High-accuracy quick assembling and disassembling structure for tokamak divertor module

A technology of tokamak and divertor, applied in the field of large-scale, high-precision and rapid assembly, which can solve problems such as ablation and damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

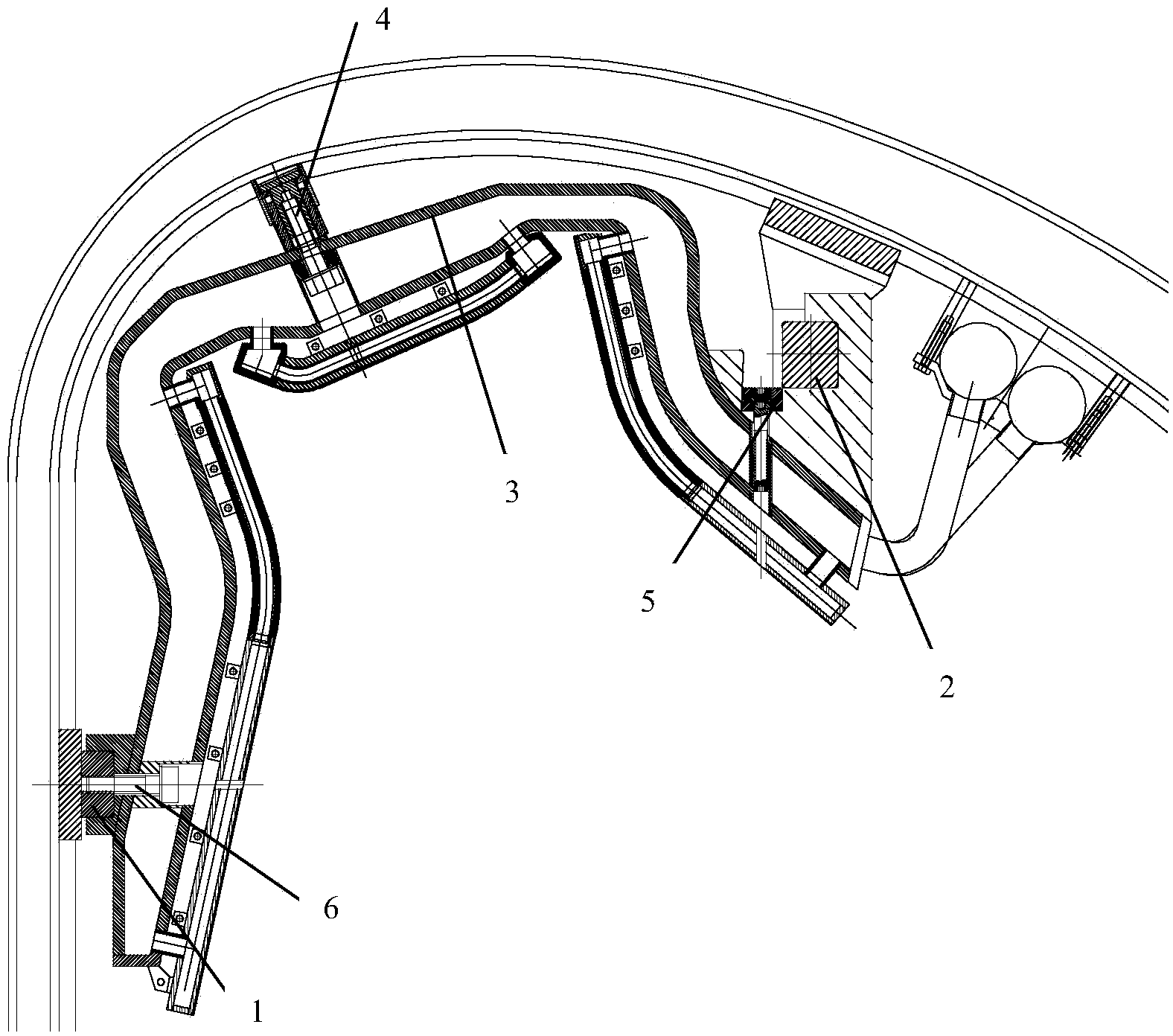

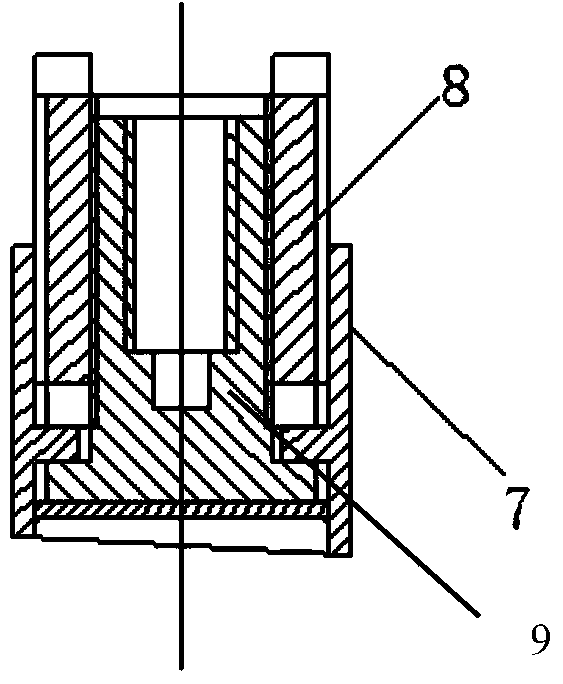

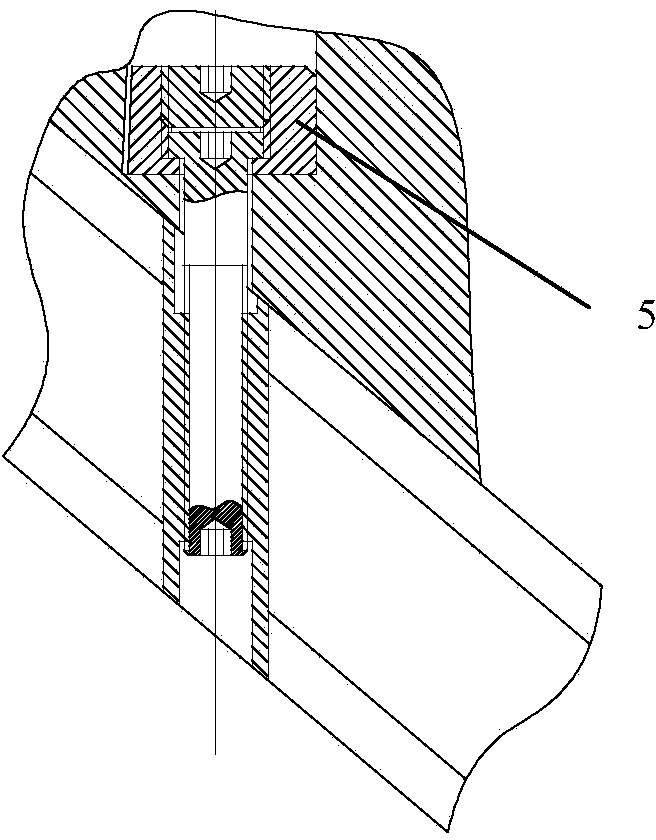

[0012] Referring to the accompanying drawings, a high-precision and quick assembly and disassembly structure of a tokamak divertor module includes 80 divertor modules 3 that are circumferentially distributed on the inner wall of the vacuum chamber at intervals of 4.5 degrees, and are installed on the outer guide rail 2 and inner guide rail 1 in the vacuum chamber. , the divertor module 3 is slidingly arranged with the outer guide rail 2 and the inner guide rail 1, and the divertor module 3 and the inner guide rail 1 are fixedly connected by connecting bolts 6, and the outer wall of the divertor module 3 has a mounting groove, and the mounting groove Cooperating with the outer guide rail 2 and the moving wedge 5, an auxiliary support 4 is provided between the divertor module 3 and the inner wall of the vacuum chamber. The auxiliary support 4 includes a sleeve 7 with a stop key fixedly connected with the vacuum chamber, and a movable The screw sleeve 8 and the central screw 9, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com