Patents

Literature

67results about How to "No bending phenomenon" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

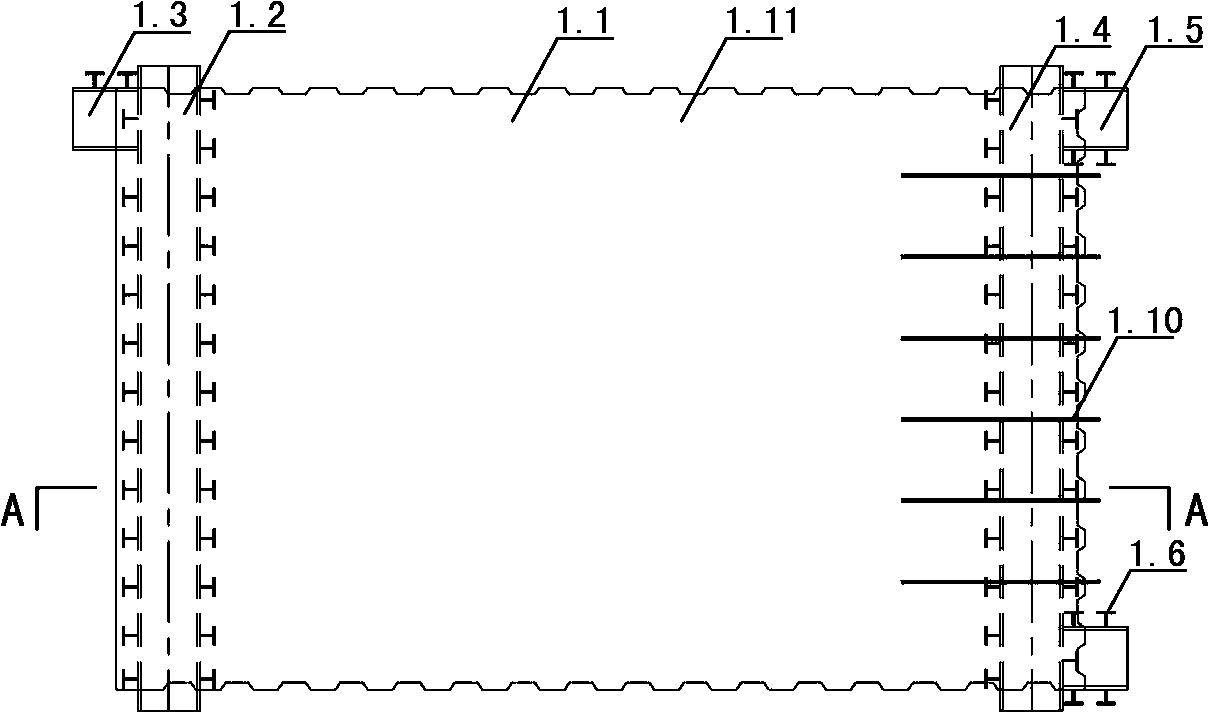

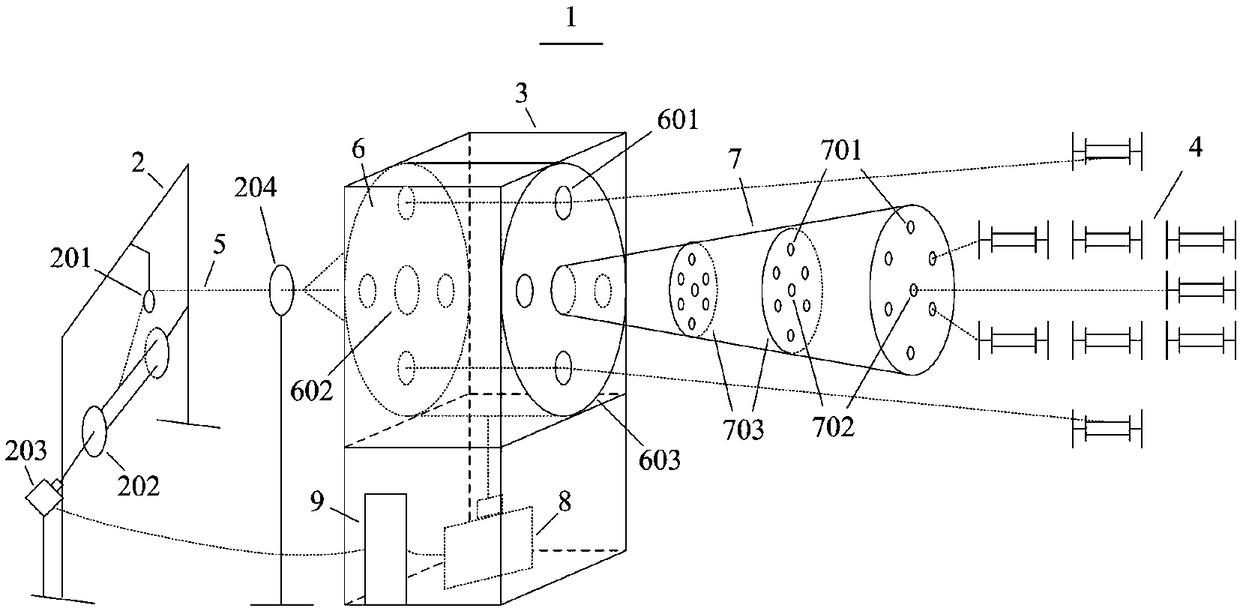

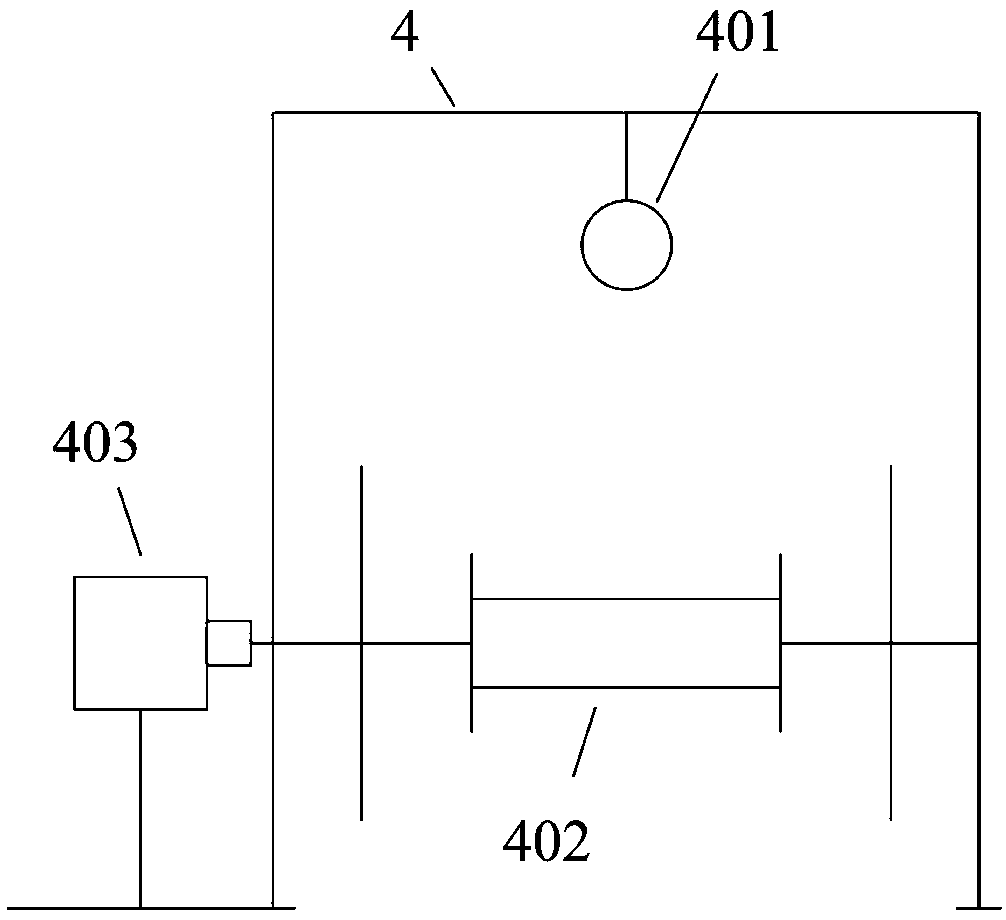

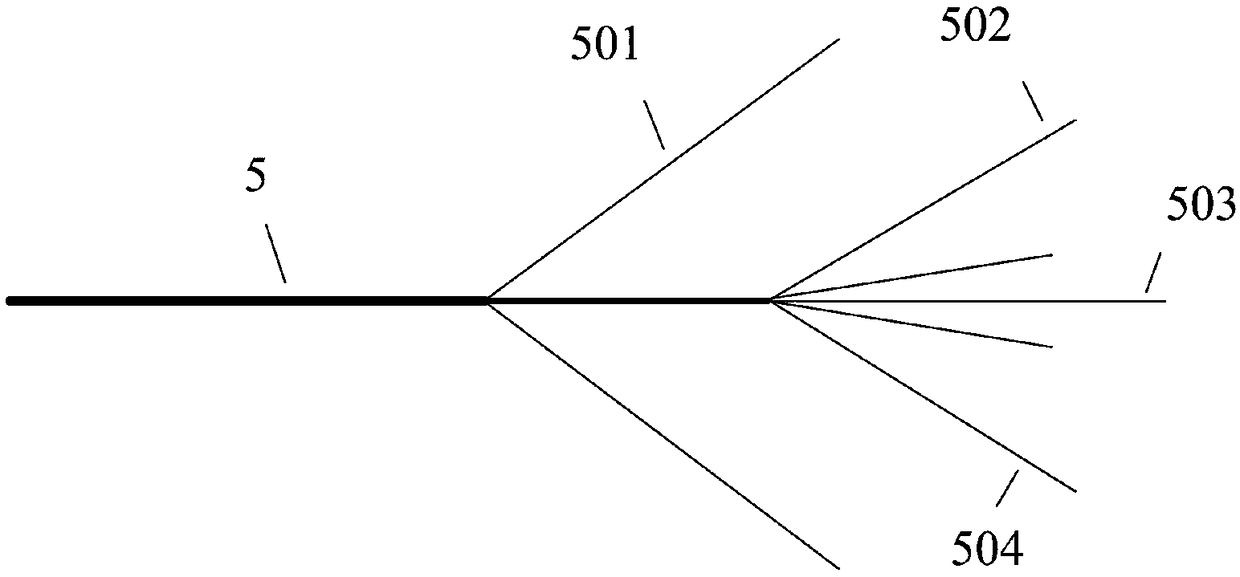

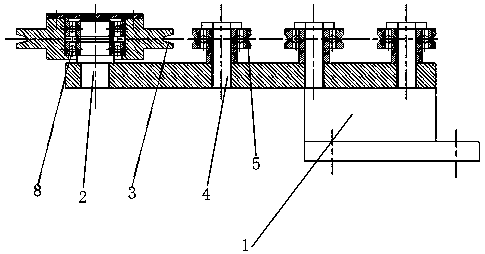

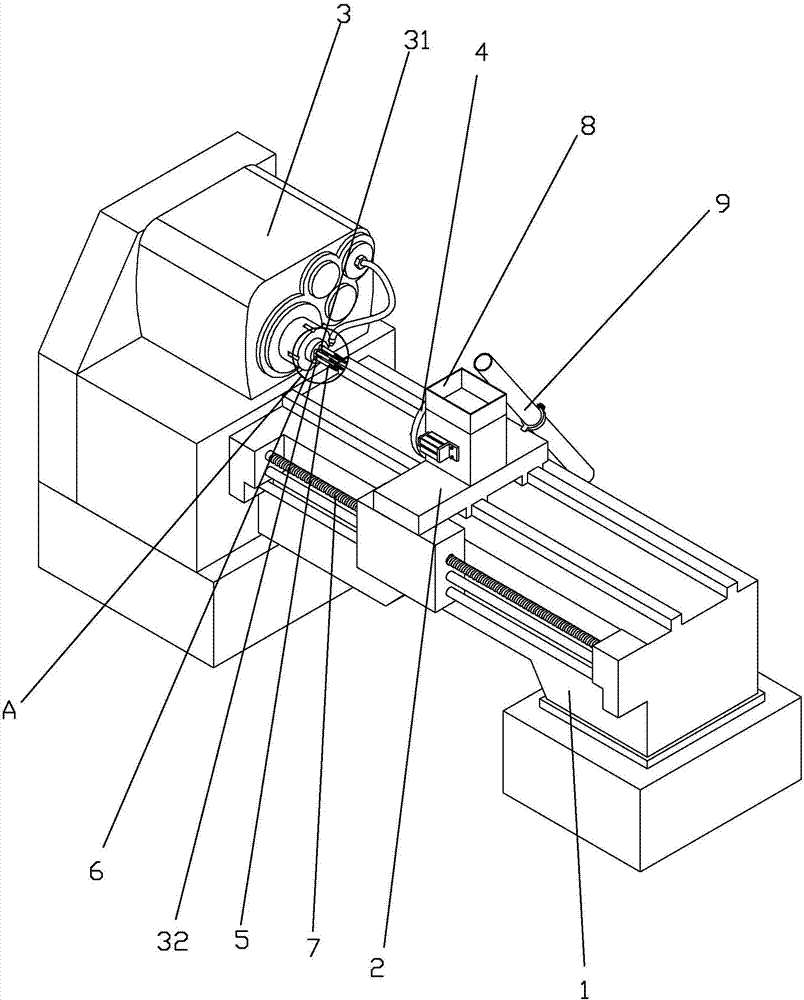

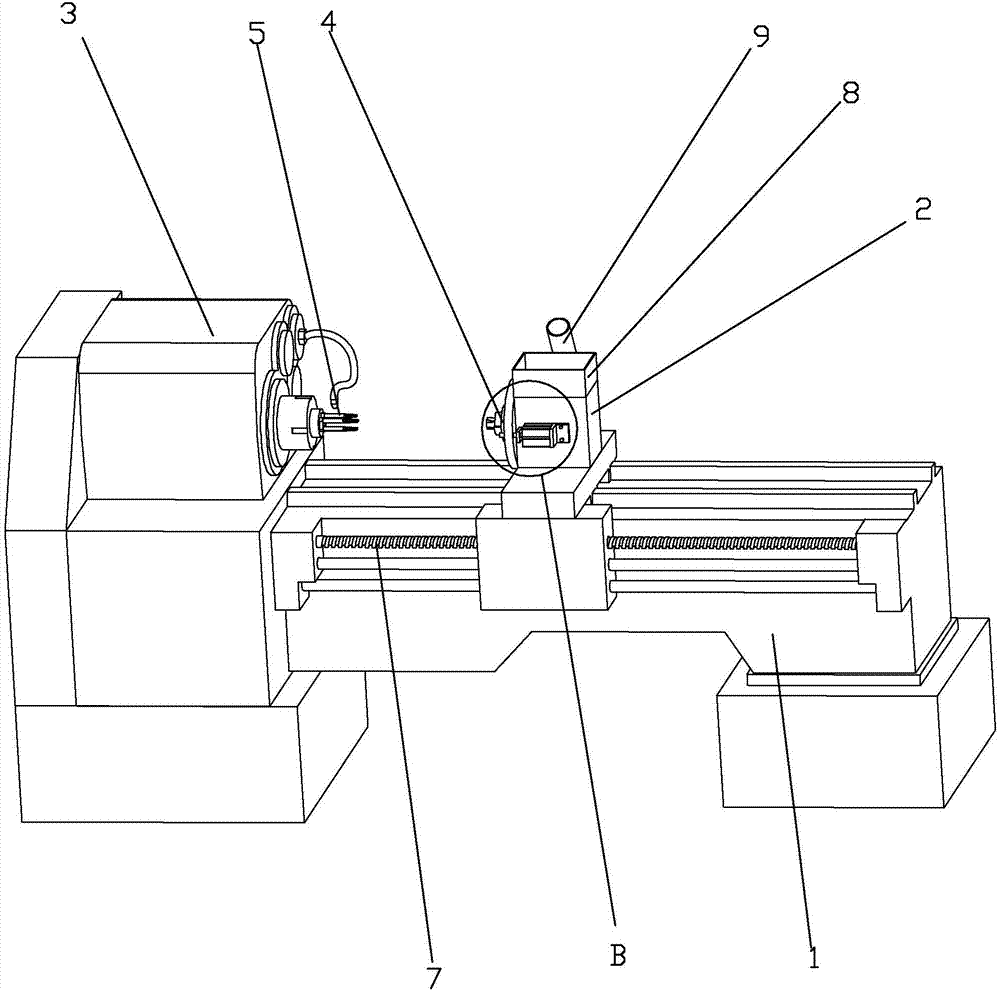

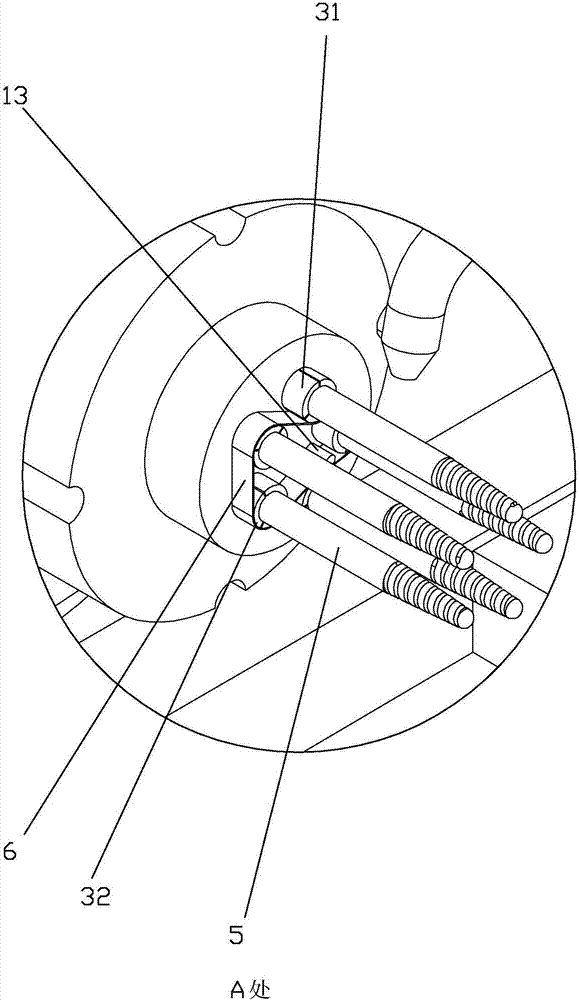

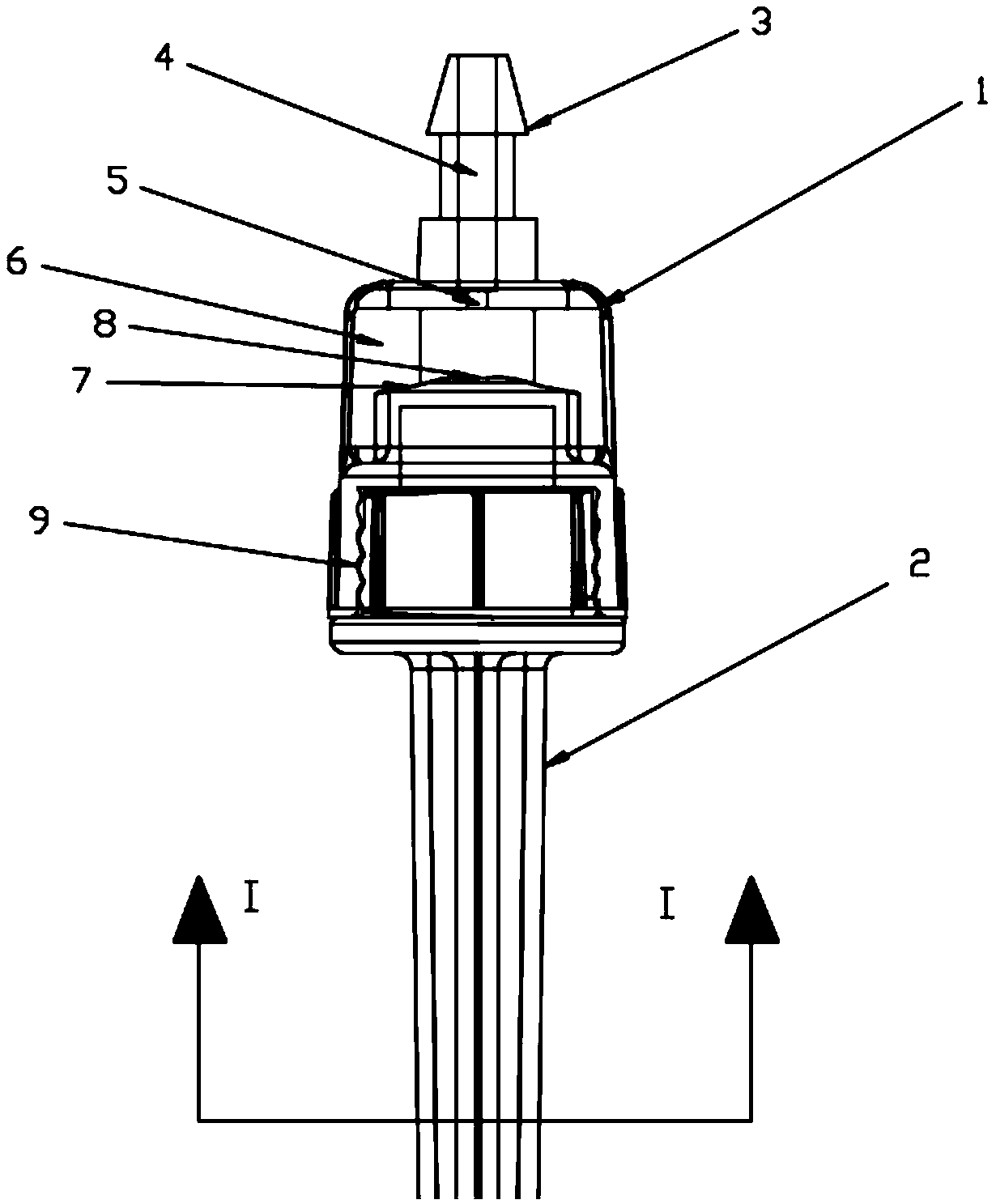

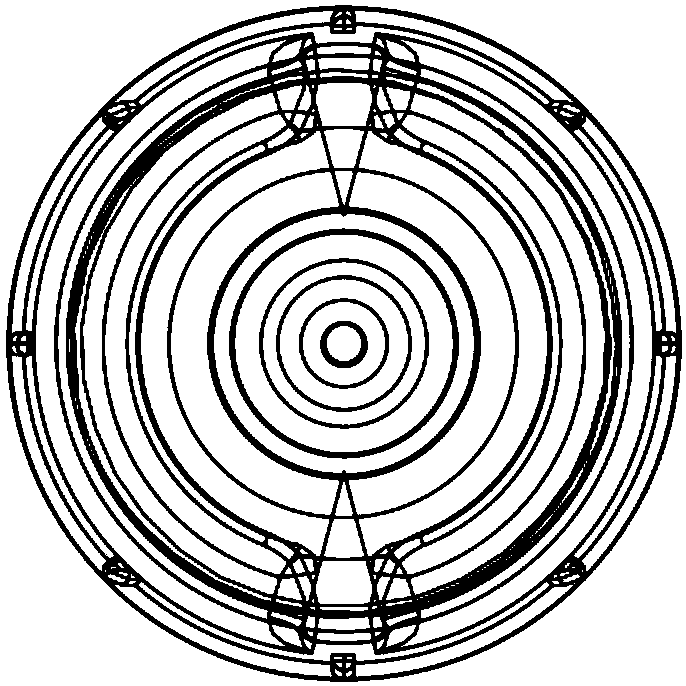

Device and method for directly quenching seamless steel pipes

InactiveCN101570813ANo bending phenomenonEasy to bendFurnace typesProcess efficiency improvementSurface coolingQuenching

