TIG arc welding electrode and TIG arc welding method

An arc welding and electrode technology, applied in arc welding equipment, welding equipment, welding media, etc., can solve the problems of high current density, lower arc pressure, and inability to reduce the difference in current density, etc., to achieve high speed and efficiency, the effect of reducing the arc pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

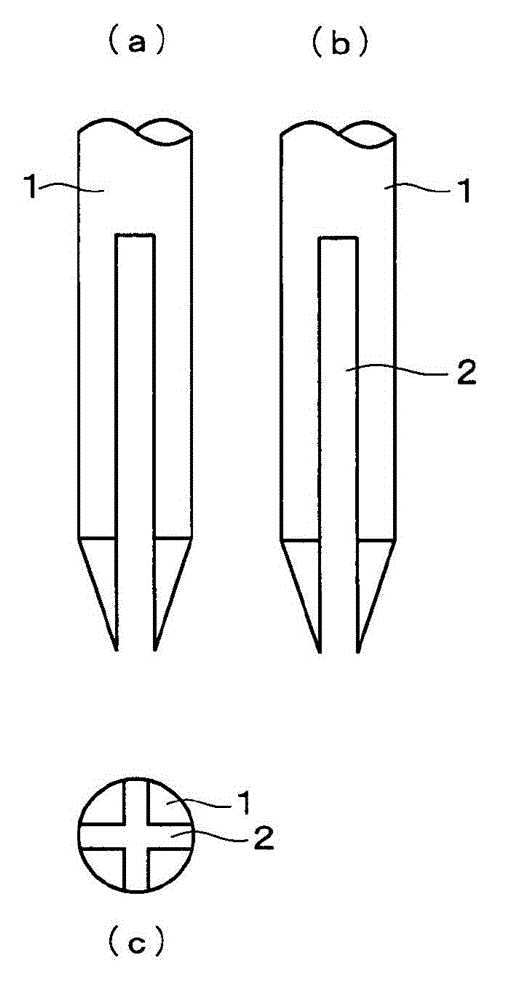

[0072] The shape of the slit-containing tungsten electrode 1 of the second embodiment of the present invention is shown in figure 2 , figure 2 (a) is the front view, figure 2 (b) is a side view, figure 2 (c) is a bottom view.

[0073] It is also possible to set a plurality of slits 2 at the tip of the electrode 1 to form more than 3 tips ( figure 2 indicates a cruciform-type slit).

[0074] In the case where the above-mentioned slit is a straight line, welding without direction can be sufficiently performed, but especially when the diameter of the tungsten electrode is larger than 5.0mm, the case of the cross can be compared with the case of the straight line. For a more non-directional weld.

[0075] Furthermore, it is also possible to change the conical shape of the tip portion of the tungsten electrode 1 in the above-mentioned embodiment 1 and embodiment 2 into a polygonal pyramid shape not shown in the figure, and obtain the same shape as the above-mentioned slit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com