Roller blind assembly with draw hoop for roller blind web

A technology of roller shutters and components, which is applied to vehicle parts, roofs, windows, etc., can solve problems such as clicking noise, and achieve the effect of ensuring operating safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

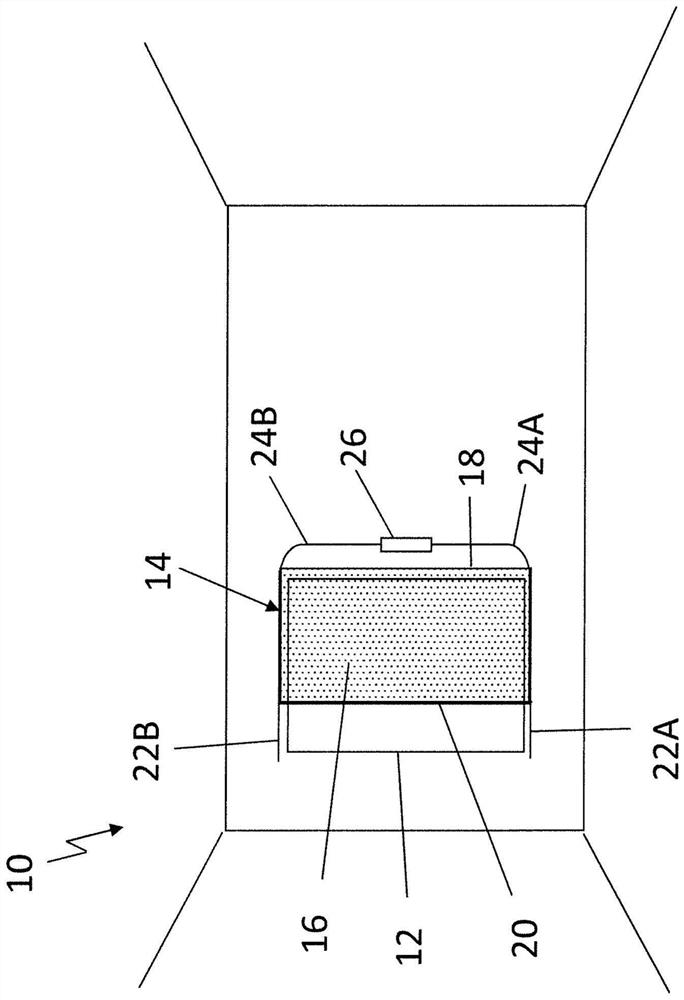

[0027] exist figure 1 shows a roof 10 of a passenger car, not shown in detail, which has a roof opening 12 which can be closed or at least partially released by means of a transparent cover element, not shown in detail here.

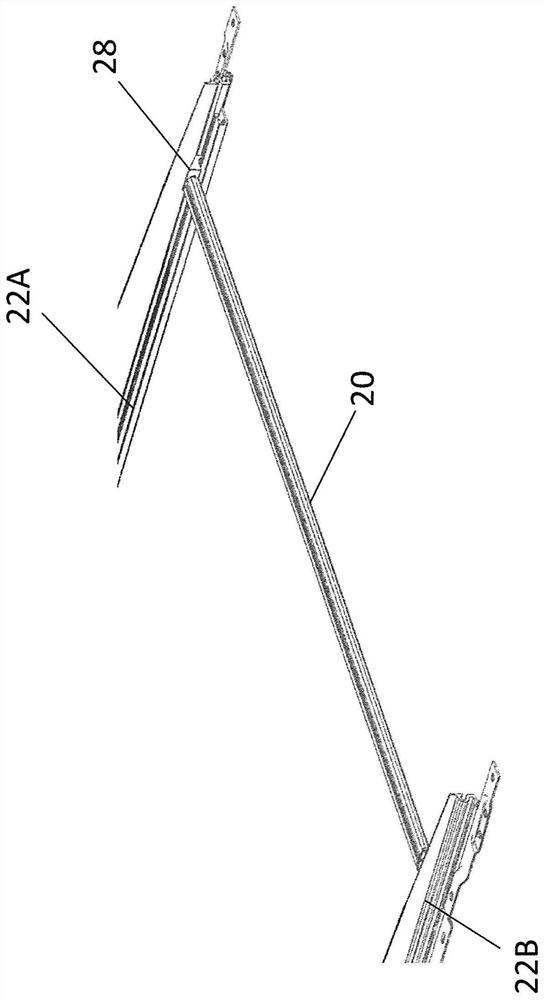

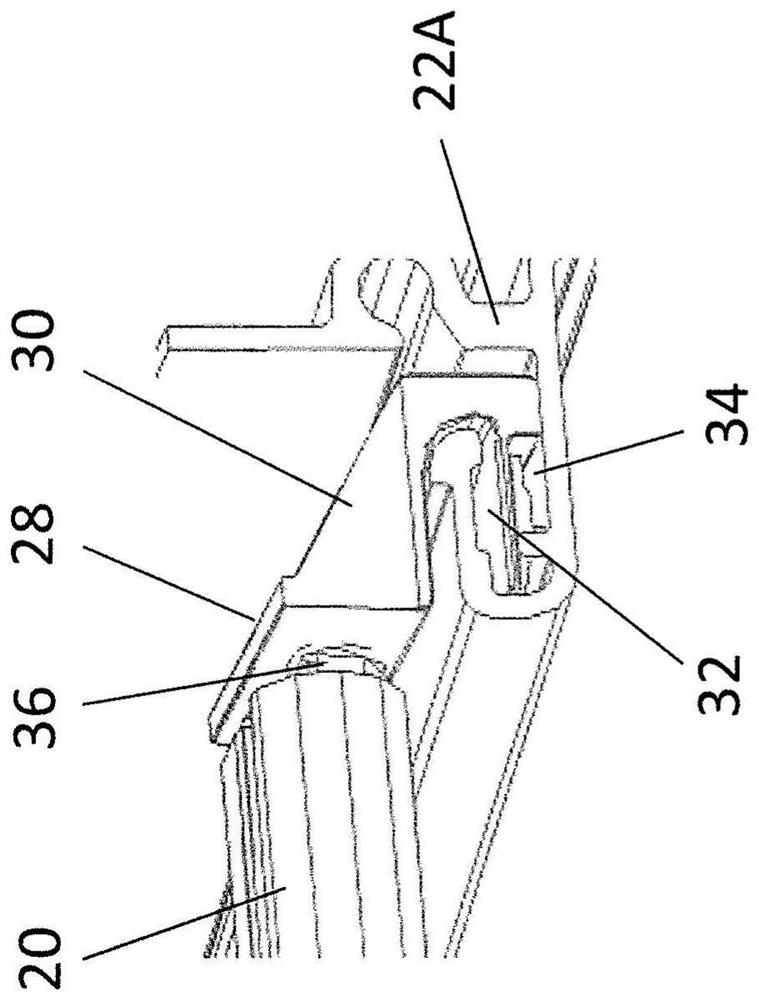

[0028] In order to be able to reduce or prevent the incidence of light through the roof opening 12, the vehicle roof 10 has a roller blind assembly 14, which comprises, as a screening element, a roll of a foldable or rollable, opaque or partially light-transmissive material. Curtain strip 16. In the region of the rear side edge of the top opening 12 , the roller blind web 16 can be rolled up into a roller blind roll 18 . On its edge facing away from the roller blind roll 18, the roller blind web 16 is provided with a pulling tent frame 20, which is the operating element of the roller blind assembly 14 and referred to Figure 2 to Figure 4 to describe in detail. The pull tent frame 20 extending in the top transverse direction is guided with its ends in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com