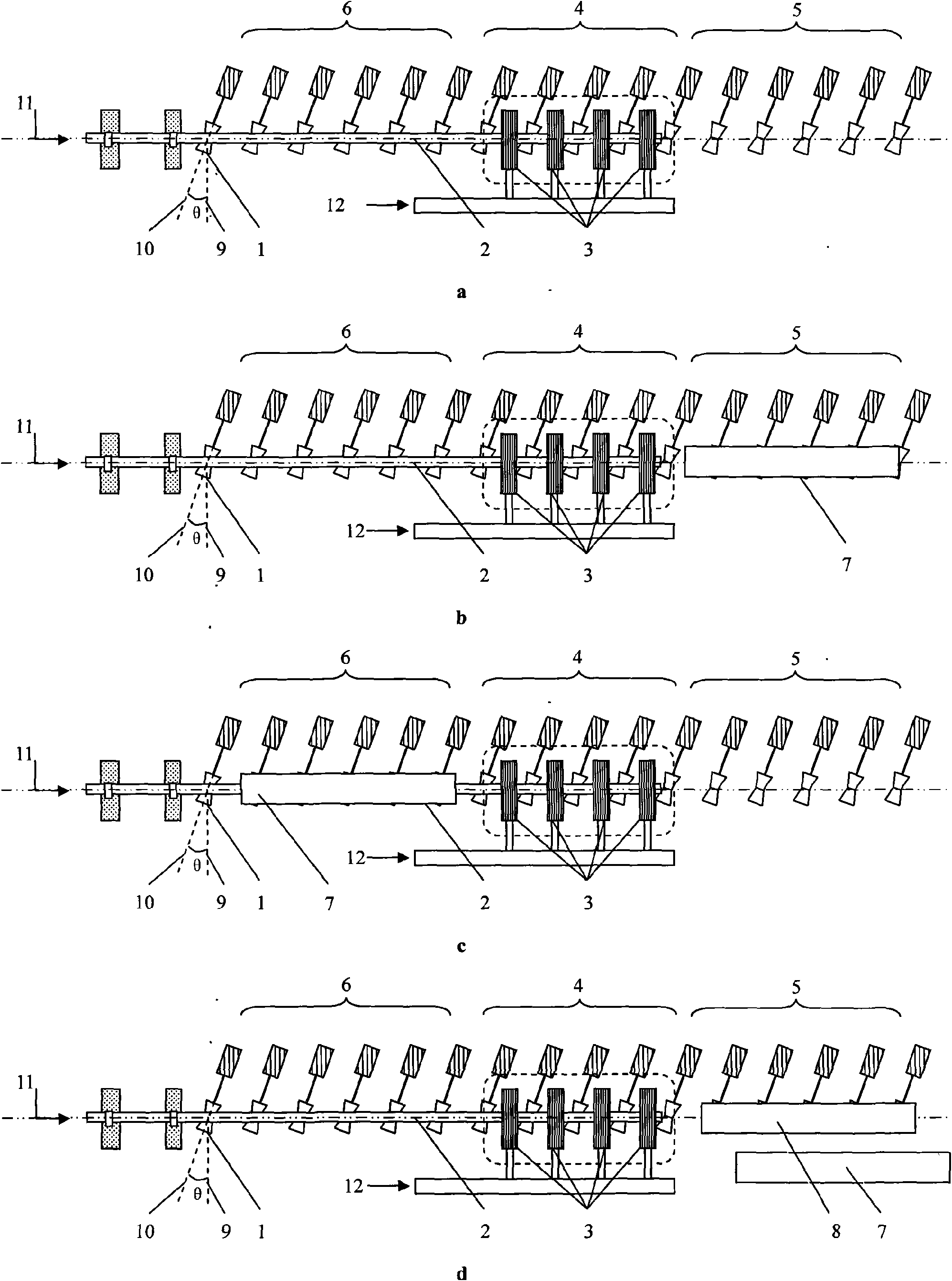

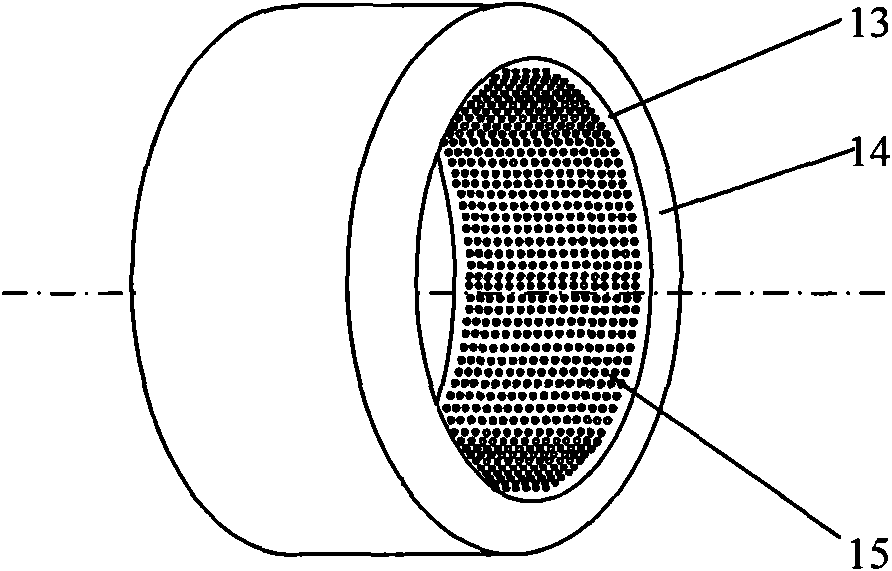

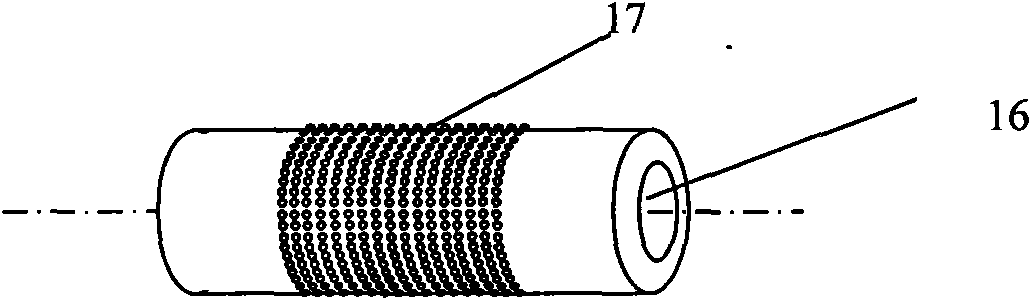

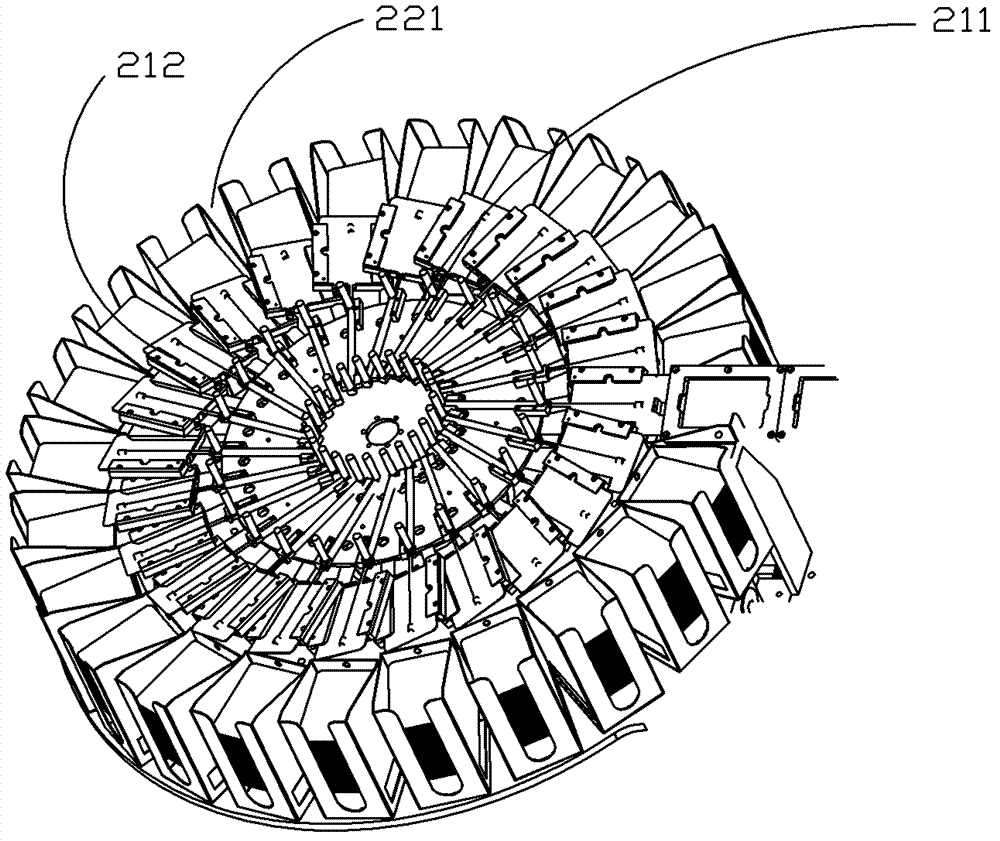

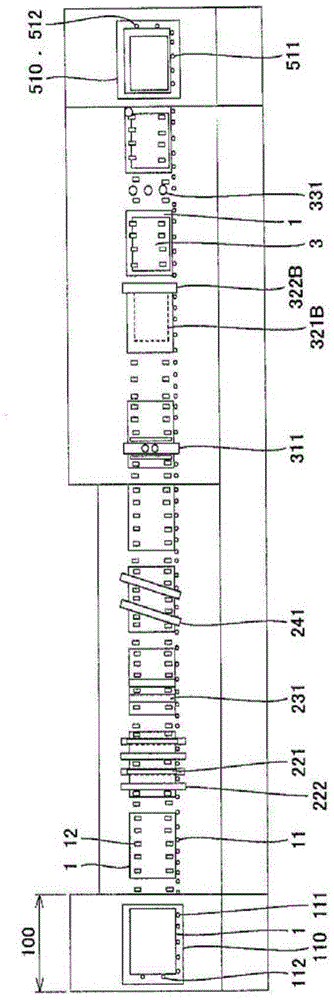

The invention provides a device and a method for directly quenching seamless steel pipes, which belongs to the technical field of metallurgy. The device comprises a variable-angle roller bed device, an outer-surface cooling device and an inner-surface cooler, wherein the inner-surface cooler is in a rod shape; the outer-surface cooling device consists of at least one annular cooler; the inner-surface cooler is positioned above the variable-angle roller bed device; and the inner-surface cooler is inserted in the middle of an annular wall. The method comprises the steps of supplying cooling media to the inner-surface cooler and the outer-surface cooling device, conveying steel pipes to the inside of the annular cooler and the outside of the inner-surface cooler and implementing quenching. The invention can solve the problem that steel pipes are easy to bend in a quenching process. The device has the advantages of simple structure and convenient operation.

Owner:刘彦春

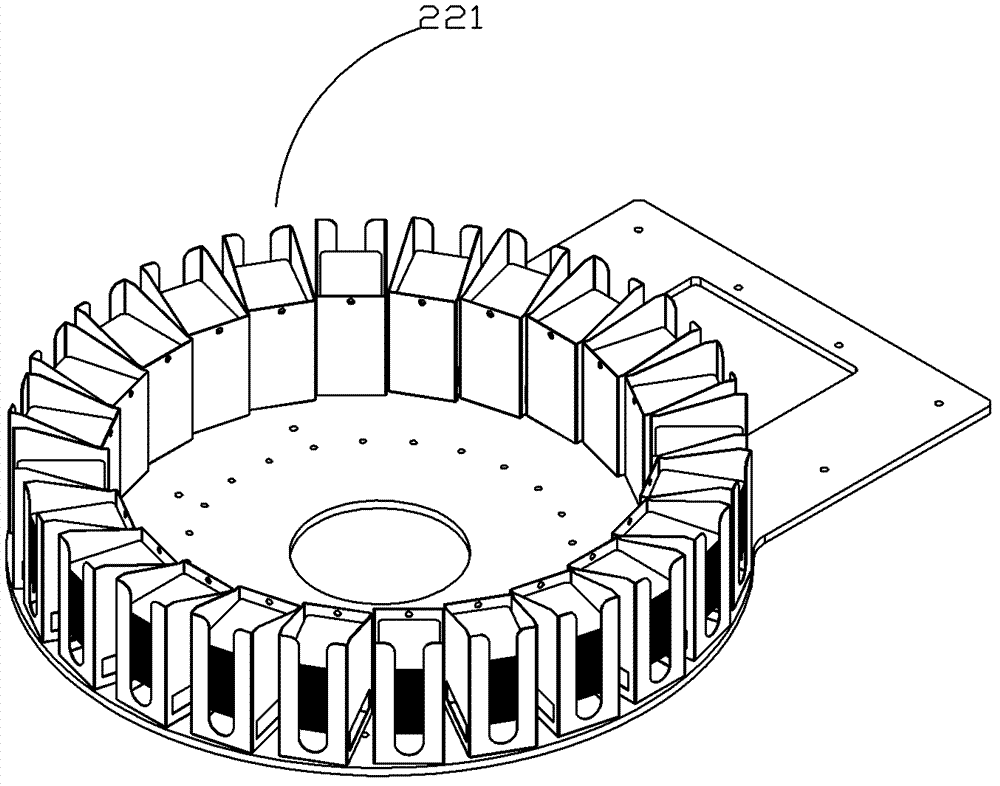

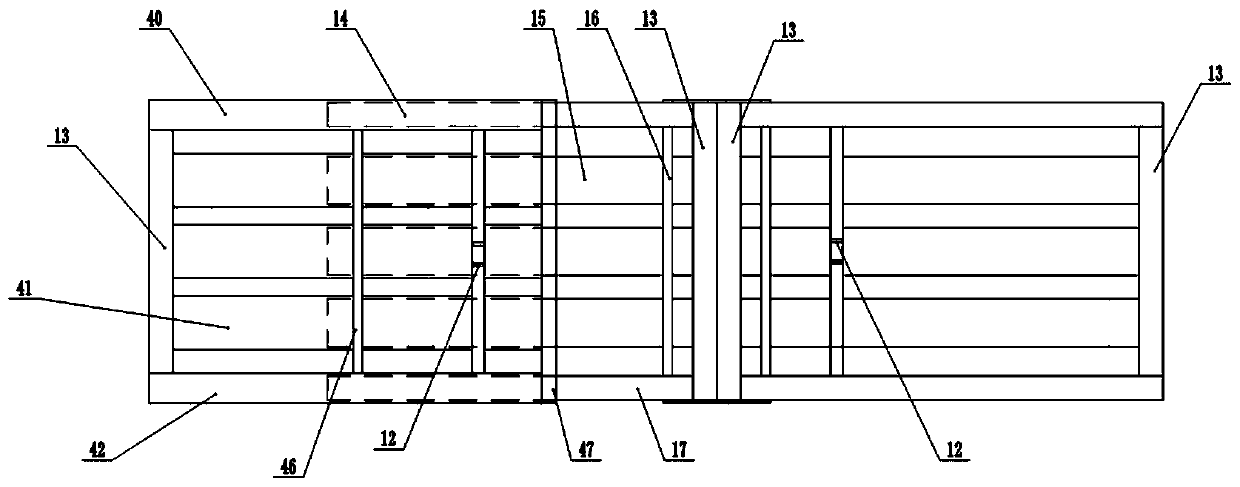

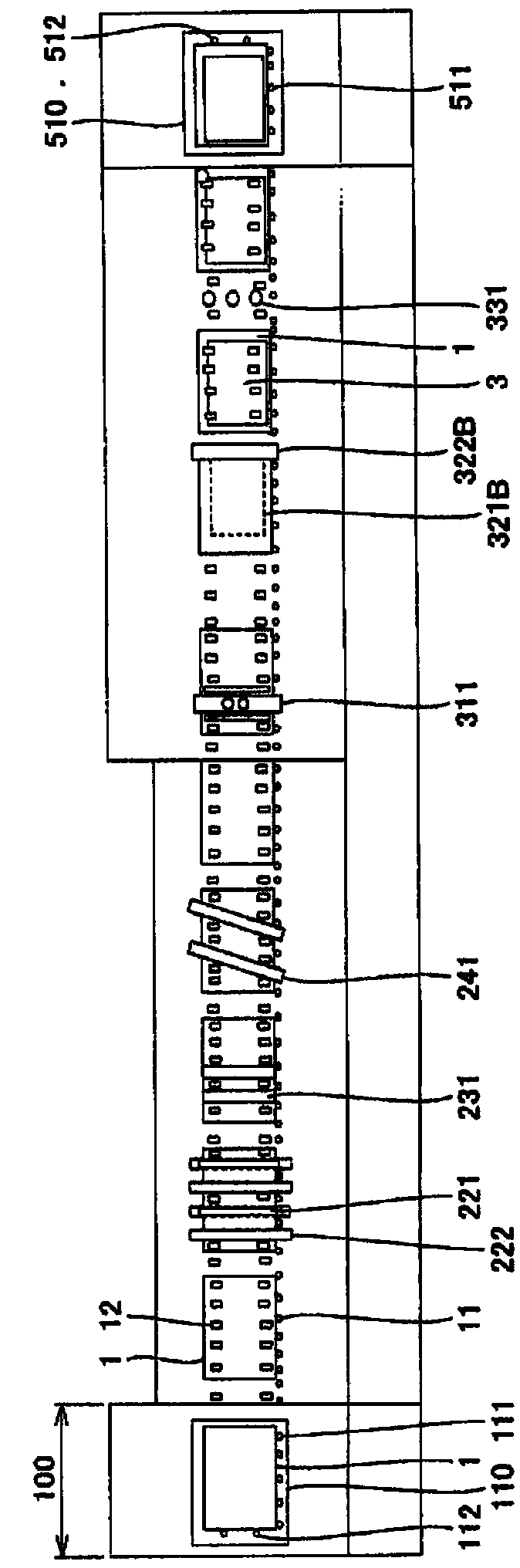

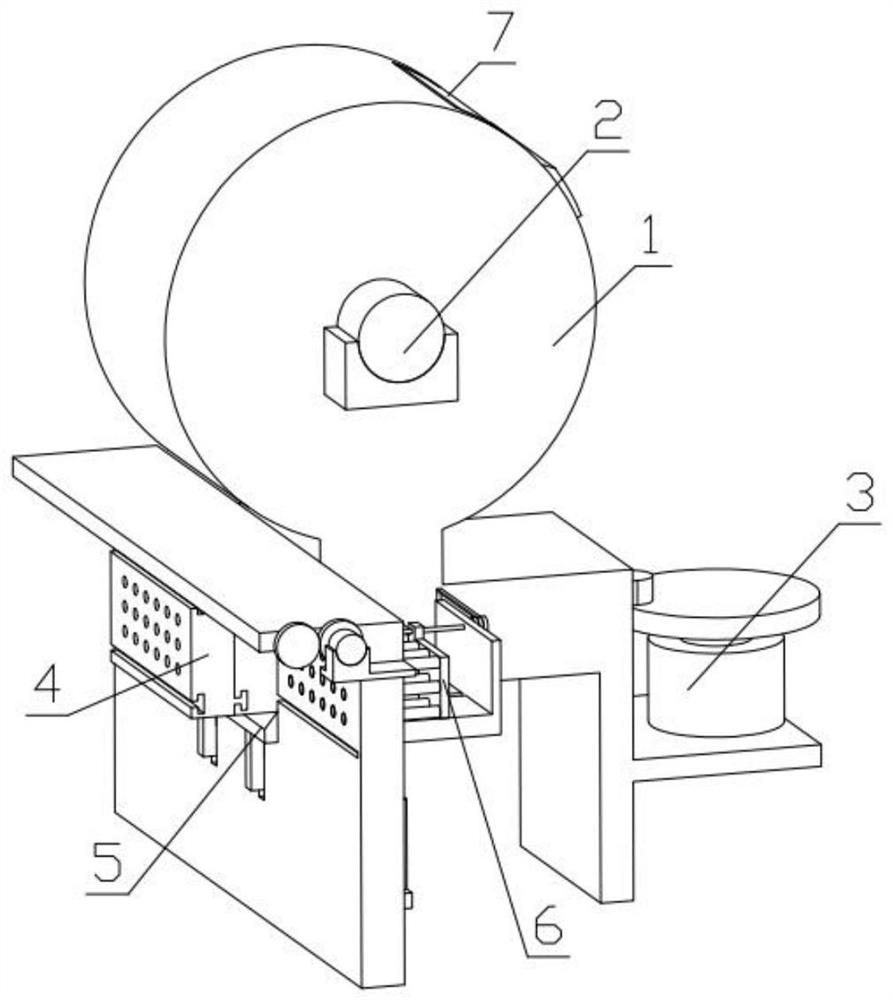

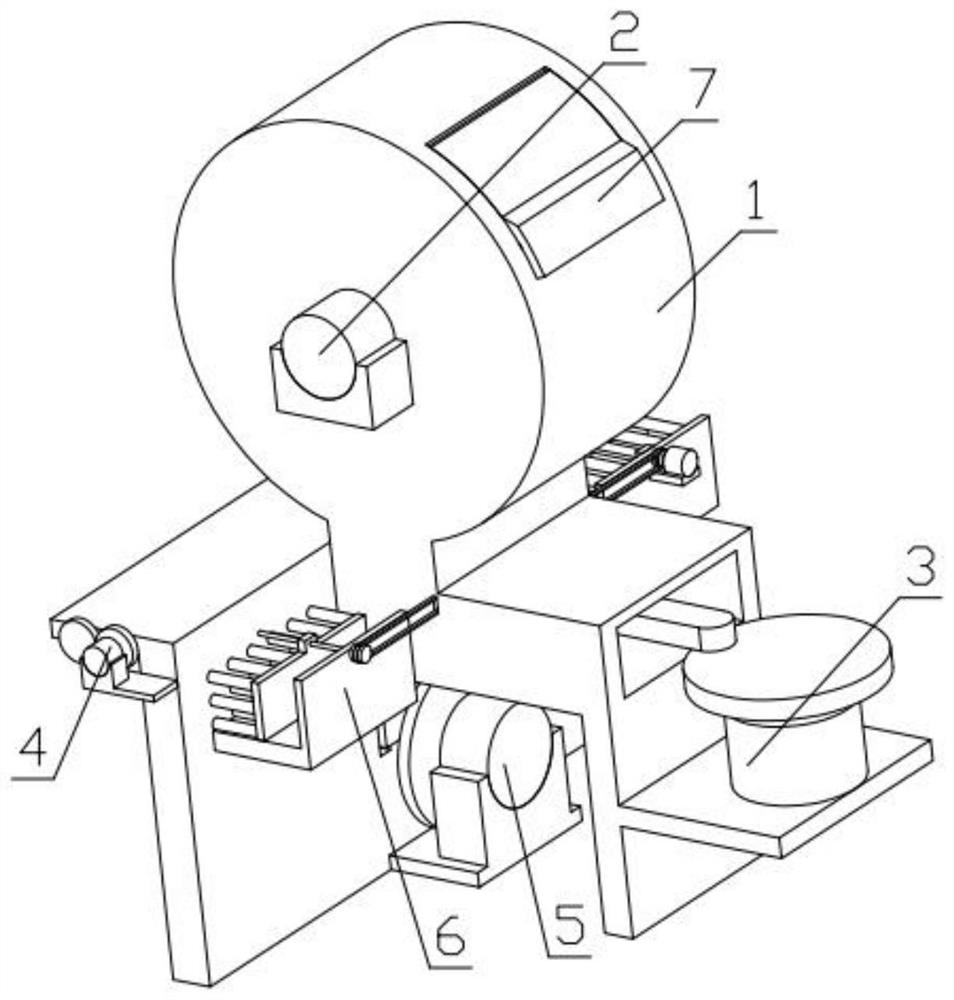

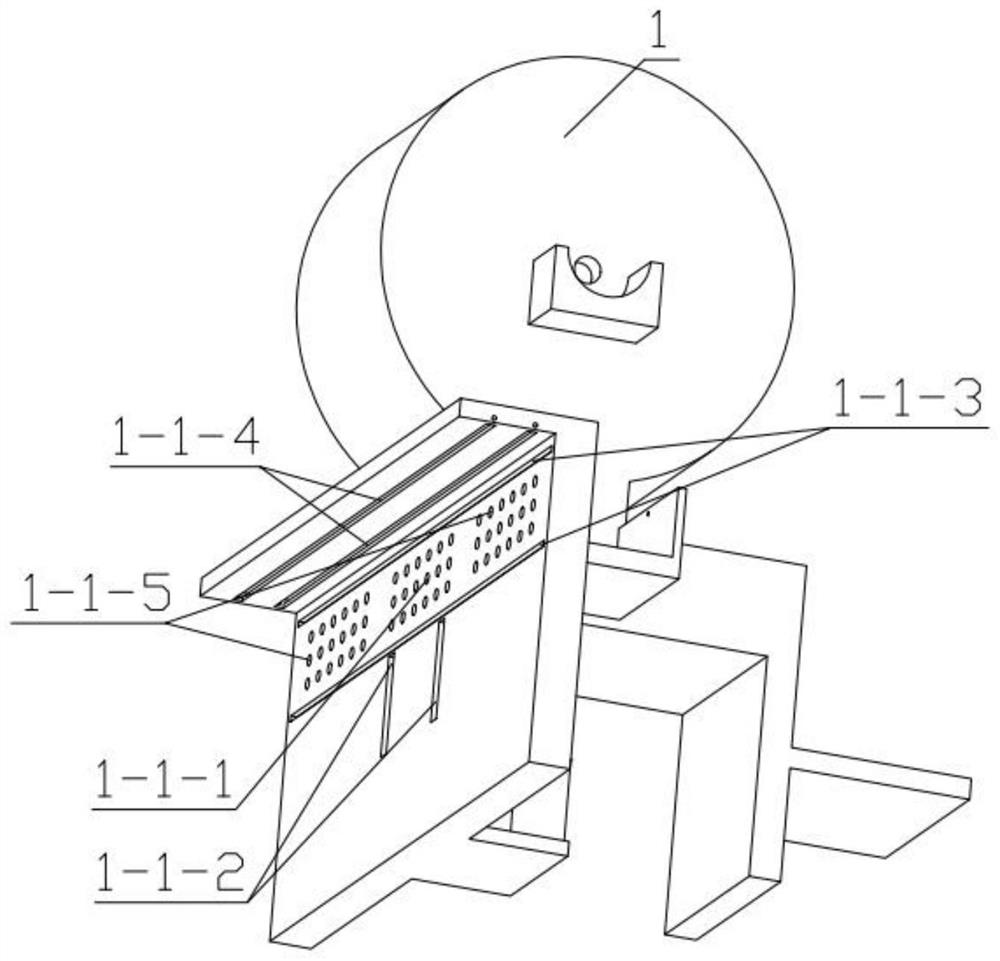

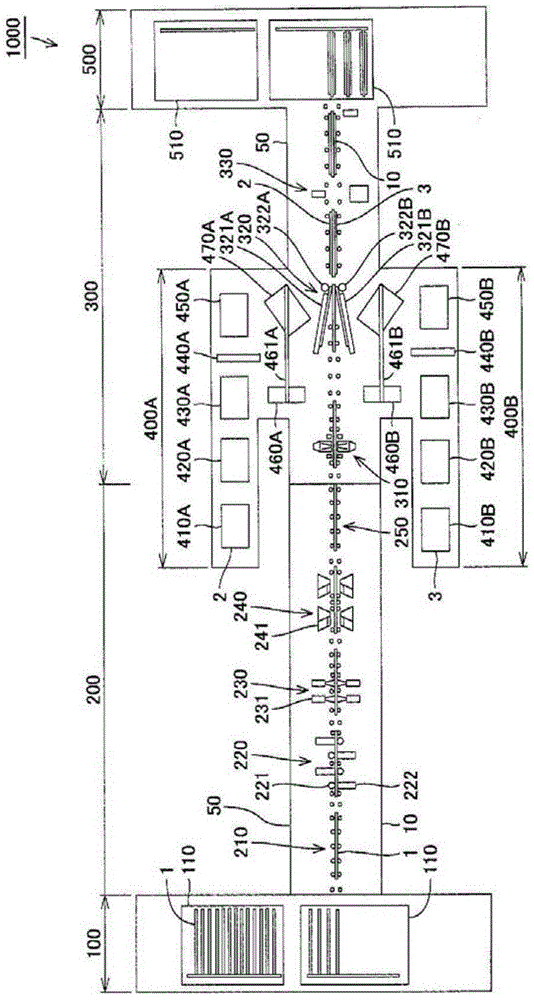

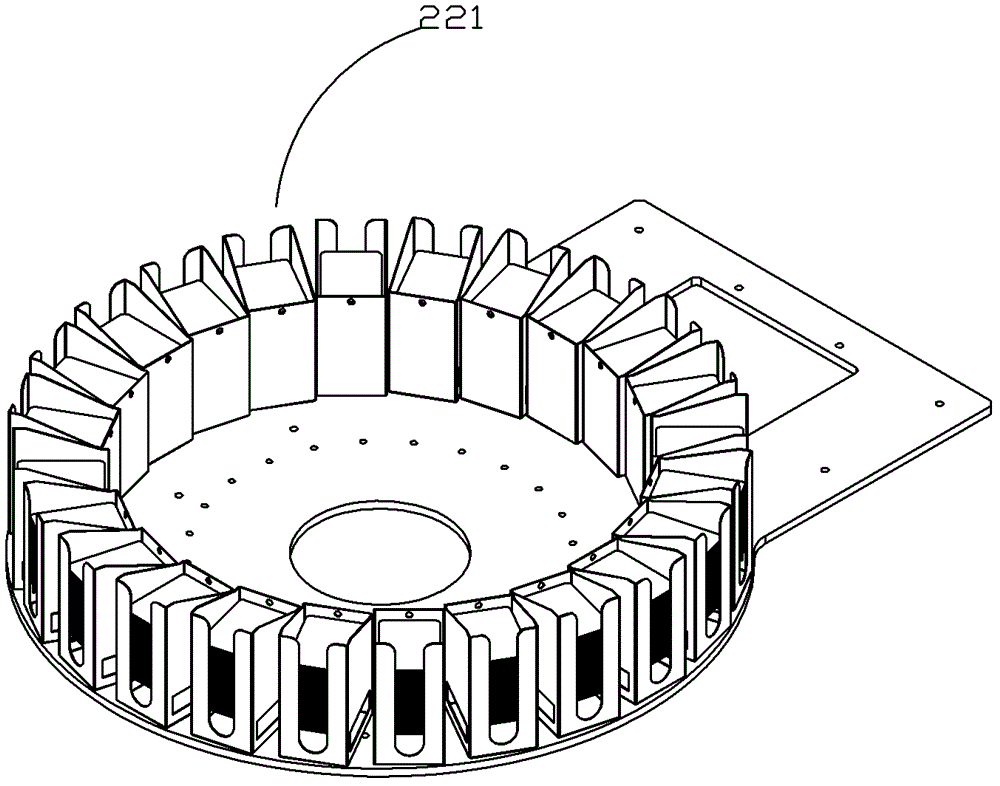

Card sorting device and automatic electric writing device with same

ActiveCN102950119ARealize intelligent classificationSolve the difficulty of classificationDigitally marking record carriersSortingElectricityInformation processing

