Skin treatment articles and methods

A product and skin technology, applied in the field of skin treatment products, can solve the problems of inefficient release and poor deposition of conditioning ingredients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

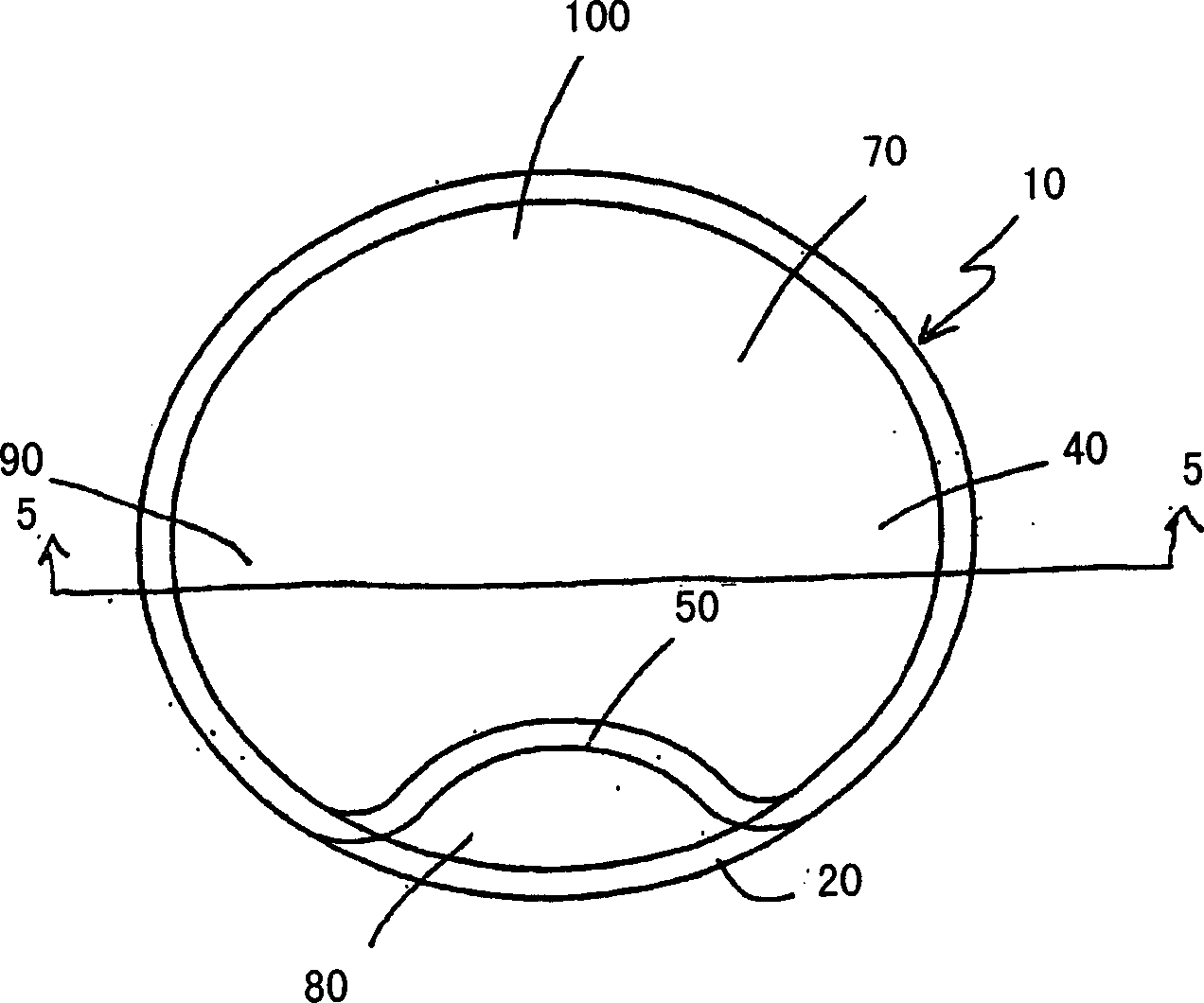

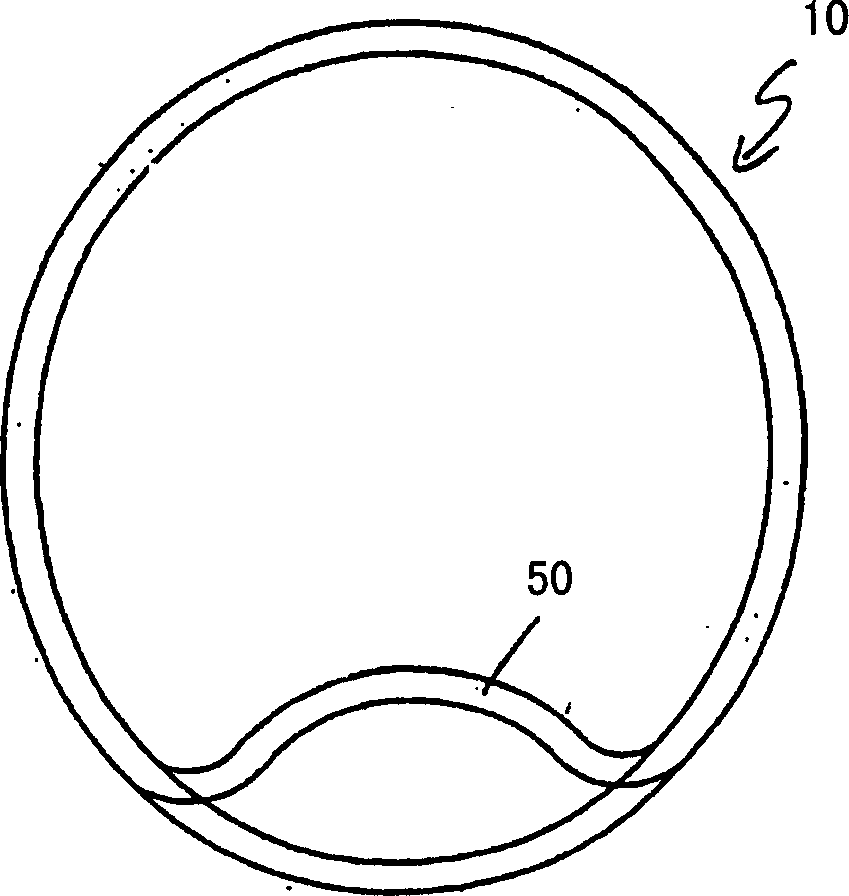

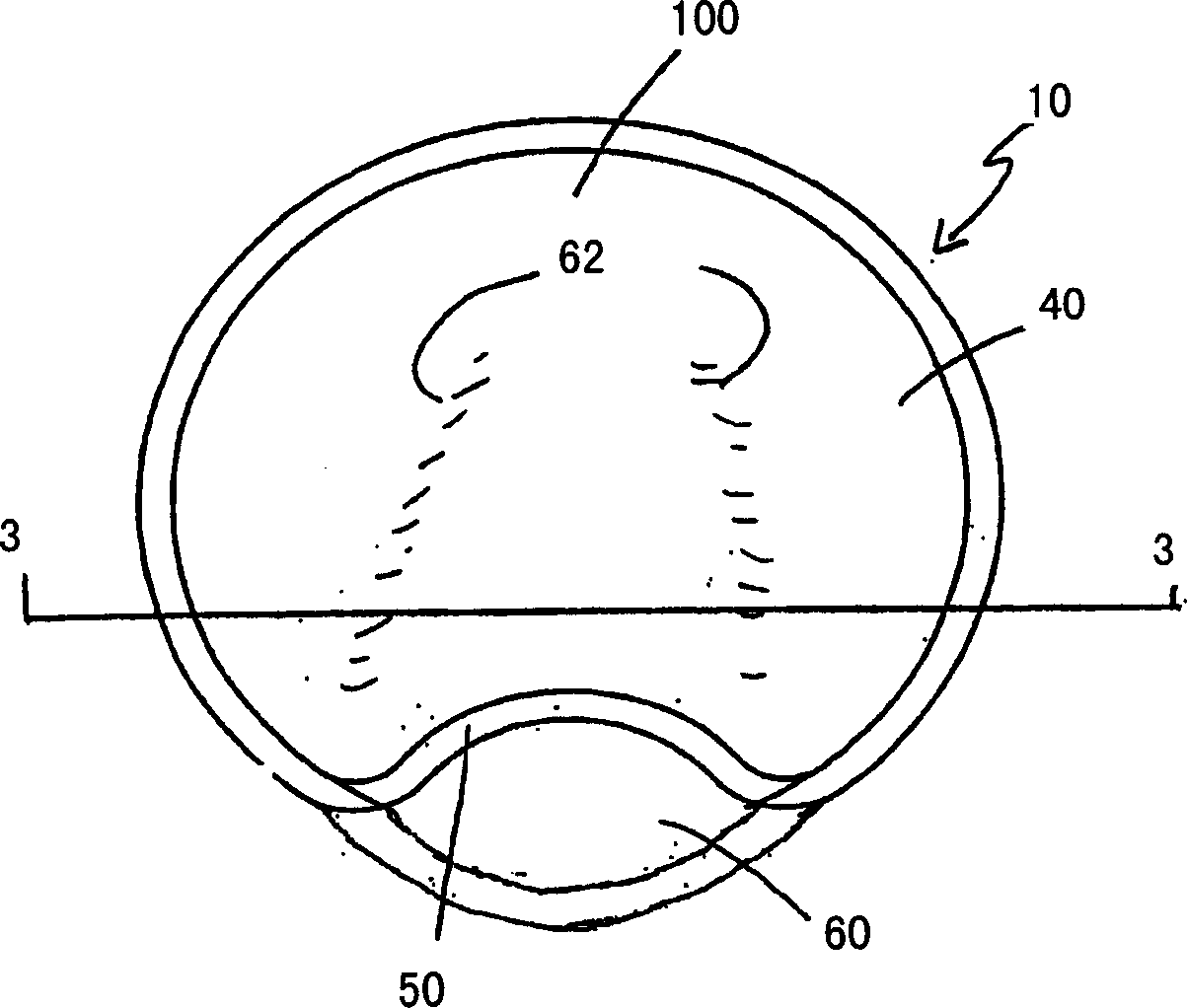

Image

Examples

Embodiment 1

[0255] Product name

[0256] Add the Atlas and Monateric together to the beaker and mix well. The butylparaben, methylparaben and propylparaben were added and mixed slowly until the paraben was dissolved. Then, PEG-8 and Glucquat were added to the beaker and mixed. Then Tegobetaine F-50, Plantaren and Phenoxetol were added and mixed. Then add the spices. Citric acid is then added and the ingredients are mixed until the citric acid is completely dissolved. The pH was adjusted to 6.4-7.2.

Embodiment 2

