Moving adjusting mechanism for transverse cutting sub-die

An adjustment mechanism and cross-cutting technology, applied in the field of stamping die, can solve the problems affecting the daily production efficiency of the cross-cut sub-die, difficult to control the moving distance and precision, and achieve the effect of simple and ingenious structure, simple adjustment and improved work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

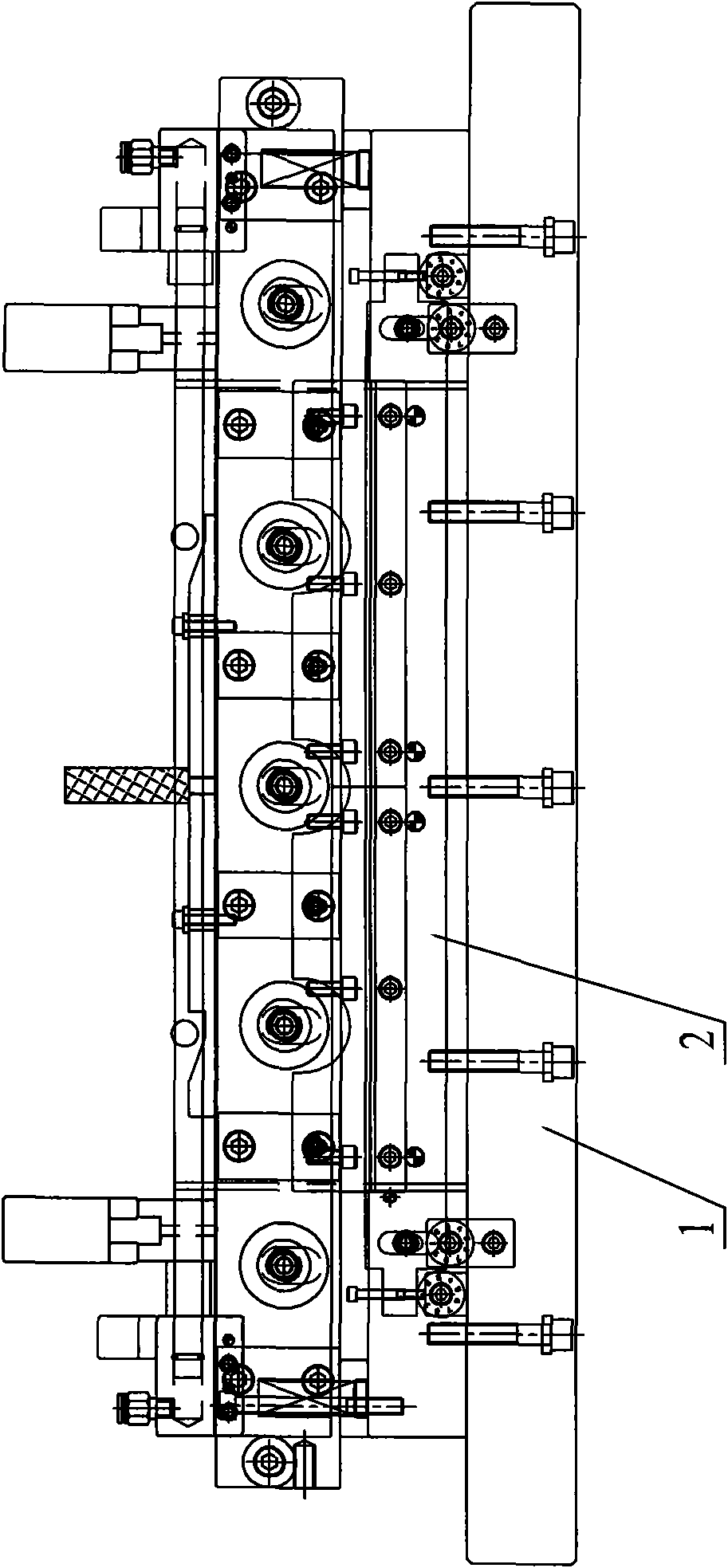

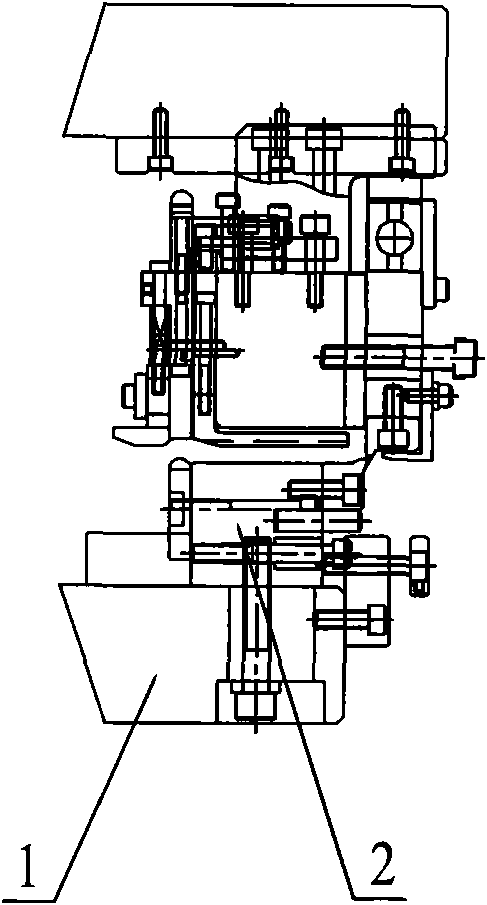

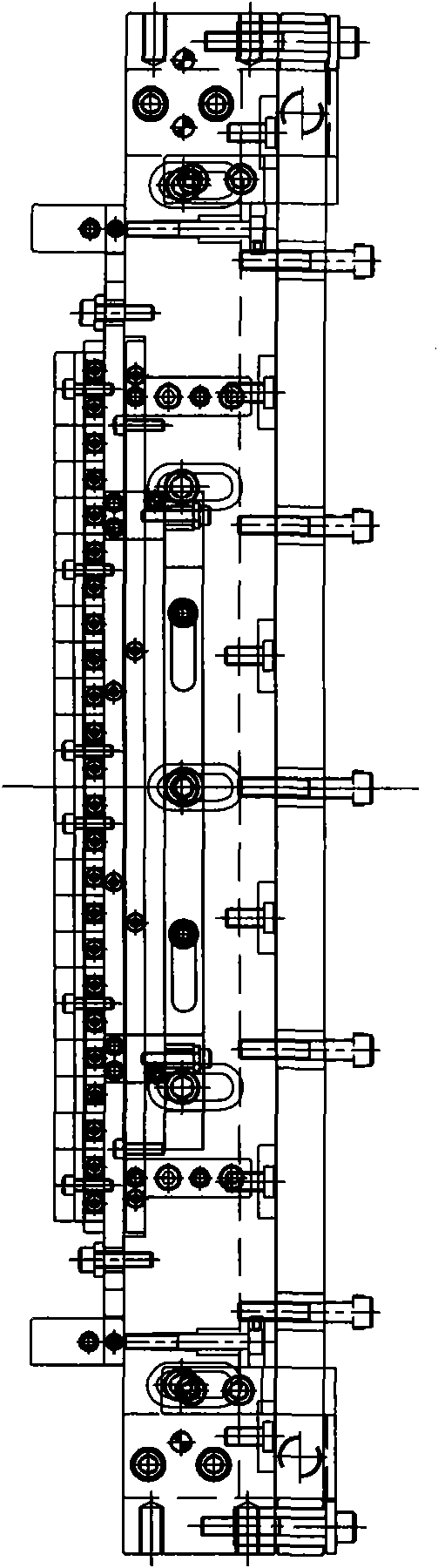

[0019] As shown in the figure, the cutting position of the cross-cut sub-die 2 includes an odd-numbered hole cross-cut position and an even-numbered hole cross-cut position, and the distance between the odd-numbered hole cross-cut position and the even-numbered hole cross-cut position is a step; The movement adjustment mechanism of the cutting sub-die 2 is mainly composed of two traveling cylinders 3 and two pressing cylinders 4, and the two traveling cylinders 3 and two pressing oil cylinders 4 are arranged on both sides of the cross-cutting sub-die 2 respectively.

[0020] Such as Figure 5 , Figure 6 As shown, the cylinder body of the traveling cylinder 3 is fixed on the large formwork 1 by bolts, the piston rod of the traveling cylinder 3 is connected to the frame body of the crosscutting sub-mould 2 through a push shaft 5, and the piston rod of the traveling cylinder 3 shrinks inwardly. , the crosscutting sub-mold 2 is located at the odd-numbered hole cross-cutting posi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com