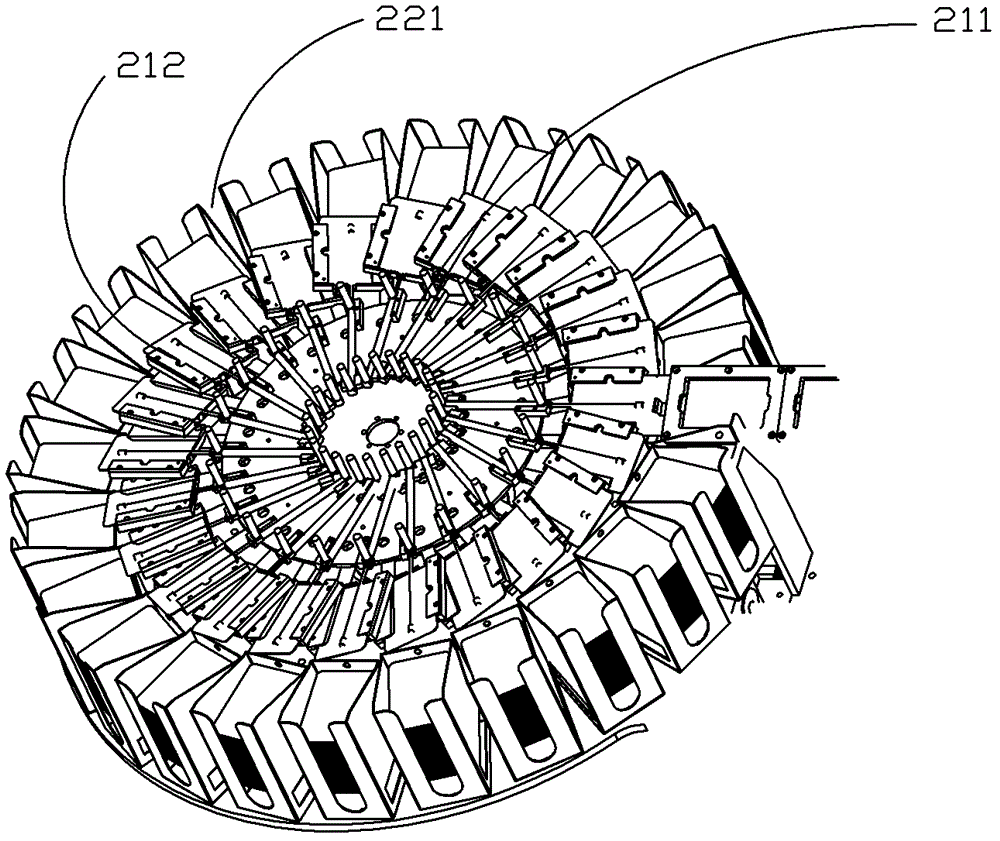

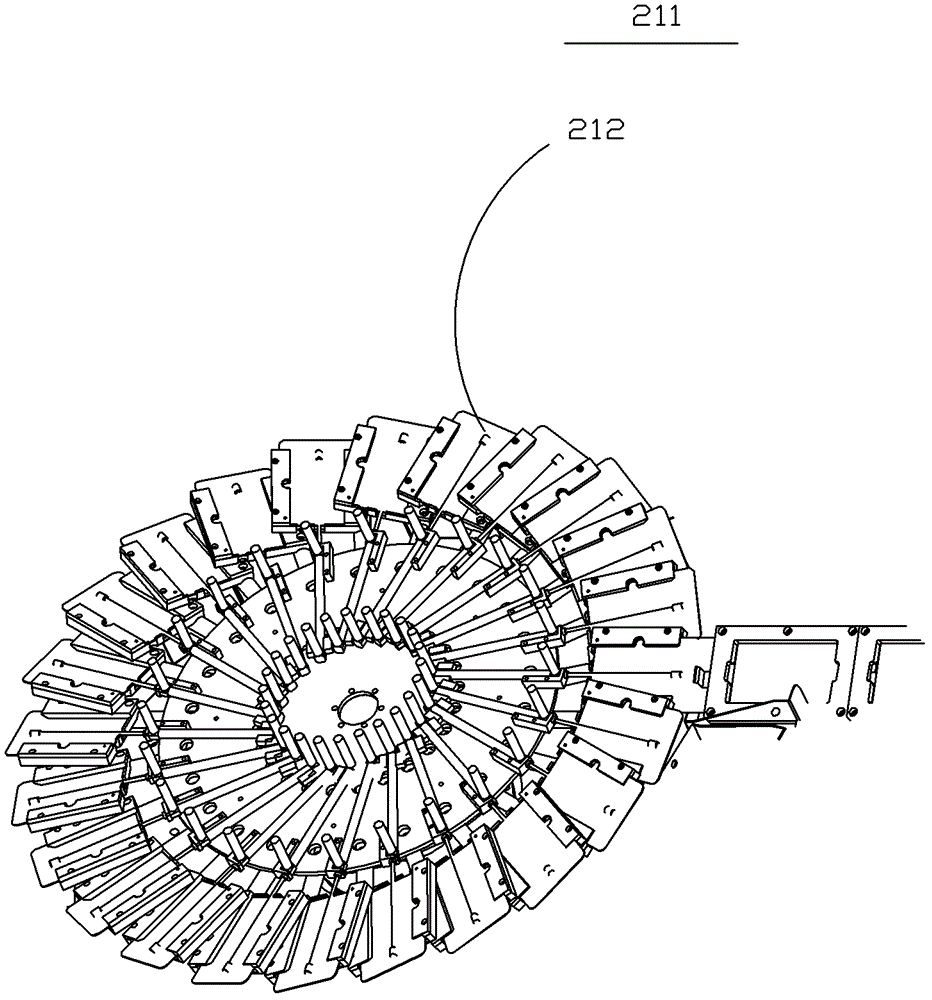

The invention provides a card sorting device and an automatic electric writing device with the same. The card sorting device comprises a card sorting plate and a rotating shaft, wherein the rotating shaft is horizontally positioned at the lower part of the card sorting plate; the card sorting plate is divided into two layers, namely, a first layer for installing an identification card temporary storage slot, and a second layer for installing a card storage slot, and the first layer can be rotated relative to the second layer; bulges, which are arranged along the circumference, are arranged at the lower bottom part of the first layer of the card sorting plate; a card pushing device for pushing an identification card out of the temporary storage slot is arranged on the card sorting plate; cam mechanisms in match with the bulges at the lower bottom part of the first layer of the card sorting plate are arranged at the end part of the rotating shaft; the automatic electric writing device comprises a base, a card feeding device, a card writing device, an information verifying device, an information processing device and the card sorting device, and the information processing device is positioned in the base; the card feeding device is positioned on the base; the card writing device and the information verifying device are positioned at the upper part of the card feeding device; and the card sorting device is positioned at the tail end of the card feeding device. The card sorting plate has the advantages of being stable, high in sorting capacity, high in efficiency, and small in size.

Owner:INT SECURITY TECH SHENZHEN +1

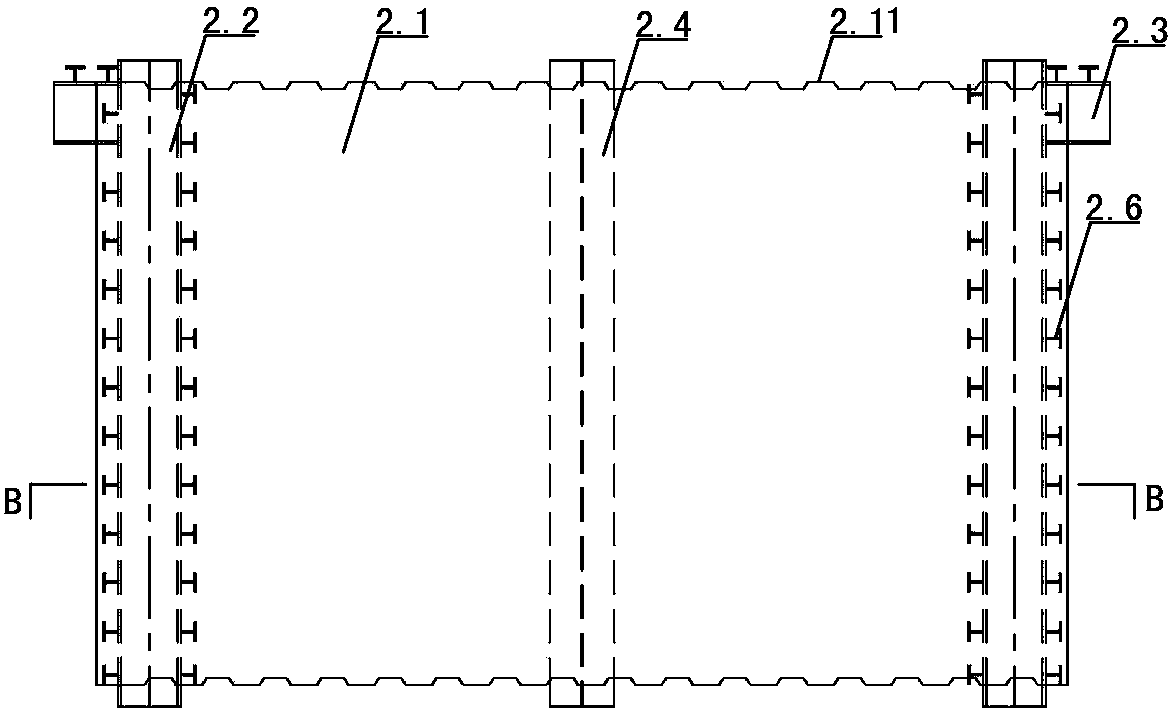

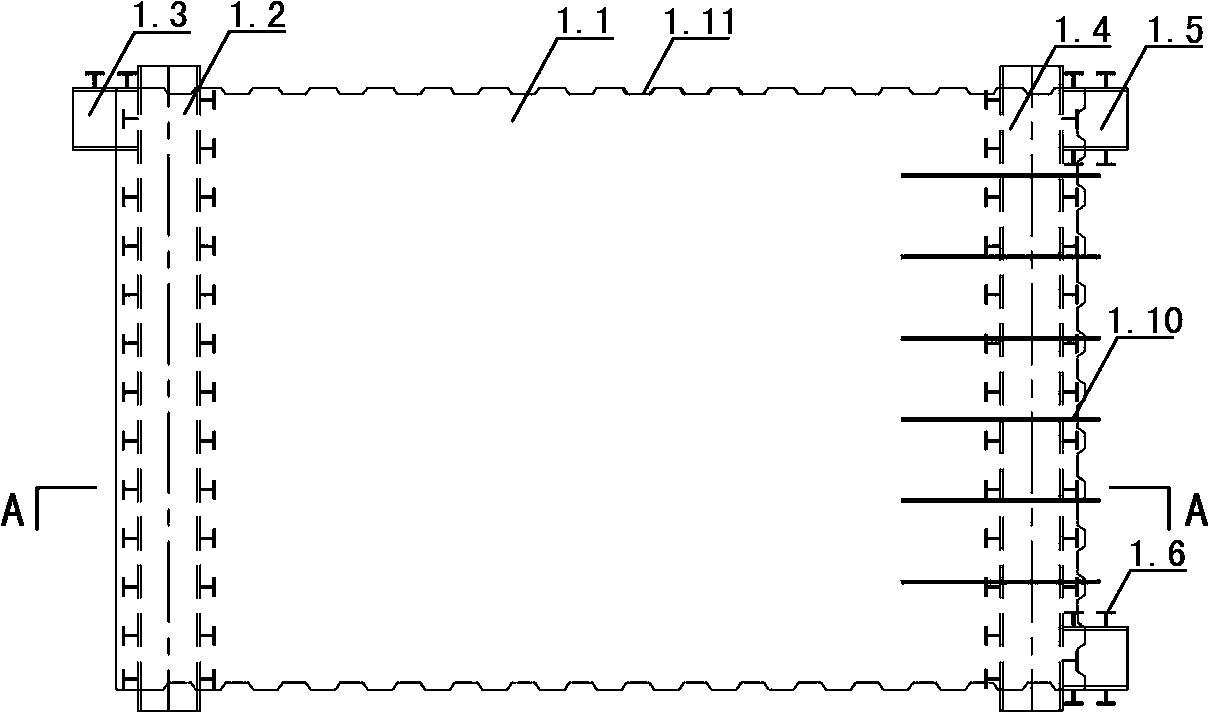

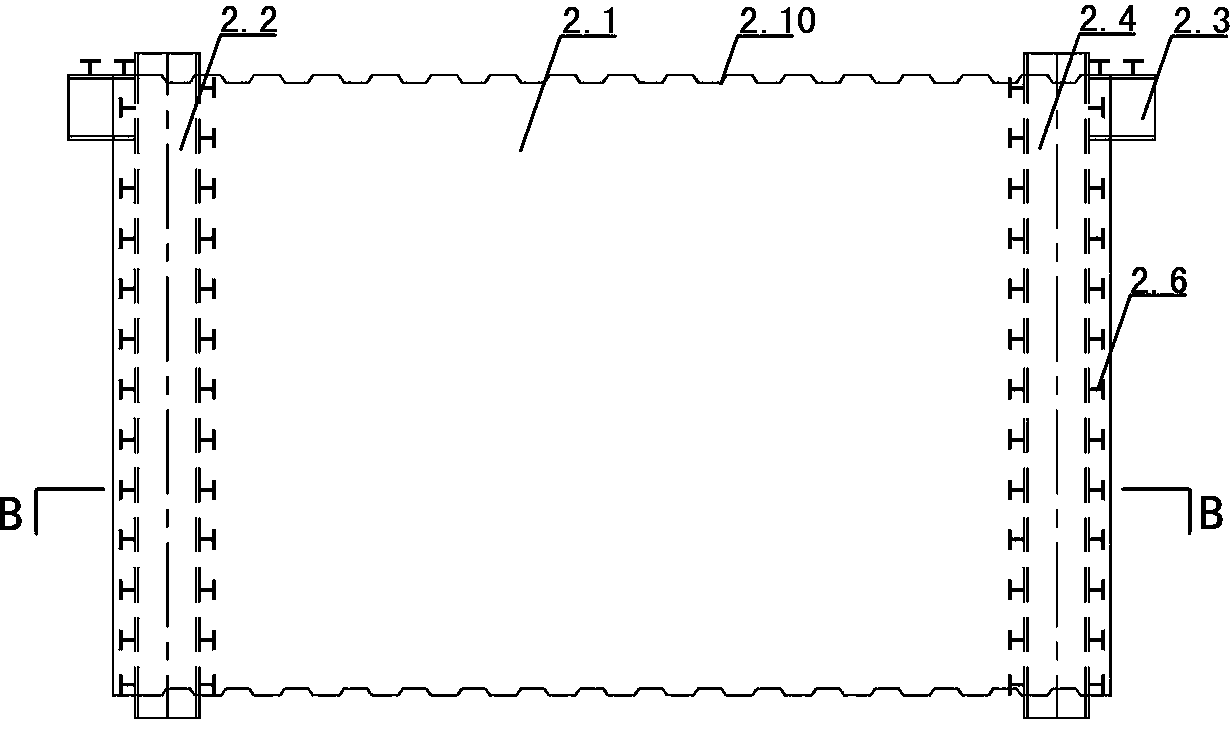

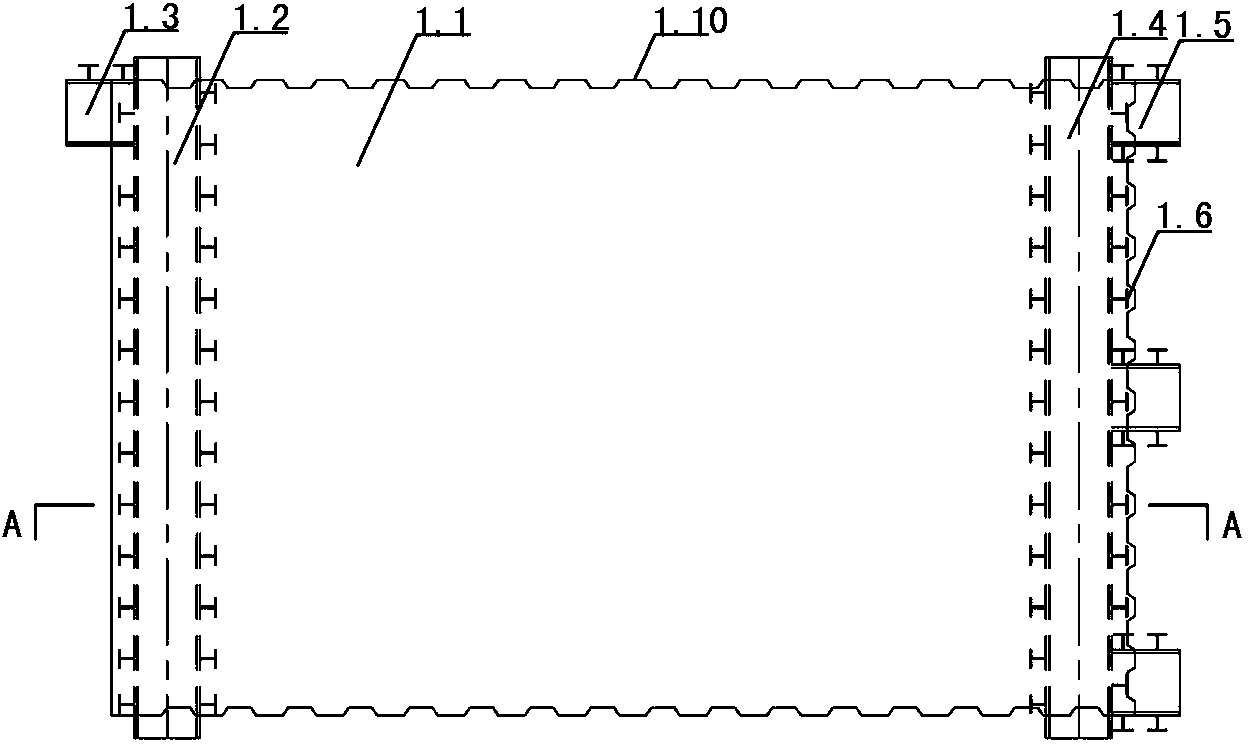

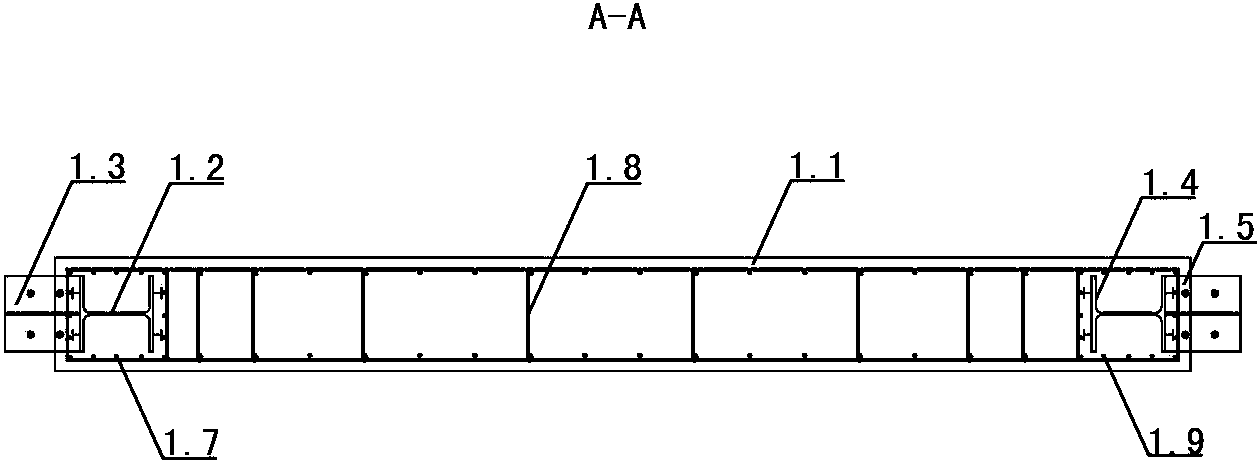

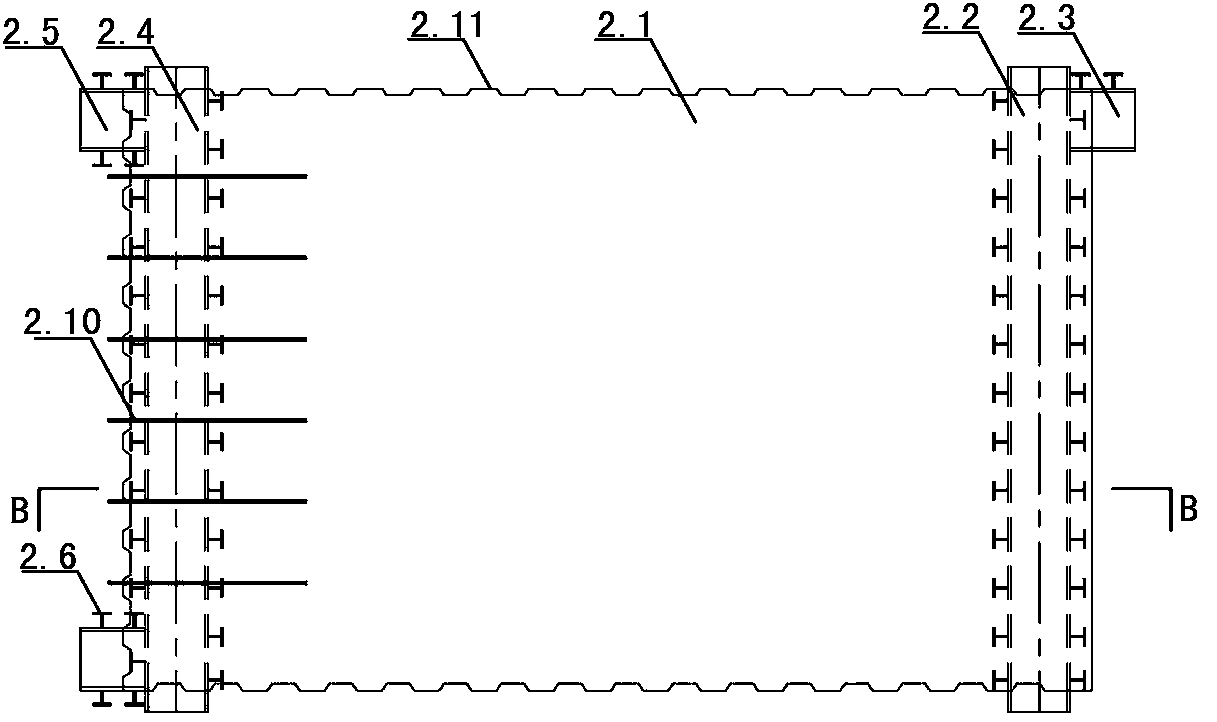

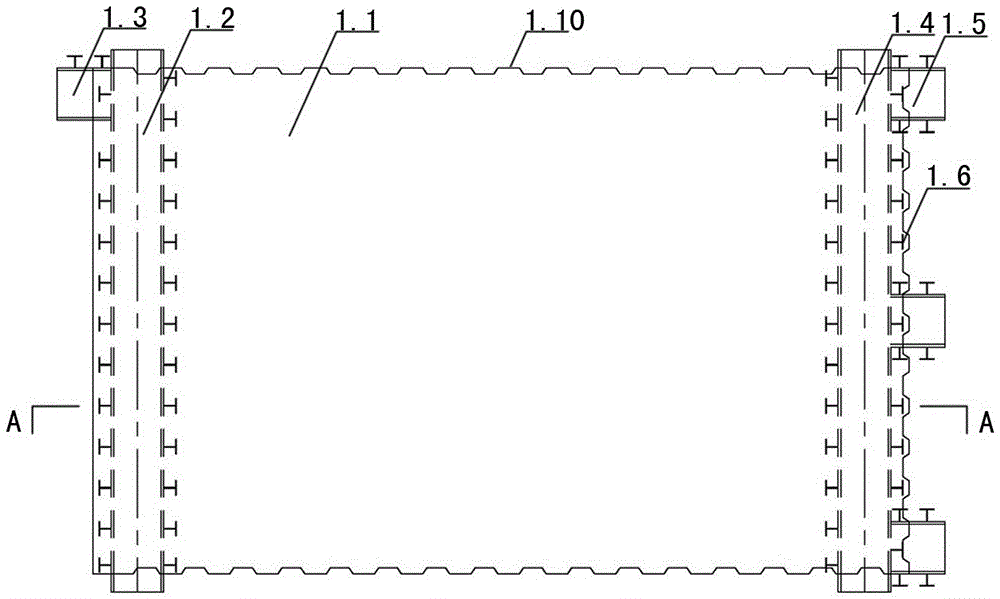

Assembly-type T-shaped mixed coupled wall and construction method thereof

Disclosed are an assembly-type T-shaped mixed coupled wall and a construction method thereof. The assembly-type T-shaped mixed coupled wall comprises a first wall unit and a second wall unit which are connected together perpendicularly and form a T shape. Both the first wall unit and the second wall unit are prefabricated parts, and the first wall unit and the second wall unit are connected through a joint post-pouring belt. According to the assembly-type T-shaped mixed coupled wall, steel beams are used for replacing concrete beams and section steel columns are used for replacing edge constraint reinforced concrete embedded columns, so that the mixed coupled wall has better energy-dissipating capacity and progressive-collapse-resistant capacity than a traditional coupled wall; prefabrication and on-site installation are conducted at the same time, therefore, the problems that the quantity of wet construction on a construction site is large and a lot of construction waste is generated are solved, building operating requirements can be met conveniently, and assembly procedures can be simplified conveniently; after butt welding is conducted on joint short beams, high rigidity is formed between the wall units, therefore, the stability of wall bodies in the construction process is facilitated, the procedure that a shear wall is prefabricated to be used as a temporary support is omitted and the construction efficiency is guaranteed. The construction method can be widely applied to construction of mixed coupled walls in constructional engineering.

