Three-way ball valve

A three-way ball valve, spherical valve core technology, applied in the direction of multi-way valve, safety valve, balance valve, etc., can solve the problems of fluid pressure, flow change, fluid pressure change, lack of working mode and use, etc., to achieve convenient control, Simple and ingenious structure, the effect of keeping the fluid pressure stable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

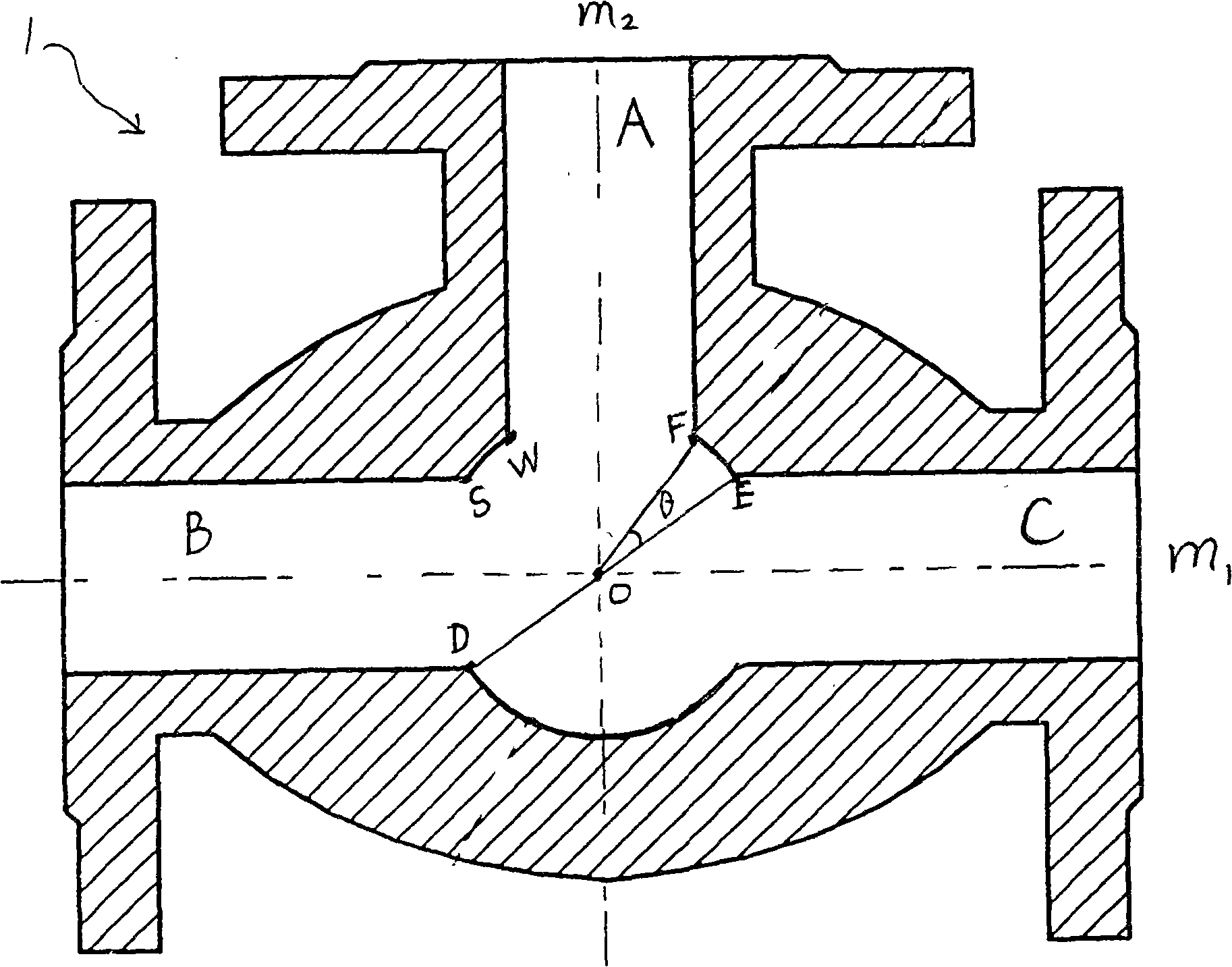

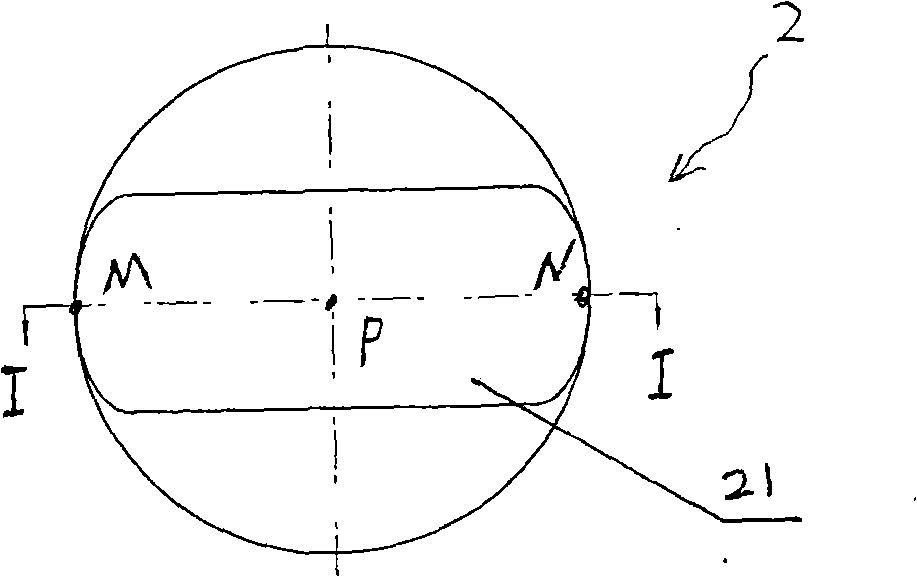

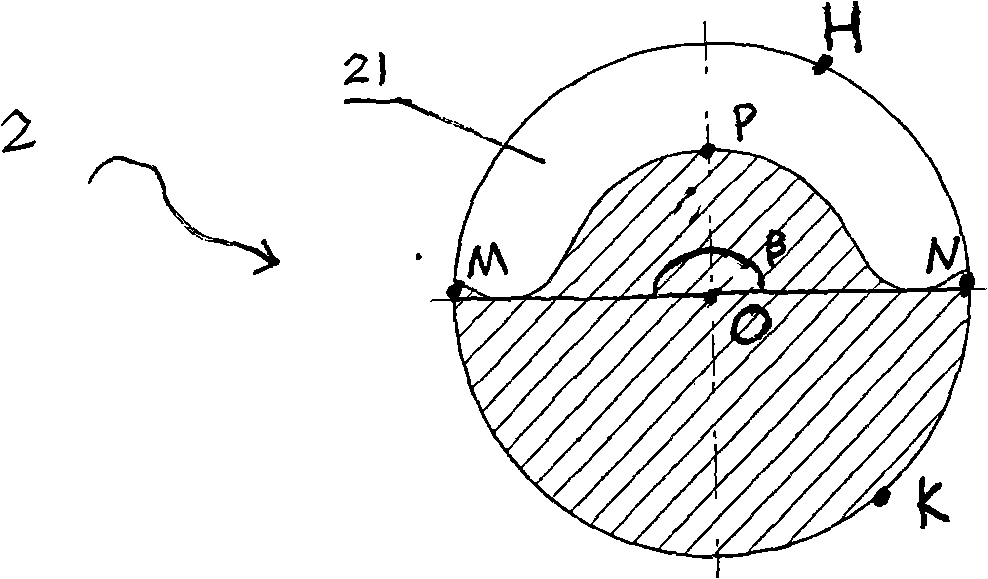

[0033] figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 The three-way ball valve shown includes a valve body 1 and a spherical valve core 2. The valve body has a main channel (A) and two branch channels (B, C). The two channel channels (B, C) are located on the same straight line. The main channel The channel is perpendicular to the two sub-channels. The main channel and the two sub-channels are distributed in a "T" shape. When the valve body 1 and the spherical valve core 2 are assembled, the intersection point O That is, the center position of the spherical spool; figure 1 As shown, there are arc-shaped parts at the junction of the main channel of the valve body and the two sub-runners, where the junction of the main channel (A) and the sub-runner (B) is the arc-shaped part SW, the main channel (A) and the sub-runner The junction of (C) is the arc-shaped part FE, and the arc-shaped part SW and the arc-shaped part FE are both matched with the spherical surface of ...

Embodiment 2

