Substrate transporting device and substrate transporting method

A substrate conveying and conveying direction technology, applied in the direction of conveyor objects, transportation and packaging, rollers, etc., can solve the problems of guide roller wear and other problems, and achieve the effect of extending life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

[0018] refer to Figure 1 to Figure 4 The first embodiment will be described.

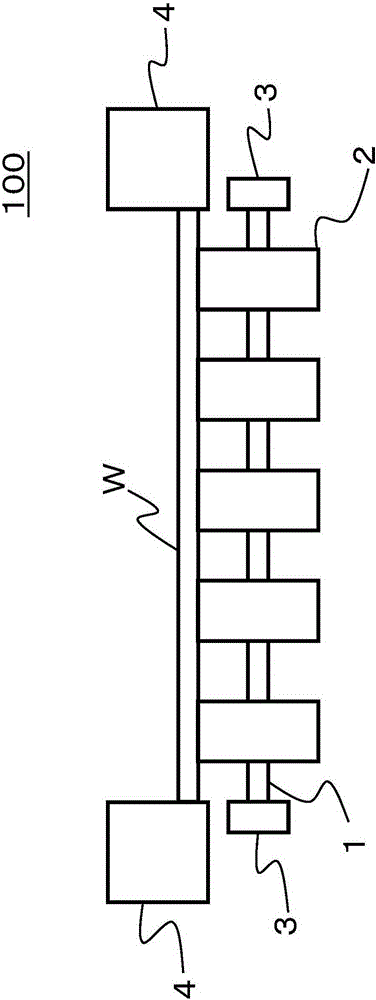

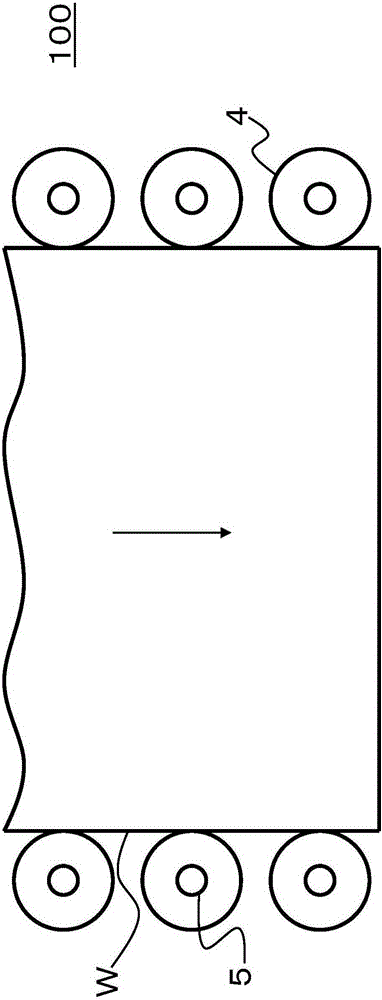

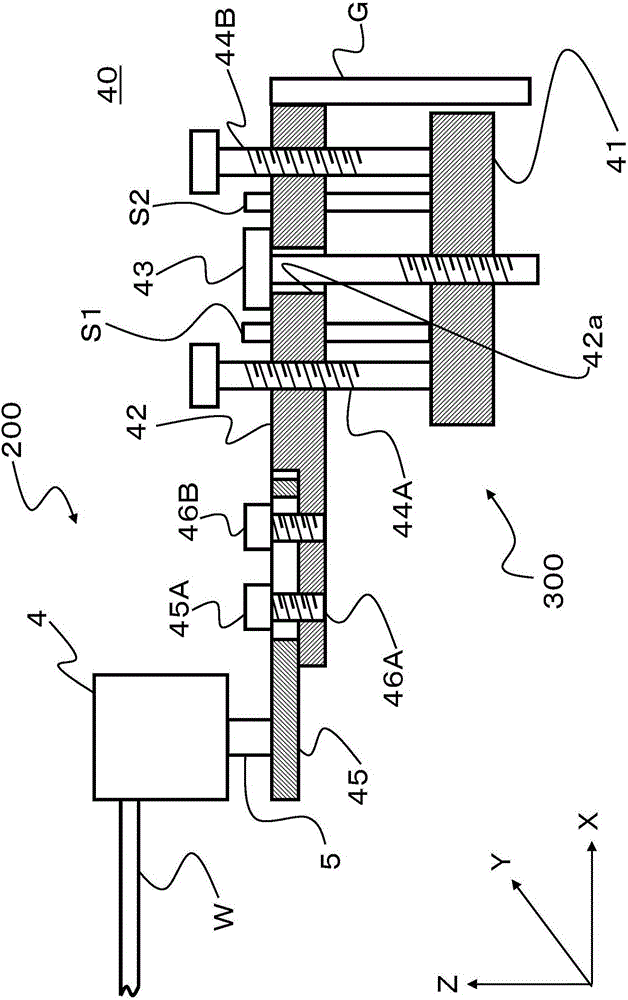

[0019] Such as figure 1 , figure 2 As shown, the substrate transfer apparatus 100 of the first embodiment has a shaft 1 provided along the transfer direction of the substrate W (in figure 1 The direction perpendicular to the paper surface) (hereinafter, also referred to as "the width direction of the substrate W") extends; the conveying roller 2, which is provided on the shaft 1 in a plurality at regular intervals, and is arranged as abuts against the lower surface of the base plate W; and a bearing 3 that holds the shaft 1 . Furthermore, a plurality of guide rollers 4 pass through shafts 5 (see figure 2 ) to set. The guide roller 4 is made of an elastic body such as rubber or resin, and is formed in a cylindrical shape having a height twice or more than the thickness of the substrate W. image 3 , Figure 4 As explained above, each guide roller 4 is configured to be capable of adjusting t...

no. 2 Embodiment approach

[0040] refer to Figure 5 , Image 6 A second embodiment will be described.

[0041] The second embodiment is basically the same as the first embodiment. Therefore, in the second embodiment, differences from the first embodiment will be described, and the same parts as those described in the first embodiment will be denoted by the same reference numerals, and descriptions thereof will be omitted.

[0042] Such as Figure 5 As shown, the substrate conveying apparatus according to the second embodiment includes a guide roller adjustment unit 400 . The X-axis adjustment mechanism of the guide roller adjustment unit 400 is the same as the X-axis adjustment mechanism 200 of the first embodiment. Unlike the first embodiment, the Z-axis adjustment mechanism includes an adjustment member (spacer member) 400A between the fixed member 41 and the second movable member 42 . The position of the guide roller 4 in the Z direction can be adjusted by preparing a plurality of adjusting mem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com