Owner:CHINA STATE CONSTRUCTION ENGINEERING CORPORATION

Forming method for large aluminum alloy die-casting fitting

The invention discloses a forming method for a large aluminum alloy die-casting fitting. First, an upper die forming region is machined on an upper die, and a low die forming region is machined on a lower die; an auxiliary cavity is machined in the position, corresponding to the lower exposed face of the die-casting fitting, of the parting face of the lower die, and an auxiliary ejector rod is arranged in the auxiliary cavity; when the upper die and the lower die are closed, the upper die forming region and the lower die forming region jointly construct a cavity of a die-casting die, a die-casting fitting is formed inside the cavity, and an auxiliary forming portion connected with the edge of the die-casting fitting is formed inside the auxiliary cavity; then, an ejector rod arranged on the lower die and the auxiliary ejector rod push the die-casting fitting and the auxiliary forming portion to move together, so that the die-casting fitting is separated from a cavity core; the die-casting fitting with the auxiliary forming portion is taken down, and the complete die-casting fitting can be obtained after the auxiliary forming portion is removed through a cutting device. The unbalanced stress when the product is ejected out can be effectively improved, in this way, deformation generated when the product is ejected out is avoided, and the forming quality of the large die-casting fitting is easily improved.

Owner:宁波环亚机械制造有限公司

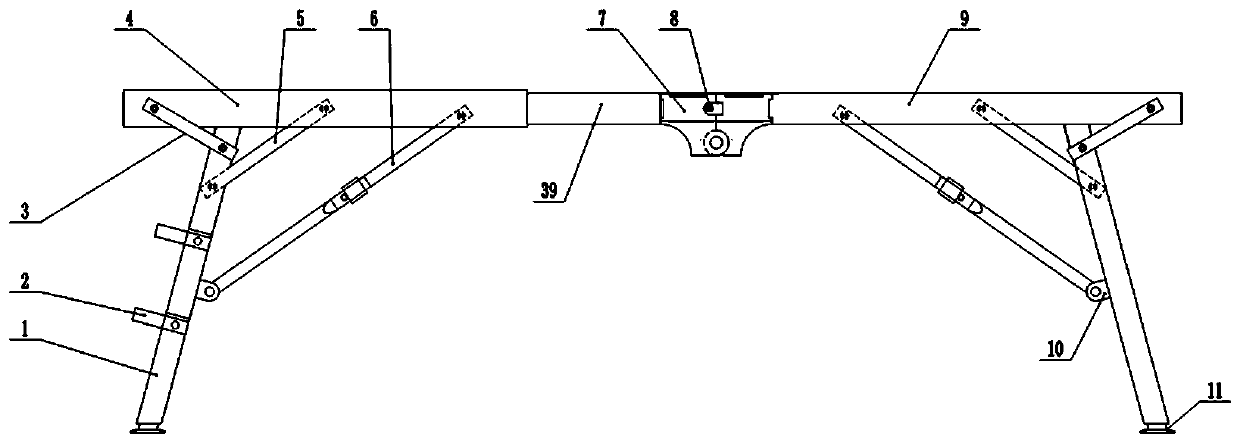

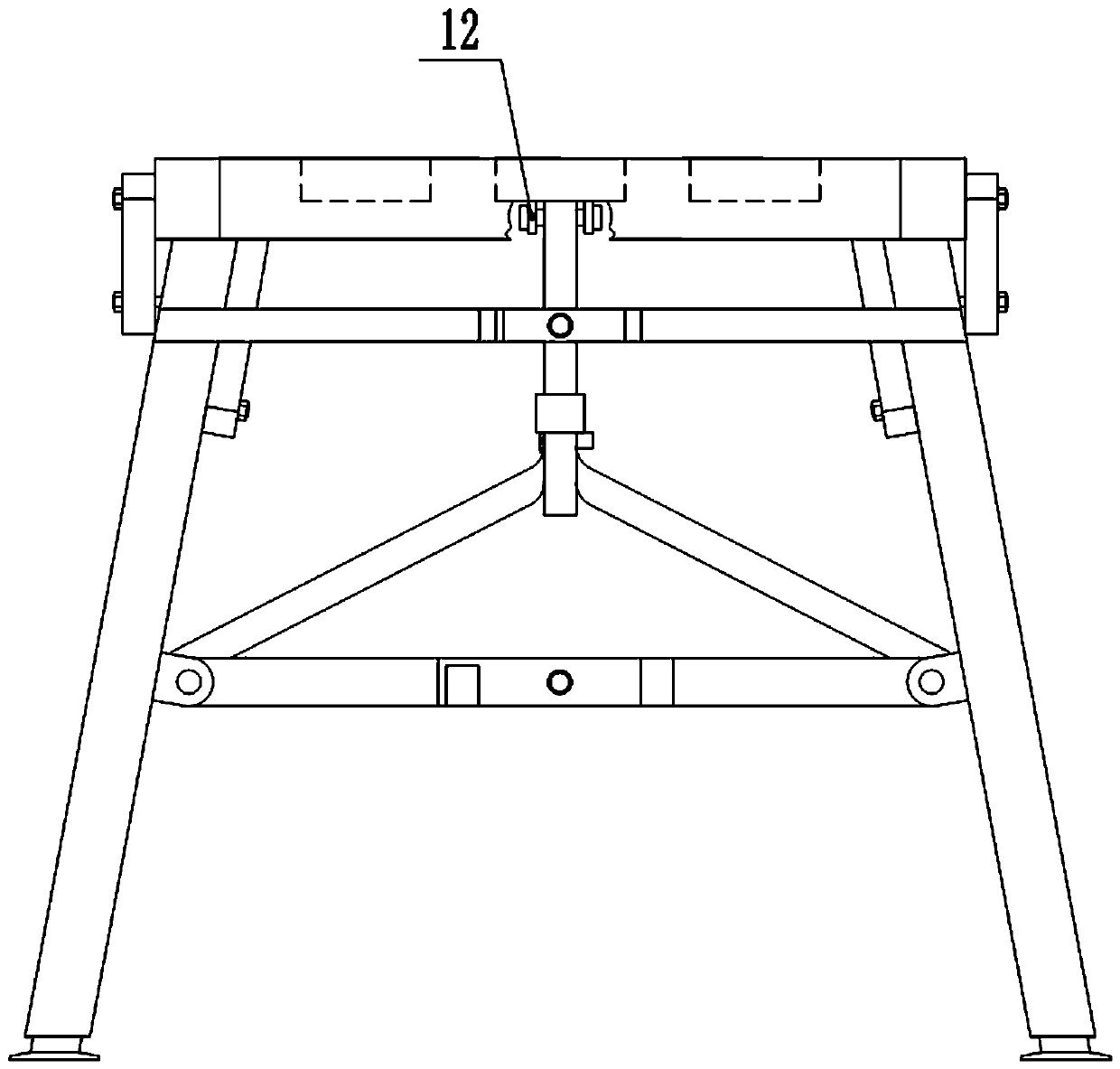

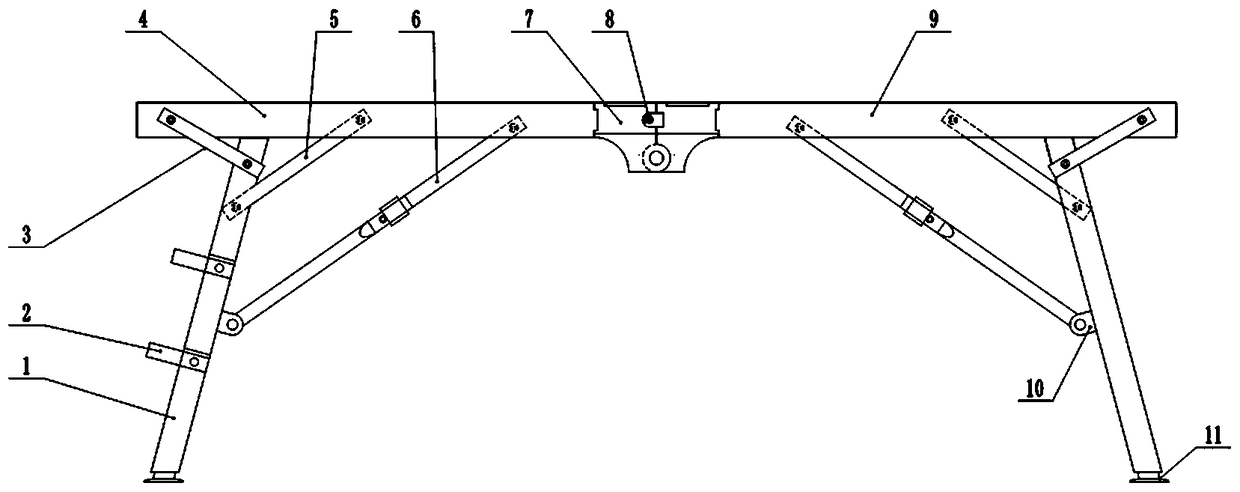

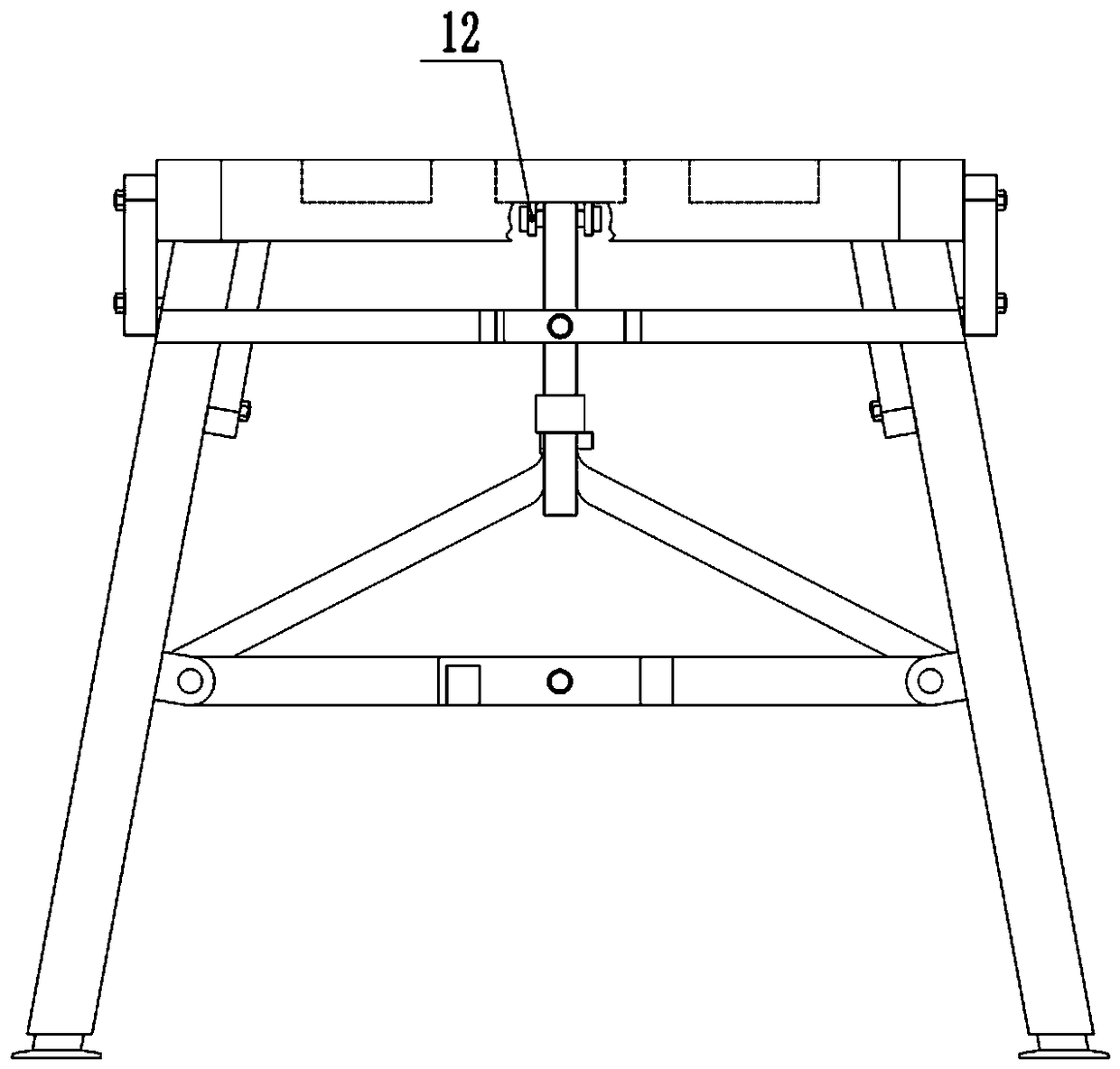

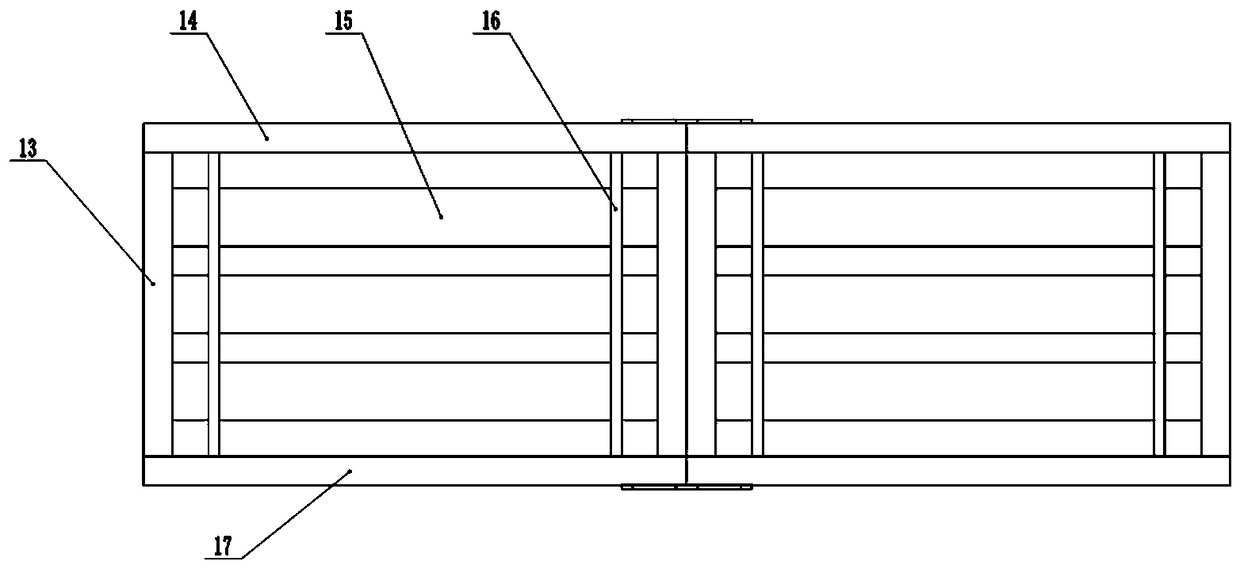

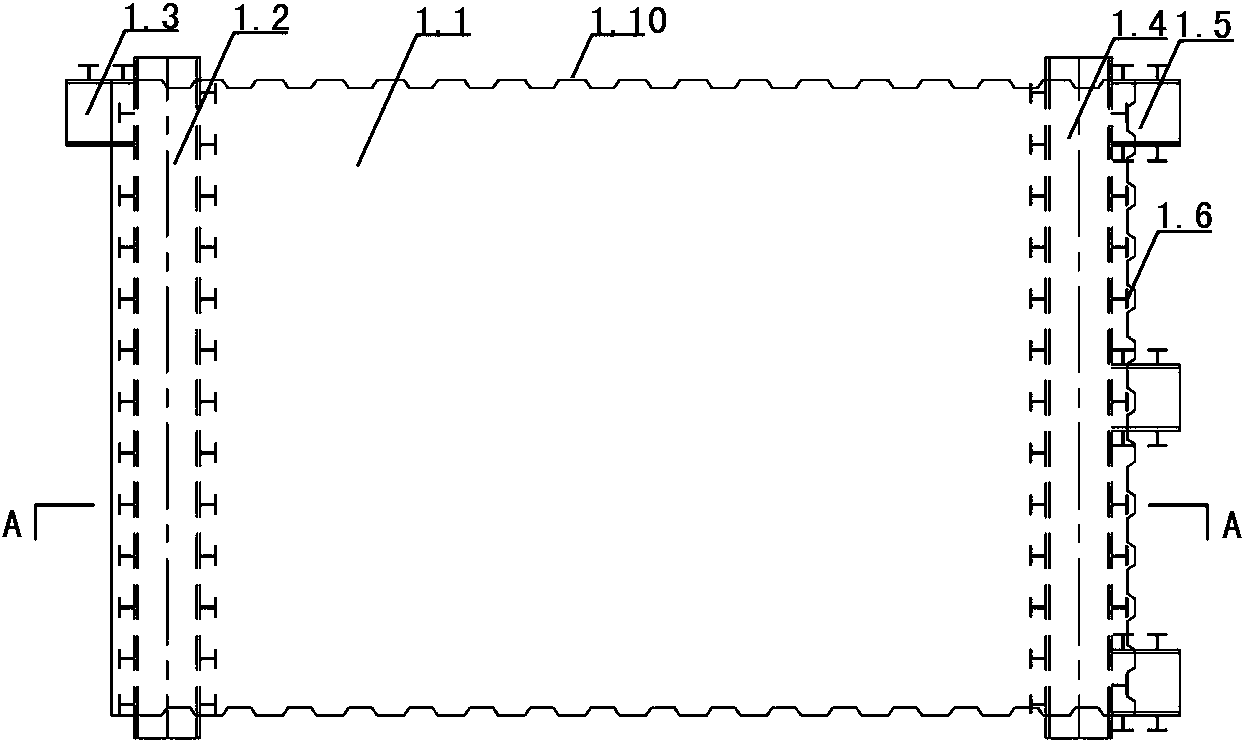

Extension-retraction folding type portable movable operation platform

ActiveCN107939026AHighlight substantiveSignificant progressBuilding scaffoldsBracing legMechanical engineering

Owner:重庆今心实业有限公司

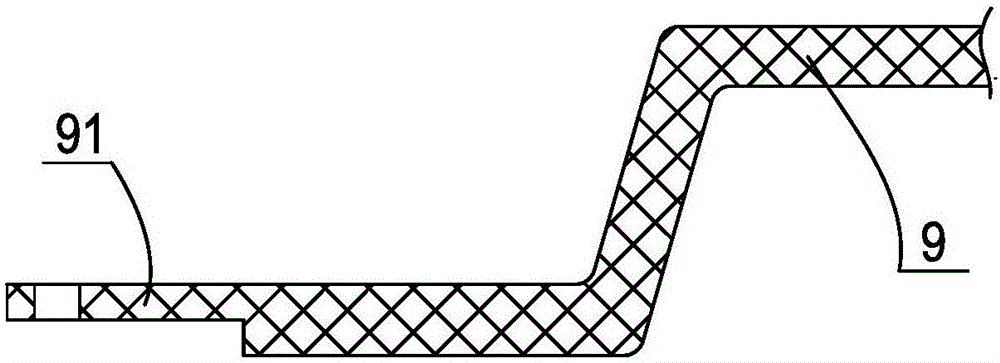

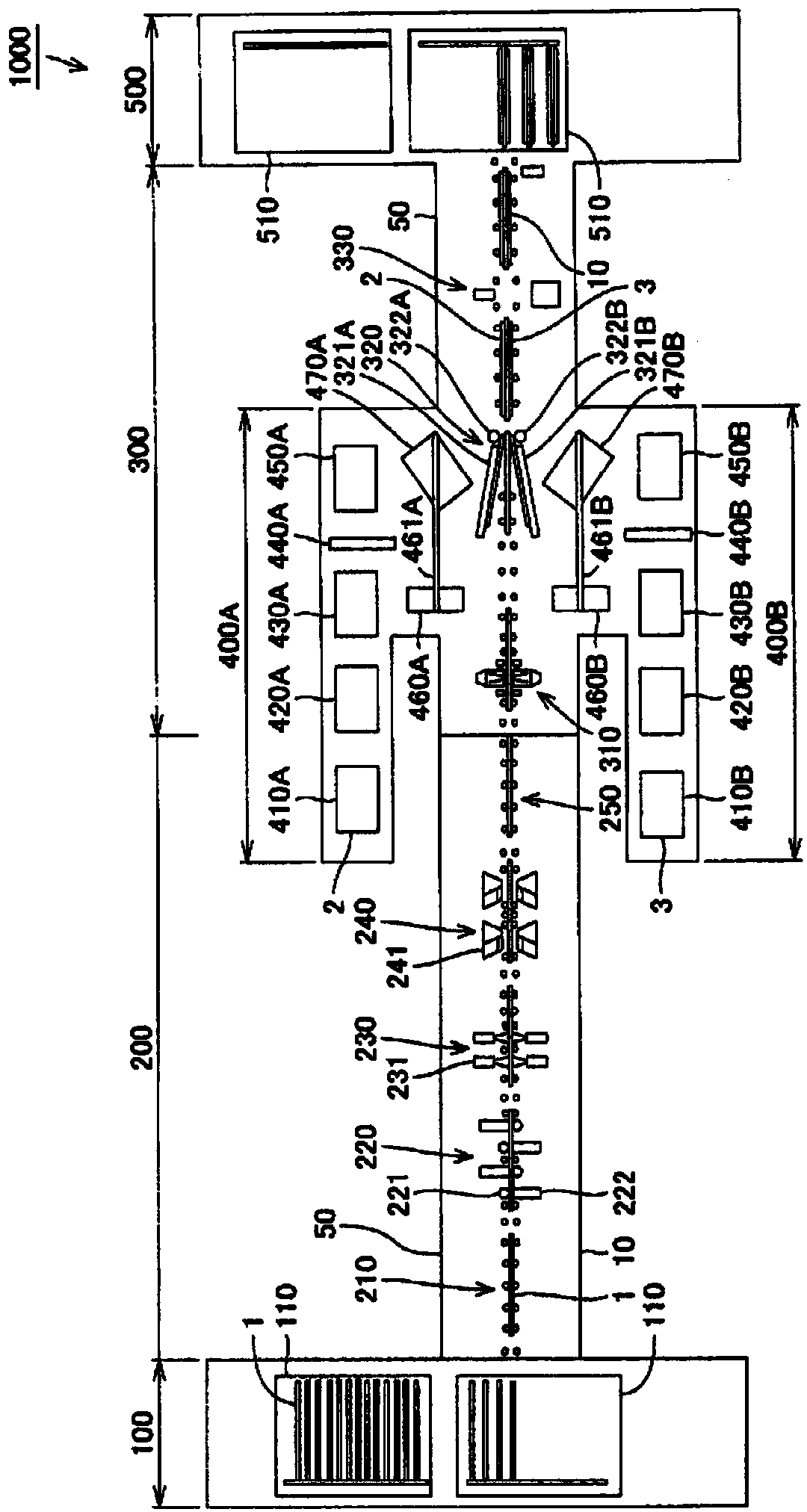

Apparatus for attaching polarized film

InactiveCN103969881ANo bending phenomenonReduce generationLaminationLamination apparatusLiquid crystal

The invention relates to an apparatus for attaching a polarized film, and especially relates an apparatus having characteristics described as follows. In a method of attaching a polarized film onto a liquid crystal element substrate, a problems is that bubbles are generated between the polarized film and the liquid crystal element substrate because the front bending of the polarized film. A caterpillar track type adhesive plate is arranged on an inclination roller and a fixed roller on the left and the right, and a polarized film is attached to the liquid crystal element substrate after the polarized film is arranged on the amooth adhesive plate. Therefore, a phenomenon of overall bending of the polarized film does not occur. When the polarized film is attached onto the surface of the liquid crystal element substrate, the possibility of bubble generation is substantially reduced. Furthermore, the liquid crystal element is prevented from being bent due to the elongation of the polarized film, and the possibility of unqualified products is eliminated.

