Method and device for torsional connection of tubular casings and related system for filling tubular casings

A technology for tubular casings and connecting equipment, which is applied in the related system fields of filling tubular casings, can solve the problems of non-durability of torsion points, and achieve the effect of saving materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

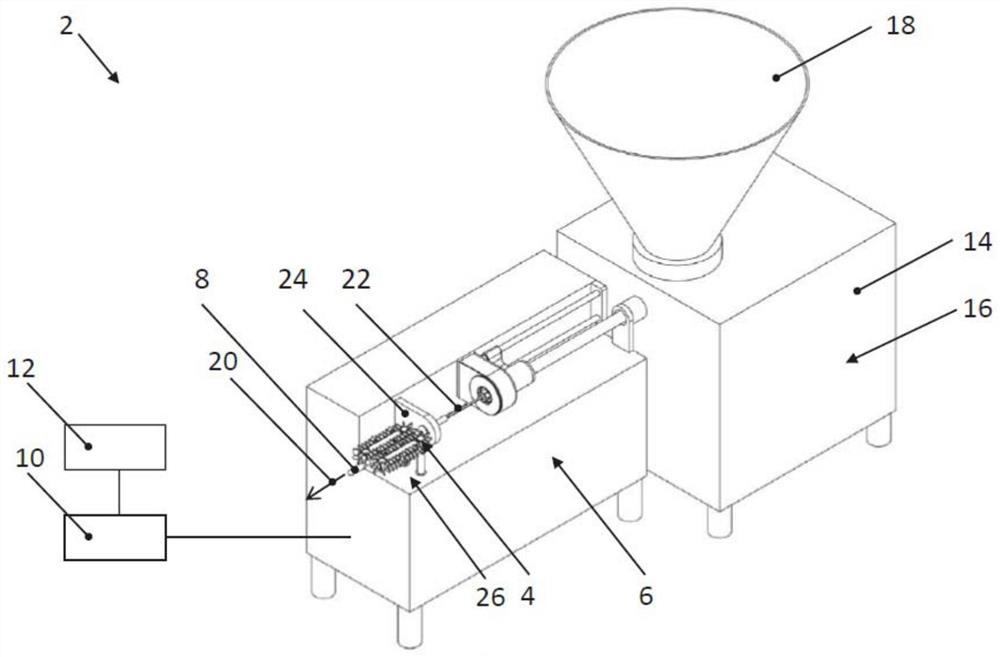

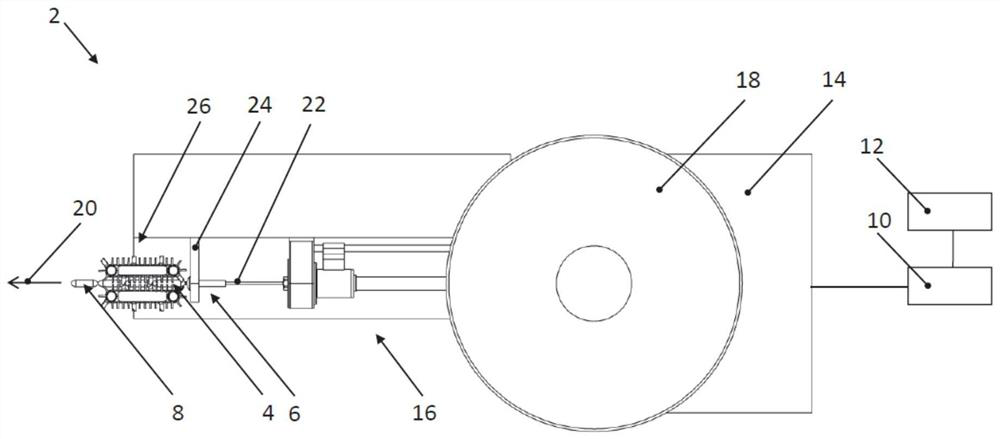

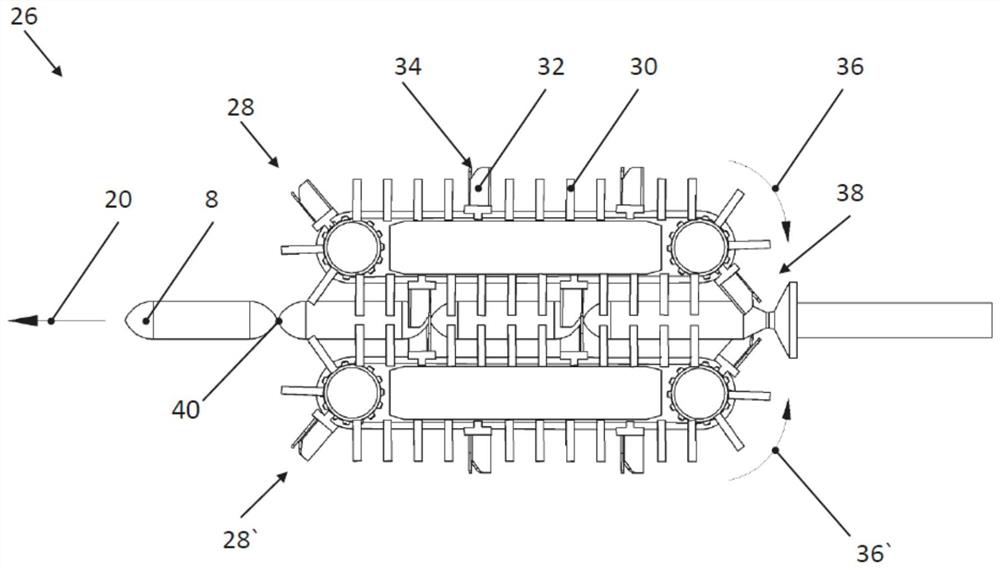

[0066] figure 1 and 2 Shown is a system 2 for producing segments from tubular sausage casings 4 filled with food material, the system comprising a stuffing machine 14 with a feed hopper 18 for receiving food material and a feed pump 16, with a feed pump 16 for feeding the food material Twist connection device 6 of filling tube 22 filled into tubular casing 4 , and segmenting device 26 .

[0067] The filling tube 22 can be driven rotationally about its longitudinal axis. The twist connection device 6 also has a casing brake 24 with a casing brake ring (not shown) which can be rotated and driven synchronously with the filling tube 22 , which ends in the region of the casing brake ring. In operation, pasty food material, in particular sausage meat pieces, is distributed into tubular casings 4 to be filled and further processed by segmenting device 26, by twisting connecting device 6 and segmenting device 26, producing individual segments, In particular individual sausage segme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com