Nd-Fe-B powder molding press

A technology of NdFeB powder, which is applied in the field of NdFeB powder molding presses, can solve the problems of impossibility of adopting near-net shape pressing technology, increase of pressing cost, production time, weight and overall size mismatch, and achieve structural Simple and ingenious, the overall size is reduced, and the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

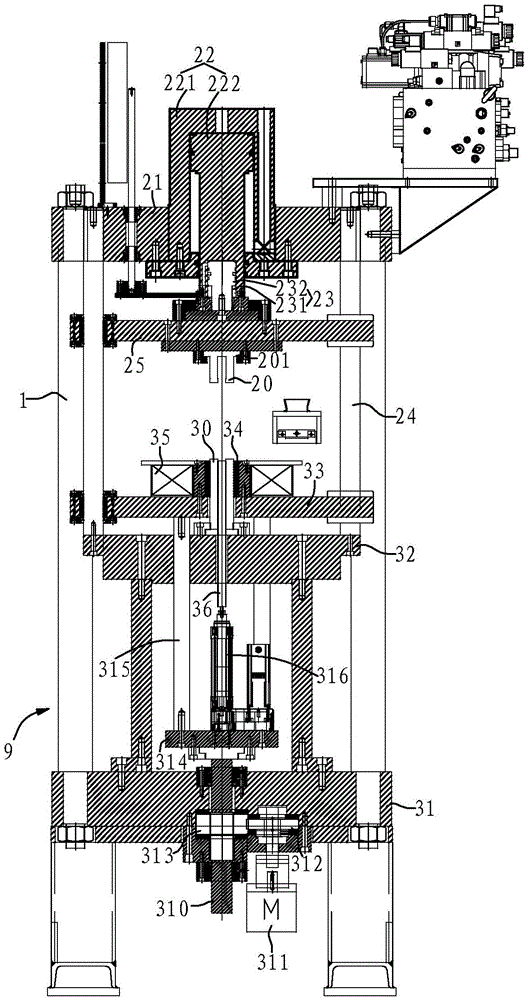

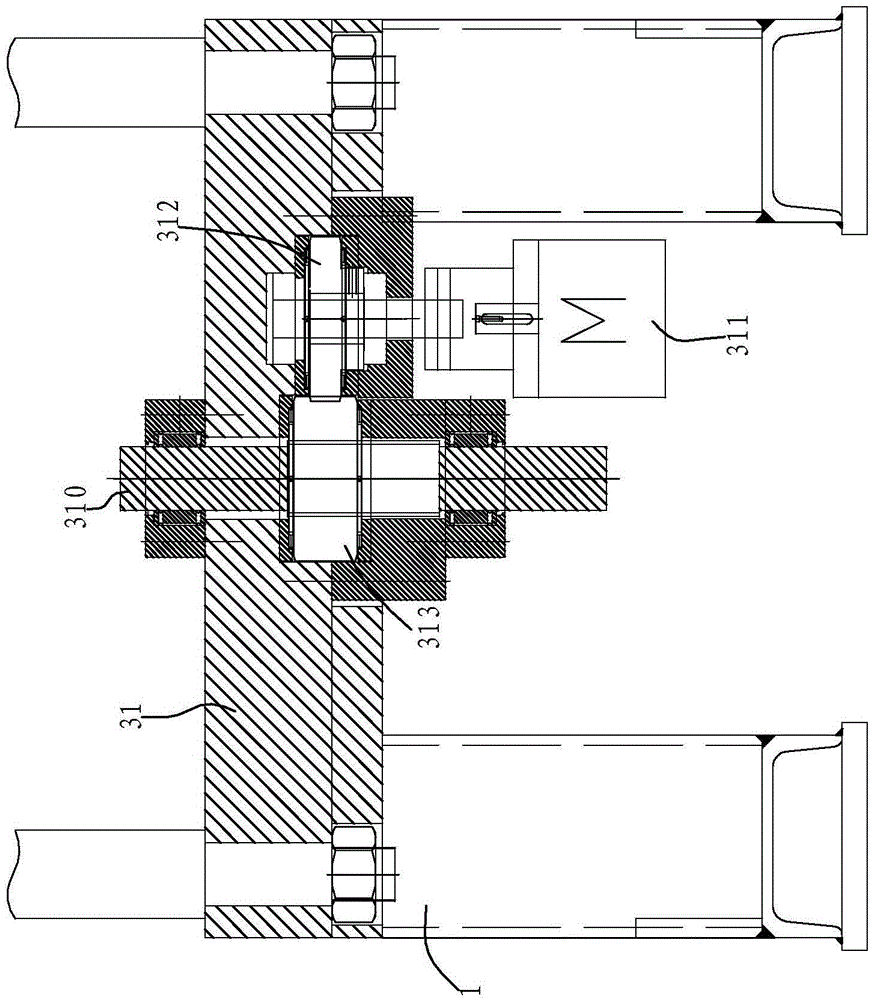

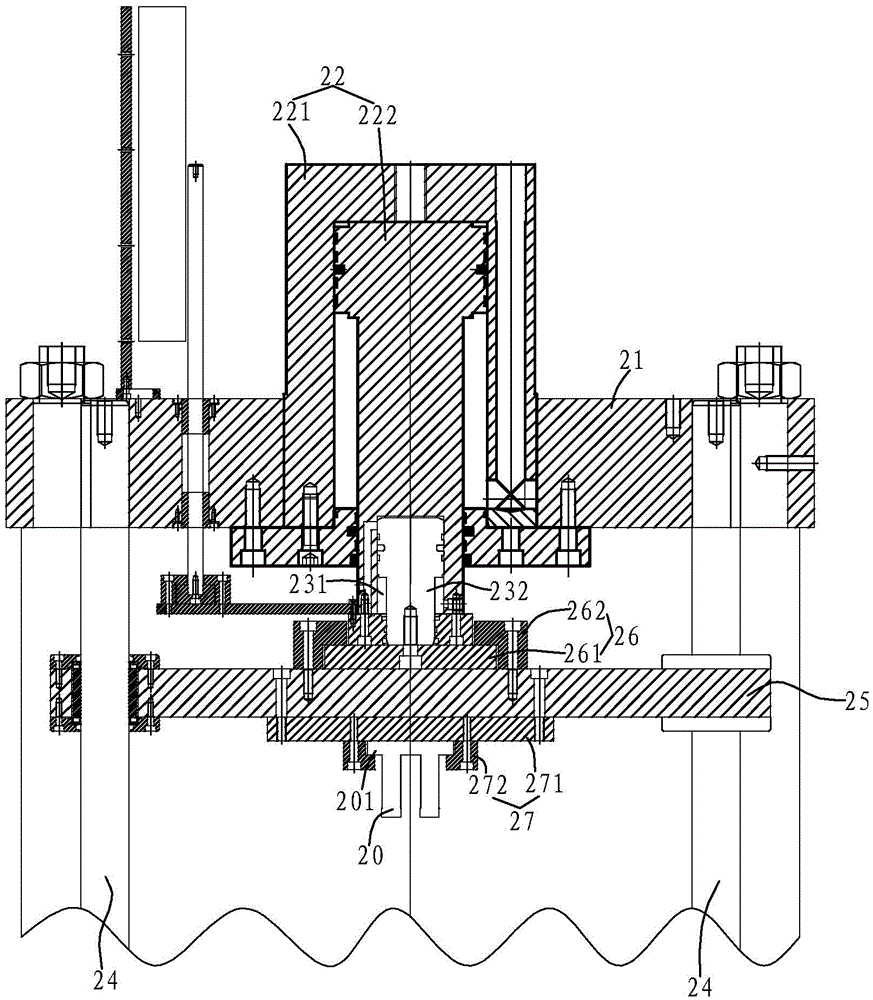

[0113] Such as Figure 1 ~ Figure 3 As shown, the upper punch assembly in this embodiment includes an upper pressing plate 21 , a main hydraulic cylinder 22 , a pressure release piston 232 , an upper punch 20 , a guide column 24 , and an upper guide plate 25 .

[0114] Wherein, the upper pressing plate 21 is fixedly installed on the top of the frame 1 , and the main hydraulic cylinder 22 is embedded and fixed in the center of the upper pressing plate 21 . The main hydraulic cylinder 22 includes a cylinder body 221 and a piston 222 , and the piston 222 can move up and down in the cylinder body 221 of the main hydraulic cylinder 22 driven by hydraulic oil.

[0115] Wherein the lower end of the main hydraulic cylinder 22 piston 222 is provided with an accommodating cavity opening downwards, and this accommodating cavity then forms a release cylinder 231, and the release piston 232 is installed in the release cylinder 231, thereby being compatible with the pressure release cylinde...

Embodiment 2

[0143] Such as Figure 4 As shown, the difference between the present embodiment and the first embodiment is only that the mold 34 , the supporting table 32 , and the lower punch 30 surround and form a lubricating cavity 4 for lubricating the inner wall of the mold 34 . The working principle of the lubricating assembly is the same as that of the first embodiment.

[0144] In addition, in this embodiment, each guide column 24 is connected between the upper pressing plate 21 and the lower pressing plate 31 . The support platform 32 is located above the lower platen 31 , and the mold 34 is installed on the support platform 32 . The lower guide plate 33 is located between the supporting platform 32 and the lower pressing plate 31 . In this embodiment, a magnetically conductive plate 37 is also provided on the support table 32, an upper coil 38 is arranged around the upper punch 20, a lower coil 39 is arranged around the lower punch 30, and the connection between the upper coil 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com