Owner:YMK

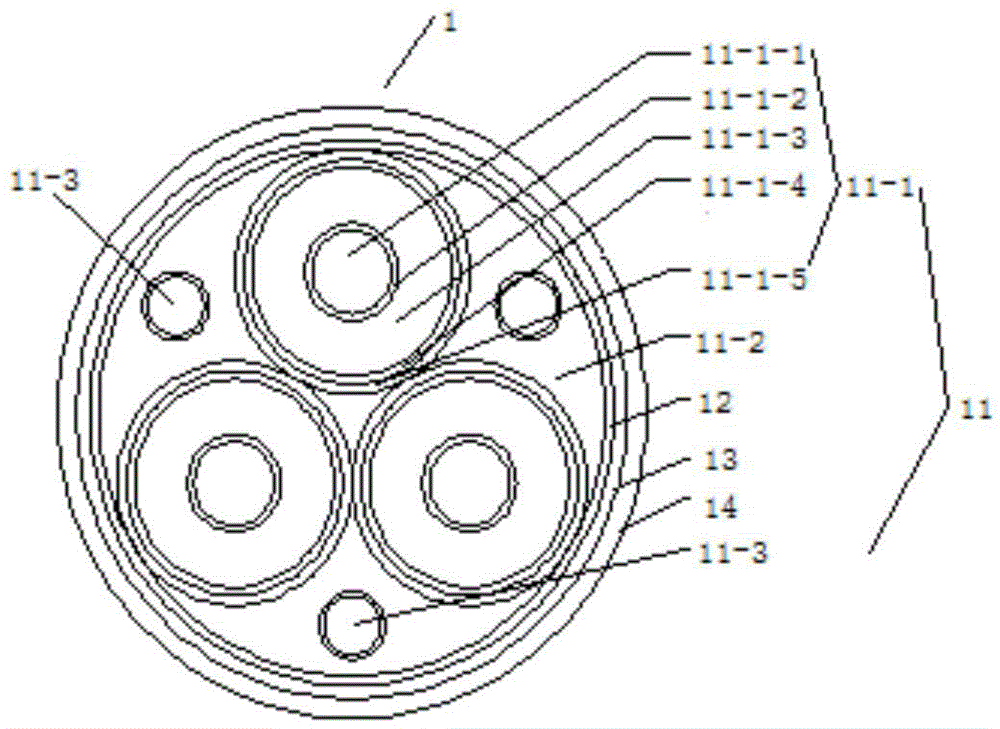

Pneumatic blowing-in optical fiber composite smart energy power cable and production method thereof

InactiveCN104810106ASettle the lossSolve problems such as fiber optic communication performance degradationPower cables with screens/conductive layersFibre mechanical structuresElectrical conductorPower cable

The invention discloses a pneumatic blowing-in optical fiber composite smart energy power cable and a production method thereof. The cable is composed of power cable bodies of embedded optical unit tubes and transmission optical fiber units. Every power cable body of the embedded optical unit tube is sequentially composed of a cable core, an inner lining layer, an armor layer and an outer sheath from inside to outside. The cable core comprises at least one insulation cable core body and filling. The insulation cable core body is sequentially composed of a conductor, a conductor shielding layer, an insulating layer, an insulating shielding layer and a metal shielding layer from inside to outside. The filling is internally provided with at least one optical unit tube. The number of the transmission optical fiber units is the same with that of the optical unit tubes. Every transmission optical fiber unit comprises an optical fiber, a cured layer, a protective layer and at least one pressure channel arranged on the surface of the protective layer. The transmission optical fiber units are suspended in the optical unit tubes of the power cable bodies. The pneumatic blowing-in optical fiber composite smart energy power cable is produced through an on-site compositing mode, and accordingly the cable is divided into two parts of the cable bodies of the embedded optical unit tubes and the transmission optical fiber units, so that the problems of power cable length loss, optical fiber communication performance degradation and the like of an existing optical fiber composite power cable composite cable in construction and installation is solved.

Owner:FAR EAST CABLE +2

Industrial bottle-cultivation white needle mushroom culture medium and preparation method thereof

The invention discloses an industrial bottle-cultivation white needle mushroom culture medium and a preparation method thereof. The sources of the raw materials of the culture medium are abundant, and the culture medium has low cost, is reasonable in proportioning, and is favorable for the growth of needle mushrooms. The culture medium comprises the following raw materials in percentage by weight: 42 to 48 percent of corncob, 13 to 17 percent of rice bran, 18 to 22 percent of aspen wood saw dust, 6 to 8 percent of red-skin winter wheat bran, 2.5 to 3.5 percent of corn flour, 2.5 to 3.5 percent of bagasse, 1.5 to 2.5 percent of liquoric root dregs and 4 to 6 percent of gypsum. The preparation method comprises the following steps of: crushing the raw materials of the needle mushroom culture medium into granules; mixing the corncob, the aspen wood saw dust and the bagasse according to the ratio, performing primary stirring for 15 minutes, and adding water gradually; adding other raw materials according to the ratio, performing secondary stirring for 30 minutes, and adding the water gradually; and testing moisture content by using a moisture tester until the moisture content is between 62.5 and 64 percent.

Owner:TIANSHUI ZHONGXING BIO TECH

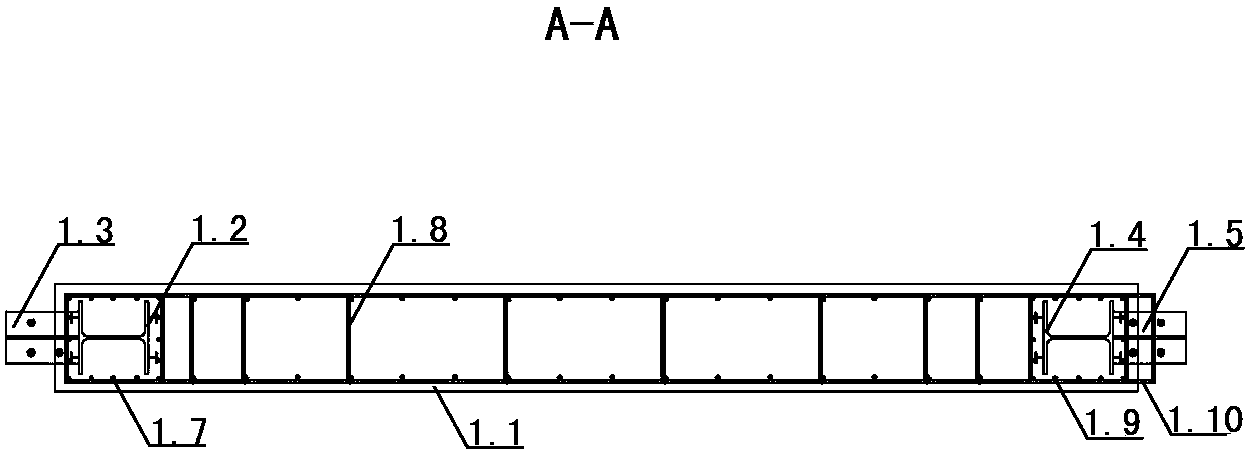

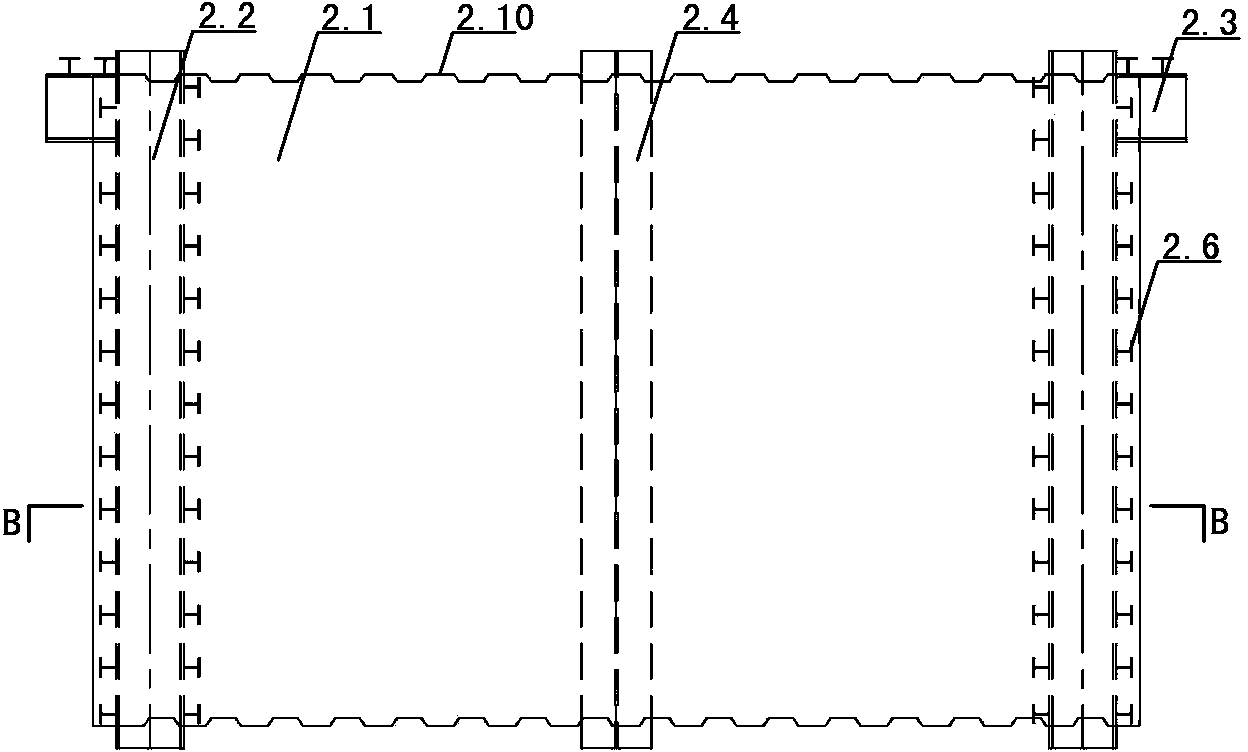

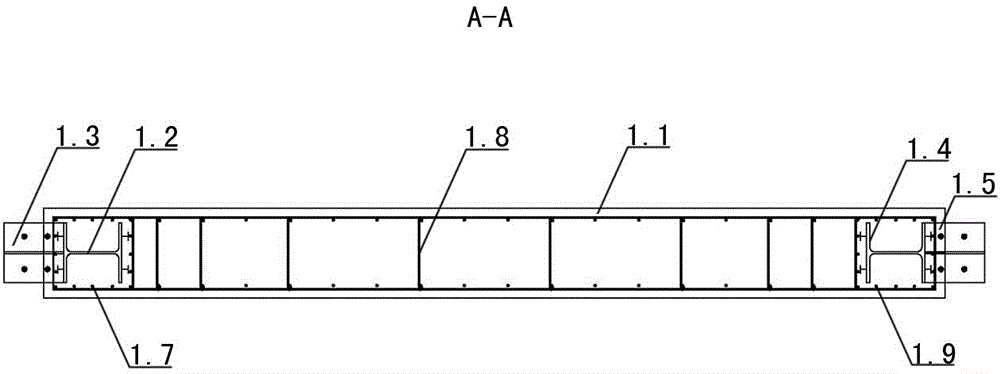

Assembly-type cross-shaped mixed coupled wall and construction method thereof

InactiveCN104032855AImprove stabilityReduce wet work loadWallsBuilding material handlingButt weldingConcrete beams

Disclosed are an assembly-type cross-shaped mixed coupled wall and a construction method thereof. The assembly-type cross-shaped mixed coupled wall comprises first wall units and a second wall unit which are connected together perpendicularly and form a cross shape. The first wall units are symmetrically distributed on the two sides of the second wall unit, the first wall units and the second wall unit are all prefabricated parts, and the first wall units and the second wall unit are connected through joint post-pouring belts. According to the assembly-type cross-shaped mixed coupled wall, steel beams are used for replacing concrete beams and section steel columns are used for replacing edge constraint reinforced concrete embedded columns, so that the mixed coupled wall has better energy-dissipating capacity and progressive-collapse-resistant capacity than a traditional coupled wall; prefabrication and on-site installation are conducted at the same time, therefore, the problems that the quantity of wet construction on a construction site is large and a lot of construction waste is generated are solved and assembly procedures are simplified; after butt welding is conducted on joint short beams, high rigidity is formed between the wall units, therefore, the stability of wall bodies in the construction process is facilitated, the procedure that a shear wall is prefabricated to be used as a temporary support is omitted and the construction efficiency is guaranteed. The construction method can be widely applied to construction of mixed coupled walls in constructional engineering.

Owner:CHINA STATE CONSTRUCTION ENGINEERING CORPORATION

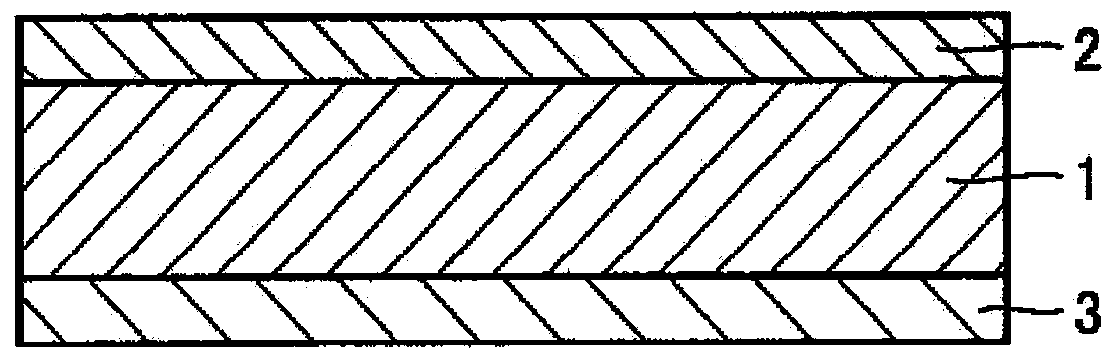

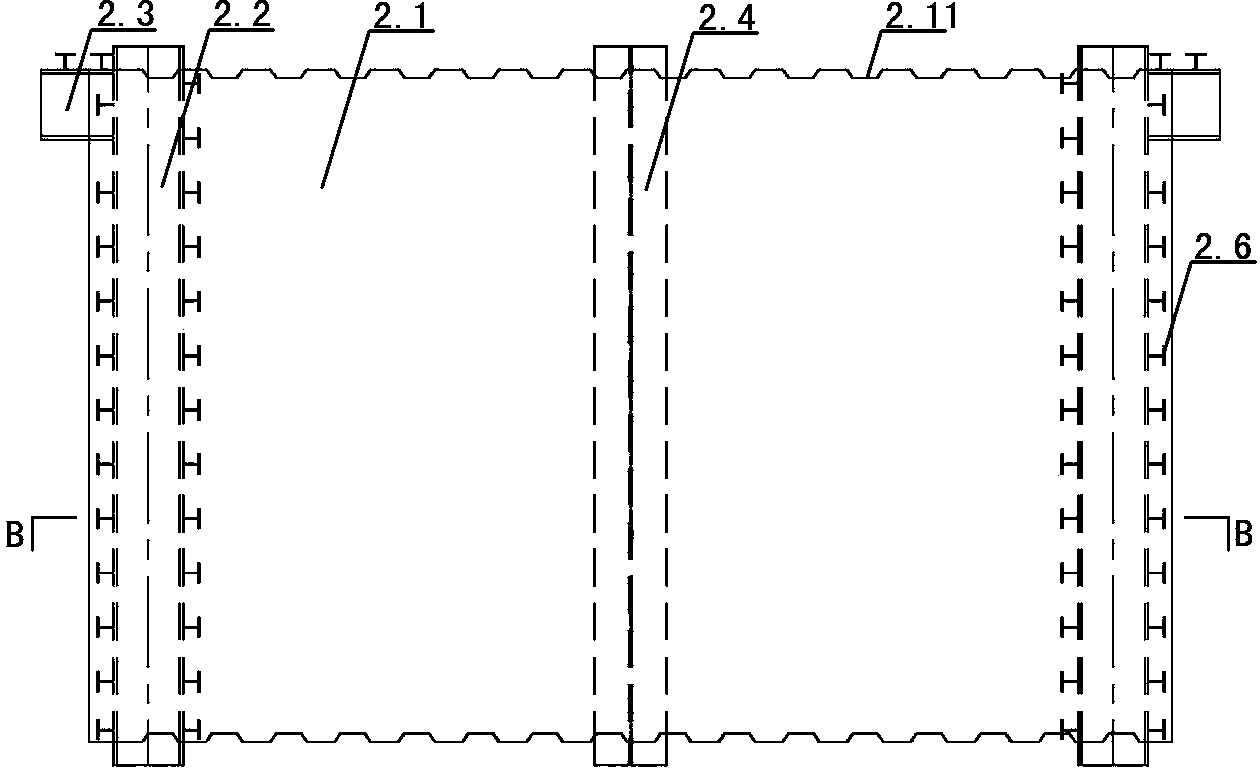

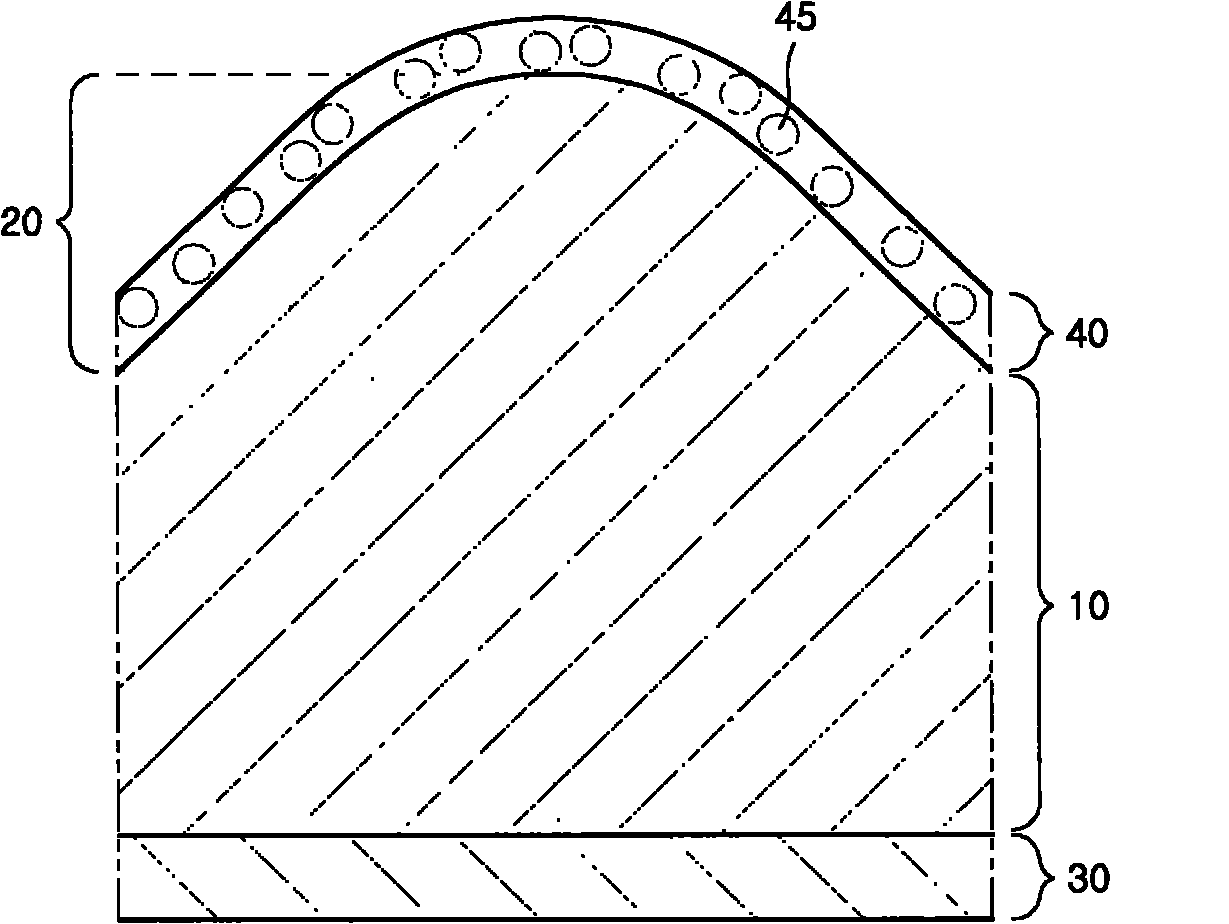

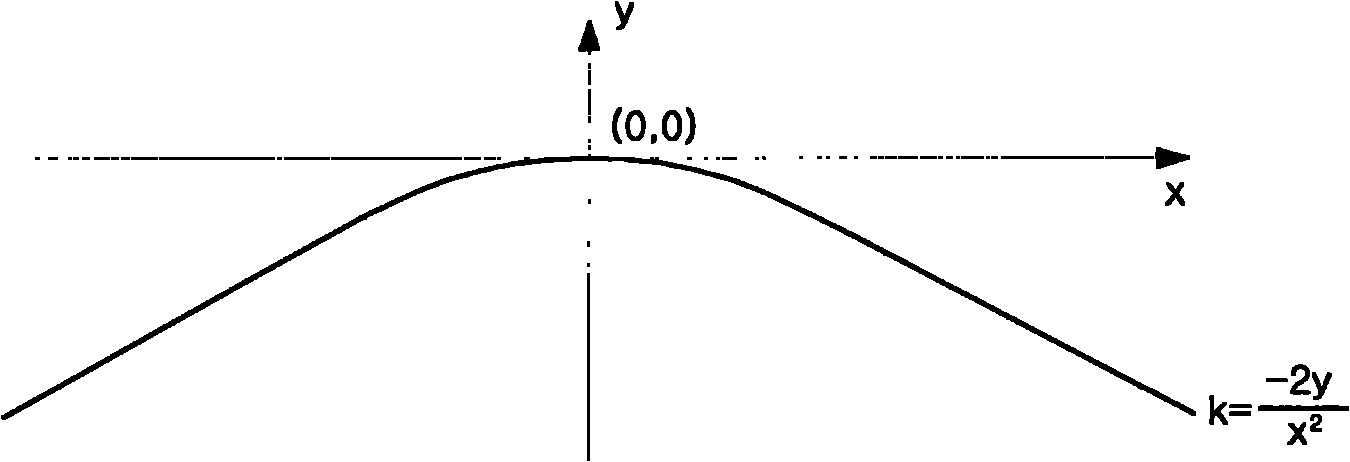

Light diffusion member

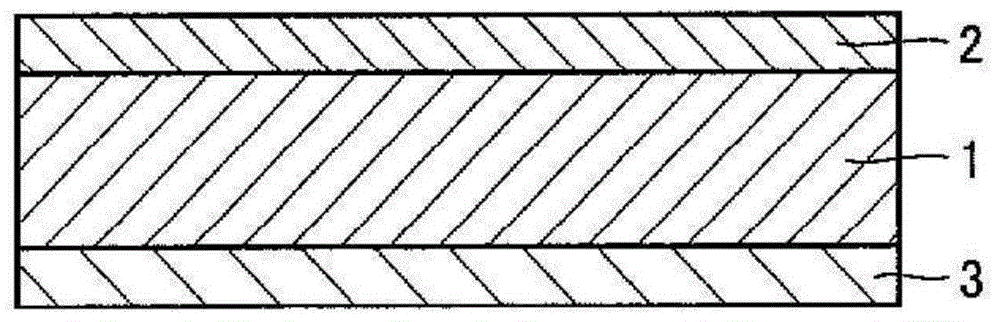

InactiveCN101881845ANo bending phenomenonDiffusing elementsSynthetic resin layered productsDiffusionOptoelectronics

The present invention provides an light diffusion assembly for minimizing expansion difference between a surface close to a light source and a surface not close to the light source so as to prevent a central part from bending forwards. Thereby, the light diffusion assembly of a better embodiment includes a substrate layer and a bottom surface layer formed on at least one surface of the substrate layer, wherein the thermal expansion coefficient of the bottom surface layer is more than 5.0*10<-5>.

Owner:KOLON IND INC

Assembly-type steel beam joint L-shaped mixed coupled wall and construction method thereof

Disclosed are an assembly-type steel beam joint L-shaped mixed coupled wall and a construction method thereof. The assembly-type steel beam joint L-shaped mixed coupled wall comprises a first wall unit and a second wall unit which are connected together perpendicularly and form an L shape. Both the first wall unit and the second wall unit are prefabricated parts, and the first wall unit and the second wall unit are connected through a joint post-pouring belt. According to the assembly-type steel beam joint L-shaped mixed coupled wall, steel beams are used for replacing concrete beams and section steel columns are used for replacing edge constraint reinforced concrete embedded columns, so that the mixed coupled wall has better energy-dissipating capacity and progressive-collapse-resistant capacity than a traditional coupled wall; prefabrication and on-site installation are conducted at the same time, therefore, the problems that the quantity of wet construction on a construction site is large and a lot of construction waste is generated are solved and assembly procedures are simplified; after butt welding is conducted on joint short beams, high rigidity is formed between the wall units, therefore, the stability of wall bodies in the construction process is facilitated, the procedure that a shear wall is prefabricated to be used as a temporary support is omitted and the construction efficiency is guaranteed. The construction method can be widely applied to construction of mixed coupled walls in constructional engineering.

