Front cap spinning forming device and technology for blast-furnace tuyere small sleeve

A technology of spinning forming and tuyere, which is applied in the direction of forming tools, metal processing equipment, manufacturing tools, etc., can solve the problems of reducing the water outlet speed, increasing the resistance of the water head, and the limited length of the extrusion front cap, so as to increase the heat dissipation rate and increase the The effect of high water output rate and strong compactness of the front cap

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

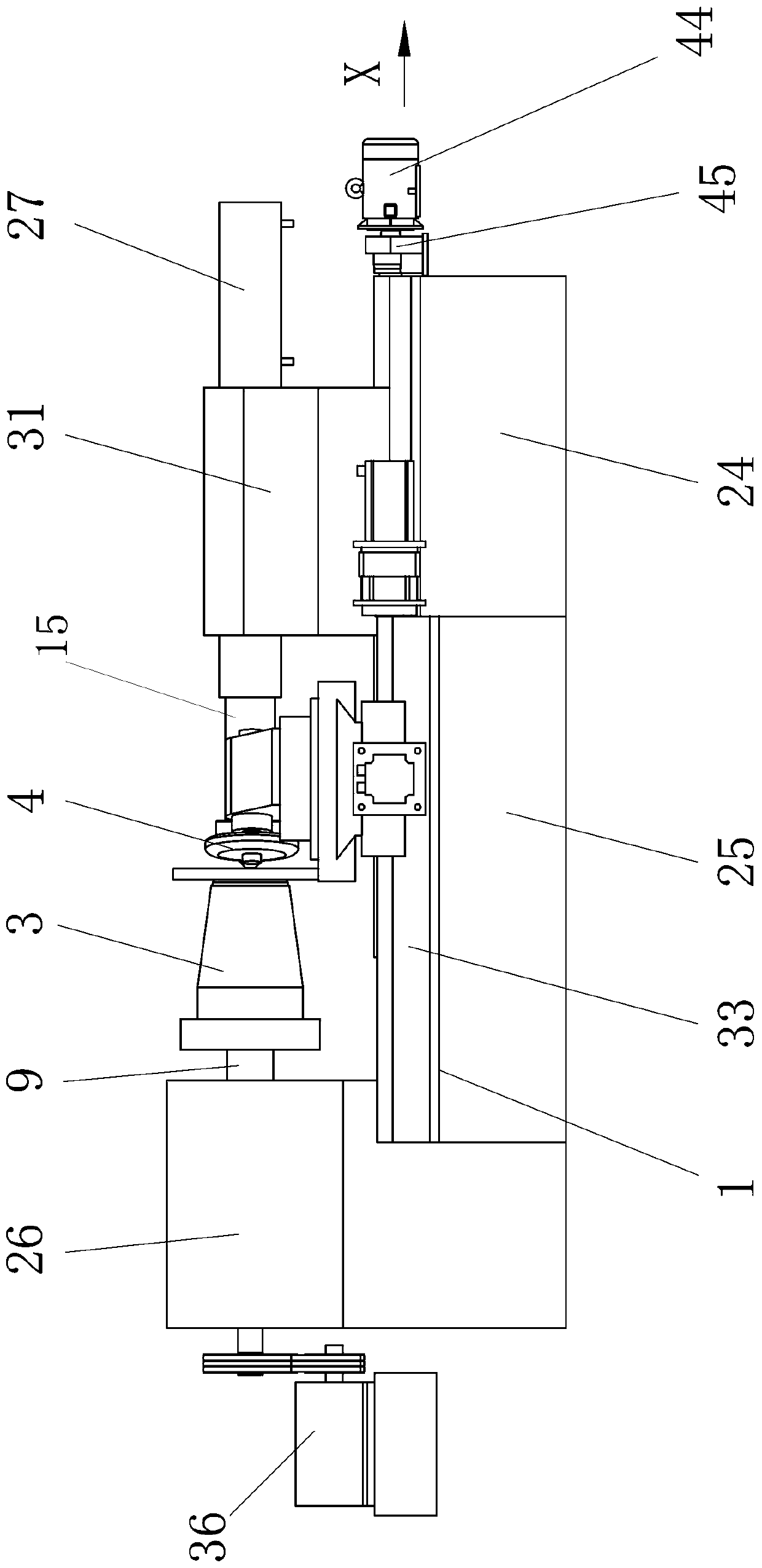

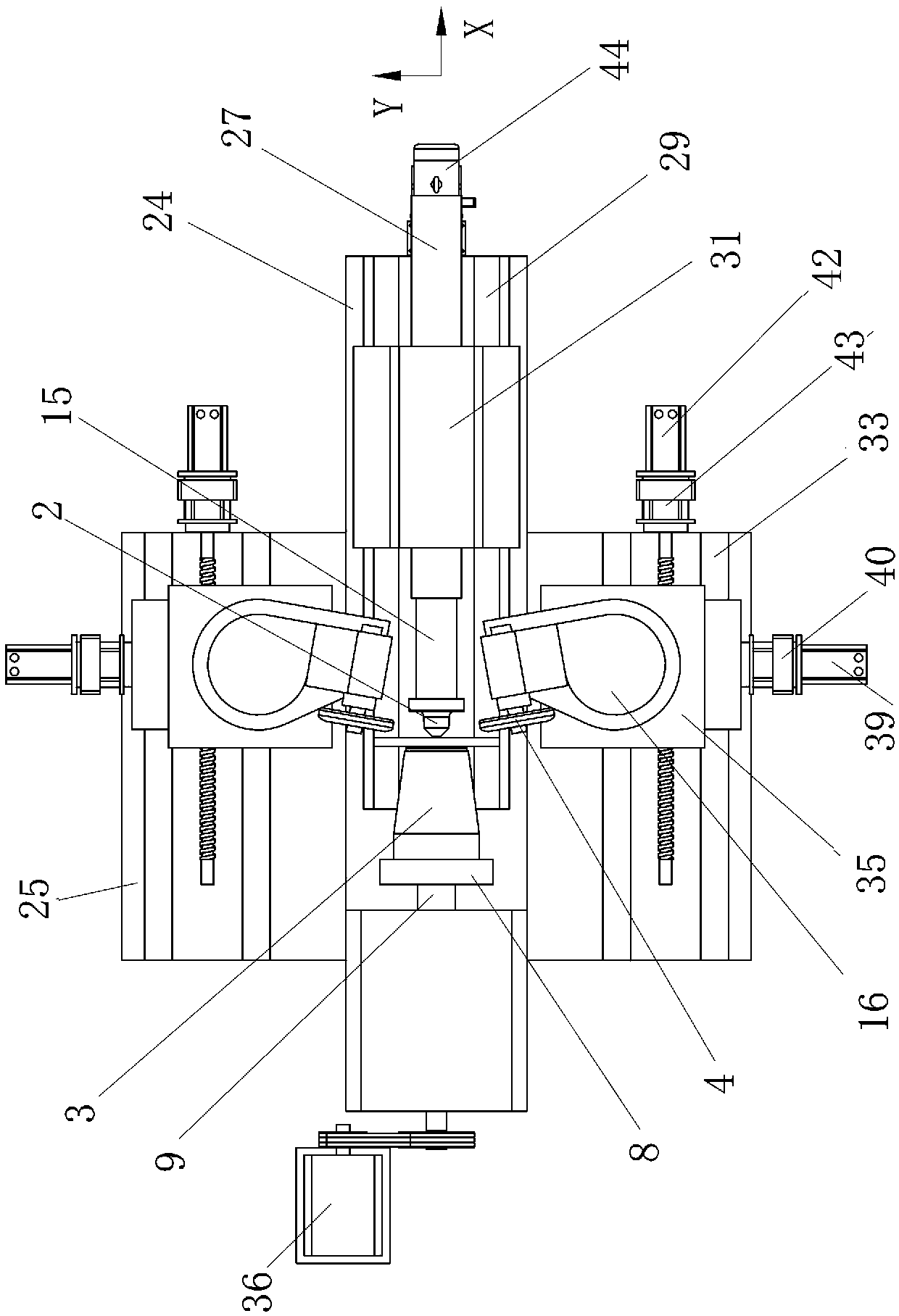

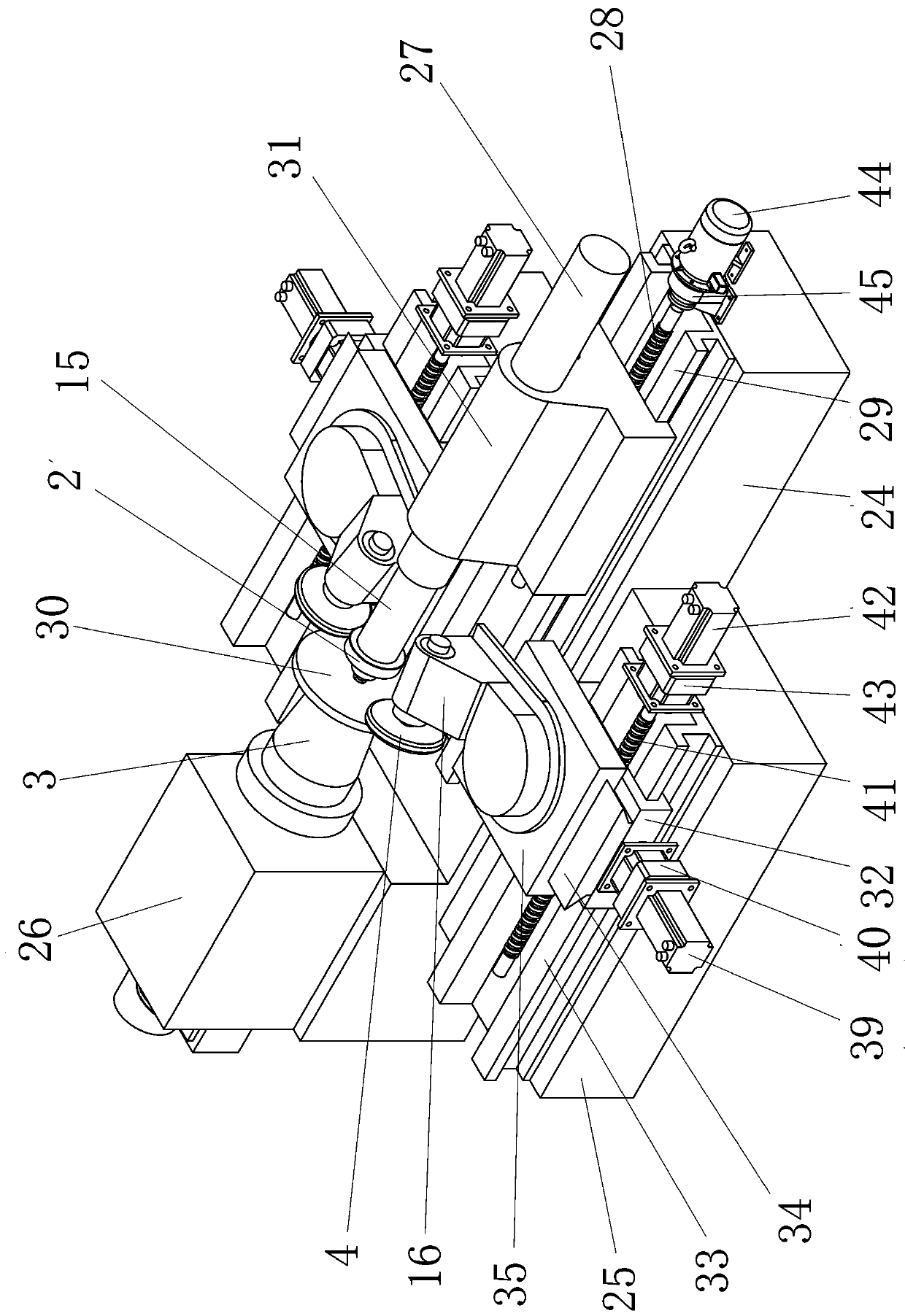

[0054] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings.

[0055] Examples such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 As shown, a front cap spinning equipment for a blast furnace tuyere cover is used to spin a copper cake blank into a front cap, including a frame 1, which is a "ten"-shaped structure, and the frame 1 includes a base 24 And two side seats 25, two side seats 25 are respectively arranged on both sides of the base 24 and vertically arranged with the base 25, the two side seats 25 are arranged symmetrically along the base 24, and the first guide rail is provided on the base 24 29. The base 25 is provided with a second guide rail 33, and both the first guide rail 29 and the second guide rail 33 are arranged horizontally.

[0056] The end o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com