Device and method for directly quenching seamless steel pipes

A technology of seamless steel pipe and quenching device, applied in the direction of quenching device, quenching agent, furnace type, etc., can solve the problems of easy bending of pipes and inability to quench large-diameter pipes, and achieve the advantages of convenient operation, simple device structure and good application prospects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

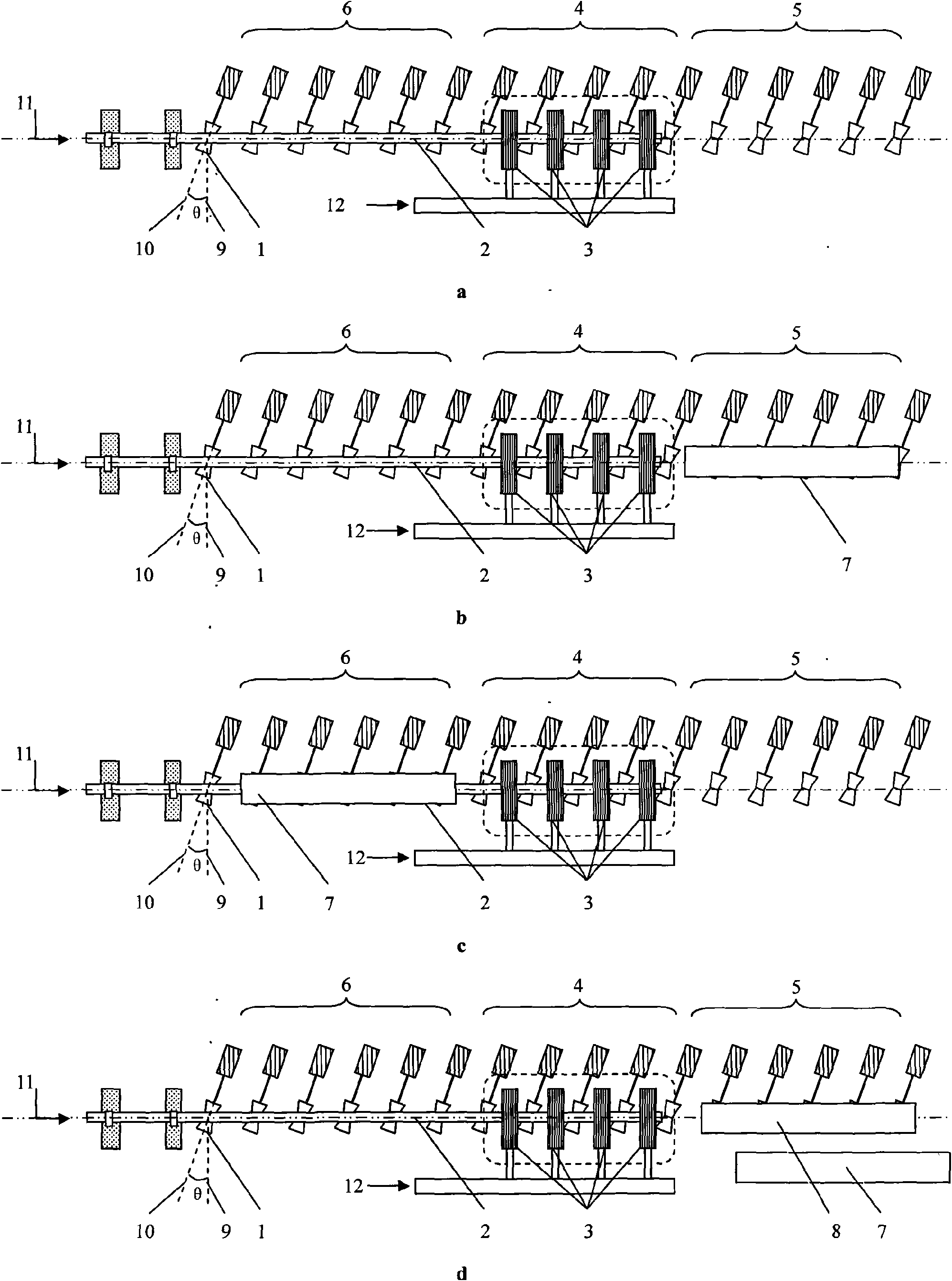

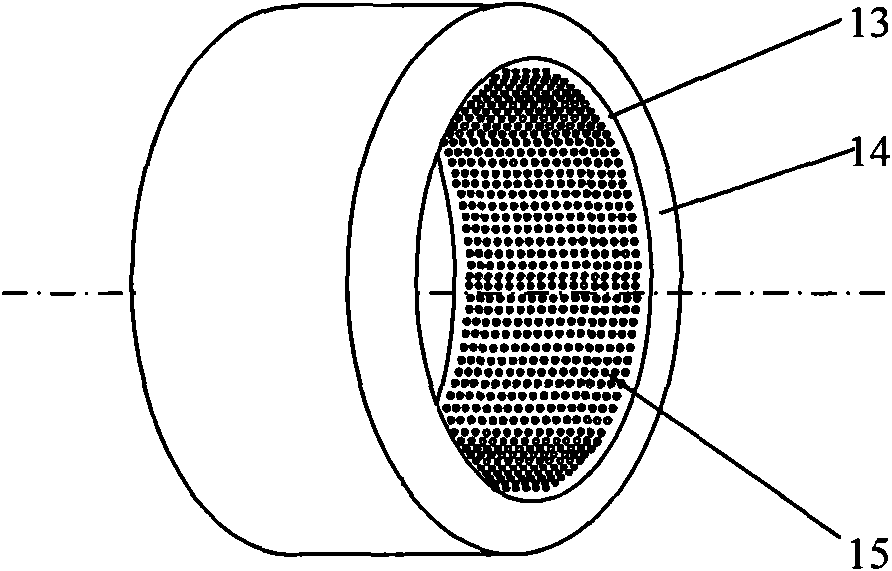

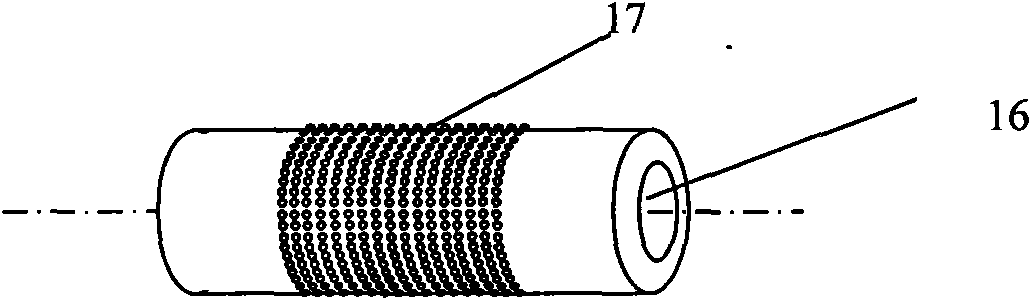

[0031] Seamless steel pipe direct quenching device such as figure 1 As shown, it includes a variable-angle roller table device, an outer surface cooling device and an inner surface cooler 2, the inner surface cooler 2 is rod-shaped, and the local structure is as follows image 3 As shown, the outer surface is provided with a water outlet 17, and the interior is provided with a water channel 16, and the water outlet 17 communicates with the water channel 16, and the water channel 16 is provided with an inner surface cooler water inlet 11; the outer surface cooling device includes 4 annular cooling device, the annular cooler 3 is structured as figure 2 As shown, it is composed of an annular wall 13 and a water cavity 14, the annular wall 14 is provided with a water spray hole 15, the water spray hole 15 communicates with the water cavity 14, and the water cavity 14 is provided with an outer surface cooler water inlet 12, The water inlets of each annular cooler communicate with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com