Owner:CHINA STATE CONSTRUCTION ENGINEERING CORPORATION

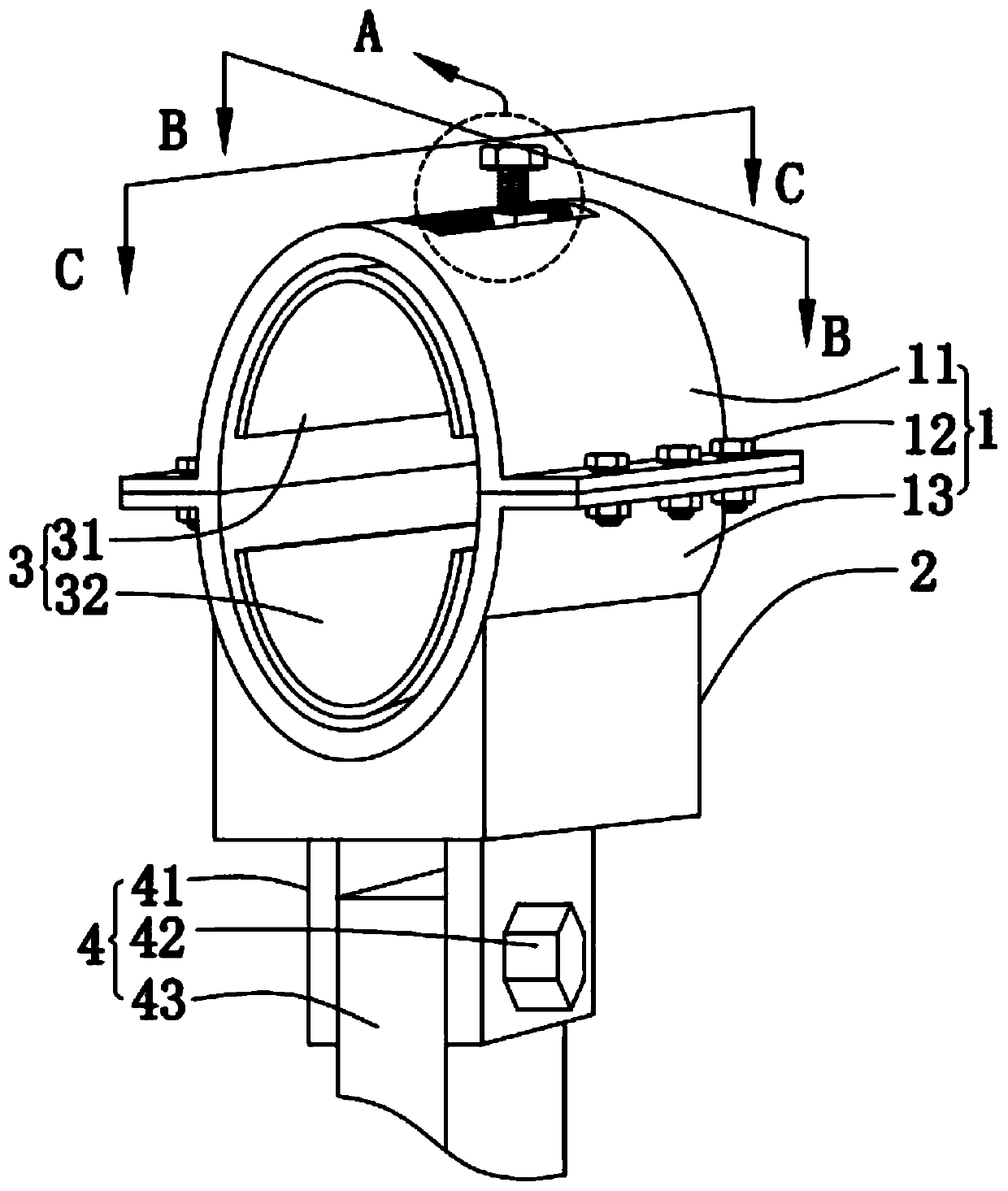

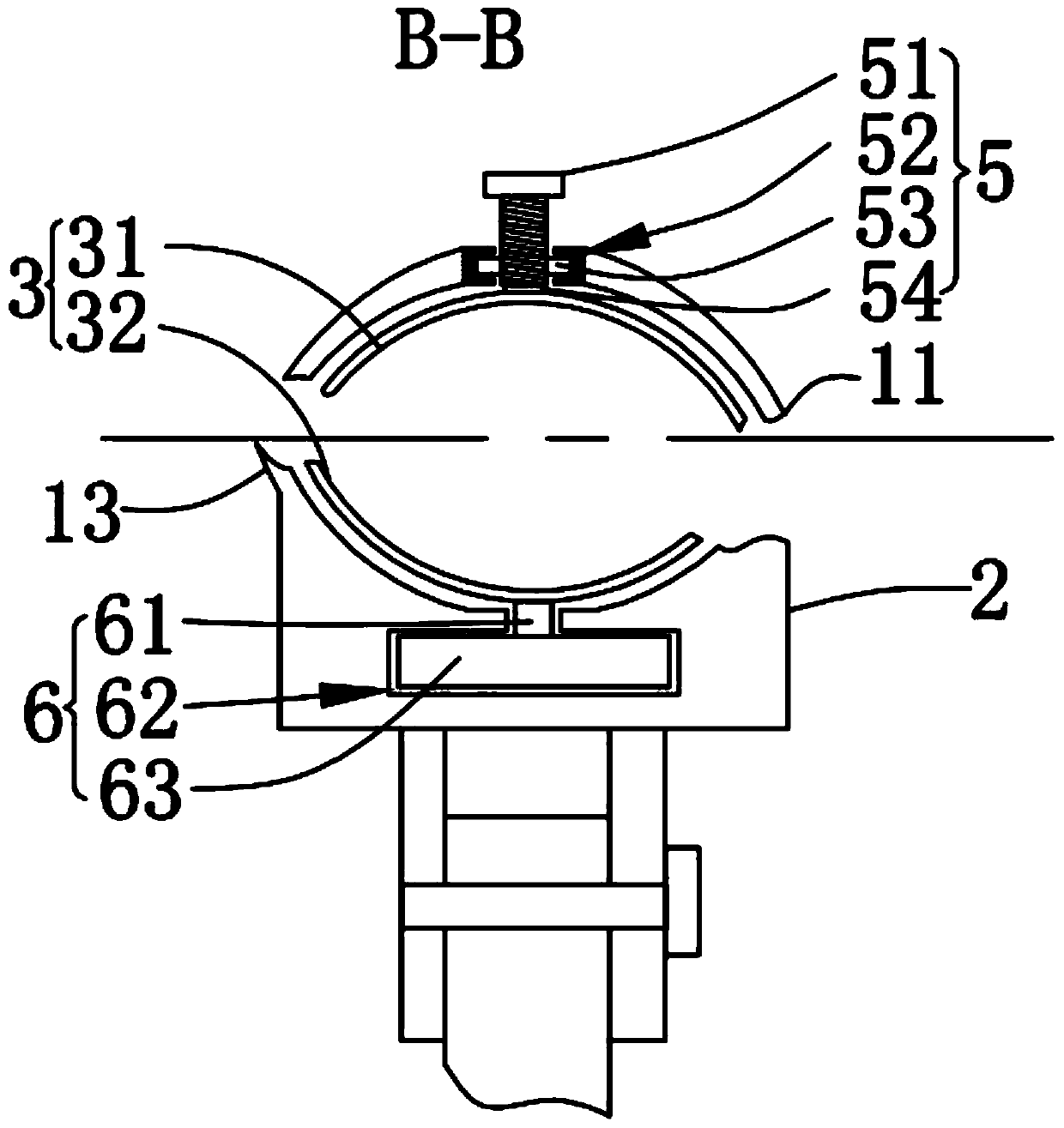

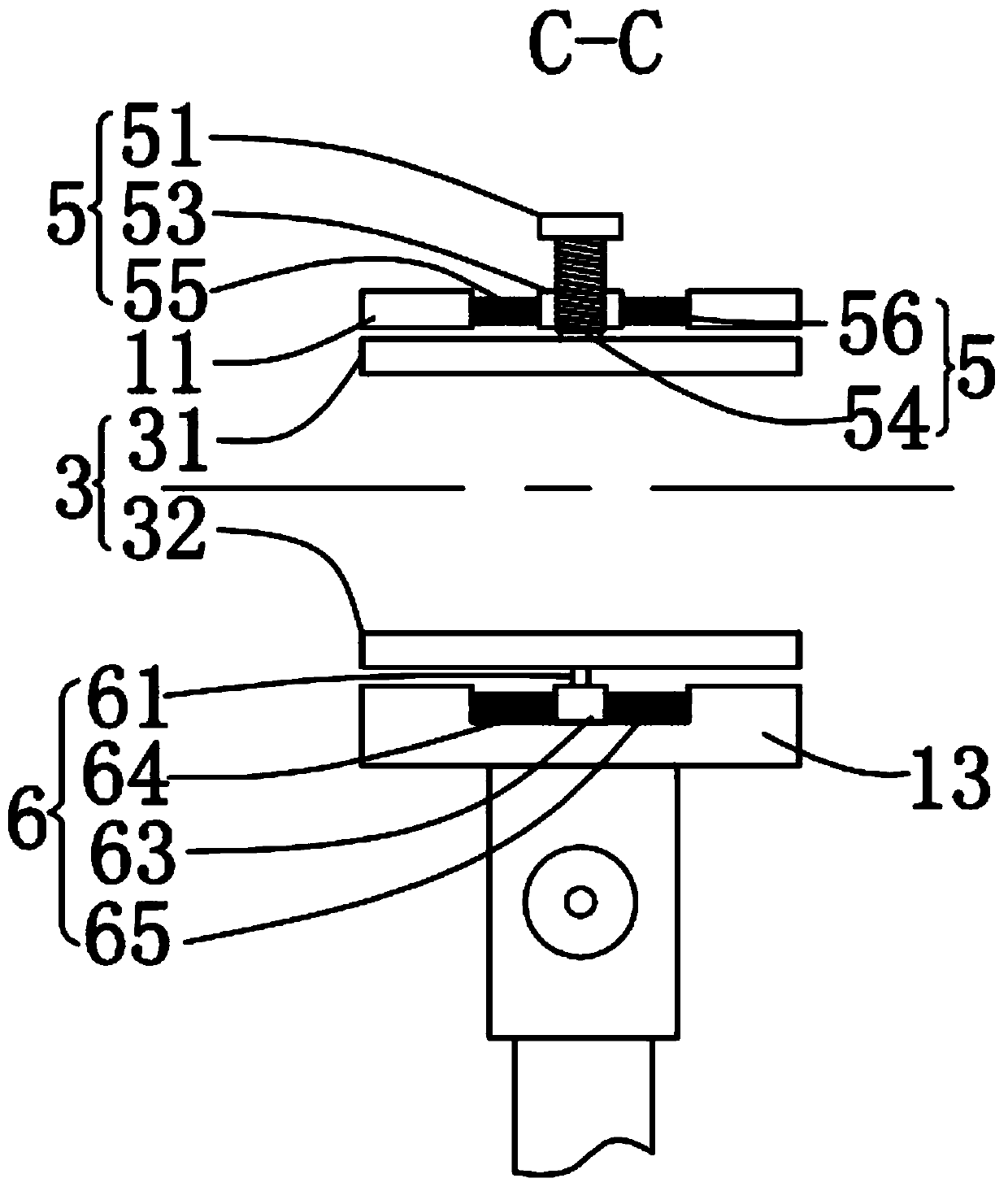

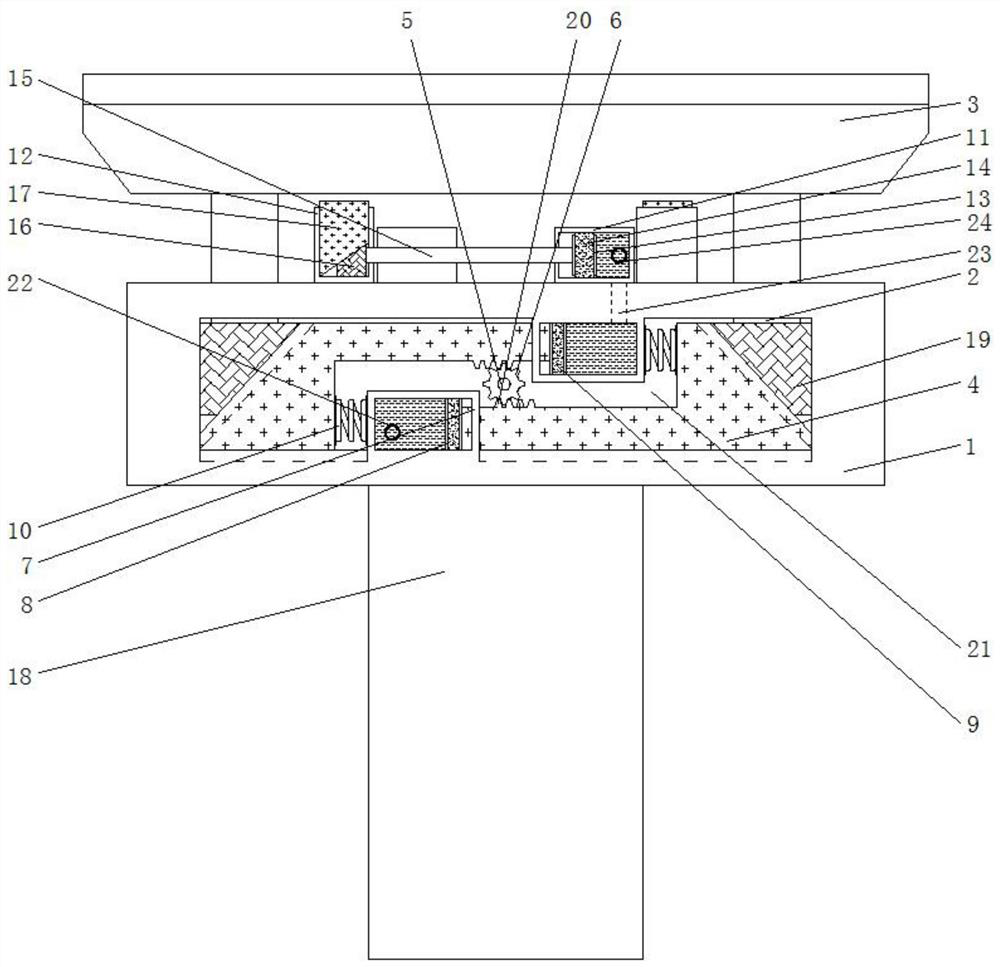

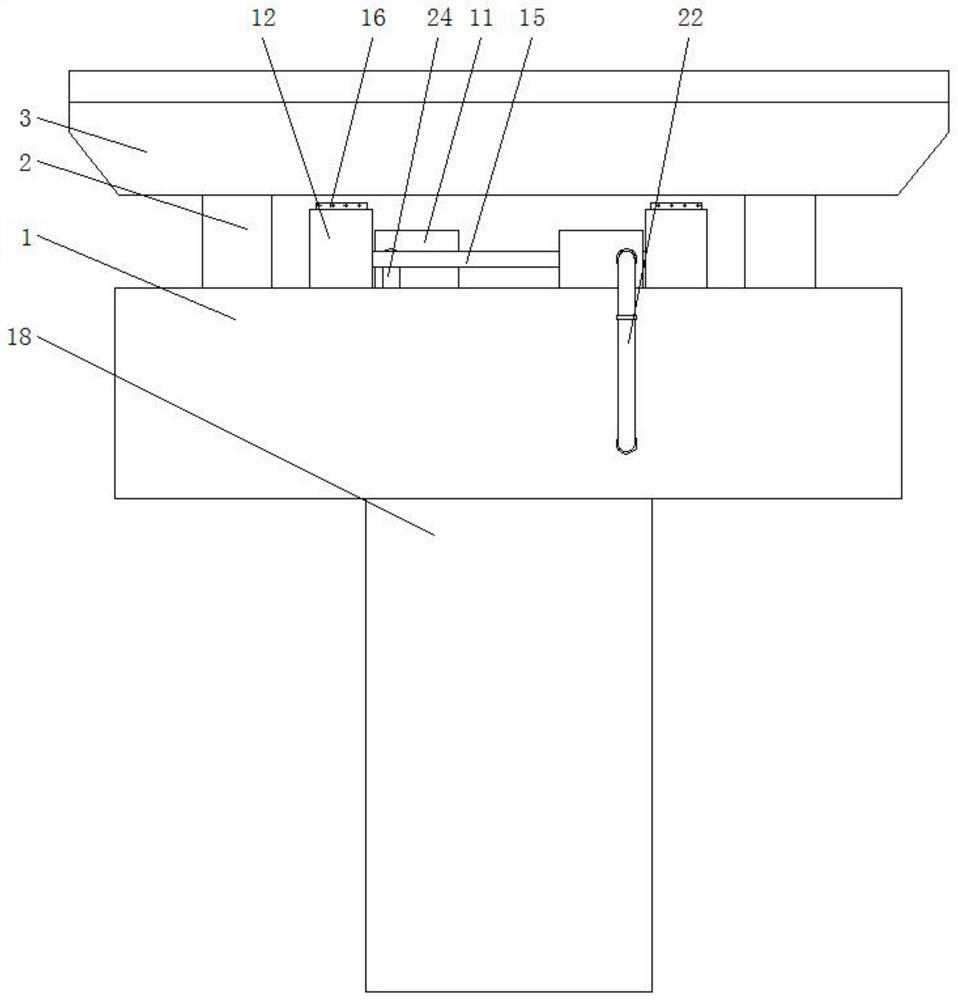

Thermal pipeline supporting device

ActiveCN110206940ANo bending phenomenonPlay a buffer rolePipe supportsPipe elementsIndustrial engineering

The invention provides a thermal pipeline supporting device which comprises a base, a fixing mechanism and an upper siding mechanism. A bolt is in threaded connection with a first sliding block and penetrates through the first sliding block; one end of a first spring is fixed to one side of the first sliding block; the other end of the first spring is fixed to one side of a first clamping groove;one end of a second spring is fixed to the other side of the first sliding block; the other end of the second spring is fixed to the other side of the first clamping groove; one end of a third springis fixed to one side of a second sliding block; the other end of the third spring is fixed to one side of a second clamping groove; a fourth spring is fixed to the other end of the second sliding block; and the other end of the fourth spring is fixed to the other side of the second clamping groove. The thermal pipeline supporting device provided by the invention has the advantage of capability onfreely moving and adjusting when a thermal pipeline is deformed.

Owner:湖南达道新能源开发有限公司

Foldable and portable mobile operation platform

PendingCN108086665AReduce volumeEasy to carry on shoulderScaffold accessoriesCable stayedElectrical and Electronics engineering

Owner:韦宇龙 +1

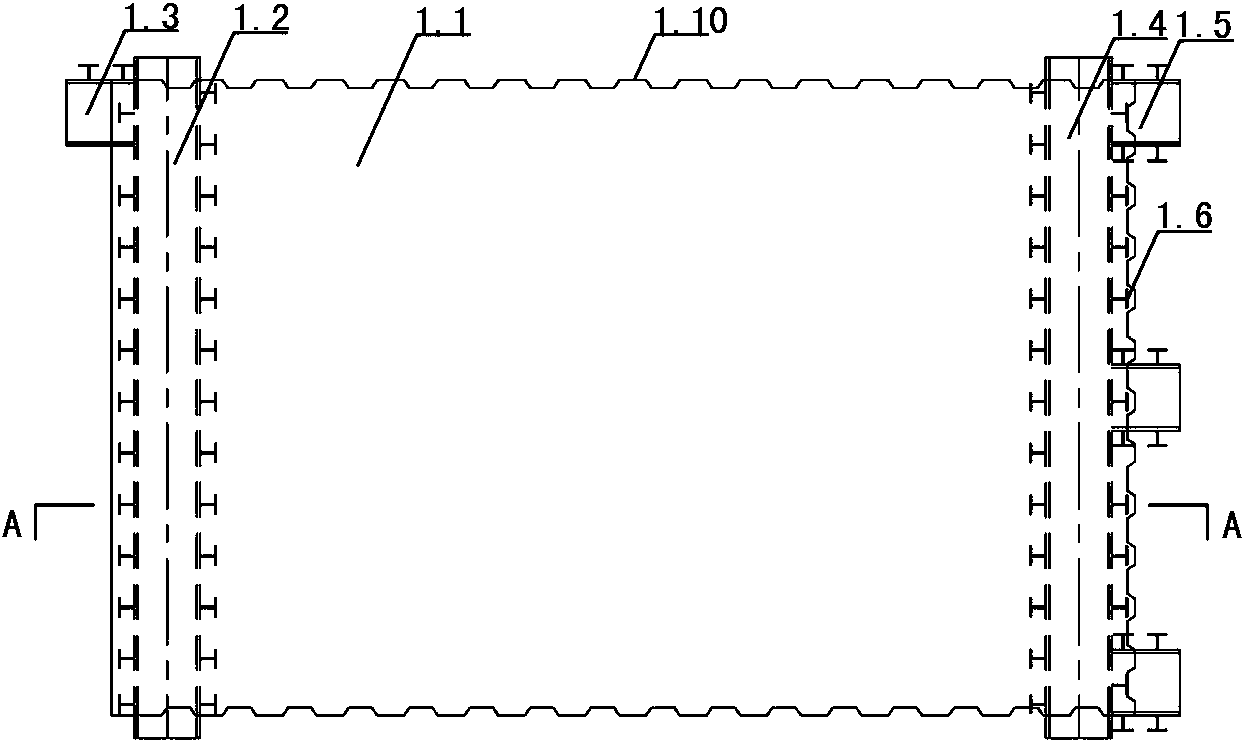

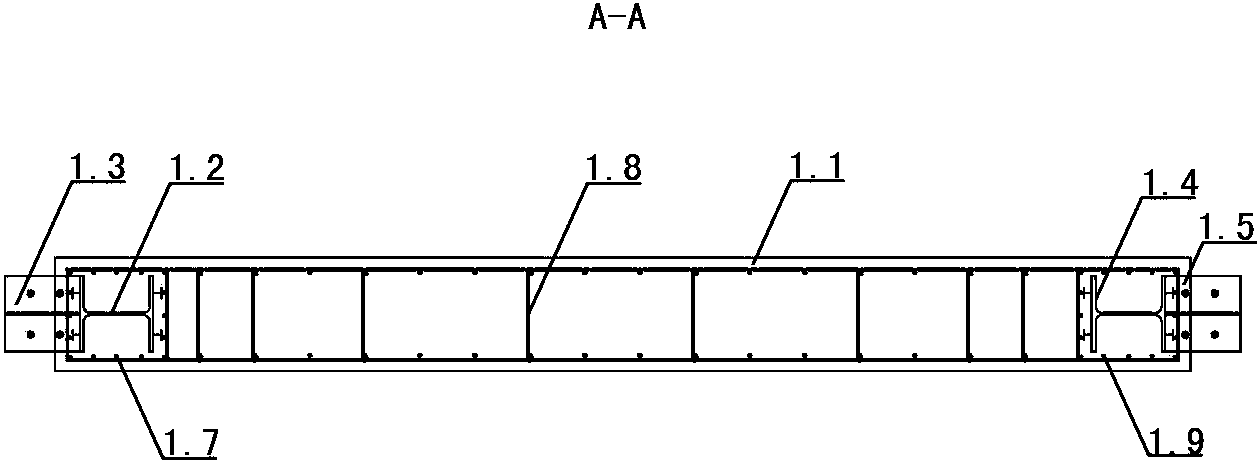

Assembly-type steel beam joint cross-shaped mixed coupled wall and construction method thereof

ActiveCN104032857ASimple construction methodFast constructionWallsShock proofingSteel columnsSteel bar

Disclosed are an assembly-type steel beam joint cross-shaped mixed coupled wall and a construction method thereof. The assembly-type steel beam joint cross-shaped mixed coupled wall comprises first wall units and a second wall unit which are connected together perpendicularly and form a cross shape. The first wall units are symmetrically distributed on the two sides of the second wall unit, the first wall units and the second wall unit are all prefabricated parts, and the first wall units and the second wall unit are connected through joint post-pouring belts. According to the assembly-type steel beam joint cross-shaped mixed coupled wall, steel beams are used for replacing concrete beams and section steel columns are used for replacing edge constraint reinforced concrete embedded columns, so that the mixed coupled wall has better energy-dissipating capacity and progressive-collapse-resistant capacity than a traditional coupled wall; prefabrication and on-site installation are conducted at the same time, therefore, the problems that the quantity of wet construction on a construction site is large and a lot of construction waste is generated are solved and assembly procedures are simplified; after butt welding is conducted on joint short beams, high rigidity is formed between the wall units, therefore, the stability of wall bodies in the construction process is facilitated, the procedure that a shear wall is prefabricated to be used as a temporary support is omitted and the construction efficiency is guaranteed. The construction method can be widely applied to construction of mixed coupled walls in constructional engineering.

