Operation support system of element assembling device, recognition method of element order and recognition method of Cassette holder order

An operation support system and component identification technology, applied in the direction of electrical components, electrical components, etc., can solve problems such as installation errors, substandard printed circuit board units, and components that cannot be installed, so as to eliminate erroneous installation, improve operational efficiency and operation. performance, avoid installation errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0062] Embodiments of the present invention will be described below with reference to the drawings.

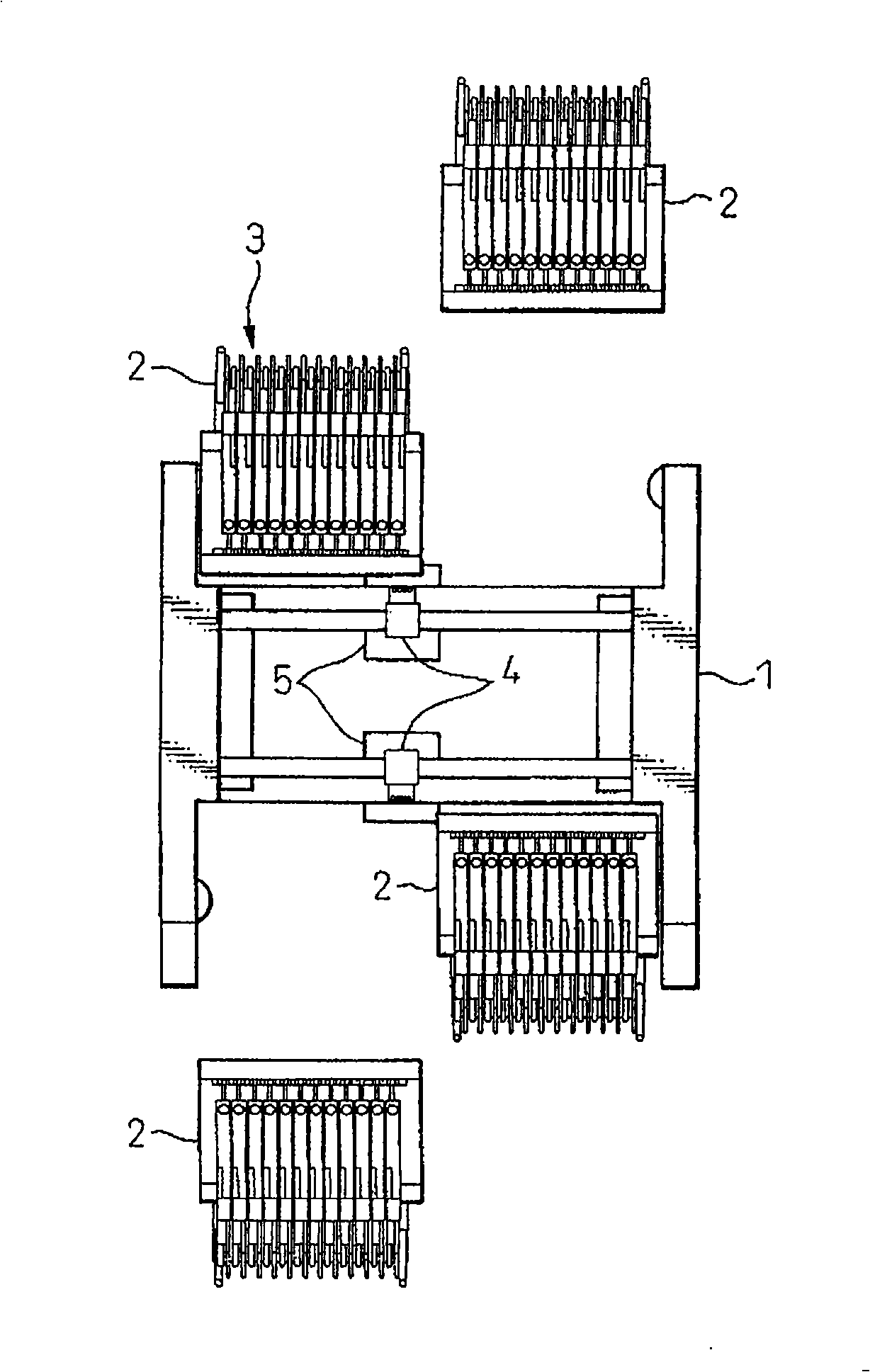

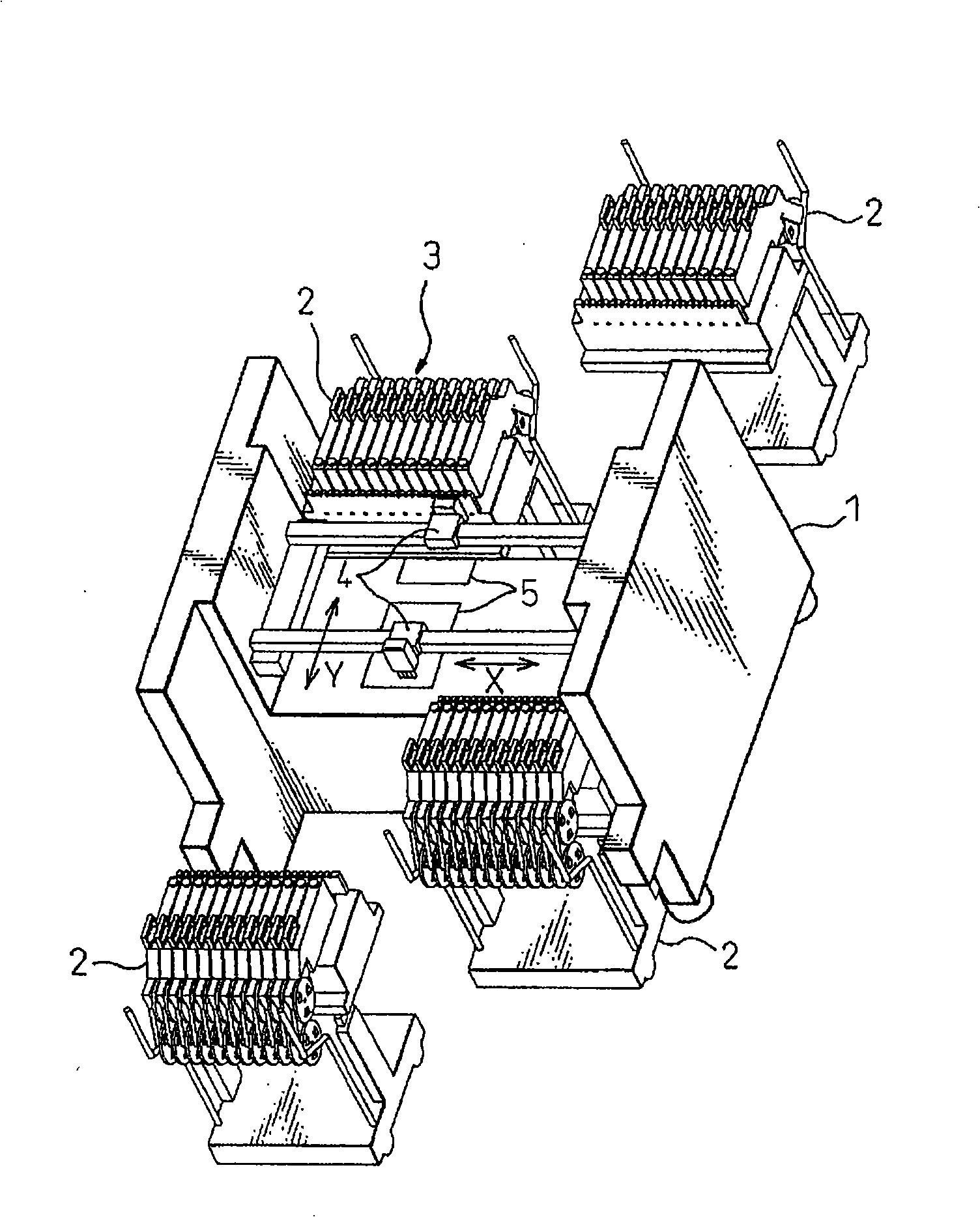

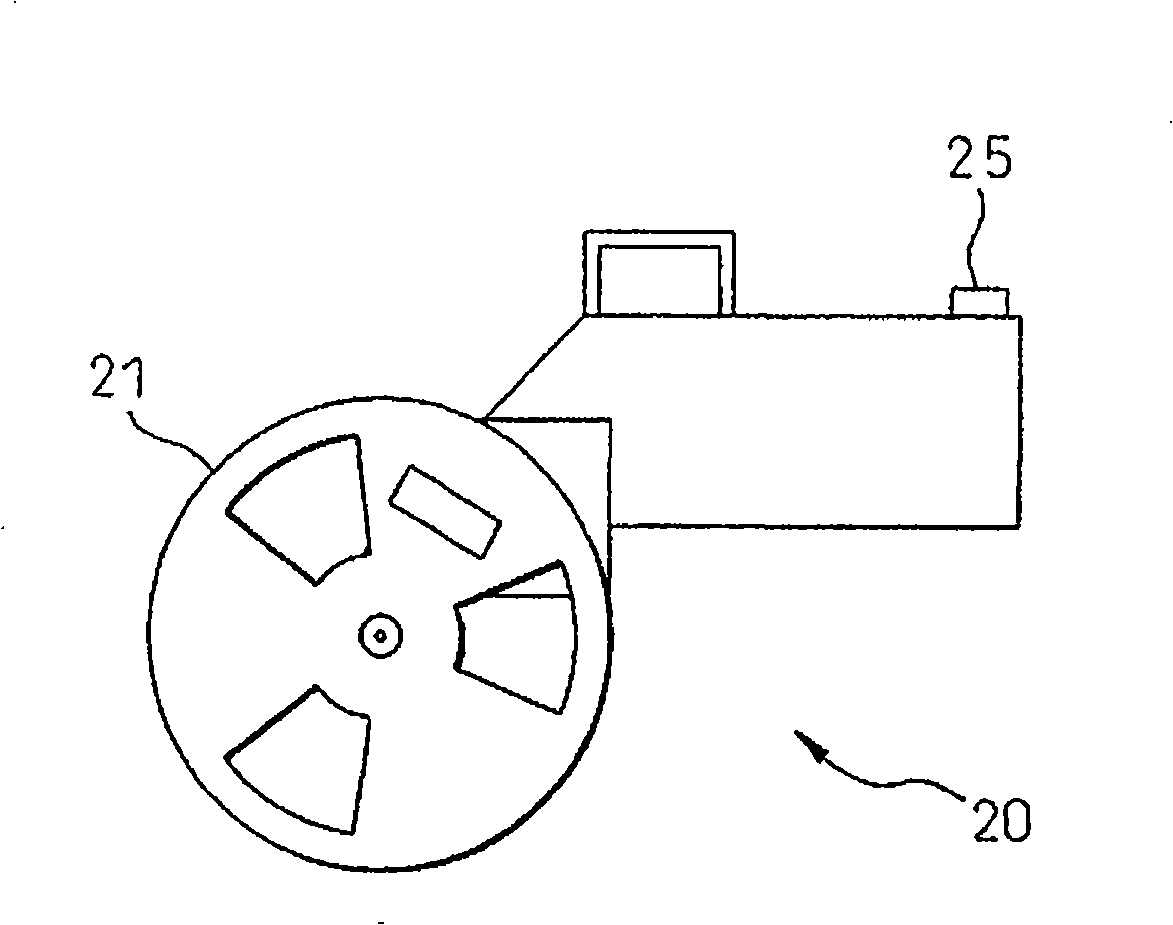

[0063] Figure 1A and Figure 1B It is a figure which shows the printed circuit board component mounting apparatus which concerns on one Embodiment of this invention. Figure 1A for top view, Figure 1B is a stereogram. Such as Figure 1A and Figure 1B As shown, in a printed circuit board component mounting device (mounting machine) 1 provided on a production line for producing printed circuit board units assembled with components on printed circuit boards, four detachable carts 2 can be mounted. Each cart 2 can be equipped with a plurality of cassettes 3 . Mounting machine 1 is equipped with two suction nozzles 4 that can move in the directions of X-axis and Y-axis. The suction nozzles 4 suck the reel wound in the cassette 3 (see figure 2 and image 3 ) on the component, transported to the printed circuit board 5 located below the suction nozzle 4, and assembled to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com