[0037] The structure of this embodiment is basically the same as that of Embodiment 1, except that the value of the geometric value is changed. The radian θ (that is, ∠EOF or ∠SOW) of the arc-shaped part at the junction of the main channel and the branch channel of the valve body in this embodiment is 10°, and image 3 The arc of the extension part MHN of the middle groove on the spherical surface of the valve core is β (ie ∠MON) and changed to 175°, and the solid part of the non-groove (ie image 3 The radian of the MKN part in ) is 185°, so there is also 180°-θ<β<180°+θ. The average depth of the groove is 1 / 3 of the spool radius.

[0038] Embodiment 2 can realize multiple different working states like Embodiment 1.

Embodiment 3

[0040] The structure of this embodiment is basically the same as that of Embodiment 1, except that the value of the geometric value is changed. In this embodiment, the radian θ (∠EOF or ∠SOW) of the arc portion at the junction of the valve main channel and the branch channel is 16°, and the arc of the groove MHN on the spherical surface of the valve core is changed from β to 185°. °, correspondingly, the solid part of the non-groove (ie image 3 The radian of the MKN part in ) is 175°, so there is also 180°-θ<β<180°+θ. The average depth of the groove is 2 / 3 of the spool radius.

[0041] The third embodiment is also the same as the first embodiment, and can realize multiple different working states.

[0042] In the second and third embodiments above, the points G and H of the spool are approximately symmetrical with respect to the center O of the sphere, so that the flow rate flowing into the channel A can still be basically adjusted during the process of adjusting and changi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radian | aaaaa | aaaaa |

| Radian | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com