Owner:CHINA STATE CONSTRUCTION ENGINEERING CORPORATION

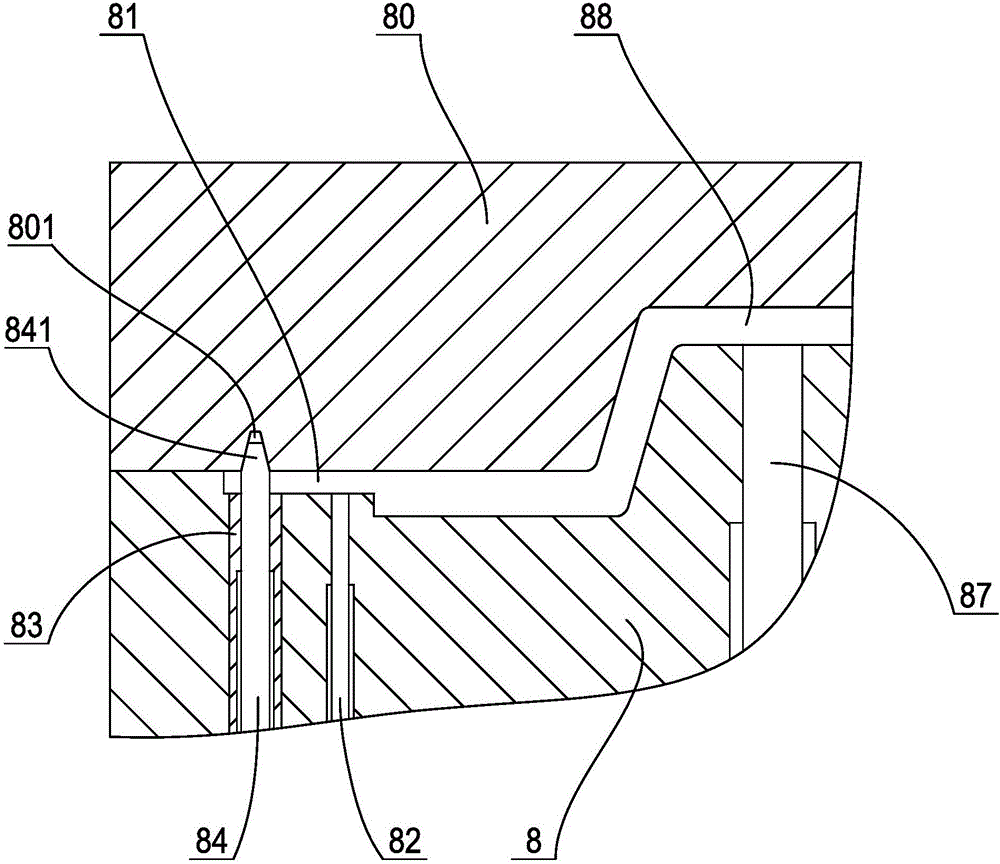

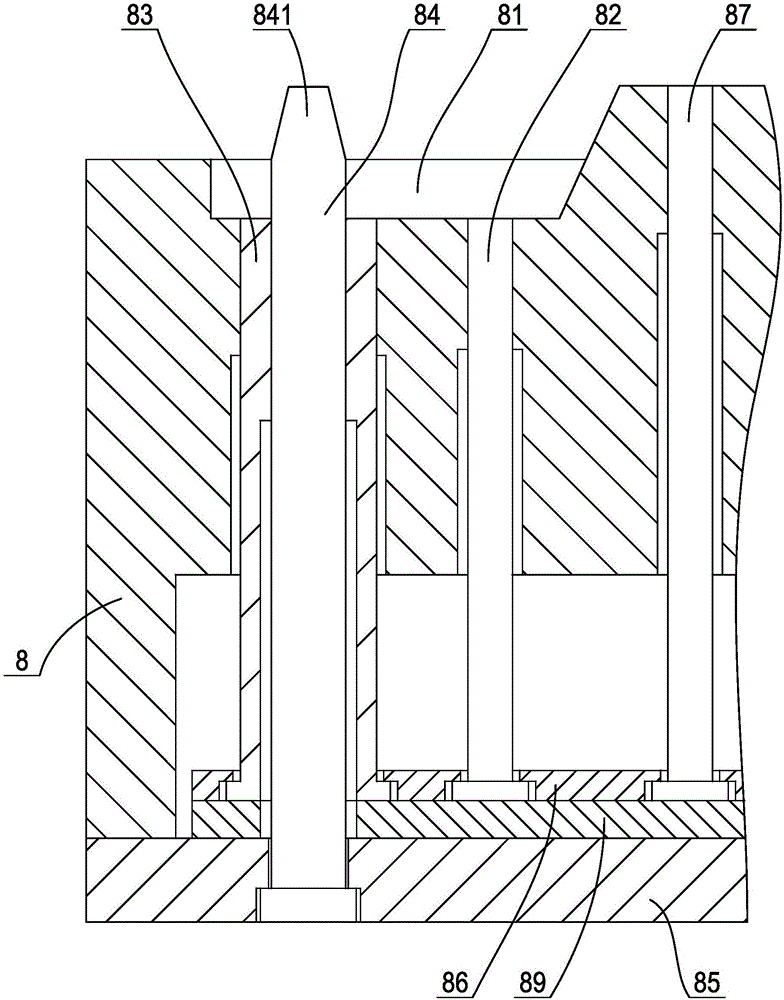

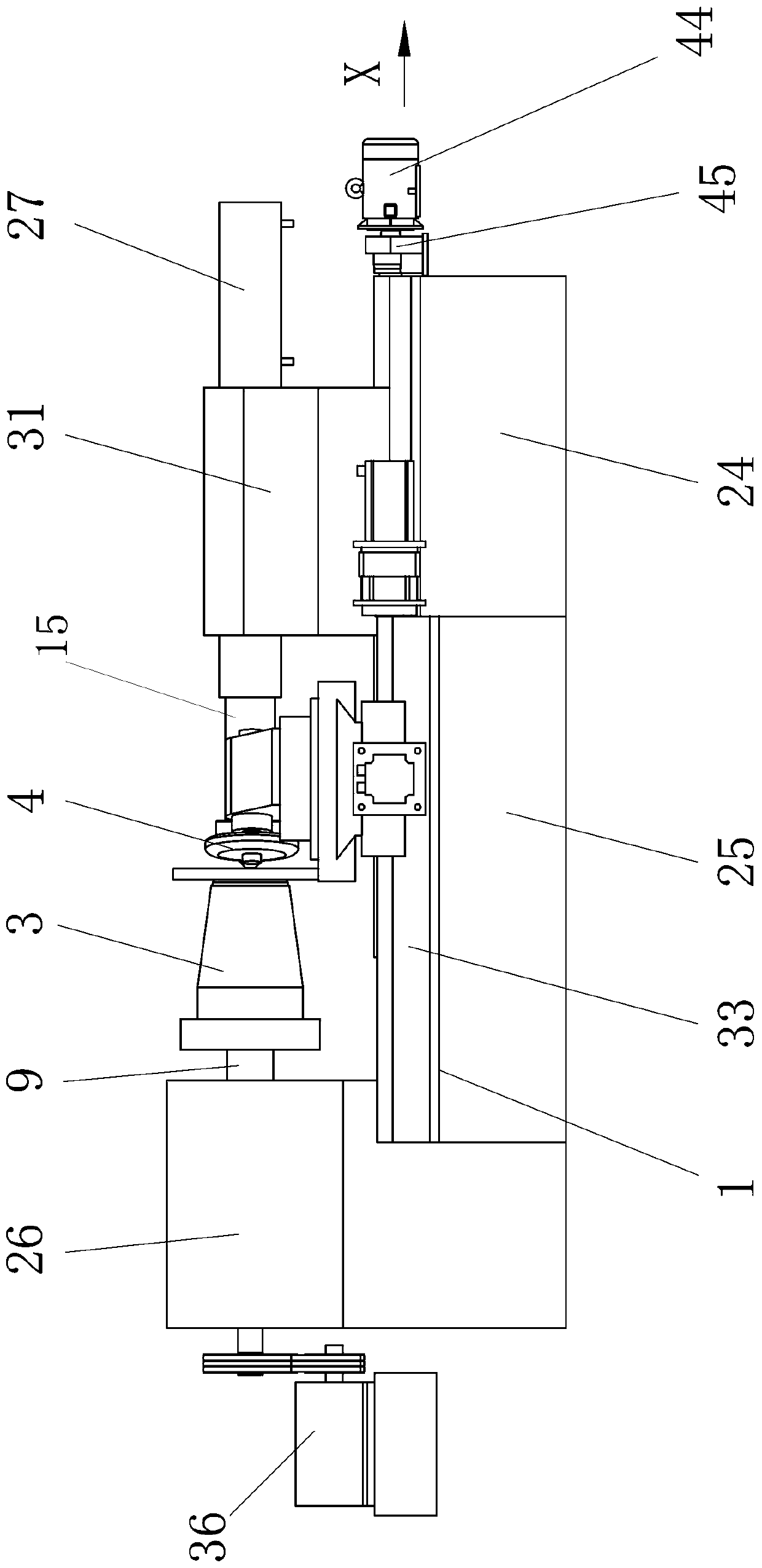

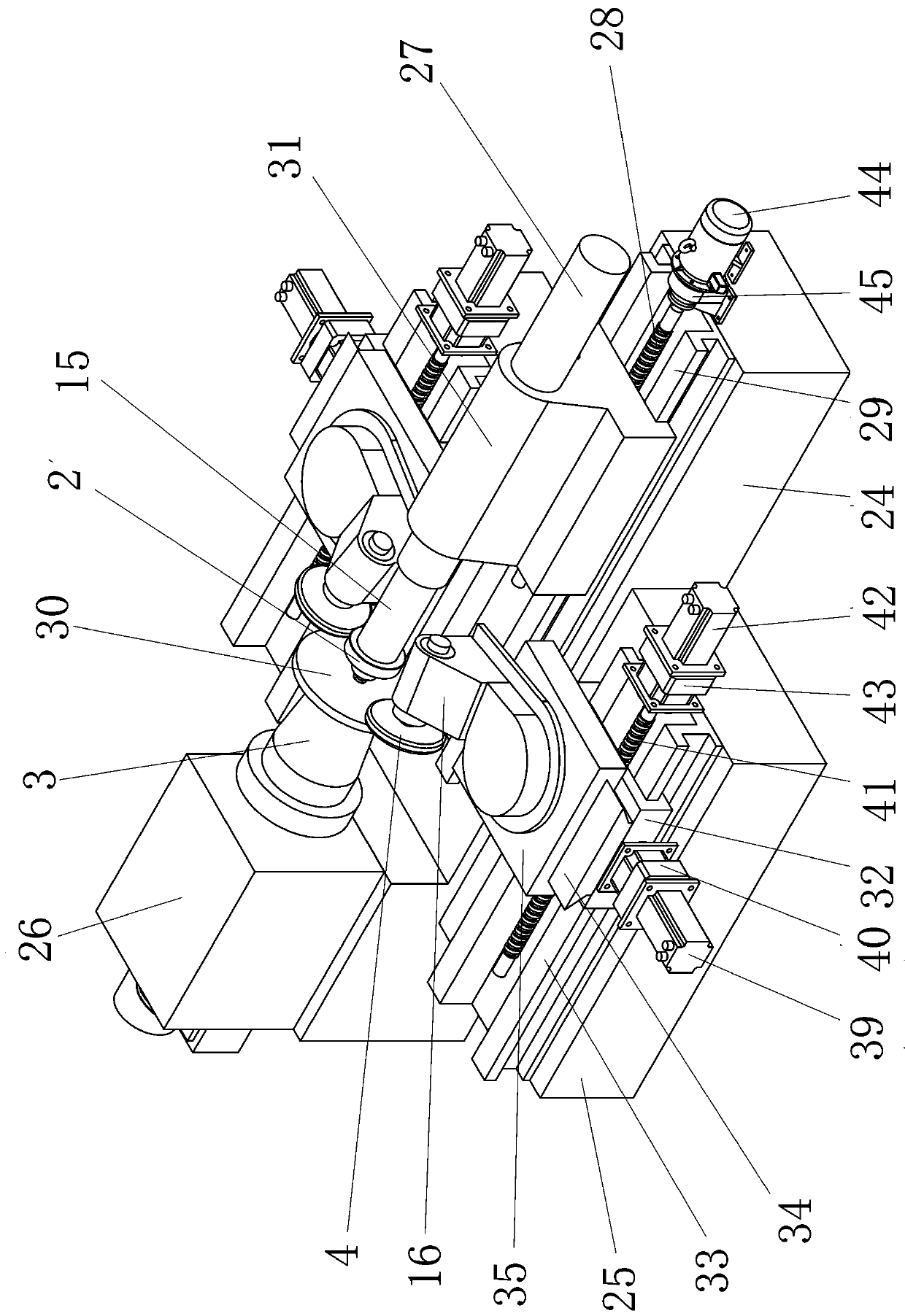

Front cap spinning forming device and technology for blast-furnace tuyere small sleeve

The invention relates to a front cap spinning forming device and technology for a blast-furnace tuyere small sleeve. The front cap spinning forming device comprises a machine frame, wherein the machine frame is of a cross-shaped structure, and the machine frame comprises a base and two side seats; a first guide rail and a second guide rail are arranged on the base, and the first guide rail and thesecond guide rail are both arranged in the transverse direction. The forming technology comprises the following steps that step1, a copper cake blank is prepared; step 2, the copper cake blank is heated; step 3, the copper cake blank is placed; and step 4, the copper cake blank is subjected to strong spinning. According to the front cap spinning forming technology for the blast-furnace tuyere small sleeve, compared with a front cap stamping forming technology, the materials are saved, secondary processing is not needed, the precision can be controlled, the heat conduction of a strong spinningfront cap in a deep-cylinder shape is 30% higher than the heat conduction of a stamping front cap in a short-cylinder shape.

Owner:山东崇盛冶金氧枪有限公司

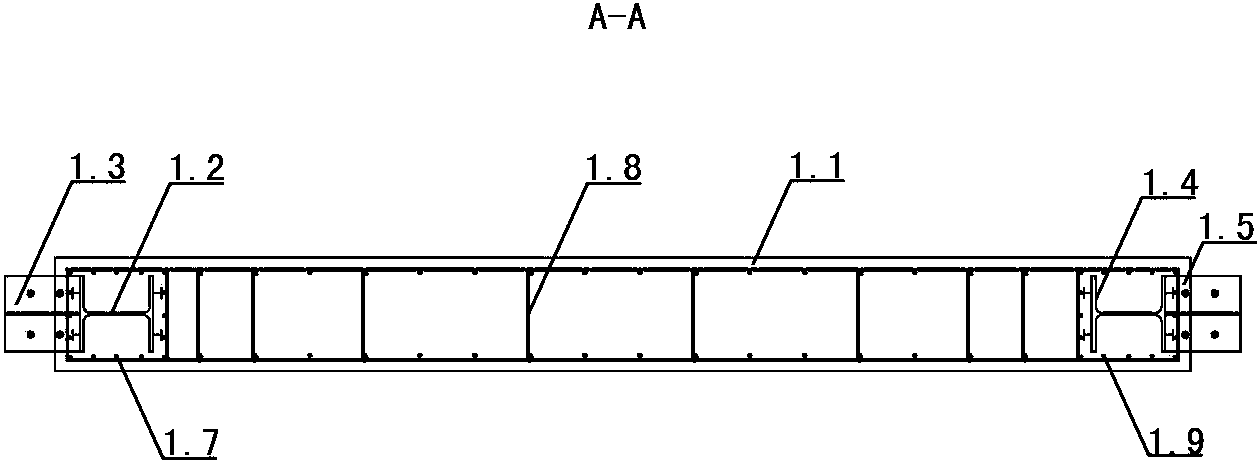

Assembly-type steel beam joint linear mixed coupled wall and construction method thereof

InactiveCN104032858AImprove stabilityReduce wet work loadWallsBuilding material handlingButt weldingConcrete beams

Disclosed are an assembly-type steel beam joint linear mixed coupled wall and a construction method thereof. The assembly-type steel beam joint linear mixed coupled wall comprises a first wall unit and a second wall unit which are connected and are arranged in a linear mode. Both the first wall unit and the second wall unit are prefabricated parts, and the first wall unit and the second wall unit are connected through a joint post-pouring belt. According to the assembly-type steel beam joint linear mixed coupled wall, steel beams are used for replacing concrete beams and section steel columns are used for replacing edge constraint reinforced concrete embedded columns, so that the mixed coupled wall has better energy-dissipating capacity and progressive-collapse-resistant capacity than a traditional coupled wall; prefabrication and on-site installation are conducted at the same time, therefore, the problems that the quantity of wet construction on a construction site is large and a lot of construction waste is generated are solved and assembly procedures are simplified; after butt welding is conducted on joint short beams, high rigidity is formed between the wall units, therefore, the stability of wall bodies in the construction process is facilitated, the procedure that a shear wall is prefabricated to be used as a temporary support is omitted and the construction efficiency is guaranteed. The construction method can be widely applied to construction of mixed coupled walls in constructional engineering.

Owner:CHINA STATE CONSTRUCTION ENGINEERING CORPORATION

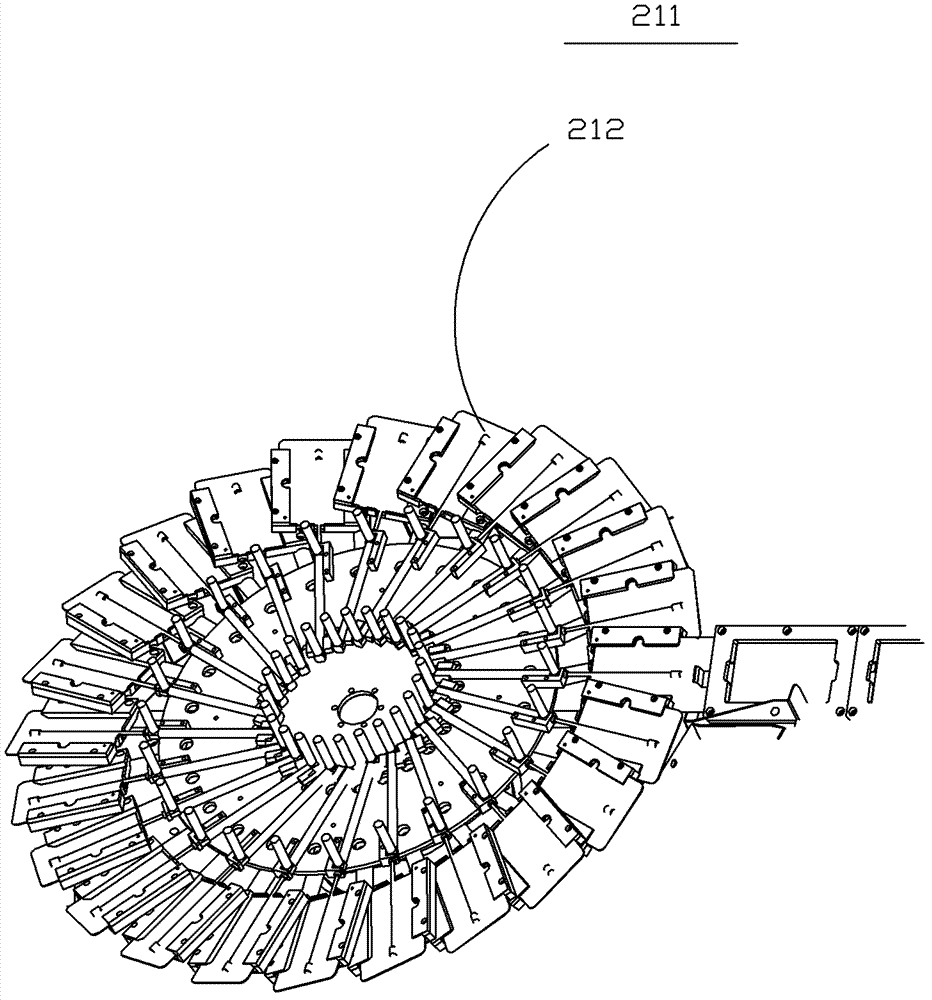

Optical cable retreating machine and realizing method thereof

InactiveCN108732704ARealize the intelligent unwinding functionEasy to operateFibre mechanical structuresYarnElectric machinery

The invention discloses an optical cable retreating machine and a realizing method thereof. The optical cable retreating machine comprises an optical cable retreating device body. The optical cable retreating device is provided with a pay-off frame, a stranding-off frame, a cable receiving frame and an optical fiber finished cable. The middle position of the pay-off frame is provided with a pay-off disc. The upper part of the stranding-off frame is provided with a stranding-off disc, and the lower part is provided with a stranding-off motor and a controller. The middle position of the cable receiving frame is provided with a cable receiving disc. One end of the cable receiving disc is connected with a cable receiving motor. The cable receiving motor is electrically connected with the controller. The controller is electrically connected with a touch screen and a starting / stopping switch. The body structure of the optical fiber finished cable comprises yarns, an optical fiber bundle pipe, a reinforcing member and a filling rope. The optical cable retreating machine and the realizing method realize high stability and high reliability in actual use and realize an intelligent cable retreating function of the optical fiber finished cable. Furthermore the optical cable retreating machine and the realizing method thereof have advantages of convenient operation, time-saving and labor-saving function, high safety and high reliability. No bundle pipe bending is caused in the cable retreating process, and cable retreating efficiency is improved. The optical cable retreating machine andthe realizing method thereof are suitable for popularization.

Owner:ANHUI UNIV OF SCI & TECH

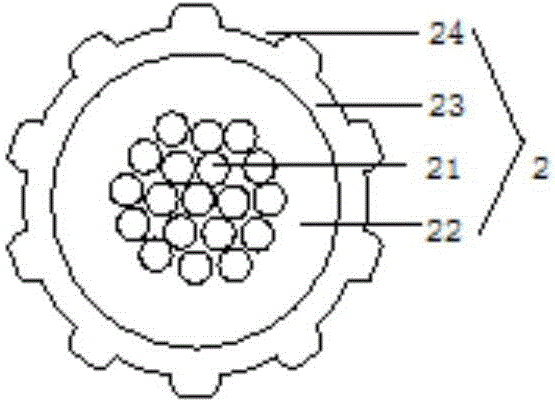

Construction technology of expanded-diameter conductors

ActiveCN103490343ANo bending phenomenonNo "bubble stock" phenomenonApparatus for overhead lines/cablesMeanderTransformer

The invention relates to a construction technology of expanded-diameter conductors. The construction technology of the expanded-diameter conductors comprises the following steps of (1) carrying out lofting on the expanded-diameter conductors, wherein the lofting carried out on the expanded-diameter conductors comprises suspended bus lofting and device lead lofting; (2) splitting the expanded-diameter conductors; (3) inserting the expanded-diameter conductors into a hydraulic pipe; (4) carrying out pressing connection on the expanded-diameter conductors through the reverse-pressing method; (5) carrying out lifting and installation on the expanded-diameter conductors processed through pressing connection. Compared with the prior art, the construction technology of the expanded-diameter conductors is accurate in lofting, the fracture surface of each expanded-diameter conductor is flat after cutting is carried out, and is perpendicular to the axis of each cable strand, and the ends of each expanded-diameter conductor are free of burrs, free of strand loosening and free of deformation; after pressing connection is carried out, the portion, close to a pressing connection tube opening, of each expanded-diameter conductor is free of swells and loosened strands, the phenomenon of a bent pressing connection tube does not exist, the tube wall of the pressing connection tube after hydraulic pressure processing is smooth, and free of cracks, the surface of each expanded-diameter conductor after pressing connection processing is free of bulged strands, the meander phenomenon does not exist when hoisting is carried out, the requirement for standardized construction is completely met, and the construction technology of the expanded-diameter conductors can be used for directing standardized construction of expanded-diameter conductors, with the diameters of 1600 or more, in high-capacity circuits of 500kV alternating-current transformer substations.

Owner:SHANGHAI MUNICIPAL ELECTRIC POWER CO +2

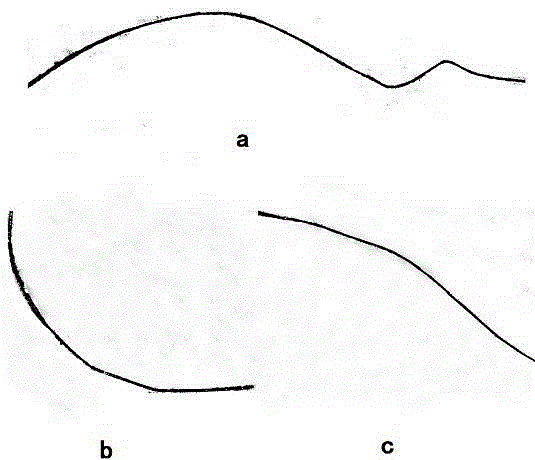

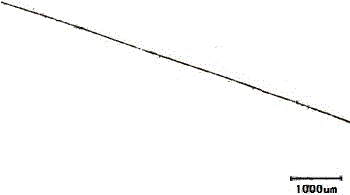

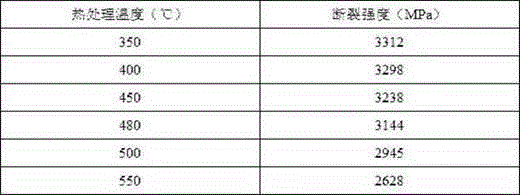

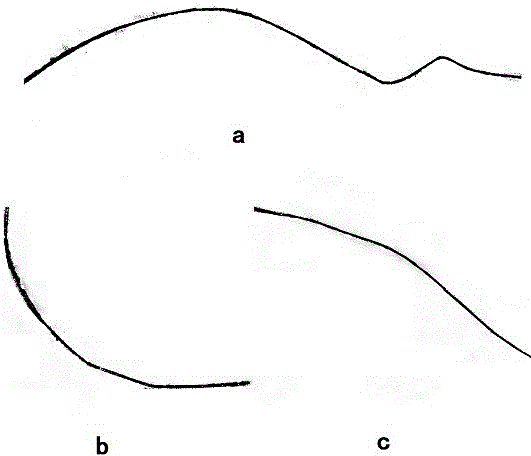

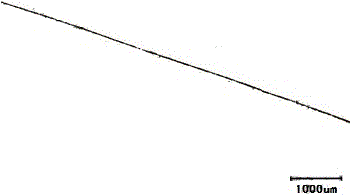

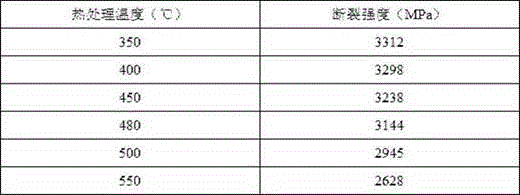

Preparing method for non-bending ultrathin tungsten wires for Z-pinch torispherical wire array

The invention discloses a preparing method for non-bending ultrathin tungsten wires for a Z-pinch torispherical wire array. The diameter of the ultrathin tungsten wires ranges from four micrometers to ten micrometers, and no bending phenomenon exists in the centimeter magnitude range. The method comprises the following steps that raw material wires are subjected to hot drawing to enable the diameter to be controlled within the range larger than or equal to 16 micrometers; a multi-pass electrolytic etching technology is carried out, a limit single-pass diameter reducing method is adopted to enable the ultrathin tungsten wires obtained after continuous electrochemical corrosion to keep the mechanical property under the condition that the bending span is slightly increased; and in annealing heat treatment, the finished tungsten wires are rewound on a quartz glass tube to be placed in a heat treatment furnace so as to be heated to 480 DEG C and conduct heat preservation for 10 minutes, the tungsten wires are cooled along with cooling of the furnace, in the period, the quartz glass tube is vacuumized, high-purity argon or high-purity nitrogen is injected in to serve as protection gas, and the finished tungsten wires are recrystallized, but the breaking strength is not obviously reduced. Compared with the traditional technology, the ultrathin tungsten wires manufactured with the preparing method have the beneficial effects that no obvious bending exists in the free state, and the breaking strength is better.