[0259] Prepare the first phase as described below. Heat the Caremelt to 65°C. The Frescolate was incorporated, and the mixture was allowed to stand.

[0260] Prepare the main ingredients as described below. Add the Atlas and Monateric together to the beaker and mix well. The Nipa paraben, methylparaben and propylparaben were added and mixed slowly until the paraben was dissolved. Then, add Carbowax, Emery and Gluquat and mix well. Then Tegobetaine, Texapon, Plantaren and Phenoxetol were added and mixed. Then add the spices. Citric acid is then added and the ingredients are mixed until the citric acid is completely dissolved. The pH was adjusted to 6.4-7.2. The mixture was heated to 65°C. Then, the first phase mixture is added to the main batch. Once dissolved, the mixture was cooled.

Embodiment 3

[0262] A skin treatment article comprising a cleanser is prepared as follows.

[0263] A 125 g sheet of spunlaced polyester / polypropylene bicomponent material (Green BayNonwovens SX 467), two 25 g sheets of thermally bonded polypropylene (TBPP) / 40hex film vacuum formed laminate (Tredegar ) and one piece of 140g 70 / 30 polyester / rayon in 8-stripe pattern, PGI. The spunlaced material was layered and arranged onto a laminate sheet with the TBPP side facing outward. The perimeter is sealed using a Jenkins extruder (operating at a suitable pressure, 300[deg.]F, residence time 6 seconds). The polyester / rayon material was aligned onto the remaining laminate, also with the TBPP facing out. The perimeter is sealed under the same conditions as described above. The resulting two sheets are layered and arranged on the laminate, facing inwards. Seal about 2 / 3 of the perimeter using a Jenkins extruder under similar conditions, leaving one end open. The surface of the spunlace was coated...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com