below.

[0027] Vaseline is a semi-liquid mixture of alkanes or saturated hydrocarbons, also called petrolatum, which is obtained by fractional distillation of petroleum. Its state is between solid and liquid at room temperature; its melting point is 35-50°C.

[0028] The main component of paraffin wax is solid alk...

Embodiment 1

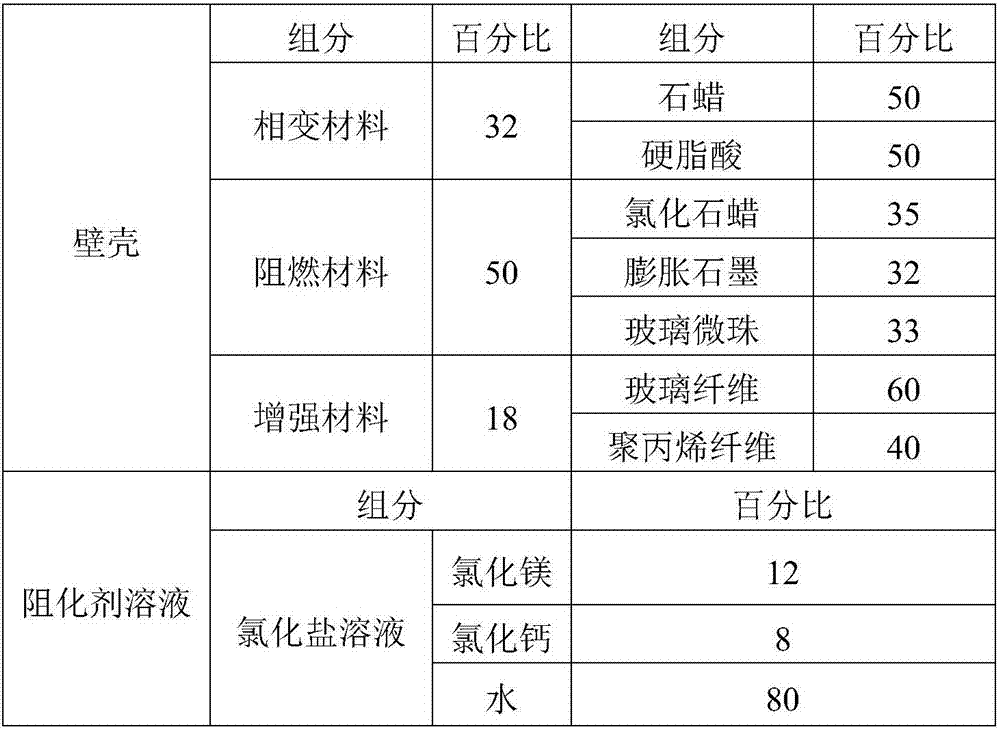

[0041] Table 1: Percentage of each component in Example 1

[0042]

[0043] With this composition, the resistance rate is 95%, the heat release rate per unit time is reduced by 70%, the ignition point is increased by 124 degrees, and the flame retardancy is greatly enhanced. The compressive strength is significantly enhanced, and the compressive strength of the composite material is increased by several hundred times compared with the paraffin-wax cell coat.

Embodiment 2

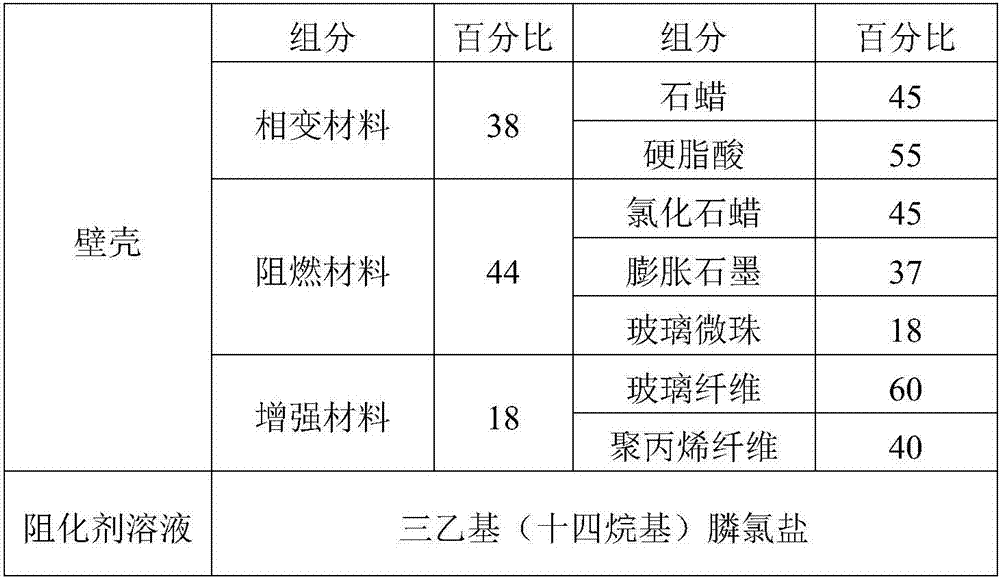

[0045] Table 2: Percentage of each component in Example 2

[0046]

[0047] With this composition, the resistance rate is 93%, the heat release rate per unit time is reduced by 60%, the ignition point is increased by 101 degrees, and the flame retardancy is greatly enhanced. The compressive strength is significantly enhanced, and the compressive strength of the composite material is increased by several hundred times compared with the paraffin-wax cell coat.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com