Owner:LASER FUSION RES CENT CHINA ACAD OF ENG PHYSICS

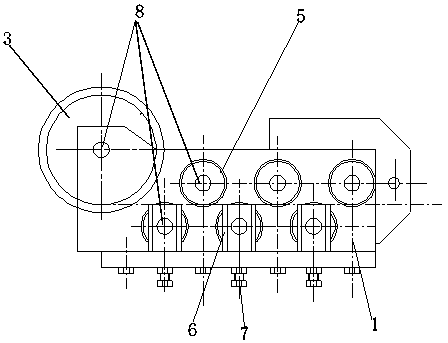

Combined type straightening deformer for wire drawing of rare earth steel strands

PendingCN107900127AReduce internal stressGood flexibilityWire straightening devicesEngineeringPulley

The invention discloses a combined type straightening deformer for wire drawing of rare earth steel strands. The combined type straightening deformer for wire drawing of rare earth steel strands comprises a deformer base, wherein a deformation main guide wheel mechanism is mounted at one end of the deformer base; upper deformation straightening guide wheel mechanism and lower deformation straightening guide wheel mechanisms are mounted on the same horizontal plane on the deformer base and positioned on the right side of the deformation main guide wheel mechanism; the number of the upper deformation straightening guide wheel mechanisms is the same as that of the lower deformation straightening guide wheel mechanisms; the upper deformation straightening guide wheel mechanisms and the lower deformation straightening guide wheel mechanisms are equidistantly arranged in a staggered manner; the deformation main guide wheel mechanism comprises a main mechanism base; a V-shaped groove deformation main guide wheel is mounted on the main mechanism base through a high-temperature bearing; the upper deformation straightening guide wheel mechanisms are the same as the lower deformation straightening guide wheel mechanisms, each upper deformation straightening guide wheel mechanism comprises a deformation straightening guide wheel mechanism base, and each lower deformation straightening guide wheel mechanism also comprises a deformation straightening guide wheel mechanism base; and a V-shaped groove straightening guide wheel is mounted on each deformation straightening guide wheel mechanism base through a high-temperature bearing. The problems that in the prior art, stress after drawing of steel wires is eliminated in completely, flexibility of smooth steel wires is poor, the steel wires are bent in a wavy manner, and flatness is not enough are solved.

Owner:无锡科茂金属材料有限公司

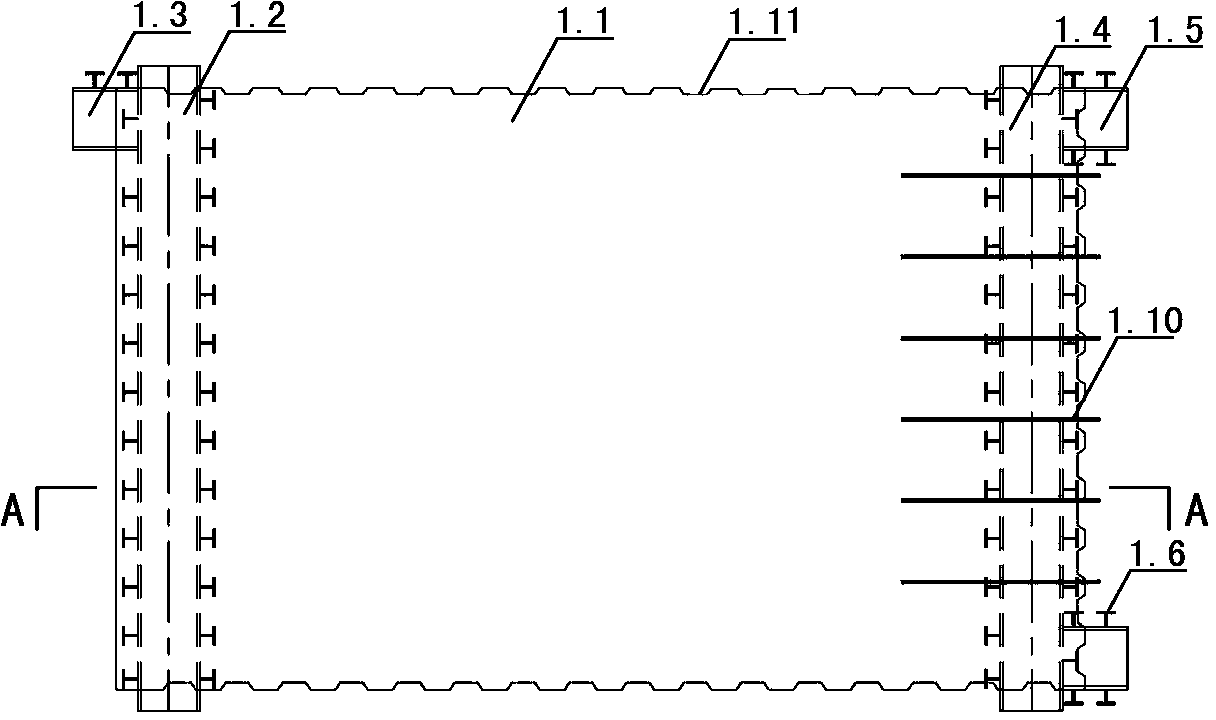

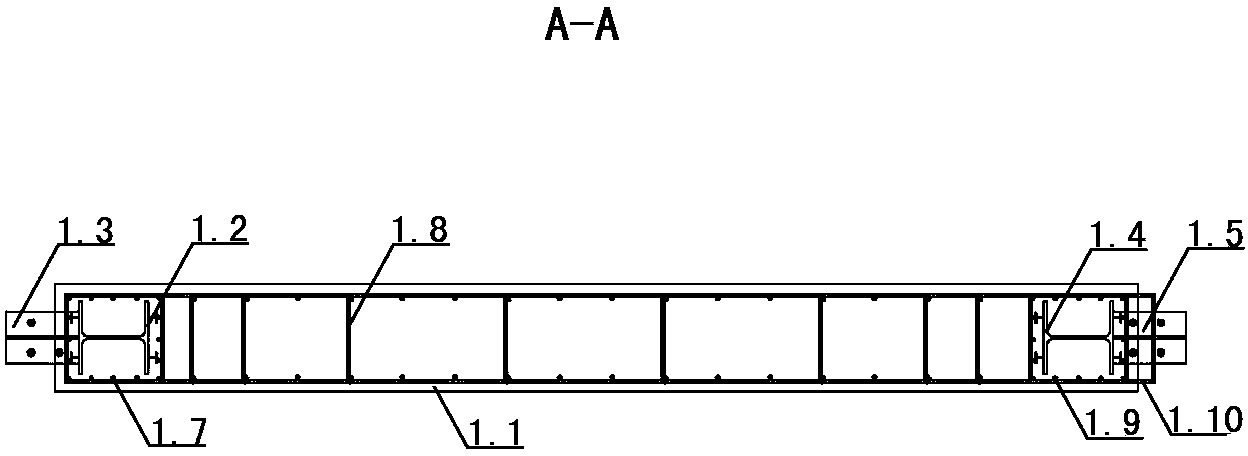

Elevated steel-concrete composite beam

ActiveCN112342899AImprove self-adjusting balance performanceExtended service lifeClimate change adaptationBridge structural detailsConcrete beamsArchitectural engineering

The invention discloses an elevated steel-concrete composite beam which comprises a cross beam and a pier stud, the cross beam is fixedly connected to the top of the pier stud, transmission bases areslidably connected to the two sides of the bottom of the inner wall of the cross beam, sliding bases are slidably connected to the sides, away from each other, of the two transmission bases, and steelbeams are fixedly connected to the tops of the two sliding bases. The tops of the two steel beams penetrate through the cross beam and extend to the position above the cross beam, a concrete plate isfixedly connected between the tops of the two steel beams, rectangular grooves are formed in the bottom of one transmission base and the top of the other transmission base, and the two transmission bases are symmetrically connected to the bottom of the inner wall of the cross beam in a staggered and sliding mode. The two sides of the bottom of the concrete slab are stressed at the same time and do not descend any more, the force is decomposed and converted, the situation that the concrete slab is stressed unevenly is reduced, the stability of the overall structure of the concrete beam is improved, the underpinning is in a straight rod shape, longitudinal and horizontal stress is conducted, and the bending phenomenon is avoided.

Owner:GUIZHOU ROAD & BRIDGE GRP

Assembly-type linear mixed coupled wall and construction method thereof

InactiveCN104032863AImprove stabilityReduce wet work loadWallsBuilding material handlingButt weldingConcrete beams

Disclosed are an assembly-type linear mixed coupled wall and a construction method thereof. The assembly-type linear mixed coupled wall comprises a first wall unit and a second wall unit which are connected and are arranged in a linear mode. Both the first wall unit and the second wall unit are prefabricated parts, and the first wall unit and the second wall unit are connected through a joint post-pouring belt. According to the assembly-type linear mixed coupled wall, steel beams are used for replacing concrete beams and section steel columns are used for replacing edge constraint reinforced concrete embedded columns, so that the mixed coupled wall has better energy-dissipating capacity and progressive-collapse-resistant capacity than a traditional coupled wall; prefabrication and on-site installation are conducted at the same time, therefore, the problems that the quantity of wet construction on a construction site is large and a lot of construction waste is generated are solved and assembly procedures are simplified; after butt welding is conducted on joint short beams, high rigidity is formed between the wall units, therefore, the stability of wall bodies in the construction process is facilitated, the procedure that a shear wall is prefabricated to be used as a temporary support is omitted and the construction efficiency is guaranteed. The construction method can be widely applied to construction of mixed coupled walls in constructional engineering.

Owner:CHINA STATE CONSTRUCTION ENGINEERING CORPORATION

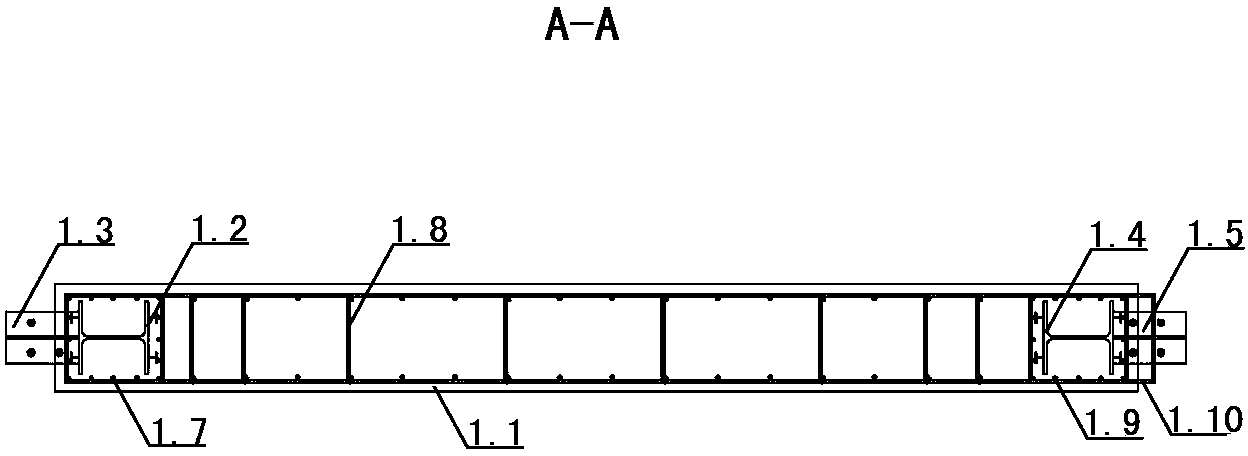

Strip-shaped feed processing device

InactiveCN112674372AGuaranteed service lifeTake advantage ofFeeding-stuffGranulation by material expressionFeed processingAgricultural engineering

The invention relates to feed processing related machinery, and in particular relates to a strip-shaped feed processing device. The strip-shaped feed processing device comprises a main body frame, a stirring and wall cleaning mechanism, a pushing mechanism, a dislocation adjusting mechanism, a conventional cutting mechanism, a long grain bending preventing mechanism and a sealing door; the sealing door is installed on the main body frame; the stirring and wall cleaning mechanism is fixedly installed on the main body frame; the pushing mechanism is fixedly installed on the main body frame; the dislocation adjusting mechanism is fixedly installed on the main body frame; the conventional cutting mechanism is fixedly installed on the main body frame; and the long grain bending preventing mechanism is fixedly installed on the main body frame. According to the strip-shaped feed processing device, small-particle feed processing and long-strip-shaped feed processing can be carried out; it is guaranteed that the long-strip-shaped feed cannot be bent in the processing process; the device has the function of cleaning the inner wall while having a stirring function; and the cleaning degree of the device is guaranteed.

Owner:哈尔滨金玉钰科技开发有限公司

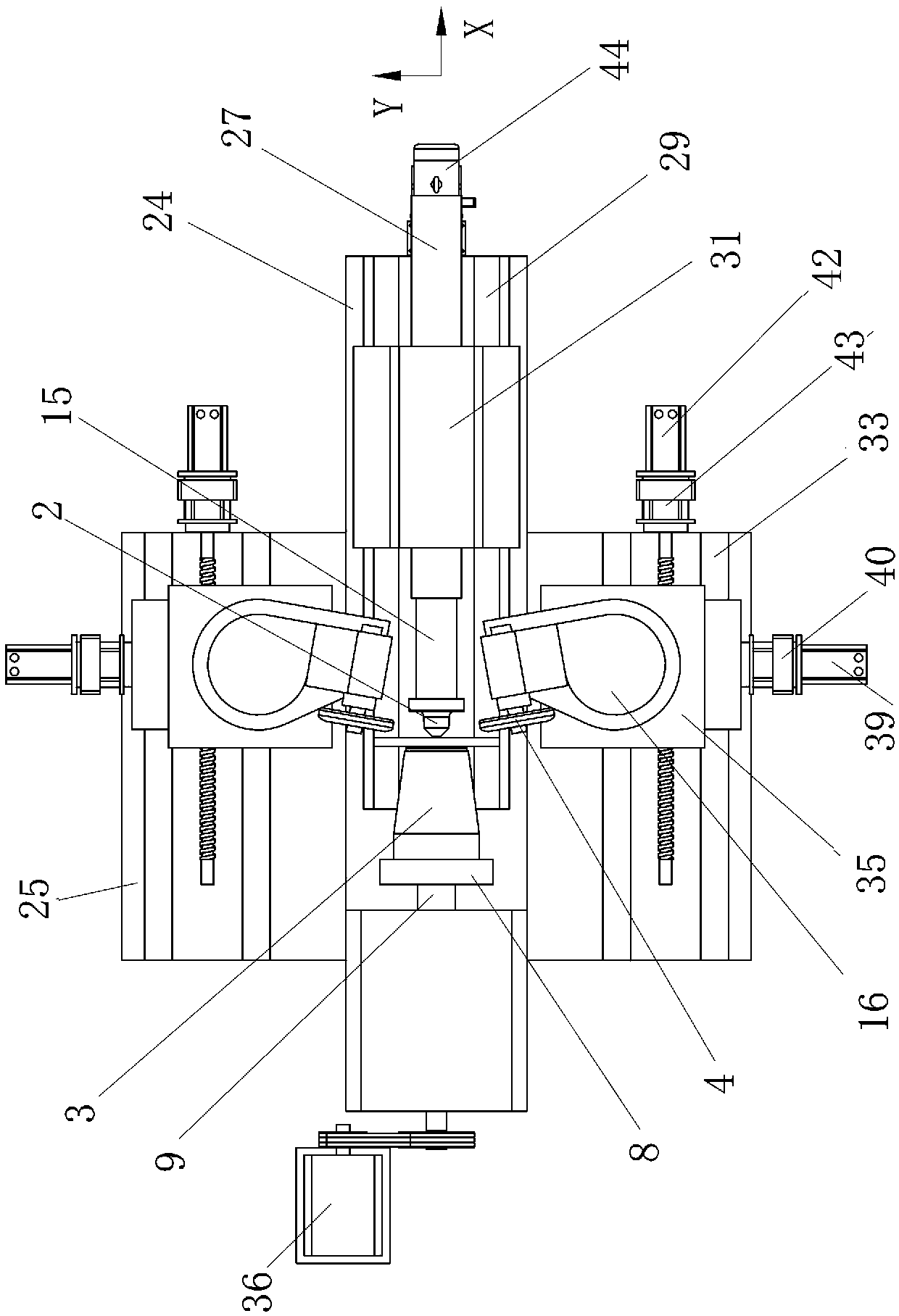

Machine tool for processing horseshoe-shaped slots of drill bit

ActiveCN107303610AImprove surface qualityReduce vibrationMilling equipment detailsCutter locationReciprocating motion

The invention discloses a machine tool for processing horseshoe-shaped slots of a drill bit. The machine tool comprises a rack, wherein a power head and a fixing seat for fixing the drill bit are arranged on the rack; power output parts are arranged on the power head; milling cutters are clamped on the output parts; a guide rail and a drive component for driving the power head or the fixing seat to move on the guide rail in a reciprocating way are further arranged on the rack; at least two power output parts are arranged on the power head; the tapered milling cutters are clamped on the power output parts; the positions of the tapered milling cutters correspond to the positions of the horseshoe-shaped slots of the drill bit to be processed; and the tapers of the tapered milling cutters are consistent to tilt angles of the horseshoe-shaped slots on the drill bit. The machine tool for processing the horseshoe-shaped slots of the drill bit can prevent an axis of the drill bit from bending when the horseshoe-shaped slots are processed.

Owner:ZHEJIANG PULANKA ROCK TOOLS CO LTD

Polarizing film attachment device

InactiveCN103969881BNo bending phenomenonReduce generationLaminationLamination apparatusOptoelectronicsLiquid crystal

The invention relates to an apparatus for attaching a polarized film, and especially relates an apparatus having characteristics described as follows. In a method of attaching a polarized film onto a liquid crystal element substrate, a problems is that bubbles are generated between the polarized film and the liquid crystal element substrate because the front bending of the polarized film. A caterpillar track type adhesive plate is arranged on an inclination roller and a fixed roller on the left and the right, and a polarized film is attached to the liquid crystal element substrate after the polarized film is arranged on the amooth adhesive plate. Therefore, a phenomenon of overall bending of the polarized film does not occur. When the polarized film is attached onto the surface of the liquid crystal element substrate, the possibility of bubble generation is substantially reduced. Furthermore, the liquid crystal element is prevented from being bent due to the elongation of the polarized film, and the possibility of unqualified products is eliminated.

Owner:YMK

Card dividing device and automatic electrical writing device with the same

ActiveCN102950119BRealize intelligent classificationSolve the difficulty of classificationDigitally marking record carriersSortingInformation processingElectricity

The invention provides a card sorting device and an automatic electric writing device with the same. The card sorting device comprises a card sorting plate and a rotating shaft, wherein the rotating shaft is horizontally positioned at the lower part of the card sorting plate; the card sorting plate is divided into two layers, namely, a first layer for installing an identification card temporary storage slot, and a second layer for installing a card storage slot, and the first layer can be rotated relative to the second layer; bulges, which are arranged along the circumference, are arranged at the lower bottom part of the first layer of the card sorting plate; a card pushing device for pushing an identification card out of the temporary storage slot is arranged on the card sorting plate; cam mechanisms in match with the bulges at the lower bottom part of the first layer of the card sorting plate are arranged at the end part of the rotating shaft; the automatic electric writing device comprises a base, a card feeding device, a card writing device, an information verifying device, an information processing device and the card sorting device, and the information processing device is positioned in the base; the card feeding device is positioned on the base; the card writing device and the information verifying device are positioned at the upper part of the card feeding device; and the card sorting device is positioned at the tail end of the card feeding device. The card sorting plate has the advantages of being stable, high in sorting capacity, high in efficiency, and small in size.

Owner:INT SECURITY TECH SHENZHEN +1

Preparation method of non-bending ultrafine tungsten wire for z-pinch quasi-spherical wire array

The invention discloses a preparing method for non-bending ultrathin tungsten wires for a Z-pinch torispherical wire array. The diameter of the ultrathin tungsten wires ranges from four micrometers to ten micrometers, and no bending phenomenon exists in the centimeter magnitude range. The method comprises the following steps that raw material wires are subjected to hot drawing to enable the diameter to be controlled within the range larger than or equal to 16 micrometers; a multi-pass electrolytic etching technology is carried out, a limit single-pass diameter reducing method is adopted to enable the ultrathin tungsten wires obtained after continuous electrochemical corrosion to keep the mechanical property under the condition that the bending span is slightly increased; and in annealing heat treatment, the finished tungsten wires are rewound on a quartz glass tube to be placed in a heat treatment furnace so as to be heated to 480 DEG C and conduct heat preservation for 10 minutes, the tungsten wires are cooled along with cooling of the furnace, in the period, the quartz glass tube is vacuumized, high-purity argon or high-purity nitrogen is injected in to serve as protection gas, and the finished tungsten wires are recrystallized, but the breaking strength is not obviously reduced. Compared with the traditional technology, the ultrathin tungsten wires manufactured with the preparing method have the beneficial effects that no obvious bending exists in the free state, and the breaking strength is better.

Owner:LASER FUSION RES CENT CHINA ACAD OF ENG PHYSICS

Prefabricated steel beam joint L-shaped mixed limb wall and its construction method

A prefabricated steel beam joint L-shaped mixed limb wall and its construction method, the fabricated steel beam joint L-shaped mixed limb wall includes a first wall unit and a second wall that are vertically connected together to form an L shape The units, the first wall unit and the second wall unit are all prefabricated components, and the two are connected by joint post-casting tapes. The present invention uses steel beams instead of concrete beams, and steel columns instead of edge-constrained reinforced concrete concealed columns, so that the hybrid connected limb wall has better energy consumption capacity and continuous collapse resistance than the traditional connected limb wall, and the factory prefabrication and on-site installation can be carried out at the same time. It solves the problems of large amount of wet work on the construction site and a lot of construction waste, and simplifies the assembly process; after butt welding of the short joints, the wall units have formed a relatively large rigidity, which is conducive to the stability of the wall during the construction process, eliminating the need for The process of prefabricated shear walls as temporary support ensures construction efficiency. It can be widely used in the construction of mixed limb walls in construction projects.

Owner:CHINA STATE CONSTRUCTION ENGINEERING CORPORATION

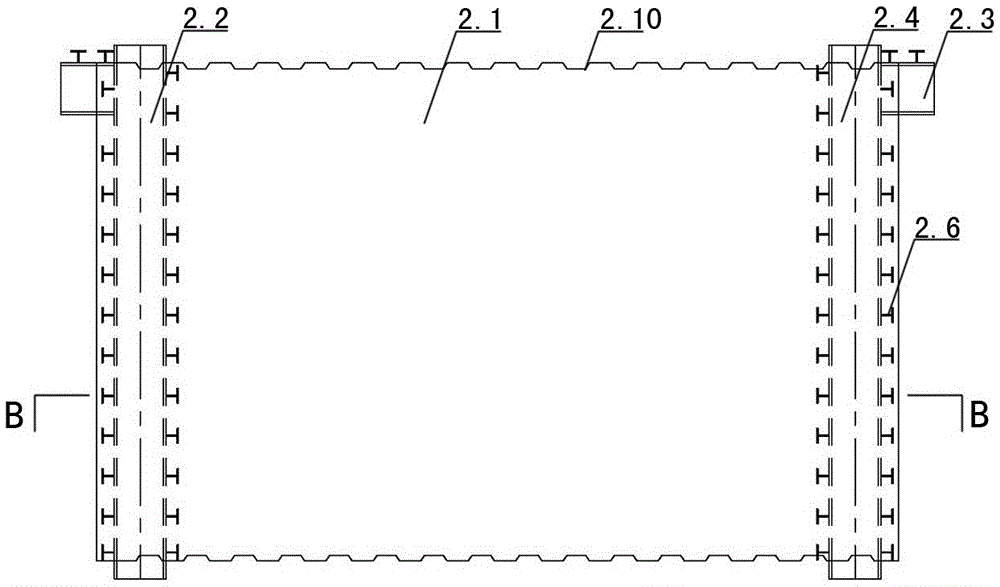

Special water irrigation device for potted scindapsus aureus and water and fertilizer integrated implementation method

PendingCN108770457AImprove irrigation effectFirmly connectedLiquid fertiliser regulation systemsPressurised distribution of liquid fertiliserSpray nozzleEngineering

The invention discloses a special water irrigation device for potted scindapsus aureus and a water and fertilizer integrated implementation method. The special water irrigation device for the potted scindapsus aureus comprises a water irrigation device upper cover and a water irrigation device inserting rod, wherein a tapered opening for fixing and connecting a capillarity tube, a water inlet, a water inlet spraying nozzle, supporting columns, a connection part, a water guide tapered surface and an impacting part are arranged at the upper end of the water irrigation device upper cover; hollowwater outlets are formed in the upper part of the water guide tapered surface, the interior of the plurality of supporting columns and the lower part of the water inlet spraying nozzle; the water inlet is designed at the top of the special water irrigation device for the potted scindapsus aureus and keeps parallel to the capillarity tube; the device is easy to connect and a bending phenomenon doesnot occur; meanwhile, the flow is easy to control and a blocking condition is not easy to occur. The water and fertilizer integrated implementation method is high in irrigation efficiency and can meet the requirements of large-scale planting of the scindapsus aureus.

Owner:SHANGHAI HUAWEI WATER SAVING IRRIGATION CORP LTD

A kind of construction technology of expanding wire

ActiveCN103490343BNo bending phenomenonNo "bubble stock" phenomenonApparatus for overhead lines/cablesCrack freeMeander

The invention relates to a construction process of an enlarged diameter wire, which comprises the following steps: (1) stake out the expanded diameter wire, including overhead bus bar stakeout and equipment lead wire stakeout; (2) open the expanded diameter wire; (3) open the expanded diameter wire Insert into the hydraulic pipe; (4) crimp the expanded diameter wire by reverse pressure method; (5) lift and install the expanded diameter wire after crimping. Compared with the prior art, the method of the present invention is accurate in lofting, the cross-section after cutting is flat and perpendicular to the axis of the wire strands, the end of the wire has no burr, no loose strands, and no deformation; after crimping, the wire near the crimping nozzle has no bulge and looseness Strands, crimping pipe without bending phenomenon, the pipe wall after hydraulic pressure is smooth and free of cracks, there is no "bubble" phenomenon on the surface of the expanded diameter wire after crimping, and there is no bending phenomenon during hoisting, which fully meets the requirements of standardized construction and can be used for Guide the standardized construction of 1600 and above expanded diameter conductors in large-capacity lines of 500kV AC substations.

Owner:SHANGHAI MUNICIPAL ELECTRIC POWER CO +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com