Assembly-type shear wall connecting structure and construction method thereof

A technology for connecting structures and shear walls, applied to walls, building components, building structures, etc., can solve the problems of difficult accurate alignment of steel ends, troublesome refilling of concrete, low construction efficiency, etc., and achieve simple and ingenious structure. Improve construction efficiency and reliable connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

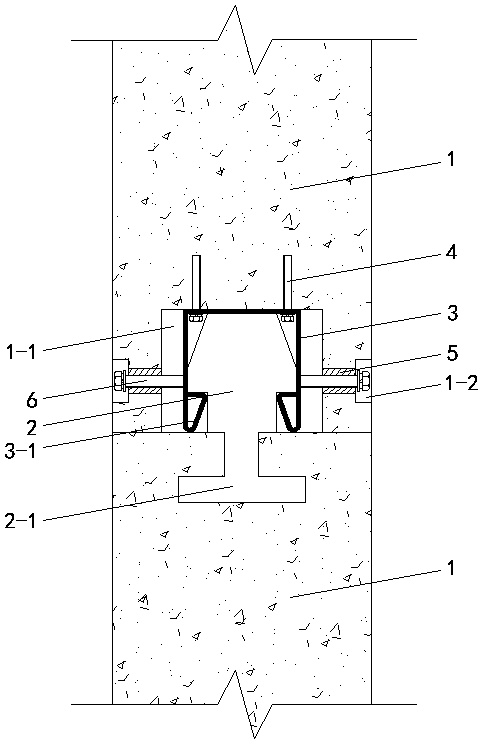

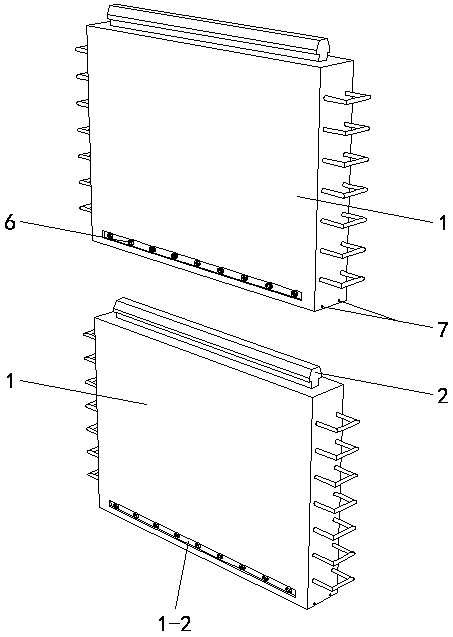

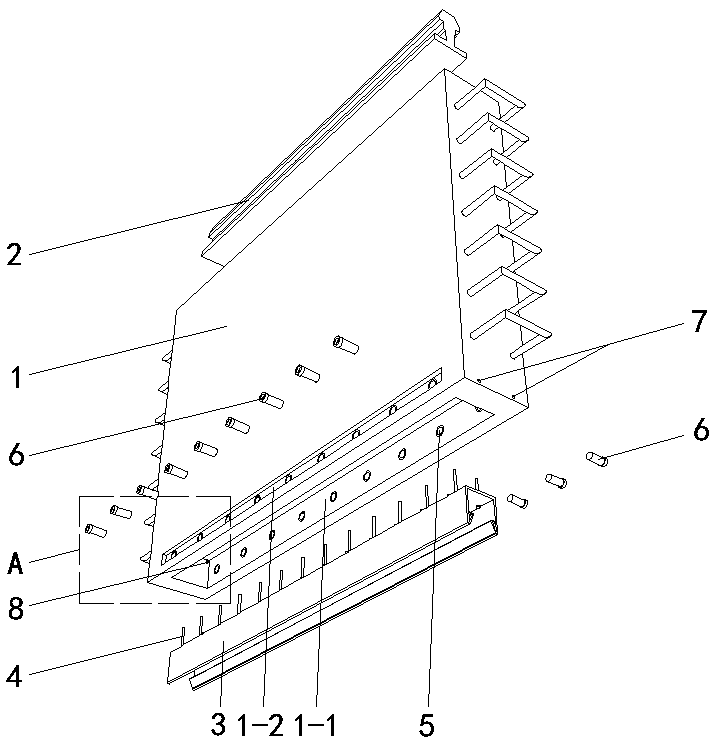

[0018] Specific implementation mode one: as Figure 1~Figure 5 As shown, the present invention discloses a prefabricated shear wall connection structure, including a plurality of shear wall monomers 1, and inserting steel parts 2 and positioning channel steels between each two shear wall monomers 1 3 connected into one body, the middle position of the upper end surface of each shear wall unit 1 is buried and fixed along its length direction with a plug-in steel part 2, and the plug-in steel part 2 is strip steel and includes an inverted T-shaped pre- The buried bottom 2-1 and the wedge-shaped exposed top 2-2, and the two sides of the wedge-shaped exposed top 2-2 are respectively provided with clamping parts 2-3, and the middle position of the lower end surface of each shear wall unit 1 is along its length direction A rectangular slot 1-1 is concavely provided, and the rectangular slot 1-1 corresponds to the inserted steel part 2 and its width is greater than the width of the i...

specific Embodiment approach 2

[0019] Specific implementation mode two: as figure 1 , 4 As shown, this embodiment is a further description of specific embodiment 1. A groove is horizontally provided on the outer sides of the groove walls on both sides of the rectangular slot 1-1 of each shear wall unit 1 in the length direction. Groove 1-2, said groove 1-2 connects a plurality of corresponding inner threaded sleeves 5, and the outer end of each said inner threaded sleeve 5 is flush with the groove bottom of corresponding groove 1-2. After the two support arms of the positioning channel steel 3 are defined by the fastening bolts 6, the shear wall monomer 1 is smoothed with mortar in the groove 1-2.

specific Embodiment approach 3

[0020] Specific implementation mode three: as figure 1 As shown, this embodiment is a further description of specific embodiment one. The width of the clip joint 3-1 of the positioning channel steel 3 is smaller than the two arms of the positioning channel steel 3 and the length direction of the rectangular slot 1-1. Spacing between side channel walls.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com