Online detecting method of spiral bevel gear machining process

A technology of spiral bevel gear and processing process, which is applied in the direction of components with teeth, metal processing equipment, gear tooth manufacturing devices, etc., can solve the problems of difficult to guarantee the processing cycle, difficult to achieve measurement, scrapped gear blanks, etc., to avoid installation effect of error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

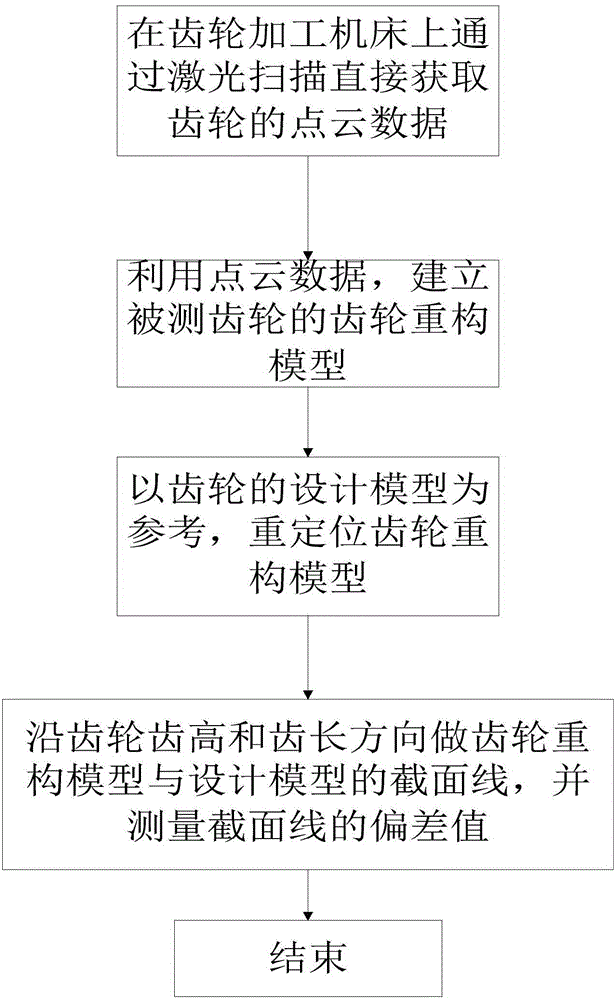

[0024] see Figure 1 to Figure 6 As shown, the online detection method of a spiral bevel gear processing process of the present invention uses a precision portable laser scanner to directly measure the point cloud data of the gear on the gear processing machine tool, and then compares it with the design size to measure the difference between the two. Deviation. The specific implementation includes the following steps:

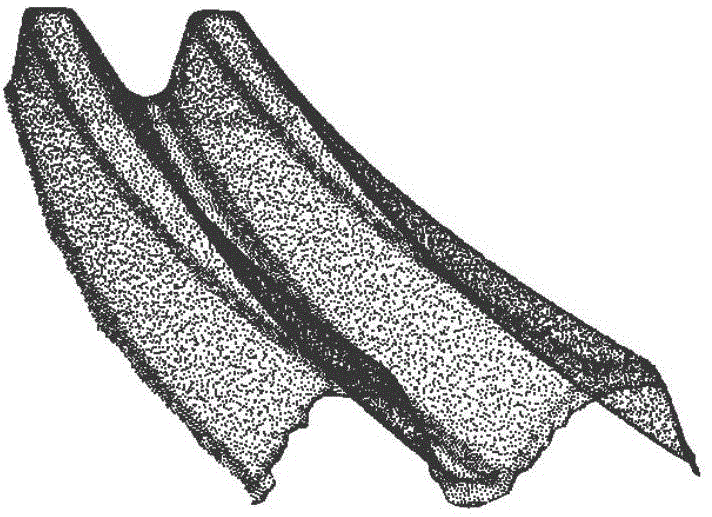

[0025] Step 1. Use the laser scanner to directly obtain the point cloud data of the gear on the gear processing machine tool, focusing on collecting the point cloud data of 2-3 gear teeth (such as figure 2 ); the point cloud data of the gear includes: the point cloud data of the tooth surface, shaft hole surface and end surface of the gear;

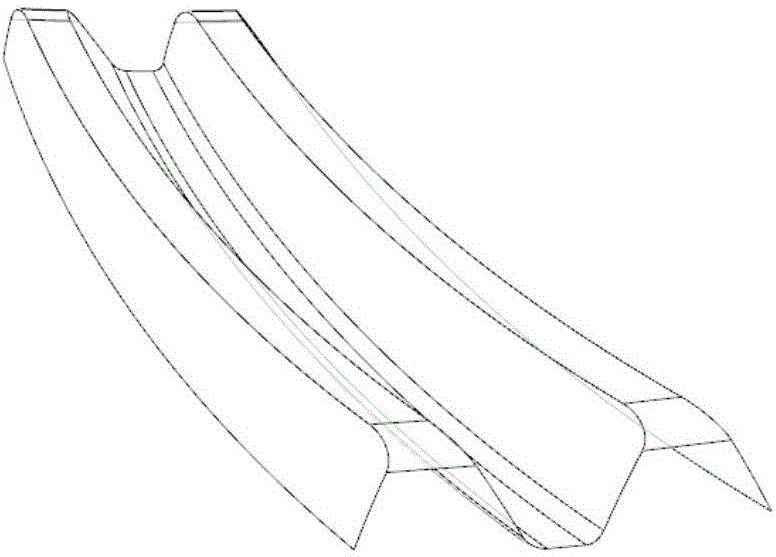

[0026] Step 2. Preprocess the point cloud data of the gear and convert it into surface data in stl format, and establish the measured gear reconstruction model according to the surface data;

[0027] Step 3, if image...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com