Apparatus for attaching polarized film

A technology for attaching devices and polarizing films, applied to lamination devices, optics, optical components, etc., can solve problems such as elongation and bending of liquid crystal element substrate 1, and achieve the effects of reducing the failure rate and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

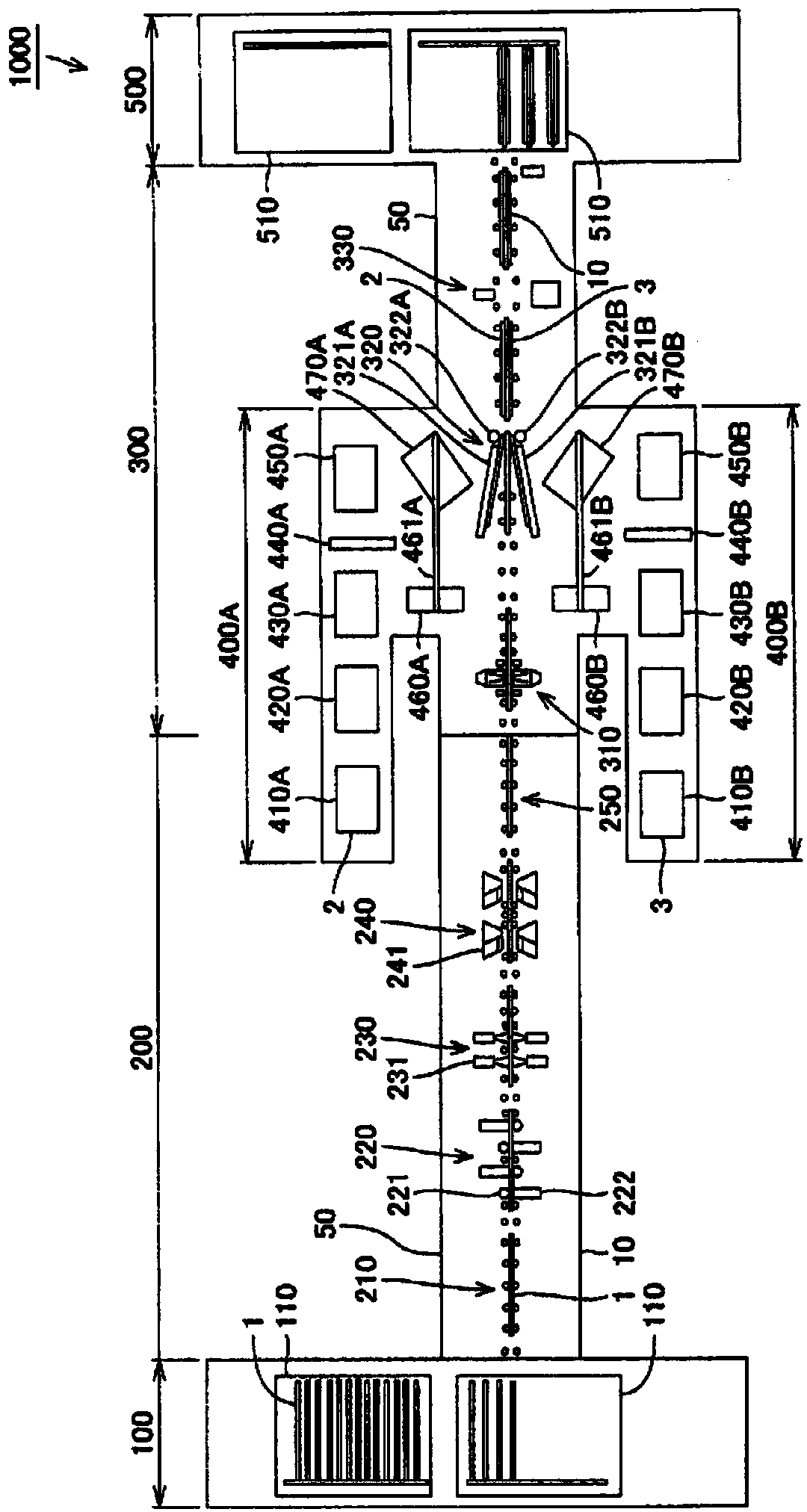

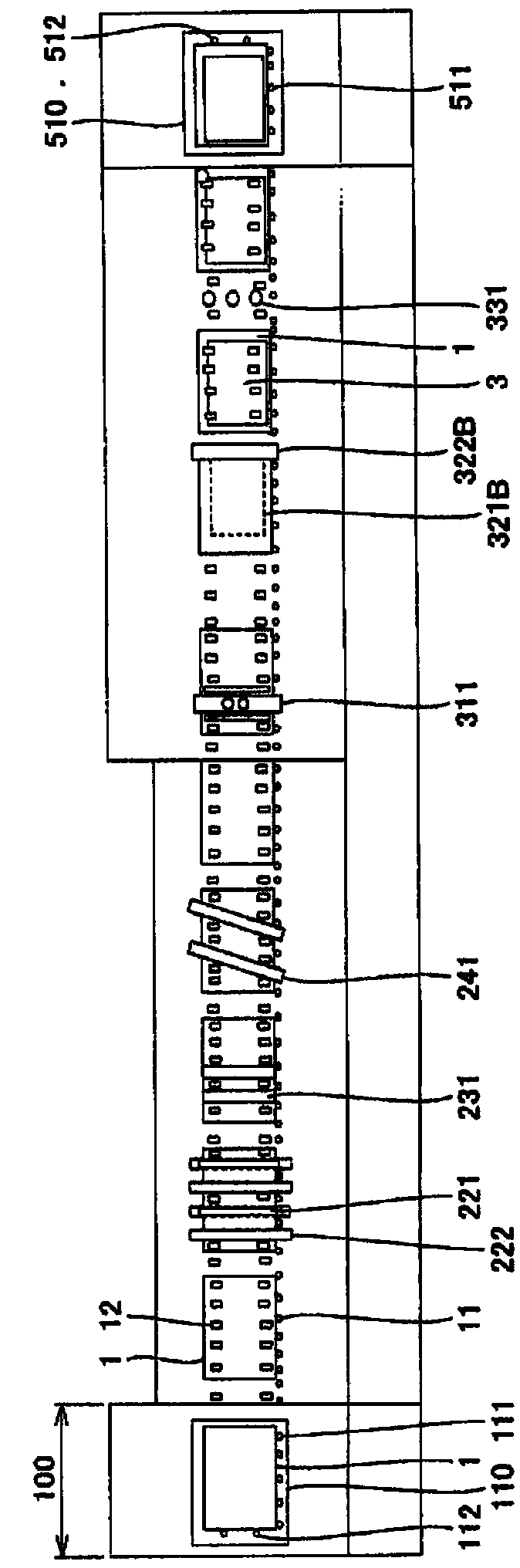

[0055] Figure 6a , 6b is a diagram illustrating a first step of attaching a polarizing film on a liquid crystal element substrate using a polarizing film attaching device according to the present invention.

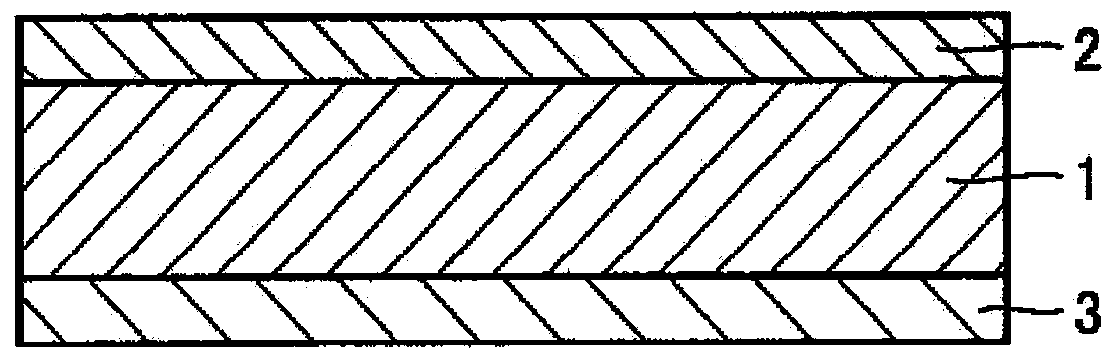

[0056] refer to Figure 6a , 6b On the adhesive plate 30 according to the present invention, under the state where the polarizing film 2 is placed, on the position where the polarizing film 2 is placed, the conveying plate 40 that absorbs the liquid crystal element substrate 1 is arranged.

[0057] The adhesive sheet 30 of the present invention is composed of polytetrafluoroethylene and an adhesive film on the polytetrafluoroethylene sheet.

[0058] The conveying plate 40 of the present invention is directed toward the direction of the arrow (refer to figure 2 ) movement, the inclined roller 20 according to the present invention can be adjusted so that its position can be tilted up and down, so as to connect with the liquid crystal element substrate 1 absorbed by th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com