Shot peen forming method realizing torsional deformation of high-rib integral panel

A technology of integral wall panel and shot peening, which is applied in the direction of spray gun, abrasive jet machine tool, used abrasive treatment device, etc. problems, to achieve the effect of broadening the application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and examples.

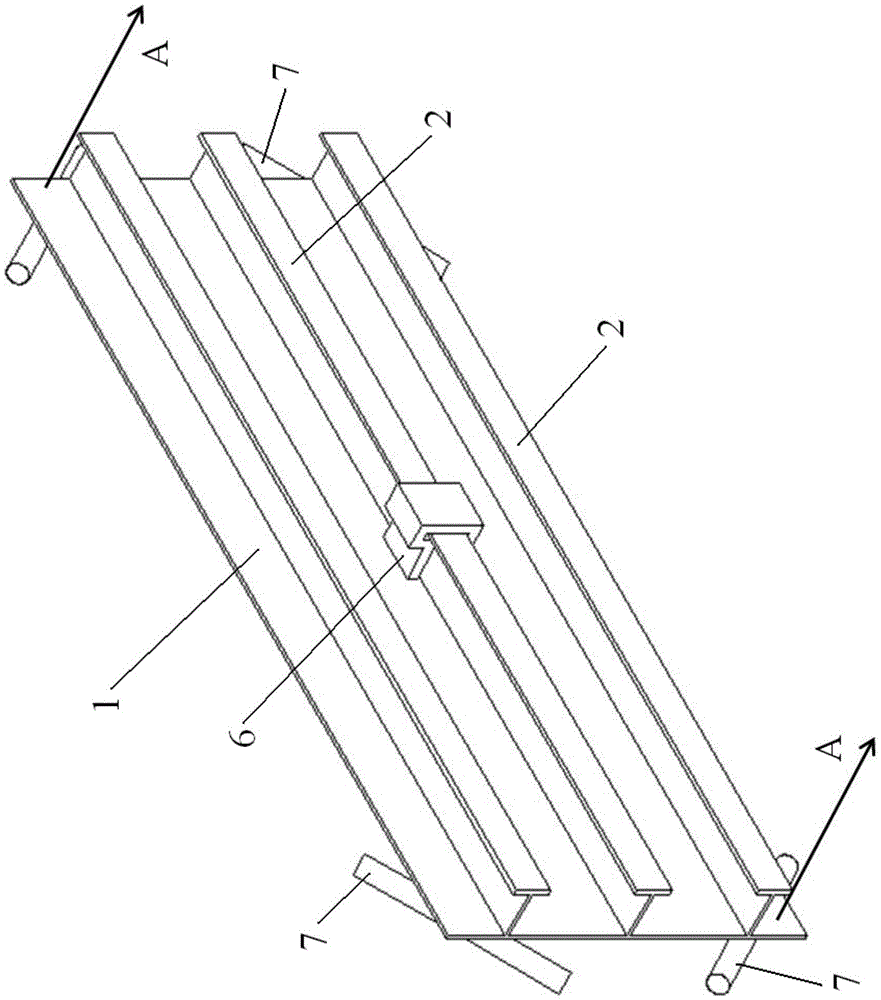

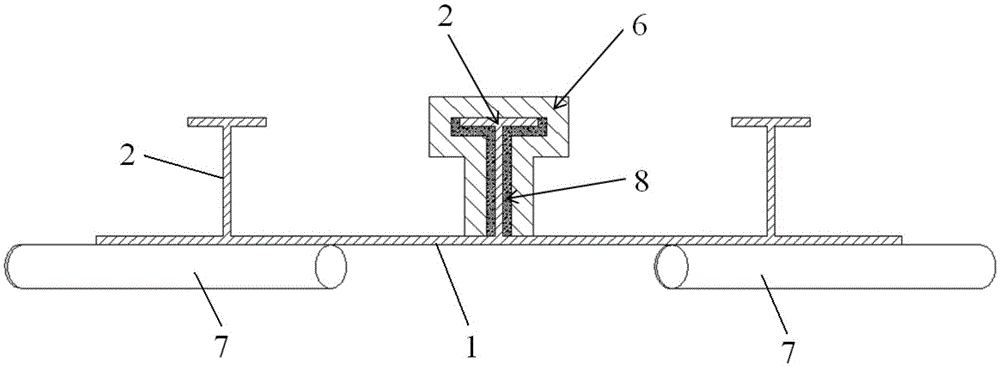

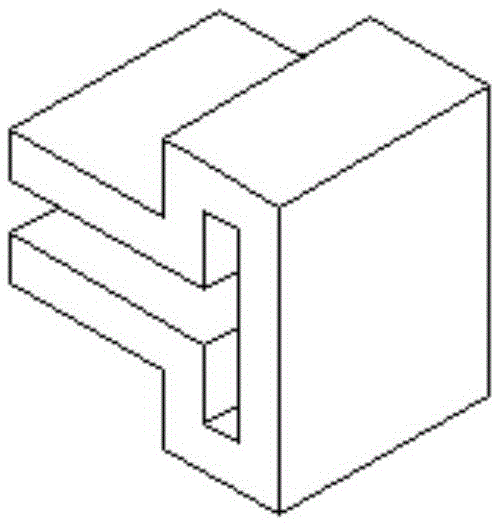

[0026] A shot peening method for torsional deformation of a high-strip integral wall panel, the high-strip integral wall panel includes a skin 1 and a high-slab 2, the high-slab 2 is arranged on the inner surface of the skin 1, and the high-slab The shot blasting forming method of the torsional deformation of the strip integral wall plate comprises the following steps:

[0027] Step 1. Fix the high-reinforced bar overall wallboard with clips;

[0028] Step 2. Apply a force pointing to the inside of the skin 1 at both ends of the high-strip integral wall plate, and apply a force pointing to the outside of the skin 1 at the middle of the high-strip integral wall plate, as shown in figure 1 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com